BY 2 At`rys.

advertisement

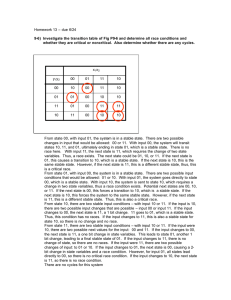

July 21, 1953 E. D. SMITH 2,646,557" ALARM AND ANNUNCIATOR DEVICE ' Filed Aug. 1'7, 1950 Power Source 2 shaqxs-?heet 1 30 |~ L29 |'/'/ 5%‘ - 4 6 8 . US we’ - A I 1,6 FIG. I evlces 2 ,l2 l4 7 v 3' JNormcLl " l9 r22 2e“ ‘3 l A/ EOWBY I I I» ‘[29 - h/ ' 2 4 s ?n ‘ 2711 '0 2' ‘2° I4 24 n 3' }To Qther I6 7 ower ' 8 22 ‘ '9 H6. 2 .2 A 28 Dewces ?g ’ / Alarm v,3 I5 26 ’ ' iurce 30 A I/ 9 w/ ' z 4 5 q ' l9 ,,/l6 ll M ‘ '. ToQther 274123 "L26 Dev'ce ' '4 2| F 25 -F|G. 3 ,|2 ' —#—— ‘ 7 '1‘lTrouble ____J '. Power Source ' ‘ I” 30 29 |'/“’ r ’ > ‘>_¢°g_7—. ‘To Other 4 6 p II |4 I916 2| 7 3| - _ IO ' 2 ' - 27 25 \ \-|2 I8 \ Clear 15 g J 26 FIG. 4 Devices '3 ) 24 INVENTOR. Eric D. Smith BY 2 At’rys. July 21, 19543 E. D. SMITH £646,557 ALARMaAND ANNUNCIATOR ‘DEVICE Filed Aug. 17, 1950 ~ 2 Sheets-Sheet 2 FIG 5 NOB/MAL FIG 6 ALARM FIG. 7 TROUBLE INVENTOR. Eric D. Smith Patented July 21‘, 1191553; UNITED 2,646,557 STATES . PATENT ' OFFICE 2,646,557 H t' ‘ - . I ALARM AND’ ANNUNCIATOR DEVICE Eric D. Smith, Chicago,’ Ill. ' Application August r1, 1950, Serial No. 180,049 12 Claims. (Cl. 340—213) 2 1 relays or housing, and can therefore be mounted singly or in any desired number or arrangement; It is a further object of the present invention to provide an annuciator wherein the pointer or reset key is so constructed that it can be plugged into or pulled out of the rest of the structure as machine, or part of a machine. ' a maybe necessary in the event of lamp failure In accordance with the principles of the present or if a change of color is desired. invention a number of alarms or annunciator de It is a still further object of the present inven vices are connected each to one machine, or one part of a machine, the annunciators being all 10 tion to provide an alarm device so constructed mounted adjacent to one another on a switch that it gives one audible signal when it is en ergized to its alarm position and 'a different board or the like. When an abnormal condition audible signal when it is energized to move from occurs on any of the machines or places that are a “trouble” position to a “clear” position. to be protected a light operates on the particular This invention relates to annunciators or alarm devices, particularly such as are adapted for use in engine rooms, power plants, industrial plants, and the like, for giving a signal of the existence of an abnormal condition at a speci?c place or 01 4 annunciator, and an audible alarm is-given. 'The 15 ‘In accordance with the principles of the present invention the visual signal or light is “off” when the annunciator is in its “normal” position, and nunciator involved indicates the type of fault or the light is on when the annunciator is in any of its off-normal positions. If a fault is one other condition involved, and the location thereof .» The present invention is particularly adapted 20 which may remain for some time the operator for use where certainty of operation is of utmost then moves the pointer, which includes the lamp, importance and where signals must indicate not to‘ the “trouble” position.v ‘In this position the only momentary alarms which can be reset at audible signal is discontinued but the visual signal once, but also must indicate abnormal conditions is continued, thus indicating the existence of a which may remain for some time, and once such 25 “trouble” condition which‘must be cleared. If abnormal conditions have occurred the annun that trouble condition is then cleared, after the, ciator must indicate the continuance of the ab visual signal of the annunciator has been moved from the “alarm” position to the “trouble” posi normal condition, and when the abnormal condition has been cleared‘ the annunciator must tion, the clearance of the trouble then causes the alarm calls the attendant’s attention to the an nunciators, and a light on the particular an affirmatively indicate that'fact. alarm indicator to move to a fourthv position, where it remains lighted indicating a “clear” condition, and a different audible signal is given to call attention to the fact that the trouble which previously existed has been cleared. The an It is a further object of the present invention to provide an annunciator which includes a lamp which is mounted on or part of a movable pointer. The separate positions of the pointer indicate the respective conditions of the circuit associated with nunciator can'then be moved from the “clear” position back to the “normal” position. that annunciator and the lighted lamp on the pointer serves to attract the operator’s attention The attainment of the above and further ob to the particular annunciator wherein the pointer jectsof the, present invention will be apparent from the following speci?cation taken in'conjunc is moved to the off-normal position. In order to accomplish the above results each particular an 40 tion with‘ the accompanying drawing forming a nunciator of the present invention has a number A v part thereof. ' In the drawing: 7 of separate positions which, for the purpose of Figure 1 is a diagrammatic view of the annun description, will be called the “normal,” “alarm,” “trouble,” and “clear” positions. . ciator, showing the circuit connections when'the It is a further object of the present invention 45 parts are in ‘their “normal” positions. Figures 2, 3 and v4 are diagrammatic views‘cor to provide an annunciator wherein the pointer responding to Figure 1 and showing the annun constitutes a manually reset key which also oper ciator in the “alarm,” “trouble.” and “clear” posi ates a spring loading device that controls the tions, respectively; . automatic operation of the annunciator so that Figures 5, 6, 7 and 8 are diagrammatic views the automatic ‘operation can be controlled by a 50 solenoid operated trip latch which requires very of -;the ‘latching and spring arrangements when little power. the parts are in their “normal,” “alarm,” “trouble” and “clear” positions, respectively; Since the pointer is also the reset key each Figure 9 is'a longitudinal View of the commu-v and requiresno additional bell reset, drop reset, 55, tator shaft and key, in partial section; alarm device or annunciator is a complete unit 3 2,646,557‘ Figures 10, 11 and 12 are sections taken on Figure 9 along the lines 10-10, H-ll, and 12-12, respectively, and looking in the direction of the arrows; Figure 13 is a front view of the pointer; and Figure 14 is a fragmentary view showing an alternate location of the control relay. Reference may now be had more particularly to the drawings wherein like reference numerals 4 a stationary brush or contact 22 in certain posi tions of the commutator shaft. The commutator ring 20 includes a ?at portion 23 that is always in engagement with the ring l8 and arcuate por tions 24 and 25 that are adapted to engage brushes or contacts 25, 21 and 28 in various posi tions of the shaft l I. The contacts 22 and 26 are connected to line conductors I’ and l, respec dicated by the reference character “A,” is tively, whereas the contacts 2'! and 28 are con nected to two different audible alarms 29 and 30 which in turn are connected to the line I’. The audible alarms 29 and 30 are designed so that adapted to be electrically connected to a power they give distinctly different sounds. designate like parts throughout. The annunciator of the present invention, in For in source, indicated by power leads I—-l', which stance, one may be a bell and the other may be may be any alternating or direct commercial 15 a buzzer. When conditions are “normal" and the current source. Figure 1 shows, schematically, parts are in the positions illustrated in Figure l the electric diagram and the relative positions of the circuits for the lamp l3 and for the alarms the parts when a remote control alarm contact 29 and 3d are open. 2 is open and the device is latched in its “nor A description will now be given of the opera mal” position. The remote alarm contact 2 is 20 tion of the device upon the occurrence of an ab an electric contact located at the place where normal condition which results in the closure of trouble is to be detected and is arranged to be the switch contacts 2. This causes energization actuated whenever trouble occurs. In the pres of the winding 4: and consequent attraction of ent instance it is shown as a normally open con the armature 6. The armature 6 pivots about tact arranged to be closed when trouble occurs. the pivot 1 and withdraws the latch 8- from the It can equally well be a normally closed contact path of the latch pin l0. This allows the rotat arranged to be opened when trouble occurs, in which event an abnormal condition would be able commutator shaft H to turn, under the action of its spring to be hereafter described, to manifested by the opening of a normally closed the position illustrated in Figure 2. In this po circuit, as will be apparent as this description 30 sition a circuit is established for the lamp l3 by proceeds. The remote alarm contact 2 controls the engagement of the commutator IS with the the circuit to the winding of an electromagnetic contact 22 and engagement of the commutator coil 4 of the relay type, which in turn controls 28 with the contact 26. At the same time the’ an armature 6. When the coil 4 is not energized commutator portion 25 engages the contact 28 the armature 6 is held in the position shown in Figure 1, which is the position away from the coil. It is held in that position by a spring or and thus completes a circuit for the audible‘ alarm 30. At this time the contact 27 is free of the commutator ring 2.4 so that no circuit is es-» by gravity as is usual in the relay art. The tablished to the audible alarm 29. The audible armature-6 is here shown as pivoted at 1 and car alarm. 30 calls the operatorsv attention to the rying at one end thereof an armature latch 8 40 annunciator and when there are many side by which, in the position shown in Figure 1, en side annunciator devices onthe switchboard the gages a commutator shaft latch pin ID that is lighted condition of the particular lamp l3 in rigid with and extends outwardly from a rotat forms the operator which annunciator has oper able commutator shaft II. The shaft is ar ated, and the position of the pointer key 12 also ranged to be turned in one direction manually by indicates which circuit is in trouble. a pointer or key I2, shown more particularly in If the alarm is av momentary type alarm the Figure 9, against the action of one or more contact 2 opens at once-and deenergizes the coil springs which serve to restore the shaft under control of the armature 6 acting through its tion of Figure l. the “normal” position, the shaft is spring biased position and leave it there because: as soon. as 4 allowing the armature-5 to return to the posi The operator can then manu latch- 8 and another latch to be later described. ally turn the key l2 back to “normal,” thus load 50 It is su?icient here to state that the pointer or ing the return spring; and latch in the “normal" key I2 is located at the front of the annunciator position as shown in Figure i. If the alarm is and carries a visible signal in the form of an, a maintainedtype alarm the contact 2. remains electric lamp I3 which may be of the glow dis closed and the coil 4 remains. energized. so that charge type or any other type as desired. It is the armature 6 remains pulled towards the. coil sufficient here to state that when the parts are 55 4, as shown in Figures 2 and 3. The-operator in the position illustrated in Figure 1, which is cannot then turn the key hack to the. “normal” to urge it to turn to the “alarm” position of Fig ure 2, but is held by the armature latch 8 against the operator releases the key iZ‘there is immedi ate restoration of the’ shaft H to the. alarmpo turning to that position. The key I2 is releasably 60 sition of Figure 2‘. The operator can, however, secured to the shaft H to turn therewith and turn the key !2 from the “alarm” position on is adapted to turn he shaft H under control of ward to the “trouble?” position indicated in;Figthearmature 6. The key l2v includes a. tip con ure 3, where the latch pin l6 engages an arma tact l4 and a ring contact. [8 that are adapted 65 ture latch, 31 at that’ end ofLthe armature 6-0p to engage commutator rings I 6‘ and 20,.respec posite where the latch 31 is located. This latches tively, on the commutator shaft II. The tip [4 the shaft in the “trouble‘f’ position. At this time is- connected to one side of the lamp by a conduc the contacts 27' and 28 are free and clear of the tor l5 while the other side of the lamp I3 is per commutator ring, 29. so that thecircuits'for both manently connected through a resistor ll to the 70 audible alarms; 29 and. so. are open.- The lamp ring 18. The commutator ring [6 which is I3 is now in its, “trouble.” position and remains mounted on the commutator shaft ll includes lighted by reason of the fact that the contact a flat portion l9 that is in contact with the tip 26 is in engagement with the portion 24 of the H. in all rotatable positions. of the shaft H, and commutator ring 28 which completesan operat— a circular portion 2| that is adapted to. engage. 76 ingcircuitior the lamp. [3. The rotatable com 2,646,557 6 mutator shaft | i "-is held in the ‘.‘trouble” position by the latch ‘3| so long. as" the armature 6 re-. mains attracted to the‘ core of the relay .by the energization of the winding 4. The operator can now tell both by'the position of. the key |2 and the lighted lamp that a “maintained” trouble ex ists on a particular circuit. - 1 > - ‘ tion counter-clockwise, as seen in Figure 6, from‘ the position of Figure 6 towards the position of Figure. '7. In the movement of the shaft II from the position of Figure 6 towards the position of Figure '7 the projecting, pin 36 ?rst engages the spring end 35 and tensions the spring. At this time the end 330i the spring remains in contact When the trouble has cleared on the particular circuit involved the contact 2 opens, thus deener gizing the winding 2 and permitting the armature < with‘ the stop pin 32. Loading of ‘the spring con tinues until the positioning cam 44 engages the 3- to'restcre to its normal position. This-moves shaft causes thepositioning cam 44 to move the stop pin 32. Therefore continued turning of the the latch 35 free of the latch pin [9 on the arma stop pin v32inthe slot 39, thus causing the two ture shaft | l and the shaft ’ therefore rotates ends 33-35 of the. spring both to move together, under its spring loading'from the positioniillus-x the end 33 of the spring following the stop pin 32. trated in Figure. 3 to the position illustrated in 15 This condition continues until the “trouble” post Figure ll. In this positionthe circuit for the lamp. ,tion of Figure 7 is reached at which time the stop I3 ‘remains closed ‘because of engagement of the pin lilrides over the latch 3|. If the “trouble” contact 26 with the portion 24 of the commutator is a maintained trouble the latch 3| is in'its latch ring 2!). At this time also the portion 25 of the ing position so that when the shaft reaches the commutator ring'iil engages the contact 2‘! and 20 position. of Figure '7 and the operator releases the establishes a circuit for the audible alarm 29. i key |2,'the pin it; is latched ‘by thelatch 3|. At This alarm, being different in sound from that this time the spring end 35 is in engagement with of the alarm 3i}; informs the operator that the the projection 36 on the pin IB and urges the previously existing trouble has been cleared. The shaft i l in a direction clockwise as seen in Figure lighted condition of the signal lamp and the'posi-i 26 7,. towards the position of Figure 8, being kept from moving to that. position by the latch 3|. tion of the key- l2 indicate the particular location where the trouble has been cleared. The opera When the trouble clears and the coil 2 is deener torv can then turn the key l2 from the “clear” gized the latch 38 swings‘out of position and thus position of Figure 4 to the “normal” positionof permits the spring end 35 to rotate the shaft i| Figure l to restore normal conditions of the until the spring end comes in contact with the annunciator “A.” When the operator has turned stop pin 32. This is the “clear” position illus the key i2‘ and therefore the shaft I | tothe “nor trated in Figures- 4 and 8. The operator can then mal” position, while thearmature 6 and its latch turn the shaft l | in a direction clockwise as seen are in their deenergized position asillustrated in in Figure '8, back to ‘the “normal” position by Figures 1 or ii, the latch pin it] rides over the 35 turning of the key l2. When the shaft is turned curved back of the latch 8 and then engages the clockwise from the position of Figure 8 to the latch which thereupon acts‘on the pin to ‘hold position of Figure 5 the stop pin 32 ?rst holds the the shaft ii against return rotation by its load spring end 35 While the projection 36 moves ‘with ing spring. > 1 ’ the spring end 33 to load the spring.‘ This con~ Reference may now be had more particularly 40 tinues until‘ the positioning cam 4-3 engages the to Figures o'through Qwhich show the mechani cal‘ arrangement for‘ biasing and actuating the commutator shaft H, The commutator shaft laitch'pin it is- rigidly secured‘to the shaft and stop pin 32. Thereafter continued turning of the shaft causes the stop pin 32- to move With the has a projection 35- against which an end of a projection 36, maintaining the loaded condition of the spring, until the stop pin it rides under and is engaged by the latch 53, at which time the coiledspring It? bears. In the “normal” position shaft | I is in its “normal” position and a release one end of the springbears against the projec tion :35 and the other end bears against-a stop pin 32 that is carried by a'lstationary plate '38, of the key i2 leaves the shaft ii latched in the “normal” position. ' Reference may now he had more particularly said pin projecting‘at right angles to the plate to Figures 9, 10, ll and 12 which show the con~ and extending through an arcuate slot 39 in the struction of the key i2 and the rotatable com plate, in which slot it ‘is slidable, being held ‘in mutator shaft. The key ?ts into the hollow end its adjusted position by a spring Washer 40 that of the shaft ! I and is held thereby friction and is pressed against the bearing plate 38 lby a pair may be inserted or withdrawn at will. The com of lock nuts iii-4| on the pin 32. Two p-in posi mutator shaft | | comprises a cylindrical insulat tioning cams 43-434 are mounted on the shaft 55 ing stud 50 which extends through a circular hole in a plate 5| on which the cams lit-44 are H to rotate therewith. These cams engage the stop pin‘ 32 and move it from one position to the formed. The plate 5| is secured to a plastic tubu other in the slot 35), depending upon the position lar sleeve 52 in any desired manner as, for and movement of the shaft H, ‘by the manual instance, by a set screw 54. The cylindrical stud 60 turning of the key i2. . . ‘ . 5i] ?ts into the s1eeve'52 and is secured thereto When the annunciator is in the normal position as by a set screw 56.’ The stud 53, plate ‘5|, and the spring urges the shaft H in a direction sleeve 52 thus constitute one unit which is the counter-clockwise as seen in Figure 5, which commutator shaft i i. The end of the stud within motion of the shaft is prevented by the latch 8. the sleeve has a longitudinal key slot 57 therein When the latch B is retracted by energizaticn of 65 for receiving a flat shank which constitutes the the coil ii and consequent movement of the arma ture 6 (Fig. l) the shaft || moves to the “alarm” tip of the key i2, as will ‘be hereinafter explained. The commutator rings 56 and 29 are mounted on the plastic tubular sleeve 52 and to that effect the ment the positioning cam 43 moves away from 70 ‘sleeve is slotted, as indicated at 58 and 59. The key l2 comprises a molded body of in the stop'pin 32 and the spring arm 33' moves-up position‘ illustrated in Figure 6.‘ In this move to engagement'with the stop pin 32. This limits the extent of rotation of the shaft ill to the sulationi'in which is embedded the lamp H, the resistor H, the tip, terminal l4 and the ring i8. ‘falarm”position illustrated .in Figure‘ 6. ' Thertip ‘terminal l4 comprises‘ a copper rod 60 The operator can then turn the key in a" direc? 75 one end of which'is ?attened. as indicated at'62, a? 8. saidimember. so that the position of the key in“ dicates the position ofthe. rotatable member, an electric signal light carried by said key, and to constitute a key that ?ts into the slot 51 of the stud 50. A body of plastic 65 is molded around the rod, the lamp [3, the resistor I1 and also holds the ring (8. One terminal of the lamp is connected directly to the rod 60 and the opposite terminal of the lamp connects through the resistors H, from which a copper conductor extends from the other terminal of the resistor to the ring I 8, that conductor also being em bedded in the plastic 65. The plastic 65 is pref erably clear transparent plastic, although it. is within the purview of this invention to use a colored transparent plastic. The key assembly may be inserted into and removed from the an nunciator by a simple plug in or pull out action. contact means controlled by the turning, of said member for controlling said signal light. 3.. In- an electric‘ alarm device a rotatable member having two stop positions and manually movable. from one stop position to the. other, spring means and meansfor loading the spring means upon rotation of the member in one direc tionfrom one stop position and in the other di rection from the other stop position, means for latching the member in positions reached upon rotation in one direction from one stop posi 15 tion and in theopposite‘ direction fromthe op When that is done the tip portion 62 engages the ?at part IQ of the commutator l6 and flexes it outwardly a very slight amount. The ?at key part 62 has a pair of slight notches therein so that the ?at portion I9 of the commutator spring. ~ 18 engages one of those notches and resiliently posite'stop position,,and electromagnetic meansv for releasing, the latch means whereby thero-v tatable spring loaded member returnsto thecor responding, stop position. 4. In an electric alarm device‘ a rotatable member having two stop positions and manually movable from one stop position to the other, At the same springmeans and means for loading the spring time the ?attened end 62 enters the key slot 51 means upon rotation of the member in one di in the stud 50 so that by turning of the key the operator can turn the shaft l l which includes 25 rection from one stop position and in the'other direction from the other stop position, means for the stud 50 and the plate 5i and the tubular latching the member in positions reached upon sleeve 52. rotation in one direction‘ from one stop position In some annunciators it is desirable to have and in the opposite direction from the opposite the annunciator indicate normal conditions upon stop position, electromagnetic means for re the existence of a closed circuit and indicate ab leasing the latch means whereby the rotatable normal conditions when that circuit is open. spring loaded member returnsto thecorrespond This result can be obtained with the annuncia ing stop position, and plug-in key means for r0 tor of the present invention by shifting the posi tating therotatable-member from one stop posi tion of the relay 4, as indicated in Figure 14-. When this is done the relay is connected in cir 35 tion to the: other and from either stop position to either spring loaded latched position, said key cuit with normal closed switch contacts 2’ that means being insertable into said rotatable mem are located on the machine or part of the ma ber and being rotatable thereby so that the posichine to be protected. The armature 6 of the re lay is therefore normally attracted by the mag tion of the key means indicates the position of netic action of the winding 4 in a closed circuit. 40 the rotatable member. When the winding 4 is open circuited, as by 5. In an electric alarm device a rotatable mem-v her-having two stop positions and manually mov opening of the switch 2’, the armature 6 is moved to its alternative position, namely, the position able from one stop position to the other, spring of Figure 2, by a spring or the like. means and means for loading the spring: means In compliance with the requirements of the’ upon rotation. of the member in one direction patent statutes I have here shown and described from one stop position and in the other direc a preferred embodiment of my invention. It is, tion from the other stop position, means for latching the member inpositions reached upon however, to be understood that the invention is not limited to the precise construction here rotation in onev direction from one stop position shown, the same being merely illustrative of the and in the opposite direction from the opposite principles of the invention. What I consider 50 stop position, electromagnetic means for releas holds the plug in the sleeve 52. ing the latch means‘whereby the rotatable spring loaded member returns to the corresponding stop loaded rotatable member, latch means for latch position, plug-in key means for rotating the ing said member in either of two positions, elec~ 55 rotatable member from one stop position to the tromagnetic latch means, means effective upon other and from either stop position to either actuation of the latch means for stopping res— spring loaded latched position, said key means toration of the member under its spring load being insertable into said rotatable member and ing in either of two different positions depend being, rotatable thereby so that the position of ing upon the position in which the member had 60 the key means indicates the position of the rotat last been latched, and a removable key ?tting able member, and signal circuits controlled from said rotatable member for turning it and being 'di?erent positions of the member. also turned by said member so that the position 6. In an electric alarm device a rotatable mem of the key indicates the position of the rotatable her having two stop. positions and manually mov member. 65 able from onestop position to the other, spring new and desire to secure by Letters Patent is: 1. An electric alarm device comprising a spring 2. An electric alarm device comprising a spring loaded rotatable member, latch means for latch ing said member in either of two positions, elec means and. means for loading, the spring means‘ upon rotation of the member in one direction from one stop position and in the'other direction tromagnetic latch means, means effective upon from the other stop position, means for latch actuation of the latch means for stopping restora 70 ing the member in positions reached upon rota tion in one direction from one stop position and tion of the member under its spring loading in either of two di?erent positions depending upon the position in which the member had last been latched, a removable key ?tting said rotatable member for turning it and being also turned by in the opposite direction from the opposite stop ‘position, electromagnetic means for releasing the latch means whereby the rotatable spring loaded member. returns to the corresponding stop posi 2,646,557 10 9 either stop position, electromagnetic means for releasing the latch means whereby the rotatable spring loaded member returns to the corre sponding stop position, and plug-in key means for rotating the rotatable member from one stop tion, and signal circuits controlled from differ ent positions of the member. '7. In combination with a number of similar electric alarm devices each including a rotatable member having a stop position, spring means and position to the other and from either stop posi means for loading the spring means upon rota tion to either spring loaded latched position, said tion of the member from the stop position, means key means being insertable into said rotatable for latching the member in its spring loaded posi member and being rotatable thereby so that the tion, electromagnetic means for releasing the latch means whereby the rotatable spring loaded 10 position of the key means indicates the position member returns to the stop position, plug-in key of the rotatable member. 11. In an electric alarm device a rotatable means for rotating the rotatable member from member having two stop positions and manually movable from. one stop position to the other, position, said key means being insertable into said rotatable member and being rotatable thereby 15 spring means and means for loading the spring means upon rotation of the member from either so that the position of the key means indicates stop position, means for latching the member in the position of the rotatable member; and signal different positions reached upon rotation from circuits common to all of said devices and con either stop position, electromagnetic means for trolled by rotation of the member of any of said devices, whereby the operation of a signal circuit 20 releasing the latch means whereby the rotatable spring loaded member returns to the correspond indicates the operation of an alarm device and the stop position to the spring loaded latched the position of the rotatable member on one of ing stop position, and signal circuits controlled the devices indicates which device has operated. from different positions of the member. 12. In an electric alarm device a rotatable 8. In an electric alarm device a rotatable mem ber having a stop position, spring means and 25 member having two stop positions and manually movable from one stop position to the other, means for loading the spring means upon rota spring means and means for loading the spring tion of the member from the stop position, means means upon rotation of the member from either for latching the member in its spring loaded posi stop position, means for latching the member in tion, electromagnetic means for releasing the latch means whereby the rotatable spring loaded 30 di?erent positions reached upon rotation from either stop position, electromagnetic means for member returns to the stop position, plug-in key releasing the latch means whereby the rotatable means for rotating the rotatable member from spring loaded member returns to the corre the stop position to the spring loaded latched sponding stop position, plug-in key means for ro position, said key means being insertable into said rotatable member and being rotatable there 35 tating the rotatable member from one stop posi tion to the other and from either stop position by so that the position of the key means indi to either, spring loaded latched position, said key cates the position of the rotatable member, sig means being insertable into said rotatable mem nal circuits controlled by rotation of the mem ber and being rotatable thereby so that the posi ber, and a signal light mounted on the key and connected in one of the circuits. 40 tion of the key means indicates the position of the rotatable member, and signal circuits con 9. In an electric alarm device a rotatable trolled from different positions of the member. member having two stop positions and manually movable from one stop position to the other, ERIC D. SMITH. spring means and means for loading the spring means upon rotation of the member from either stop position, means for latching the member in 45 References Cited in the ?le of this patent di?erent positions reached upon rotation from either stop position, and electromagnetic means for releasing the latch means whereby the rotatable spring loaded member returns to the Number UNITED STATES PATENTS Name Date 350,450 1,083,566 1,142,102 1,510,587 1,554,048 Tucker ___________ __ Oct. 5, Stone ____________ __ Jan. 6, Kettering ________ __ June 8, Diegel ____________ __ Oct. 7, Thomas _________ __ Sept. 15, spring means and means for loading the spring means upon rotation of the member from either 55 1,576,276 Hedges et al _______ __ Mar. 9, 1926 1,664,215 Hunt ___________ __ Mar. 27, 1928 stop position, means for latching the member in 2,116,947 2,434,065 Ketay ___________ __ May 10, 1938 Courtney __________ __ Jan. 6, 1948 corresponding stop position. 50 10. In an electric alarm device a rotatable member having two stop positions and manually movable from one stop position to the other, di?erent positions reached upon rotation from 1886 1914 1915 1924 1925