Technical Report for the Midas Mine and Mill, Elko County, Nevada

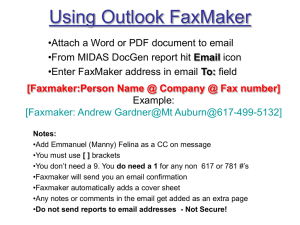

advertisement