Air Quality Impact Assessment – BHP Billiton Illawarra Coal

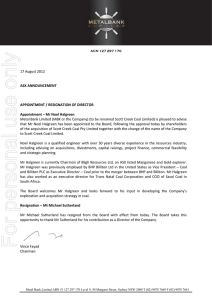

advertisement