WeKcelo HEC Properties

advertisement

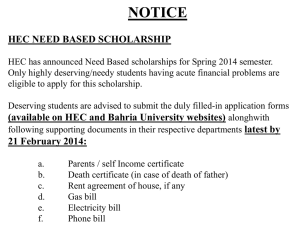

1 TM WeKcelo HEC Hydroxyethylcellulose A Nonionic Water-Soluble Polymer WeKcelo TM HEC and Its Applications 2 WeKcelo HEC A Nonionic Water-Soluble Polymer CONTENTS PAGE A GUIDE TO WHERE AND WHY WEKCELO HEC IS USED . . . . . . . . . . . . . ……………………….3 CHEMISTRY . . . . . . . . . . . . . . . . . . . . . . . ………………………………………………………………..4 GRADES AND VISCOSITY……………………………………………………………………….………..4 SURFACE TREATMENT AND DISPERSION . . . . . . . . . . . . . . . . . . . . . . . . . . . …………………….4 CHEMICAL AND PHYSICAL PROPERTY . . . . . . . . . . . . . . . . . . . . . . . . . . . ……………………….5 FUNCTION OF WEKCELO HEC . . . . . . . . . . . . . . . . . . . . . …………………………………….…….6 DISSOLVING WEKCELO HEC HEC IN WATER . . . . ………………………………………………..…. 7 SOLUBILITY IN ORGANIC SOLVENTS . . . . . . . . . . . . . . ………………………………………………8 PROPERTIES OF SOLUTIONS OF WEKCELO HEC HEC . . . . . . . . . . . . . . . . . …………….. . . . . 9 EFFECT OF CONCENTRATION . . . . . . . . . . . . . . . . …………………………………………………… 9 EFFECT OF BLENDING . . . . . . . . . . . . . . . . . . . . . ………………………………………………………9 EFFECT OF SHEAR RATE . . . . . . . . . . . . . . . . . ………………………………………………………..10 EFFECT OF MIXED SOLVENTS . . . . . . . . . . . . . . ………………………………………………………10 EFFECT OF PH . . . . . . . . . . . . . . . . . . . . . . . . ……………………………………………………………10 VISCOSITY STABILITY . . . . . . . . . . . . . . . . . . . . . ………………………………………………………11 USE OF DEFOAMERS . . . . . . . . . . . . . . . . . . . . . ……………………………………………………….11 TOLERANCE FOR INORGANIC SALTS . . . . . . . . . . . . . ……………………………………………….11 3 WeKcelo HEC -- HYDROXYETHYLCELLULOSE A NONIONIC WATER-SOLUBLE POLYMER WeKcelo HEC hydroxyethylcellulose is a nonionic water-soluble polymer derived from cellulose. its solutions are unaffected by cations. It is used to produce solutions having a wide range of viscosity. Pseudoplastic is the specific property of this kind liquid . pseudoplastic— viscosity depending on the amount of shear stress applied. We suggests the use of WeKcelo HEC as a thickener, protective colloid, binder, stabilizer, and sus-pending agent in a variety of industrial applications, including pharmaceuticals, textiles, paper, adhesives, decorative and protective coatings, emulsion polymerization, ceramics, and many miscellaneous uses. For a guide to these uses, see Table 1. Figure 1 — Coatings Cosmetics Adhesives Miscellaneous Pharmaceuticals Polymerization Paper Textiles Laundry Aids Binders Guide to use WeKcelo HEC Latex paint Texture paint Thickening and protective colloid Water-binding Hair conditioners Toothpaste Liquid soaps and bubble bath Hand creams and lotions Thickening and stabilizing Wallpaper adhesives Latex adhesives Plywood adhesives Thickening and lubricity Thickening and water-binding Thickening and solids holdout Joint cements Hydraulic cements Plaster Caulking compound and putty Printing inks Asphalt emulsions Thickening Water-binding and set retarder Water-binding Thickening Thickening and rheology control Thickening and stabilizing Lotions and emulsions Jellies and ointments Thickening and stabilizing Thickening and water-binding PVAC and acrylic latices PVC suspension Protective colloid and surface activity Protective colloid and surface activity Upon your request , our people could make suggestion for you 4 CHEMISTRY The WeKcelo HEC hydroxyethylcellulose polymer is a hydroxy-ethyl ether of cellulose. The structure of the cellulose molecule, showing its chain composed of anhydroglucose units. Each anhydroglucose unit contains three hydroxyls capable of reaction. By treating cellulose with sodium hydroxide and reacting with ethylene oxide, hydroxyethyl groups are introduced to yield a hydroxyethyl ether. The reaction product is purified and ground to a fine white powder. SUBSTITUTION Each anhydroglucose unit in the cellulose molecule has three reactive hydroxyl groups, shown in blue in Figure 1. The number that is substituted in any reaction is known as the “degree of substitution,” or DS. Theoretically, all three hydroxyls can be substituted. The product from such a reaction would have a DS of 3. Hydroxyethyl groups can be introduced into the cellulose molecule in two ways. First, ethylene oxide reacts at the hydroxyls in the cellulose chain. Second, ethylene oxide, reacting at previously substituted hydroxyls, can polymerize to form a side chain. The average number of moles of ethylene oxide that become attached to each anhydroglucose unit in cellulose, in the two ways described, are called moles of substituent combined, or MS. In reacting ethylene oxide with cellulose to form the hydroxyethyl cellulose ether , solubility in water is achieved as the degree of substitution is increased. By selecting appropriate reaction conditions and moles of substituent, complete hydration in water is obtained. WeKcelo HEC , which has optimum solubility in water, has an MS of 2.5. An idealized structure of WeKcelo HEC is shown in Figure 2. This example has an MS of 2.5 (5 ethylene oxide groups/2 units) and a DS of 1.5 (3 hydroxyls substituted/2 units). Figure 2 Idealized Structure of WeKcelo HEC n-2 2 GRADES AND VISCOSITY TYPES Figure 3. Available WeKcelo HEC grade and viscosity Type Viscosity 2.0% , 20°C, Brookfield RV, cps ) Viscosity( NDJ-1 2.0% 20 °C cps WeKcelo HEC 300 250-650 250-800 WeKcelo HEC 5000 3,500-5,000 4,500-5,500 WeKcelo HEC 10000 5,500-8,000 9,500-10,500 WeKcelo HEC 15000 8,000-10,000 14,000-16,000 WeKcelo HEC 20000 9,000-13,000 19,000-21,000 WeKcelo HEC 30000 15,000-20,000 28,000-32,000 WeKcelo HEC 50000 22,000-30,000 55,000-65,000 WeKcelo HEC 100H 45,000-60,000 85,000-110,000 5 Retarded solubility All grades and types of WeKcelo HEC can be treated to provide a powder that displays fast dispersion without lumping when added to water. This treatment does not alter the solution viscosity. Some grades and viscosity types are available without this treatment if desired. Anyzme Resistant Grade To offer longer self-life of the final paint , and protect cellulose ether from enzyme attack , , available . These grades are designated by the letter B (e.g., WeKcelo HEC 30000B ) WeKcelo HEC has Bio-stable grade PARTICLE SIZE Usually, for coating industry , WeKcelo HEC is powder of 100mesh , this is the idea particle size which will guarantee the good flowability of powder , and easy hydration after adding into water . Figure 4 — Typical Properties of WeKcelo HEC HEC PRODUCT SAFETY Read and understand the Material Safety Data Sheet (MSDS) for WeKcelo HEC before using this product. 6 Properties of WeKcelo HEC WeKcelo HEC is a white to light tan, free-flowing powder. It dissolves readily in water to give clear, smooth, viscous solutions that are nonionic. ■Excellent Thickening efficiency For latex paint especially high PVC paint, WeKcelo HEC help give excellent apply property .Flocculation will not happen when paint is thick , Compare with normal HEC, WeKcelo HEC has better thickening efficiency,economical formulation could be realized when users decrease dosage. In the meantime ,property of scrub resistance improved . ■Good Rheological property Aqueous solution of WeKcelo HEC is non-Newtonian liquid .Pseudoplastic is the specific property of this kind liquid . During immobile storage, it keeps best thickening and open can performance. When pouring paint ,it will keep as medium viscosity , which will give paint good fluidity and less spatter. During brushing and rolling, paint can easily apply, in the meantime,spatter is well controlled . Finally, when brushing finished, paint viscosity will recoveri,coating start to have anti sagging property mmediately. ■Dispersion and Solution All WeKcelo HEC has been surface treated as retarded type. Lump can be avoided when putting dry powder into water. Delay solubility will ensure hydration start after WeKcelo powder well dispersed . Well designed and treated WeKcelo HEC,can ideally adjust dissolve speed and viscosity build up. ■Color acceptance New developed technology make WeKcelo HEC solution has better color acceptance . Which will ensure final paint has more vivid color performance . ■Storage stability General WeKcelo HEC grades already have good enough enzyme resistance .It is generally recommended for most paint customers. Poperly store WeKcelo HEC HEC in closed containers a period of a year for viscosity stability , average viscosity retention was 85 % minimum. 7 DISSOLVING WeKcelo HEC IN WATER WeKcelo is readily soluble in either hot or cold water. However, as with most water-soluble thickeners, the particles have a tendency to agglomerate, or lump, when first wetted with water. Thus, the time required to achieve complete solution of WeKcelo HEC is usually governed by the degree of lumping that is allowed to develop during the solution process. In general, the low-viscosity types are more easily dissolved than are the high-viscosity types. WeiKem has solved the problem of lumping and slow dis-solving by producing a surface-treated grade of WeKcelo HEC, known as the Retarded-grade. This grade disperses without lump-ing when added to water. After an inhibition period, the dispersed particles begin to dissolve and smooth, lump-free solutions are readily achieved. Now all WeKcelo HEC type are treated as Retarded type . This is because retarded type is necessary for coating , construction , cosmetic application . For other application , we could have non-treated type available upon customer’s specific usage . Advantage of Retarded solubility WeKcelo HEC with delay solubility is designed to be added to water without lumping, and thus greatly facilitates solution preparation. Within minutes the R-treatment dissolves and viscosity begins. Some 15 minutes later, the viscous solution is clear. Hydration of the WeKcelo HEC particles has been inhibited. When the particles are added to water, they disperse without lumping and, following a predetermined delay, begin to dissolve. This process permits the preparation of clear, smooth, viscous solutions in a short period of time by simply adding the R-grade to water and stirring to prevent settling of the particles, until the polymer is completely dissolved. The inhibition period, from the initial wetting to the start of dissolution, is referred to as the hydration time of WeKcelo HEC . This hydration time can be varied to meet specific needs. The typical range is 4 to 25 minutes. The hydration time is markedly affected by two factors: the pH and temperature of the water. Figure 4 illustrates the magnitude of these effects and shows that both a higher temperature and a higher pH decrease the hydration time. After the initial hydration time has been satisfied, the polymer begins to dissolve, usually evidenced by an increase in viscosity of the system. Time is then required for complete dissolution of the particles. This dissolution time, also known as the solution time, is also significantly affected by pH and temperature; the longer the hydration time, the longer the solution time. ◆Temperature and PH has effect on Hydration time. Increase PH to 8.0-10.0, will shorten the time 40-60%; temperature increase will shorten this time as well. Generally, it is recommended that the Retarded-grade be added to room-temperature water at neutral or slightly acidic pH. If higher pH or higher temperature is used, the hydration time may be sufficiently decreased so that lumping occurs as the dry product is added to the aqueous system. Figure 5 General WeKcelo HEC type viscosity build up speed 8 Figure 6 — Solubility Behavior in Organic Solvents Solvent Alcohols Ethanol:water (70:30 by wt) (60:40 by wt) (30:70 by wt) Cold 25°C Hot 55-60°C Partially soluble Partially soluble Soluble Partially soluble Partially soluble Soluble Swollen Swollen Swollen Partially soluble Partially soluble Soluble — Insoluble Partially soluble Soluble Soluble Insoluble Glycols Ethylene glycol Glycerin Propylene glycol — Acids Formic (90%) Miscellaneous Aniline Dimethyl formamide Dimethyl sulfoxide Ethylene chlorohydrin Solvent Alcohols Methanol (anhydrous) Ethanol (anhydrous) Cold 25°C — Soluble Soluble Hot 55-60°C Insoluble Insoluble Insoluble Insoluble Insoluble Insoluble Insoluble Insoluble Methyl Cellosolve Cellosolve Insoluble Insoluble Insoluble Acids Glacial acetic Insoluble — Miscellaneous Aniline N-acetylethanolamine Mineral spirits Toluene Insoluble Insoluble Insoluble Insoluble Insoluble Esters Ethyl lactate Methyl salicylate Ethers — — — — 9 PROPERTIES OF SOLUTIONS OF WeKcelo TM HEC WeKcelo HEC hydroxyethyl cellulose is soluble in both cold and hot aqueous solution , which differs from methylcellulose, methyl ydroxypropyl ellulose . Solutions of WeKcelo HEC are non-Newtonian in flow, since they change in viscosity with rate of shear. Because WeKcelo HEC is ensively used to modify the viscosity of solutions,dispersions, emulsions, and the like, the effect of a number of factors on solution viscosity will be discussed in detail. Effect of Concentration When WeKcelo HEC is dissolved in water, viscosity ncreases rapidly with concentration . The viscosity-concentration relationship tion” point and does not precipitate from aqueous solution at is nearly linear , when we stabilize the temperature . Figure 7 . Effect of concentration vs Viscosity of solution Effect of Blending Two viscosity types of WeKcelo HEC can be blended to obtain an intermediate viscosity. Because viscosity is an exponential function of concentration and degree of polymerization, the viscosity resulting from blending is not an arithmetic mean. Our technician is ready to give you suggestion upon cutomer’s specific viscosity requirement . 10 Effect of Shear Rate Aqueous solution of WeKcelo HEC is non-Newtonian liquid .Pseudoplastic is the specific property of this kind liquid . This behavior differ s from the 60 m e - dependent vi scos i ty change that is us ual ly cal led thi xot ropy For example , when you use WeKcelo HEC 30000, ◆During immobile storage, WeKcelo HEC 30000 will keep best thickening and open can performance. ◆When pouring paint ,coating consists of WeKcelo will keep as medium viscosity , which will give paint good fluidity and less spatter. ◆During brushing and rolling, paint can easily apply, in the meantime,spatter is well controlled . ◆Finally, when brushing finished, paint viscosity will recoveri,coating start to have anti sagging property mmediately. Figure 8. Viscosity vs Share rate Effect of pH on Viscosity of Solutions of WeKcelo HEC Solutions of WeKcelo HEC undergo little viscosity change over thepH range of 2 to 12. However, solutions possess the greatest viscosity stability in the pH range of 6.5 to 8.0. Below pH 3, solutions may show some drop in viscosity resulting from acid hydrolysis. This is common to all water-soluble polysac According to our Lab test , PH below 2 will make specific grade aqueous solution viscosity drop around 25-35% . all grades . Thus R&D of WeiKem is ready to test for our customer for all PH system . But it is not certain for 11 VISCOSITY STABILITY General WeKcelo HEC grades already have good enough enzyme resistance .It is generally recommended for most paint customers. Poperly store WeKcelo HEC HEC in closed containers a period of a year for viscosity stability , average viscosity retention was 85 % minimum. Special Bio-Stable grades are available from WeiKem as well, which can offer special longer storage time. average viscosity retention was 93 % minimum in same situation . Any way , since solutions of WeKcelo HEC are not immune to biological attack, it is recommended that a preservative be added when the solutions are to be stored. USE OF DEFOAMERS Solutions of WeKcelo HEC HEC are mildly surface active. They are lower in surface tension than water, If any difficulty is encountered with air entrainment in solutions, a defoamer should be utilized. which can be added to the water prior to solution preparation. TOLERANCE FOR INORGANIC SALTS Because of its solubility and nonionic character, WeKcelo HEC can be dissolved in many salt solutions that will not dissolve other water-soluble polymers. Data in Table VI show that WeKcelo HEC is soluble in most 10% salt solutions and many of the 50% (saturated) salt solutions. 12 Cellulose and Its Derivatives WeiKem Chemical Co.,Ltd Sales and R&D office : No. 28 Xifeng Road , Xinji Town , Yizheng ,Yangzhou City , Jiangsu . China Plant : Hanjiang Industry Zone, No. 217 Kaifa West Road , Yangzhou ,Jiangsu .China Plant: Daoxu Town , Shaoxing City , Zhejiang , China Tel : 0086-514-87783286 / Email : sales@wei-chem.com Fax : 0086-514-85107332 www.wekcelo.com The products and related information provided by WeiKem Chemical editions. PRINTED IN China , th by Aug 15 , 2009 .