Limit Switches C116 Sensors Catatlog

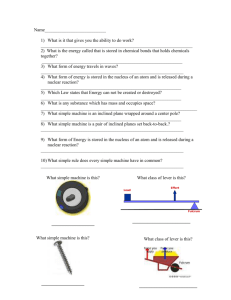

advertisement