Vimana Notion Design Team, India

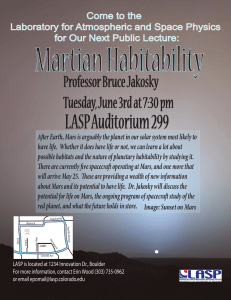

advertisement