Astec Advanced Power Systems

IM6C75AA

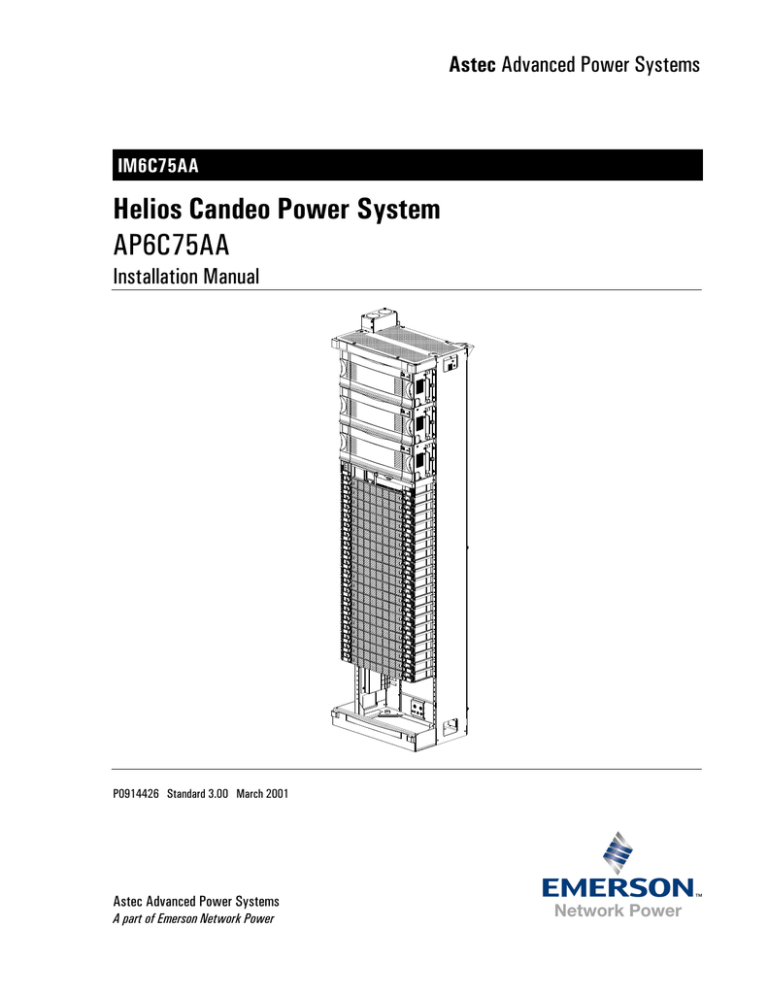

Helios Candeo Power System

AP6C75AA

Installation Manual

P0914426 Standard 3.00 March 2001

Astec Advanced Power Systems

A part of Emerson Network Power

Astec Advanced Power Systems

Helios Candeo Power System

AP6C75AA

Installation Manual

Document Number: IM6C75AA

Document Issue: 3.00

Document Status: Standard

Release Date: March 2001

P0914426

2001 Astec Advanced Power Systems Ltd.

All rights reserved

Printed in Canada

The information contained in this manual is the property of Astec Advanced Power Systems Ltd and is subject to change without

notice. Astec Advanced Power Systems Ltd reserves the right to make changes in design or components as progress in engineering

and manufacturing may warrant. Except as specifically authorized in writing by Astec Advanced Power Systems Ltd, the holder of

this manual shall keep all information contained herein confidential and shall protect same, in whole or in part, from disclosure and

dissemination to all third parties, and use the same for installation purposes only. Changes or modifications not expressly approved

by the party responsible for compliance could void the user’s authority to operate this equipment.

Astec Advanced Power Systems

A part of Emerson Network Power

Helios, Helios Candeo, Advanced Power Systems and the Helios Candeo logo are trademarks of Astec International Ltd. The

Emerson logo is a trademark and a service mark of Emerson Electric Co.

Helios Candeo Power System – AP6C75AA Installation Manual

5

Publication history

March 2001

Standard Issue 3.00. Revisions and improvements throughout the manual and

convert to latest Emerson template. (ECN102-25123)

January 2001

Standard Issue 2.0. Minor revisions throughout the manual and change from

Astec to Emerson identity.

December 2000

Standard Issue 1.0. General revision throughout to add latest information and

comments from field trial. The document is now rated Standard.

October 2000

Preliminary Issue 3.0. Third draft of this manual. General revision throughout to

add latest information.

August 2000

Preliminary Issue 2.0. Second draft of this manual. General revision throughout

for field trial purposes.

February 2000

Preliminary Issue 1.0. First draft of this manual for tech trial purposes.

Helios Candeo Power System – AP6C75AA Installation Manual

6 Publication history

This page is left blank intentionally.

IM6C75AA P0914426 Standard 3.00 March 2001

7

Contents

1.

1.1.

1.2.

1.3.

1.4.

About this document

13

Purpose of this document............................................................................................ 13

Applicability of this document ..................................................................................... 13

How this document is organized .................................................................................. 16

Reference documents.................................................................................................. 16

2.1.

2.2.

2.3.

2.4.

Preparation

17

Installation overview ................................................................................................... 17

Tools and test equipment ............................................................................................ 17

Precautions ................................................................................................................. 18

Receiving the material................................................................................................. 20

2.

3.

Locating and erecting the frame(s)

21

3.1. General ....................................................................................................................... 21

3.1.1.

Isolation considerations.................................................................................. 21

3.1.1.1. Floor isolation pad..................................................................................... 21

3.1.1.2. Top isolation ............................................................................................. 21

3.1.2.

Waterproof floor considerations ..................................................................... 21

3.2. Locating the frame(s) .................................................................................................. 22

3.2.1.

Marking the floor............................................................................................ 22

3.3. Floor anchoring ........................................................................................................... 23

3.3.1.

Drilling the floor.............................................................................................. 23

3.3.1.1. Concrete floor........................................................................................... 23

3.3.1.2. Wood floor ................................................................................................ 24

3.3.2.

Standard concrete floor anchoring.................................................................. 25

3.4. Erecting the frame(s)................................................................................................... 25

3.5. Securing the frame(s) in place ..................................................................................... 27

Helios Candeo Power System – AP6C75AA Installation Manual

8 Contents

3.5.1.

Standard anchoring in a concrete floor ........................................................... 27

3.5.2.

Wood floor...................................................................................................... 28

3.5.3.

Earthquake anchoring..................................................................................... 29

3.5.4.

Raised floor.................................................................................................... 30

3.6. Securing adjacent frames............................................................................................ 31

3.7. Installing the interframe DC link bar between adjacent frames DC backbones ............. 32

3.8. Top support................................................................................................................. 35

3.9. Installation of frame earthquake bracing kit(s)............................................................. 36

3.10. Module installation ...................................................................................................... 37

4.

Cabling and connecting

39

4.1. General ....................................................................................................................... 39

4.1.1.

Basic ruling .................................................................................................... 39

4.1.2.

Connecting lugs.............................................................................................. 40

4.1.3.

Torque values for bolted connections ............................................................. 43

4.1.4.

Cabling layout ................................................................................................ 43

4.2. Cabling and connecting the grounding leads ................................................................ 45

4.2.1.

Connecting the power plant frame ground (or safety ground) lead(s)............... 45

4.2.2.

Connecting the power plant battery return reference (BRR) lead .................... 48

4.3. Cabling and connecting the AC supplies for the rectifiers ............................................ 49

4.3.1.

Segregation between AC conductors and other conductors ............................ 49

4.3.2.

Cabling and connecting the rectifier AC interface modules ............................. 50

4.4. DC cabling and connecting .......................................................................................... 54

4.4.1.

Segregation from AC cables ........................................................................... 55

4.4.1.1. Connecting the battery cables in the Battery Connection Module(s) .......... 55

4.4.1.2. Connecting the DC load cables.................................................................. 56

4.5. Miscellaneous cabling and connecting ......................................................................... 62

4.5.1.

Connecting the Remote Sense leads to the batteries ...................................... 65

4.5.2.

Connecting the alarms to the office alarm circuit............................................ 66

4.5.3.

Installing and connecting the temperature probes........................................... 67

4.5.4.

Connecting of the interframe data link cable(s)............................................... 69

4.5.5.

Connecting the uninterrupted DC supply leads................................................ 69

4.5.6.

Connections at the communication ports ........................................................ 70

4.6. Final connections at the batteries................................................................................ 70

5.

Start-up and adjustment procedures

73

General ....................................................................................................................... 73

Voltage levels.............................................................................................................. 73

Installation of the rectifiers on the frame(s)................................................................. 73

Initial start-up, testing and adjustment of the system.................................................. 75

5.1.

5.2.

5.3.

5.4.

IM6C75AA P0914426 Standard 3.00 March 2001

Contents 9

6.

End of job routines and turnover

77

6.1. General ....................................................................................................................... 77

6.2. Designation ................................................................................................................. 77

6.2.1.

Frame numbering............................................................................................ 77

6.2.2.

Rectifiers........................................................................................................ 78

6.2.3.

Distribution .................................................................................................... 78

6.3. Installing the top cover................................................................................................ 80

6.4. Installation of the optional cabinet look-alike covers and door ..................................... 80

6.5. Touch-up of damaged and/or scratched painted surfaces ............................................ 81

6.6. Equipment turnover ..................................................................................................... 81

Appendix A: Drawings

83

Appendix B: Recommended AC generator requirements for APS power systems

85

Appendix C: Recommended replacement parts

87

Appendix D: Technical service assistance

89

List of terms

93

List of Figures

Figure 1.1 – Perspective view of a typical top fed AP6C75AA Helios Candeo power system .... 14

Figure 1.2 – Perspective view of a typical bottom fed AP6C75AA Helios Candeo power

system ........................................................................................................................ 15

Figure 3.1 – Floor anchor marking pattern ................................................................................ 23

Figure 3.2 – Appropriate method of lifting a Helios Candeo frame by its top ............................. 27

Figure 3.3 – Assembly stack-up for standard concrete anchors ................................................ 28

Figure 3.4 – Assembly stack-up for wood floor anchors............................................................ 28

Figure 3.5 – Assembly stack-up for earthquake concrete anchors............................................. 30

Figure 3.6 – Typical methods of anchoring a frame on a raised floor......................................... 30

Figure 3.7 – Alternate method of anchoring the rods to the sub-floor........................................ 31

Figure 3.8 – Top view of the interframe linking plate ................................................................ 31

Figure 3.9 – Securing adjacent frames...................................................................................... 32

Figure 3.10 – Top view of an installed interframe DC link bar between adjacent frames DC

backbones (top or bottom fed)..................................................................................... 33

Figure 3.11 – Perspective view of a bottom installed interframe DC link bar between

adjacent frames DC backbones (top fed applications).................................................. 34

Figure 3.12 – Perspective view of a top installed interframe DC link bar between adjacent

frames DC backbones (bottom fed applications) .......................................................... 34

Figure 3.13 – Exploded view of the bolting material for the interframe DC link bar ................... 35

Figure 3.14 – Typical top support group for standard frames.................................................... 36

Helios Candeo Power System – AP6C75AA Installation Manual

10 Contents

Figure 3.15 – Special support group for isolated applications.................................................... 36

Figure 3.16 – Installation of the frame earthquake bracing kit .................................................. 37

Figure 4.1 – Typical cabling layouts for top-fed Helios Candeo power system installations ....... 44

Figure 4.2 – Typical installation of the power system frame ground lead .................................. 47

Figure 4.3 – Connection of the frame ground lead inside the frame ........................................... 47

Figure 4.4 – Typical installation of the power system battery return reference ground lead...... 48

Figure 4.5 – Typical conduit, AC box and channel installation for bulk wiring (top fed

applications only) ........................................................................................................ 51

Figure 4.6 – Typical layout of individual armored cables inside the frame upright...................... 51

Figure 4.7 – Typical layout of individual armored cables on the outside of the frame ................ 52

Figure 4.8 – Cabling and connecting the rectifier AC interface modules .................................... 52

Figure 4.9 – Connecting the battery cables inside a Battery Connection Module....................... 56

Figure 4.10 – Cabling and connecting inside a Distribution 500 module .................................... 58

Figure 4.11 – How to remove load clips .................................................................................... 59

Figure 4.12 – Setting the J2 jumper for standard or mid-trip circuit breaker alarm.................... 59

Figure 4.13 – Enlarged view of installed angle bracket for cables larger than 2/0 ..................... 59

Figure 4.14 – Typical cabling layout inside top-fed and bottom-fed Helios Candeo power

systems ...................................................................................................................... 60

Figure 4.15 – Typical method of tapping a riser cable to a larger cable for a large load............. 62

Figure 4.16 – Connector layout inside the System Manager (front cover open) ......................... 63

Figure 4.17 – Wiring layout on the Battery Connection Module................................................. 64

Figure 4.18 – Method of connecting the Remote Sense lead to the batteries ............................ 66

Figure 4.19 – Side view of a temperature probe ....................................................................... 67

Figure 4.20 – Locating a temperature probe for external battery temperature measurements ... 68

Figure 4.21 – Locating a temperature probe for ambient temperature measurements ............... 68

Figure 4.22 – Connections of the interframe data link cable(s).................................................. 69

Figure 5.1 – Perspective view of a rectifier with the locking latches in the open position.......... 74

Figure 6.1 – Typical stamping of AP6C75AA Helios Candeo frame(s) ....................................... 78

Figure 6.2 – Typical stamping on the label inside a Distribution Module .................................... 79

Figure 6.3 – Typical stamping tags for conductors.................................................................... 79

Figure 6.4 – Installation of the optional cabinet look-alike covers.............................................. 81

List of Tables

Table 4.1 – Flammability rating of wires and cables for the United States ................................ 40

Table 4.2 – Flammability rating of wires and cables for Canada ............................................... 40

Table 4.3 – Connecting facilities of the AP6C75AA Helios Candeo power system .................... 40

Table 4.4 – Two-hole connecting lugs....................................................................................... 41

Table 4.5 – Cable size equivalents (AWG to Metric) .................................................................. 42

Table 4.6 – Torque values for bolted connections ..................................................................... 43

Table 4.7 – Recommended cable size for the frame ground collector......................................... 46

Table 4.8 – Preferred cable sizes and quantities for the AC input supply of the rectifiers.......... 50

Table 4.9 – Terminal assignment of the J4 connector on the System Manager......................... 62

Table 4.10 – Terminal assignment of the J7 connector on the System Manager....................... 63

Table 4.11 – Terminal assignment of the J8 connector on the System Manager....................... 63

Table 4.12 – Terminal assignment of the TB1 to TB4 terminal blocks and J11 connector on

the Battery Connection Module ................................................................................... 64

IM6C75AA P0914426 Standard 3.00 March 2001

Contents 11

List of Procedures

Procedure 3.1 – Marking the floor for the anchor positions....................................................... 22

Procedure 3.2 – Drilling for the anchor positions in a concrete floor.......................................... 24

Procedure 3.3 – Drilling for the anchor positions in a wood floor .............................................. 24

Procedure 3.4 – Installing and setting standard anchors in a concrete floor .............................. 25

Procedure 3.5 – Lifting and locating a Helios Candeo frame at its final location........................ 26

Procedure 3.6 – Securing the frame(s) to a concrete floor using standard anchors (nonearthquake applications) ............................................................................................. 27

Procedure 3.7 – Securing the frame(s) to a wood floor ............................................................. 28

Procedure 3.8 – Securing the frames to a concrete floor with earthquake anchors................... 29

Procedure 3.9 – Installing the interframe DC link bar between adjacent frames DC

backbones................................................................................................................... 32

Procedure 4.1 – Installing and connecting the power plant frame ground leads......................... 46

Procedure 4.2 – Installing and connecting the battery return reference lead ............................. 49

Procedure 4.3 – Cabling and connecting the rectifier AC interface modules .............................. 53

Procedure 4.4 – Connecting the battery cables at the Helios Candeo power system................. 55

Procedure 4.5 – Connecting the distribution loads .................................................................... 61

Procedure 4.6 – Installing and connecting the Remote Sense leads........................................... 65

Procedure 4.7 – Installing and connecting the temperature probes............................................ 67

Procedure 4.8 – Connecting the battery string cables at the batteries ...................................... 70

Procedure 5.1 – Inserting the rectifiers in the frame ................................................................. 75

Procedure 6.1 – Installing the doorframe .................................................................................. 80

Helios Candeo Power System – AP6C75AA Installation Manual

12 Contents

This page is left blank intentionally.

IM6C75AA P0914426 Standard 3.00 March 2001

13

1.

1.1.

About this document

Purpose of this document

This document provides detailed guidelines and procedures for the installation

of an AP6C75AA Helios Candeo power system.

This document is intended to be used by Astec Advanced Power Systems

installers, and non-Astec installers such as value added resellers and subcontractors, installing power equipment on behalf of Astec Advanced Power

Systems, as well as end users performing their own installation.

Note: Hazardous voltages are present in the AP6C75AA Helios Candeo

power system and the installation must be done by qualified personnel only. It

is strongly recommended that the installation personnel have basic power

installation training as is available from Astec Advanced Power Systems

(course No. M601).

1.2.

Applicability of this document

This document applies specifically to the initial installation of an AP6C75AA

Helios Candeo power system. For upgrades or modifications to an existing

AP6C75AA Helios Candeo power system, refer to the “Maintenance” Chapter

of user manual UM6C75A, or the specific method of procedure (MOP)

developed specifically for the project.

For installation guidelines applying to other equipment, refer to the applicable

Astec Advanced Power Systems manuals or, in the case of non-Astec equipment

(ex.: batteries), refer to manufacturer’s guidelines.

Specific Customer requirements may sometimes override the guidelines in the

present manual. In such cases, a written Customer agreement must be obtained.

The following illustrations show typical top fed and bottom fed AP6C75AA

Helios Candeo power systems.

Helios Candeo Power System – AP6C75AA Installation Manual

14 About this document

Figure 1.1 – Perspective view of a typical top fed AP6C75AA Helios Candeo power system

IM6C75AA P0914426 Standard 3.00 March 2001

About this document 15

Figure 1.2 – Perspective view of a typical bottom fed AP6C75AA Helios Candeo power system

Helios Candeo Power System – AP6C75AA Installation Manual

16 About this document

1.3.

How this document is organized

This document is divided into seven parts:

1)

2)

3)

4)

5)

6)

7)

1.4.

Front matters: contain the document information, the Table of Contents

and the present Chapter.

Preparation: describes the procedures when receiving, handling and

storing the equipment, the tools and test equipment requirements, and the

warning and cautions.

Physical installation: describes the procedures to install, level, align and

anchor the AP6C75AA Helios Candeo power system frame(s) and the

associated hardware.

Cabling and connecting: describes the procedures to cable and connect the

safety and reference grounds for the system, the AC supply for the

rectifiers, the batteries and the loads, as well as the wiring for the alarms

and the optional equipment such as battery disconnect unit(s).

Equipment start-up and adjustment procedures: describes the procedures

to insert the rectifiers and to bring the power system to a fully operational

state.

End of job routines and turnover: describes the items to be completed to

ensure that the equipment meets all applicable quality standards before it

is turned over to the Customer.

Appendices: provide information on drawings, Customer services,

technical support, and feedback form for the manual, as well as a list of

terms describing the acronyms and abbreviations used throughout the

document.

Reference documents

In addition to the present manual, it is recommended that the following

documentation be also available to perform the installation of the AP6C75AA

Helios Candeo power system:

• user manual UM6C75A, Description, Operation and Maintenance Manual

for the AP6C75AA Helios Candeo power system,

• user manual 167-7011-010, Voltage levels for controllers and rectifiers,

• other Astec Advanced Power Systems manuals as required, such as:

AP6C18MC/MD battery disconnect:

user manual UM6C18MC/MD

• all job specifications and drawings,

• other applicable manufacturer’s user guides (for example: batteries)

• specific Customer requirements and guidelines, if any.

IM6C75AA P0914426 Standard 3.00 March 2001

17

2.

Preparation

2.1.

Installation overview

The following is the recommended sequence for the installation and start-up

procedures. The sequence may change according to job and site conditions.

•

•

•

•

•

•

•

•

•

•

•

•

2.2.

Obtain the recommended tools and test equipment.

Read the "Precautions" section carefully.

Check that all the equipment and materials have been delivered.

Proceed with the physical installation of the power system frame(s).

Install and connect the safety and reference ground cables.

Install and connect the AC input cabling for the rectifier.

Install and connect the DC cabling between the AP6C75AA Helios Candeo

and the batteries.

Connect the loads to the Distribution Module(s) as required.

Install and connect the wiring for the optional equipment as required.

Install and connect the external alarm and monitoring wiring as required.

Insert the rectifiers in the rectifier frame(s).

Start-up, verify and adjust the complete system.

Tools and test equipment

The following tools and test equipment are required:

•

•

•

•

•

•

•

•

•

•

•

•

dolly truck

safety goggles

screwdriver, flat blade, 10 mm (3/8 in.)

screwdriver, flat blade, 2 mm (3/32 in.)

cable strippers/electrician’s knife

wire stripper

linesman pliers

hacksaw

cable cutters (up to 750 kcmil)

crimper and die set (up to T&B 15 ton head)

open end and box end wrench sets

socket set (12.5 mm [1/2 in.] drive)

Helios Candeo Power System – AP6C75AA Installation Manual

18 Preparation

•

•

•

•

•

•

•

•

•

•

•

•

2.3.

ratchet set (12.5 mm [1/2 in.] drive)

torque limiting wrench (10 mm [3/8 in.] drive)

canvas sheets, 1 m x 2 m (4 ft x 6 ft)

hammer drill

13 mm (1/2 in. [standard]) or 18 mm (11/16 in. [earthquake]) concrete bit

vacuum cleaner

Hilti HST 3/8” anchor setting tool

digital multimeter, Fluke 8050A or equivalent

clamp-on ammeter, Fluke 36 or equivalent

dry load bank, 48 V, 5 kW minimum

a portable computer equipped with modem and RS-232 ports

if two or more Helios Candeo frames are installed on your project, add a

large rubber mallet to the above list

Precautions

The following precautions shall be followed at all time when handling and

installing power equipment:

WARNING

Preventing electrical shocks

For safety reasons, the frame ground leads must always be

connected before any other leads. This is to prevent the

frame(s) and any other metallic structures from carrying

dangerous AC or DC voltage levels.

WARNING

Protecting the equipment against electrical damage.

Do not perform the final connecting of the battery leads to the

batteries before being instructed to do so in the appropriate

section of this manual.

WARNING

High Current Hazard

The rectifiers, and especially the batteries, can deliver high

current should a short to ground occur. When working on live

equipment, remove all personal jewelry, use properly insulated

tools, and cover any live busbars with a canvas sheet to prevent

short circuits caused by falling tools or parts.

IM6C75AA P0914426 Standard 3.00 March 2001

Preparation 19

WARNING

Protecting personnel against electrical shocks.

The power plant cabling shall be performed by qualified

personnel in conformance with local and national electrical

codes.

Input voltages to the rectifiers are at a dangerous level. Ensure

that the circuit breakers are locked in the OFF position at the

AC service panel before attempting to work on the power

plant. Dangerous voltages may still be present at the terminals

even if the rectifiers are OFF. Use a voltmeter to verify for the

presence of such voltages. Do not switch circuit breakers to

ON until the entire system has been assembled and that you

have been instructed to do so in the appropriate procedure.

Improper wiring can cause personal injury and equipment

damage. Verify for proper polarity of the battery leads before

connecting them to the power plant by clearly identifying the

positive and the negative leads.

CAUTION

Safety and equipment protection

Power equipment is heavy (pre-assembled frames, batteries,

etc.). Use a dolly truck, forklift, or hoist whenever possible for

handling and moving the equipment. If a forklift is used, do not

remove the shipping crates before the equipment has been

moved near its final installation location. If a dolly truck is used,

the shipping packages may be removed at the point of

reception. When handling frames with equipment mounted on

them, care must be exercised to ensure that they do not tip

over, as some of these are top heavy.

CAUTION

Protecting the equipment against damages when lifting

If a Helios Candeo frame needs to be lifted by its top for

moving or locating purposes, the appropriate hardware and

method described in the next Chapter must be used in order to

insure that no damages are caused to the top of the frame.

Helios Candeo Power System – AP6C75AA Installation Manual

20 Preparation

CAUTION

Protection of Customer premises

Protect the floors and walls against damage when handling the

equipment.

CAUTION

Preventing over torque damage

Do not over torque nuts and bolts. Over torquing causes the

threads to strip or the bolt to break. Use the appropriate torque

values indicated in each section.

CAUTION

Preventing personal injuries

When cutting material, always use the appropriate safety

equipment, such as gloves and goggles. Use a flat file to deburr

cuts.

CAUTION

Optimizing equipment life

To optimize the service life of this equipment, make sure there

are no obstructions in front of the ventilation openings.

2.4.

Receiving the material

The individual AP6C75AA Helios Candeo power system frames are shipped as

pre-assembled and pre-tested power frames, including the System Manager, the

rectifiers, the Battery Connection Module and the Distribution Module(s). Other

material such as the AC box, cables, wires, connecting material, fuses, and

mounting hardware are shipped separately.

Upon receiving the AP6C75AA Helios Candeo power system frame(s), System

Manager and rectifiers, remove the packaging and inspect for damage. Verify

that all material ordered is received and is in good condition. Report any missing

or damaged items to your Astec Advanced Power Systems Customer Services

department. Refer to Appendix D for the telephone number of the nearest

Customer Services department.

IM6C75AA P0914426 Standard 3.00 March 2001

21

3.

Locating and erecting the frame(s)

3.1.

General

This Chapter provides an overview of the requirements and procedures to be

followed when locating, erecting, aligning, leveling and anchoring the

AP6C75AA Helios Candeo power system frame(s).

3.1.1. Isolation considerations

In systems where ISG (isolated system ground) topology is used, hardware for

isolating the frame(s) from the floor is supplied per the specifications. It is

important that this isolation equipment be installed properly to preserve the

integrity of the isolated system ground system.

3.1.1.1. Floor isolation pad

The floor isolation pad is a sheet of isolating material that is inserted between

the floor and the bottom of the frame. Anchoring holes that match those of the

frame are provided in this isolation pad. The anchoring hardware also includes

special isolating washers and bushings. Refer to the anchor assembly stack-up

drawings in Figure 3.3 and Figure 3.5 further in this Chapter.

3.1.1.2. Top isolation

If the floor isolation kit is provided, it means that ISG topology is desired and

that the top of the equipment must also be kept isolated. If the top of the frame

is to be attached to the overhead structure (see section 3.8 further in this

Chapter), and if the overhead structure (auxiliary framing and cable racks) meets

ISG requirements, the top of the frame(s) may be attached directly to it with

metallic hardware. However, if the overhead structure does not meet ISG

requirements, special hardware shall be used to prevent electrical continuity

between the top of the frame(s) and the overhead structure.

3.1.2. Waterproof floor considerations

In locations where the natural water table is high, the building floor lying on or

in the ground may be of a special waterproof design to prevent water from

seeping through it.

Such floors must not be drilled for anchoring of the frame(s).

Helios Candeo Power System – AP6C75AA Installation Manual

22 Locating and erecting the cabinets

In non-earthquake areas, it may be permitted to locate the frame(s) on the floor

without floor anchoring. In earthquake areas, it may be necessary to pour a new

slab of concrete over the existing floor and to anchor the frame(s) into that new

slab.

At all times, it should be the Customer’s responsibility to provide the methods

and/or building modifications required for such applications.

3.2.

Locating the frame(s)

Use the floor plans and the specifications to determine where the AP6C75AA

Helios Candeo power system frame(s) will be located.

Note 1: There shall be a spacing of at least 6” (15 cm) between the back of

the Helios Candeo frame(s) and a wall or any other obstruction, this for

proper ventilation purposes.

Note 2: There shall be a spacing of at least 30” (75 cm) between the front of

the Helios Candeo frame(s) and a wall or any other equipment or obstruction,

this for safe and proper circulation of maintenance personnel.

Note 3: As mentioned in the previous Chapter, the AP6C75AA Helios

Candeo power system frames are shipped as pre-assembled and pre-tested

power frames, including the System Manager, the rectifiers, the Battery

Connection Module and the Distribution Module(s). Since it is required to

remove the rectifiers from the frame(s) in order to perform the AC input

cabling for the rectifiers per section 4.3.2 of Chapter 4, it is suggested to

remove all the rectifiers from the frame(s) now as this will lighten the frame

and thus ease the installation effort. Store the rectifiers in a safe location, and

do not reinstall these until told to do so in the appropriate section of this

manual.

3.2.1. Marking the floor

Use the template supplied with each Helios Candeo frame to mark the floor for

the anchor positions of the frame(s). Proceed as described in Procedure 3.1 and

as illustrated in Figure 3.1.

Procedure 3.1 – Marking the floor for the anchor positions

Step

1

2

3

Action

Use the floor plan to locate the template in the exact final position of the frame.

Use a marker pen to mark the floor for the anchor hole positions.

Repeat steps 1 and 2 for any other frame, if applicable.

–end–

IM6C75AA P0914426 Standard 3.00 March 2001

Locating and erecting the cabinets 23

Figure 3.1 – Floor anchor marking pattern

23.63”

2.00”

19.58”

16.15”

Preferred location for

the anchors

1.43”

12.15”

15.0”

Non-preferred location for

the anchors

Front

3.3.

Floor anchoring

Note: Floor anchoring requirements may be different where the equipment is

earthquake braced. Specific requirements for such applications shall be either

covered in the job specifications or provided by the Customer.

3.3.1. Drilling the floor

3.3.1.1. Concrete floor

For applications where concrete floor anchoring is used, drill the floor as

described in the following procedure.

CAUTION

Preserving the integrity of earthquake installations

If the application is earthquake but regular anchors were

provided in the specifications, do not use the latter since the

installation will not meet earthquake requirements. Approved

earthquake type anchors shall be ordered to complete the

installation as required to meet earthquake requirements.

However, if the application is non-earthquake but earthquake

anchors were provided in the specifications, the latter can be

used if standard anchors are not readily available, in order to

avoid time loss while waiting for standard anchors. The

earthquake anchors will only provide a stronger and better

support.

Helios Candeo Power System – AP6C75AA Installation Manual

24 Locating and erecting the cabinets

Procedure 3.2 – Drilling for the anchor positions in a concrete floor

Step

Action

1

Check with the customer and architect floor plans that there are no pipes,

conduits, beams or any other obstructions in the concrete slab that could

interfere with the drilling.

2

Place the inlet of a vacuum cleaner near the floor marking in such a way that it

will pick-up the dust while drilling the hole.

3

Start the vacuum cleaner.

4

Use a hammer drill equipped with the appropriate size masonry drill bit to drill

the hole; maintain the drill at a 90° angle with the floor.

Note 1: For standard anchors (HILTI HDI 3/8” or 10 mm) supplied with

Advanced Power Systems equipment, use a 1/2” (13 mm) drill bit.

Note 2: For earthquake anchors (HILTI HSL 11/16” or 18 mm) supplied with

Advanced Power Systems equipment, use an 11/16” (18 mm) drill bit.

Note 3: For standard anchors, the depth of the hole should be the length of the

anchor plus 1/8” (3 mm). For earthquake anchors, the depth of the hole should

be 4” (102 mm).

5

After drilling the hole, use the vacuum cleaner to clean all the dust in and

around the hole.

6

Repeat steps 2 to 5 for every anchoring hole for the frame.

7

Repeat steps 2 to 6 for any other frame, if applicable.

–end–

3.3.1.2. Wood floor

For applications where wood floor anchoring is used, drill the floor as described

in the following procedure.

Procedure 3.3 – Drilling for the anchor positions in a wood floor

Step

Action

1

Check with the customer and the architect floor plans that there are no pipes,

conduits, beams or other obstructions in the wood floor that could interfere

with the drilling.

2

Use a drill equipped with the appropriate size wood drill bit to drill the hole;

maintain the drill at a 90° angle with the floor.

Note: The size of the hole should be approximately 60% of the size of the lag

screw.

–continued–

IM6C75AA P0914426 Standard 3.00 March 2001

Locating and erecting the cabinets 25

3

After drilling the hole, use the vacuum cleaner to clean all the wood chips and

dust in and around the hole.

4

Repeat steps 2 and 3 for every anchoring hole for the frame.

5

Repeat steps 2 to 4 for any other frame, if applicable.

–end–

3.3.2. Standard concrete floor anchoring

Standard concrete floor anchoring is that type used in non-earthquake areas. If

standard concrete floor anchoring is used, the anchors must be installed and set

now as described in the following procedure (refer to Figure 3.3) before erecting

the frame(s).

Procedure 3.4 – Installing and setting standard anchors in a concrete floor

Step

Action

1

Drop the anchor into the hole drilled per Procedure 3.2.

2

Insert the appropriate setting tool into the anchor and hit it with a hammer to

expand the anchor until the collar of the setting tool rests against the shoulder

of the anchor.

3

Remove the setting tool.

4

Repeat steps 1 to 3 for every anchor for the frame.

5

Repeat steps 1 to 4 for any other frame, if applicable.

–end–

3.4.

Erecting the frame(s)

CAUTION

Protect the equipment against damages when lifting.

If a Helios Candeo frame needs to be lifted by its top for

moving or locating purposes, the appropriate hardware and

method described below must be used in order to insure that

no damages are caused to the top of the frame. The same

method applies to lift the frame out of its shipping crate.

Each Helios Candeo frame is shipped with a stiffening bar and two lifting

eyebolts installed at the factory (see Figure 3.2). Do not remove, loosen or

replace these eyebolts and this stiffening bar until the frame is properly installed

and anchored to the floor at its final location. These eyebolts and stiffening bar

shall be reinstalled should the frame needs to be lifted by its top at anytime.

Helios Candeo Power System – AP6C75AA Installation Manual

26 Locating and erecting the cabinets

There is only one appropriate method to lift a Helios Candeo frame by its top

and it is described in the following procedure and illustrated in Figure 3.2. This

method also applies when lifting the frame out of its shipping crate.

CAUTION

Protect the AC box against damages when lifting the frame.

If provided, the optional AC box used for the AC feeds of the

rectifiers is shipped separately. If, for any reason, this AC box

has been installed prior to lifting the frame by its top, remove it

to prevent damages to it during lifting.

Procedure 3.5 – Lifting and locating a Helios Candeo frame at its final location

Step

Action

1

Install a shackle in each factory-installed eyebolt at the top of the frame,

ensuring that the factory-installed stiffening bar is also present.

2

Install a lifting sling of appropriate weight capacity and length as shown in

Figure 3.2.

Note: It is important that the length be appropriate to maintain an angle of

more than 45°.

3

Use a hoist of appropriate weight capacity to lift the frame up and of the floor.

4

If the hoist is of the mobile type, use it to carry the frame to its final location.

If the hoist is of the fixed type, lower the frame on a dolly or forklift to carry

the frame to its final location. Then, the same hoisting method described in

steps 1 to 3 shall be used to lift the frame off the dolly or forklift and lower it

to its final location on the floor.

5

Use the same procedure for any other frame, if applicable.

–end–

IM6C75AA P0914426 Standard 3.00 March 2001

Locating and erecting the cabinets 27

Figure 3.2 – Appropriate method of lifting a Helios Candeo frame by its top

Typical sling

arrangement

Shackle

Never use the sling

without shackles as this

may break the eyebolts

Direction

of pull

Shackle

Do not use at 45° or less

Top of frame

Stiffening bar:

DO NOT

REMOVE

PRIOR TO

LIFTING

3.5. Securing the frame(s) in place

3.5.1. Standard anchoring in a concrete floor

Secure the frame(s) to a concrete floor using standard anchors as described in

the following procedure (refer to Figure 3.3).

Procedure 3.6 – Securing the frame(s) to a concrete floor using standard anchors

(non-earthquake applications)

Step

Action

1

If applicable, install the floor isolation pad where the frame is to be installed.

2

Lower the frame to its exact final position over the anchoring holes (and the

isolation pad if applicable).

3

Install the anchoring stud in each anchoring hole.

4

Install the anchoring hardware for each anchor; follow the stack-up order

shown in Figure 3.3.

5

Level the frame for proper horizontal and vertical leveling as required using

incompressible shims.

6

Tighten each anchor applying a torque of 25 ft-lb (34 N-m).

7

Repeat steps 1 to 6 for any other frame, if applicable.

–end–

Helios Candeo Power System – AP6C75AA Installation Manual

28 Locating and erecting the cabinets

Figure 3.3 – Assembly stack-up for standard concrete anchors

Threaded rod

Flat washer

Split ring washer

Flat washer

Hex nut

Isolating bushing

Frame base

Isolation pad

(optional)

Concrete

floor

3/8" (10 mm)

drop in anchor

3.5.2. Wood floor

Secure the frame(s) to a wood floor as described in the following procedure

(refer to Figure 3.4).

Procedure 3.7 – Securing the frame(s) to a wood floor

Step

Action

1

Lower the frame in its exact final position, over the anchoring holes drilled per

Procedure 3.3.

2

Install the anchoring hardware for each anchor position; follow the stack-up

order shown in Figure 3.4.

3

Level the frame for proper horizontal and vertical levelling as required as

required using incompressible shims.

4

Tighten each lag screw as required.

5

Repeat steps 1 to 4 for any other frame, if applicable.

–end–

Figure 3.4 – Assembly stack-up for wood floor anchors

Washer

Washer

Lag screw

IM6C75AA P0914426 Standard 3.00 March 2001

Locating and erecting the cabinets 29

3.5.3. Earthquake anchoring

Earthquake anchoring is that type used in earthquake areas up to Zone 4 per

requirements from Telcordia Technologies (formerly Bellcore).

CAUTION

Preserving the integrity of earthquake installations

The AP6C75AA Helios Candeo power system frame is

earthquake qualified when properly anchored to a 3000 psi

(2.11 kg per sq. mm) concrete floor. The earthquake

qualification is not valid otherwise.

CAUTION

Preserving the integrity of earthquake installations

Zone 4 (Bellcore) earthquake rating of the power system

cannot be guaranteed on floors other than concrete. When

installed on a wooden floor, the installation is not earthquake

qualified.

Secure the frame(s) to a concrete floor using earthquake anchors as described in

the following procedure (refer to Figure 3.5).

Procedure 3.8 – Securing the frames to a concrete floor with earthquake anchors

Step

Action

1

If applicable, install the floor isolation pad where the frame is to be installed.

2

Lower the frame to its exact final position over the anchoring holes (and the

isolation pad if applicable).

3

Drop the anchors into the holes drilled per Procedure 3.2.

4

If necessary, use a hammer to insert the anchors until the upper edge of their

upper anchor sleeves is flush with the frame base. See Figure 3.5.

Note: The penetration hatch marks on the upper anchor sleeve are at least

flush with the concrete floor or below it.

5

Install the anchoring stud in each anchoring hole.

6

Install the anchoring hardware for each anchor; follow the stack-up order

shown in Figure 3.5.

7

Level the frame for proper horizontal and vertical leveling as required as

required using incompressible shims.

–continued–

Helios Candeo Power System – AP6C75AA Installation Manual

30 Locating and erecting the cabinets

8

Set each anchor applying a torque of 60 ft-lb (81 N-m).

9

Repeat steps 1 to 8 for any other frame, if applicable.

–end–

Figure 3.5 – Assembly stack-up for earthquake concrete anchors

Threaded rod

Flat washer

Plate washer

Frame base

Hex nut

Belleville washer

Insulating bushing (optional)

Isolation pad

(optional)

Leveling shims

Sleeve

Collapsible sleeve

Top of sleeve flush

with frame base

Expanding sleeve

Cone

Concrete

floor

Penetration hatch marks

(can be lower than floor

level)

3.5.4. Raised floor

The methods of securing a Helios Candeo frame on a raised floor may vary

according to the type of raised floor being used and specific Customer

requirements. Figure 3.6 and Figure 3.7 show typical suggested methods of

securing a Helios Candeo frame on a raised floor. Note that these illustrations

are for reference only and that the shown method for earthquake applications is

not certified.

Figure 3.6 – Typical methods of anchoring a frame on a raised floor

Raised

floor

Raised

floor

5/8”

anchor

5/8” threaded

rods, four per

framework

5/8” anchor

In non-earthquake applications

IM6C75AA P0914426 Standard 3.00 March 2001

5/8” threaded rods,

eight per framework (four

vertical, four at an angle)

Adjustable sets of

90° brackets, eight

per framework

In earthquake applications

Locating and erecting the cabinets 31

Figure 3.7 – Alternate method of anchoring the rods to the sub-floor

Cantruss or Unistrut channels anchored to floor, then rods bolted to channels.

Specific requirements and procedures for the anchoring of power frames may be

supplied either by the job specifications, by the Customer or by the raised floor

manufacturer.

3.6.

Securing adjacent frames

Adjacent frames are secured to each other using the interframe linking plate

(P0916605) shown in the following illustration. This plate is shipped with every

frame. Note that the lifting eyebolts and stiffening bar must be removed prior to

installing the plate. Note also that if top supports are used per section 3.8, the

installation of the plate will be part of it.

Figure 3.8 – Top view of the interframe linking plate

Figure 3.9 shows the typical method of securing adjacent frames to each other

with the interframe linking plate.

Helios Candeo Power System – AP6C75AA Installation Manual

32 Locating and erecting the cabinets

Figure 3.9 – Securing adjacent frames

Use the interframe linking plate

(shown in the previous illustration) to

secure adjacent frames to each

other. Screw finger tight only until the

interframe DC link bar and top

supporting hardware are installed.

3.7.

Installing the interframe DC link bar between adjacent frames DC backbones

Install and secure the interframe DC link bar between adjacent frame DC

backbones as described in the following procedure and as illustrated in Figure

3.10, Figure 3.11, Figure 3.12, and Figure 3.13. The procedure is the same for

top or bottom fed applications, as well as from the 2nd to the 3rd frame, from the

3rd frame to the 4th frame, and so on.

CAUTION

Prevent damages to equipment

Handle the interframe DC link bar very carefully to prevent any

damages that could prevent the bar from being properly fitted

into place.

Procedure 3.9 – Installing the interframe DC link bar between adjacent frames DC

backbones

Step

1

Action

For a top fed application, install the anchor protective covers supplied as part of

the DC link bar kit over the anchoring studs that will be close to it once the DC

link bar is installed. To do so, peel of the protective paper over the stick-on tape

on the small tabs of the protective covers and secure in place by pressing firmly

in place as shown in Figure 3.10 and Figure 3.11.

–continued–

IM6C75AA P0914426 Standard 3.00 March 2001

Locating and erecting the cabinets 33

2

Carefully slide the interframe DC link bar into position. Enter through the front

or through the openings made for that purpose in the frame uprights, whichever

is most convenient, as shown by the arrows in Figure 3.10.

3

Align the mounting holes on the interframe DC link bar with the mounting holes

on the back bone inside the first frame and secure in place using the hardware

supplied for that purpose. Refer to Figure 3.13.

Note: If it is difficult to do the final aligning of the holes, use a rubber mallet

and give horizontal blows on the bar as required. DO NOT use a metal tool, as

this will damage the bar.

4

Align the mounting holes on the interframe DC link bar with the mounting holes

on the back bone inside the second frame and secure in place using the

hardware supplied for that purpose. Refer to Figure 3.13.

Note 1: It may be necessary to loosen the frame from the floor anchors and to

loosen the interframe linking plate installed per section 3.6 in order to be able to

do so.

Note 2: Again, If it is difficult to do the final aligning of the holes, use a rubber

mallet and give horizontal blows on the bar and/or the frame as required. DO

NOT use a metal tool, as this will damage the bar and/or the frame.

5

Install safety liners to protect the connections at each end of the DC link bar(s)

as required. Refer to Figure 3.12.

6

Once the interframe linking bar is properly secured, tighten the interframe

linking plate at the top of the frames and retighten the framework(s) to the

floor if loosen per note 1 in step 4.

–end–

Figure 3.10 – Top view of an installed interframe DC link bar between adjacent frames DC backbones

(top or bottom fed)

Tab with stick-on tape

Tab with stick-on tape

Anchor cover cap

Anchor cover cap

(top fed applications only)

DC link bar

Front

Helios Candeo Power System – AP6C75AA Installation Manual

34 Locating and erecting the cabinets

Figure 3.11 – Perspective view of a bottom installed interframe DC link bar between adjacent frames

DC backbones (top fed applications)

Anchor

cover cap

Figure 3.12 – Perspective view of a top installed interframe DC link bar between adjacent frames DC

backbones (bottom fed applications)

IM6C75AA P0914426 Standard 3.00 March 2001

Locating and erecting the cabinets 35

Figure 3.13 – Exploded view of the bolting material for the interframe DC link bar

3.8.

Top support

The type of frame used for the Candeo power system is designed for

freestanding seismic applications and must not be attached to any other

structure than the supporting floor in order to maintain the anti-seismic

qualification in seismic applications.

In non-seismic applications, if the top of the frame is to be attached to any

overhead structure, the standard method consists of using standard hardware to

attach the top of the frame to a ceiling or wall supported overhead structure

(auxiliary framing).

Follow standard installation drawings supplied through the specifications. Figure

3.14 shows a typical top support group for standard frames.

Helios Candeo Power System – AP6C75AA Installation Manual

36 Locating and erecting the cabinets

Figure 3.14 – Typical top support group for standard frames

A

Shown without the cable rack for clarity

Interframe link

plate if two or

more frames

are provided

Auxiliary framing

A

Cable rack

Front view

Front

VIEW A - A

Frame channel

upright

Note: If the installation is attached to an overhead structure attached to the

ceiling or walls and that the site requires ISG grounding topology, then top

isolation hardware must always be used along with the top supporting

hardware (see section 3.1.1.2 and Figure 3.15),

Figure 3.15 – Special support group for isolated applications

A

A

A0802264

5” wraparound

isolating sheet

(one per channel)

Side view of

top of frame

VIEW A - A

3.9.

Installation of frame earthquake bracing kit(s)

If the installation is seismic qualified, install the optional earthquake bracing

kit(s) provided for the frame(s) of your AP6C75AA Helios Candeo power

system as shown in the following illustration.

Note 1: It may be necessary to remove some modules to install the

earthquake bracing kit(s).

Note 2: All positions that are not occupied by equipment on the frame

(System Manager, rectifiers, Distribution Modules, etc.) must be filled with

blank panels in order to maintain the seismic qualification of the system.

IM6C75AA P0914426 Standard 3.00 March 2001

Locating and erecting the cabinets 37

Figure 3.16 – Installation of the frame earthquake bracing kit

P0909060

relay rack

7 foot high

(not part of kit)

P0909058

strap

(2 places)

P0916463

hex jam nut

(4 places)

P0432022

hex nut

(4 places)

P0912564

tapered bushing

(4 places)

P0916467

button head screw

(4 places)

P0382879

Lock washer

(4 places)

Note: On one of the bracing bar, it may be necessary to relocate the

P0432022 hex nut behind the bar in order to clear some of the amber plastic

caps protecting the head of the screws holding the backbone in place. Do not

remove these plastic caps and be careful not to break these since the screws

are carrying the potential (+ or –) of the backbone portion they are holding.

3.10. Module installation

Once the physical installation of the frame(s) and associated hardware is

completed, install/reinstall the equipment modules that require cabling

operations (System Manager, Battery Connection Modules and Distribution

Modules).

Note: Ensure that the mounting rails on each set of two adjacent modules are

properly engaged into each other before sliding the module into the frame in

order that each module is mounted in a perfect horizontal position and at the

appropriate level to match the mounting holes on the frame uprights. The top

of the framework is also equipped with a mounting rail to guide and secure

the first module at the top of the frame.

Helios Candeo Power System – AP6C75AA Installation Manual

38 Locating and erecting the cabinets

The rectifiers do not require any cabling and shall not be installed until told to

do so in the appropriate Chapter.

Follow the equipment specifications provided for your job, observing the

position numbers punched onto the frame uprights near the mounting holes.

IM6C75AA P0914426 Standard 3.00 March 2001

39

4.

Cabling and connecting

4.1.

General

This Chapter covers the cabling and connecting procedures for the AP6C75AA

Helios Candeo power system. These procedures are divided into five sections:

•

•

•

•

cabling and connecting the frame and reference grounds,

cabling and connecting the AC supply for the rectifiers,

cabling and connecting the DC cables from the batteries,

cabling and connecting the DC cables between the Helios Candeo power

system and the loads, and

• miscellaneous cabling.

4.1.1. Basic ruling

The followings are basic rules applying to cabling and connecting:

• It is very important that properly sized conductors be installed between the

AC service panel and the rectifiers, as well as between the power plant, the

batteries and the loads. The protective circuits in the equipment, the

performance, and the overall safety of the equipment depend on the proper

amperage and acceptable voltage drops.

• Although DC power wiring and cabling in telecommunication applications

tend to exceed electrical code requirements, mostly due to the voltage drop

requirements, all applicable electrical code(s) take precedence over the

guidelines and procedures in the present Chapter, wherever applicable.

• When terminal lugs are used, these should be of the crimped type, shall have

two holes for ground cables, and should preferably have two holes also for

other cables.

• DC leads are usually all black. However, there may be exceptions where the

Customer requires that the equipment ground be green, and some battery

feeders be color coded if several feeds are used.

• All wires and cables used shall be made of copper covered with insulation

having the flammability rating required by the governing code. Refer to

Table 4.1 and Table 4.2 for guidelines based on the National Electrical Code

(USA) and the Canadian Electrical Code (Canada) respectively.

Helios Candeo Power System – AP6C75AA Installation Manual

40 Cabling and connecting

Table 4.1 – Flammability rating of wires and cables for the United States

If the cables are used in:

Plenum (note 1)

Commercial buildings, including risers

Commercial buildings, general purpose (no risers)

they must meet the following rating (note 2):

UL910 (“CMP” marking) (or FT1 in conduit)

UL1666 (“CMR” marking)

UL1581 or IEEE383 (“CMG” or “CM” marking)

Table 4.2 – Flammability rating of wires and cables for Canada

If the cables are used in:

Plenum (note 1)

Commercial buildings

they must meet the following rating (note 3):

FT6 (“CMP” marking) (or FT1 in conduit)

FT4 (“CMR” marking)

Note 1: * Plenums are defined as suspended ceilings or raised floors whose

space is used in the handling of air.

Note 2: If the building is a utility as defined by the NEC Article 90-2(b)(4),

then UL VW1 rated cable is permitted but not preferred.

Note 3: If the building is a utility as defined by the CEC Section 0, then FT1

rated cable is permitted but not preferred.

4.1.2. Connecting lugs

Table 4.3 shows the connecting facilities available on the Helios Candeo

bussing, while Table 4.4 shows the two-hole connecting lugs available from

Astec Advanced Power Systems. Table 4.5 provides a list of equivalent metric

size cables for commonly used American Wire Gauging (AWG) cables.

Note: Since the Helios Candeo is a very compact power system, the turning

radius for cabling within the frame is limited. It is therefore recommended to

use only flex type cables.

Table 4.3 – Connecting facilities of the AP6C75AA Helios Candeo power system

Connecting point

–48 V and BR busbars in the Battery

Connection Module

•

•

Single load clip in a Distribution Module

Double load clip in a Distribution Module

BR+ busbar in a Distribution Module

Copper angle for large cable on BR busbar

•

•

•

•

Available terminations

6 sets of holes for either 3/8” bolts at 1” c-c or 1/2” bolts at

1-3/4” c-c per busbar

5 sets of holes for 1/4” bolts at either 1” c-c or 5/8” center

per busbar

1 set of 1/4” studs at 5/8” c-c per circuit breaker position

1 set of 3/8” studs at 1” c-c per circuit breaker position

20 sets of holes tapped for 1/4” bolts at 5/8” c-c

1 set of holes tapped for 3/8” bolts at 1” c-c

–continued–

IM6C75AA P0914426 Standard 3.00 March 2001

Cabling and connecting 41

Top and bottom frame ground connecting

plate

•

•

•

1 set of holes tapped for 1/4” bolts at 5/8” c-c

1 set of holes tapped for 3/8” bolts at 1” c-c

1 set of holes tapped for 1/2” bolts at 1-3/4” c-c

Table 4.4 – Two-hole connecting lugs

Terminal lug

CPC

Gauge

Bolt size

Holes spacing

C-C (in.)

Tongue width

(approx. in.)

A0355546

A0724948

A0344529

A0379437

A0377621

A0367944

A0376705

A0605216

A0378678

A0772786

A0902814

A0720337

A0668456

A0666799

A0668309

A0618236

A0600125

A0297944

A0368972

A0380048

A0320864

A0902928

A0368787

A0297945

A0297946

A0361762

A0297947

A0320863

A0616116

A0297949

10 AWG

10 AWG

8 AWG / 8 Flex

8 AWG / 8 Flex

8 AWG / 8 Flex

6 AWG / 6 Flex

6 AWG / 6 Flex

6 AWG / 6 Flex

4 AWG / 4 Flex

4 AWG / 4 Flex

4 AWG / 4 Flex

2 AWG

2 AWG

2 Flex

2 Flex

1/0 AWG

1/0 AWG

1/0 AWG

1/0 AWG

2/0 AWG or 1/0 Flex

2/0 AWG or 1/0 Flex

2/0 Flex

2/0 Flex

2/0 AWG or 1/0 Flex

2/0 Flex

4/0 AWG

4/0 AWG

4/0 Flex

4/0 Flex (NT*)

4/0 Flex

1/4 in.

1/4 in.

1/4 in.

1/4 in.

3/8 in.

1/4 in.

1/4 in.

3/8 in.

1/4 in.

1/4 in.

3/8 in.

1/4 in.

3/8 in.

1/4 in.

3/8 in.

1/4 in.

1/4 in.

3/8 in.

1/2 in.

1/4 in.

3/8 in.

1/4 in.

3/8 in.

1/2 in.

1/2 in.

3/8 in.

1/2 in.

3/8 in.

3/8 in.

1/2 in.

5/8 in.

1 in.

5/8 in.

1 in.

1 in.

5/8 in.

1 in.

1 in.

5/8 in.

1 in.

1 in.

5/8 in.

1 in.

5/8 in.

1 in.

5/8 in.

1 in.

1 in.

1.75 in.

5/8 in.

1 in.

5/8 in.

1 in.

1.75 in.

1.75 in.

1 in.

1.75 in.

1 in.

1 in.

1.75 in.

0.43 - 0.47

0.41 - 0.47

0.43 - 0.47

0.41 - 0.47

0.57

0.42 - 0.45

0.58

0.58

0.5 - 0.56

0.5

0.58

0.59 - 0.61

0.67

0.67 - 0.68

0.67 - 0.68

0.75

0.75

0.75

0.75

0.83

0.83

0.94

0.94

0.75

0.94

1.03

1.03

1.25

0.76

1.25

Fits single (S)

and/or double

(D) load clips

S

S

D

S

D

S

D

S

D

S

D

S

D

S

D

S

D

D

D

D

–continued–

Helios Candeo Power System – AP6C75AA Installation Manual

42 Cabling and connecting

A0902943

A0352982

A0297951

A0320862

A0902946

A0320865

A0361885

A0297952

A0902953

A0322413

A0320867

A0379473

A0654576

A0297954

A0322414

A0617599

A0320866

313 kcmil

350 kcmil

350 kcmil

373 kcmil

373 kcmil (NT*)

373 kcmil

500 kcmil

500 kcmil

535 kcmil

535 kcmil (NT*)

535 kcmil

750 kcmil

750 kcmil (NT*)

750 kcmil

777 kcmil

777 kcmil (NT*)

777 kcmil

3/8 in.

3/8 in.

1/2 in.

3/8 in.

3/8 in.

1/2 in.

3/8 in.

1/2 in.

3/8 in.

3/8 in.

1/2 in.

3/8 in.

3/8 in.

1/2 in.

3/8 in.

3/8 in.

1/2 in.

1 in.

1 in.

1.75 in.

1 in.

1 in.

1.75 in.

1 in.

1.75 in.

1 in.

1 in.

1.75 in.

1 in.

1 in.

1.75 in.

1 in.

1 in.

1.75 in.

1.38

1.29 - 1.34

1.29 - 1.34

1.52 - 1.63

0.96

1.52 - 1.61

1.52 - 1.61

1.52 - 1.61

1.81

1.63

1.81

1.89 - 1.94

1.63

1.89 - 1.94

2.17 - 2.19

1.63

2.17

–end–

Note: * NT means narrow tongue.

Table 4.5 – Cable size equivalents (AWG to Metric)

Cable size (see notes 1 and 2)

20 AWG

18 AWG

16 AWG

14 AWG

12 AWG

10 AWG

8 AWG

6 AWG

4 AWG

2 AWG

0 AWG (or 1/0)

00 AWG (or 2/0)

0000 AWG (or 4/0)

313 MCM (or kcmil)

350 MCM (or kcmil)

373 MCM (or kcmil)

Circular mils

1020

1624

2583

4107

6530

10380

16510

26250

41740

66370

105600

133100

211600

313600

350000

373700

Square millimeters

0.519

0.8232

1.309

2.081

3.309

5.261

8.368

13.30

21.15

33.63

53.48

67.42

107.2

159

177.36

189

–continued–

IM6C75AA P0914426 Standard 3.00 March 2001

Equivalent metric cable

1

1

1.5

2.5

4

6

10

16

25

35

50 or 70

70

120

150 or 185

185

185 or 240

Cabling and connecting 43

500 MCM (or kcmil)

535 MCM (or kcmil)

750 MCM (or kcmil)

777 MCM (or kcmil)

500000

535300

750000

777700

253.36

271

380.00

394

300

300

400

400

Note 1: For large cables, sizes are expressed using the shortcut notation

MCM or kcmil which both represent “thousands of circular mils”.

Note 2: Wire sizes 0, 00 and 0000 are also represented as 1/0, 2/0 and 4/0

respectively.

4.1.3. Torque values for bolted connections

Bolted connections should be properly tightened to ensure appropriate contact

without stressing or breaking the bolts. This is done by using a torque wrench to

apply the appropriate torque value. The following Table provides a list of torque

values applying to various sizes of bolts.

Table 4.6 – Torque values for bolted connections

Bolt size

#8

#10

1/4”

5/16”

3/8”

7/16”

1/2”

5/8”

3/4”

7/8”

1”

Threads/inch

32

36

24

32

20

28

18

20

16

24

14

20

13

20

11

10

9

8

Torque (in-lb)

18

20

23

32

80

100

140

150

250

275

400

425

550

575

920

1400

1950

2580

Tension (lb)

625

685

705

940

1840

2200

2540

2620

3740

3950

5110

5120

6110

6140

7350

9300

11100

12900

4.1.4. Cabling layout

The AP6C75AA Helios Candeo power system makes use of plug-in interfaces

that reduce cabling operations to a minimum. The cabling required to be done at

the time of installation is very straightforward.

• The rectifier’s AC cables enter the frame on the left side, as viewed from the

front, and are brought to the rectifier AC interface modules, some inside the

fame upright and some on the outside of the frame for individual armored

cables, or through the AC channel for the bulk wiring option.

Helios Candeo Power System – AP6C75AA Installation Manual

44 Cabling and connecting

• The battery cables are entering the frame through the center, at the top for a

top-fed system, or at the bottom for a bottom-fed system.

• The load cables to the protection devices and the battery return busbars

inside the Distribution Modules are entering the frame through the center, at

the top for a top-fed system, or at the bottom for a bottom-fed system.

• The system alarm interface cable with the outside world shall always exit the

main cabinet on the left side, as viewed from the rear.

Figure 4.1 shows typical cabling layouts for top-fed Helios Candeo power

system installations (note that your equipment may be different than that shown

in this illustration).

Figure 4.1 – Typical cabling layouts for top-fed Helios Candeo power system installations

System equipped with:

1 - Battery Connection Module

1 - large Distribution Module

1 - small Distribution Module

IM6C75AA P0914426 Standard 3.00 March 2001

System equipped with:

1 - Battery Connection Module

2 - small Distribution Modules

Cabling and connecting 45

4.2.

Cabling and connecting the grounding leads

This section covers the cabling and connecting of the grounding leads for the

AP6C75AA Helios Candeo power system: the frame or safety ground lead(s) for

the frame(s) and the battery return reference (BRR) ground lead for the system.

CAUTION

Follow local requirements and electrical code.

The grounding methods described in this section are generic.

Specific local, provincial, state or federal electrical codes and

grounding requirements, as well as specific Customer or

communication equipment requirements shall prevail.

CAUTION

Maintain the integrity of the frame or safety ground.

The frame or safety ground shall not be confused with the

reference ground lead, nor with the battery return leads. The

frame or safety ground shall be wired in such a way as not to be

carrying any AC or DC current at any time.

Note 1: In some equipment sites, depending on the grounding topology and

the size of the building, the floor ground bar (FGB) and the building principal

ground (BPG) may be the same busbar.

Note 2: In some equipment sites, depending on the grounding topology, the

power plant battery return reference ground bar (BRR) may be determined as

being the single point ground (SPG). Then, the battery return reference (BRR)

lead is usually run to the floor ground bar (FGB).

4.2.1. Connecting the power plant frame ground (or safety ground) lead(s)

Unless specifically instructed otherwise in the specifications or by the Customer,

the frame ground leads, also referred to as the safety ground leads, are usually

connected as described in Procedure 4.1 and as shown in Figure 4.2 and Figure

4.3.

Note 1: The frame ground collector cable is normally sized according to its

length (distance between the main DC distribution cabinet and the FGB or

BPG) as well as the maximum fuse or circuit breaker size that can be provided

in the power plant. Refer to the following Table for the AP6C75AA Helios

Candeo power system.

Note 2: The frame ground drop into the Helios Candeo frame shall be the

same size as the frame ground collector. The frame ground drop into battery

stands, racks or stacks is usually No. 6 AWG.

Helios Candeo Power System – AP6C75AA Installation Manual

46 Cabling and connecting

Table 4.7 – Recommended cable size for the frame ground collector

Cable length

0 to 20’

20 to 40’

40 to 80’

80 to 160’

Recommended size (see notes 1 and 2)

No. 2 AWG

No. 0 AWG

No. 0000 AWG

No. 500 kcmil

Procedure 4.1 – Installing and connecting the power plant frame ground leads

Step

Action

1