Kang_Jin_Hee - University of Waterloo

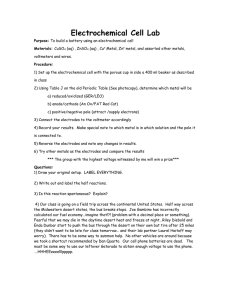

advertisement