Laboratory Quality Manual Rev 2013

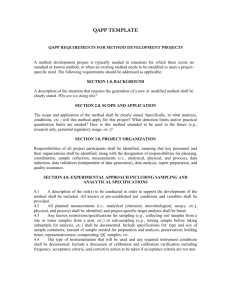

advertisement