Zimbabwe Assisted Pull System: Design of Ordering and Resupply

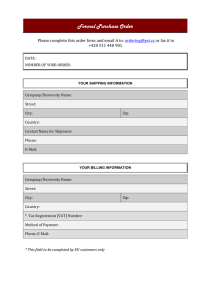

advertisement