Coating Multi-walled Carbon Nanotubes with Uniform Silica Shells

advertisement

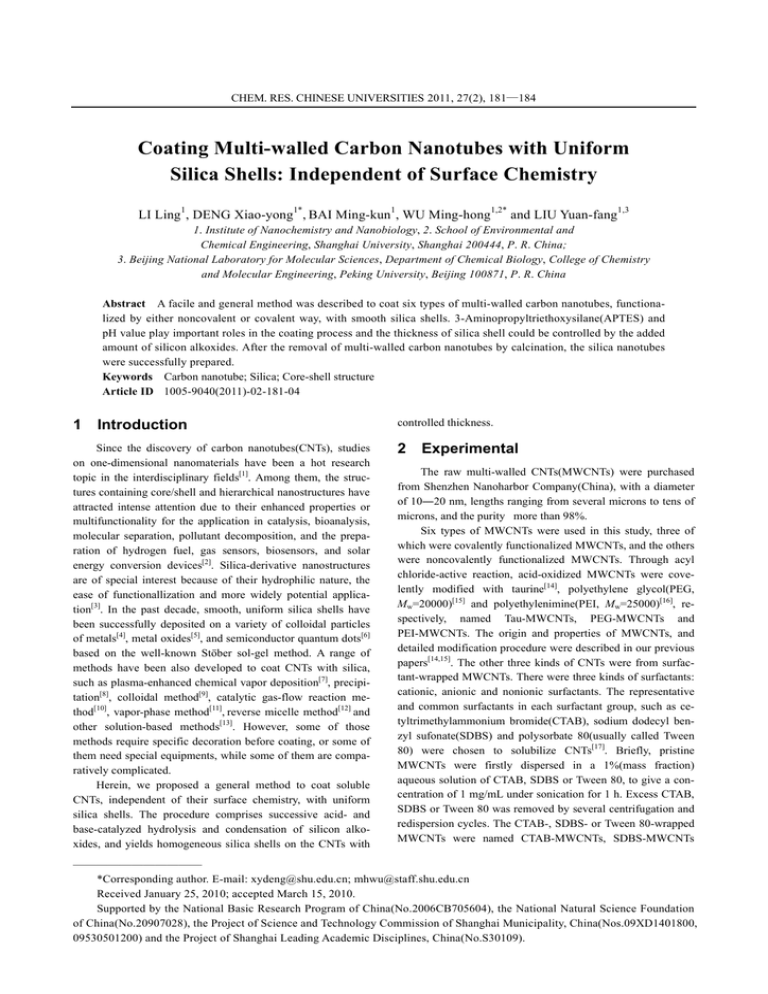

CHEM. RES. CHINESE UNIVERSITIES 2011, 27(2), 181—184 Coating Multi-walled Carbon Nanotubes with Uniform Silica Shells: Independent of Surface Chemistry LI Ling1, DENG Xiao-yong1*, BAI Ming-kun1, WU Ming-hong1,2* and LIU Yuan-fang1,3 1. Institute of Nanochemistry and Nanobiology, 2. School of Environmental and Chemical Engineering, Shanghai University, Shanghai 200444, P. R. China; 3. Beijing National Laboratory for Molecular Sciences, Department of Chemical Biology, College of Chemistry and Molecular Engineering, Peking University, Beijing 100871, P. R. China Abstract A facile and general method was described to coat six types of multi-walled carbon nanotubes, functionalized by either noncovalent or covalent way, with smooth silica shells. 3-Aminopropyltriethoxysilane(APTES) and pH value play important roles in the coating process and the thickness of silica shell could be controlled by the added amount of silicon alkoxides. After the removal of multi-walled carbon nanotubes by calcination, the silica nanotubes were successfully prepared. Keywords Carbon nanotube; Silica; Core-shell structure Article ID 1005-9040(2011)-02-181-04 1 Introduction Since the discovery of carbon nanotubes(CNTs), studies on one-dimensional nanomaterials have been a hot research topic in the interdisciplinary fields[1]. Among them, the structures containing core/shell and hierarchical nanostructures have attracted intense attention due to their enhanced properties or multifunctionality for the application in catalysis, bioanalysis, molecular separation, pollutant decomposition, and the preparation of hydrogen fuel, gas sensors, biosensors, and solar energy conversion devices[2]. Silica-derivative nanostructures are of special interest because of their hydrophilic nature, the ease of functionallization and more widely potential application[3]. In the past decade, smooth, uniform silica shells have been successfully deposited on a variety of colloidal particles of metals[4], metal oxides[5], and semiconductor quantum dots[6] based on the well-known Stöber sol-gel method. A range of methods have been also developed to coat CNTs with silica, such as plasma-enhanced chemical vapor deposition[7], precipitation[8], colloidal method[9], catalytic gas-flow reaction method[10], vapor-phase method[11], reverse micelle method[12] and other solution-based methods[13]. However, some of those methods require specific decoration before coating, or some of them need special equipments, while some of them are comparatively complicated. Herein, we proposed a general method to coat soluble CNTs, independent of their surface chemistry, with uniform silica shells. The procedure comprises successive acid- and base-catalyzed hydrolysis and condensation of silicon alkoxides, and yields homogeneous silica shells on the CNTs with controlled thickness. 2 Experimental The raw multi-walled CNTs(MWCNTs) were purchased from Shenzhen Nanoharbor Company(China), with a diameter of 10―20 nm, lengths ranging from several microns to tens of microns, and the purity more than 98%. Six types of MWCNTs were used in this study, three of which were covalently functionalized MWCNTs, and the others were noncovalently functionalized MWCNTs. Through acyl chloride-active reaction, acid-oxidized MWCNTs were covelently modified with taurine[14], polyethylene glycol(PEG, Mw=20000)[15] and polyethylenimine(PEI, Mw=25000)[16], respectively, named Tau-MWCNTs, PEG-MWCNTs and PEI-MWCNTs. The origin and properties of MWCNTs, and detailed modification procedure were described in our previous papers[14,15]. The other three kinds of CNTs were from surfactant-wrapped MWCNTs. There were three kinds of surfactants: cationic, anionic and nonionic surfactants. The representative and common surfactants in each surfactant group, such as cetyltrimethylammonium bromide(CTAB), sodium dodecyl benzyl sufonate(SDBS) and polysorbate 80(usually called Tween 80) were chosen to solubilize CNTs[17]. Briefly, pristine MWCNTs were firstly dispersed in a 1%(mass fraction) aqueous solution of CTAB, SDBS or Tween 80, to give a concentration of 1 mg/mL under sonication for 1 h. Excess CTAB, SDBS or Tween 80 was removed by several centrifugation and redispersion cycles. The CTAB-, SDBS- or Tween 80-wrapped MWCNTs were named CTAB-MWCNTs, SDBS-MWCNTs ——————————— *Corresponding author. E-mail: xydeng@shu.edu.cn; mhwu@staff.shu.edu.cn Received January 25, 2010; accepted March 15, 2010. Supported by the National Basic Research Program of China(No.2006CB705604), the National Natural Science Foundation of China(No.20907028), the Project of Science and Technology Commission of Shanghai Municipality, China(Nos.09XD1401800, 09530501200) and the Project of Shanghai Leading Academic Disciplines, China(No.S30109). 182 CHEM. RES. CHINESE UNIVERSITIES and Tween 80-MWCNTs, respectively. All the above six kinds of MWCNTs are easily watersoluble and the surface chemistry of them was assessed by zeta potential measurement, which was performed on a ZetaSizer 3000HSA(Malvern Instruments Ltd., Worcestershire, UK). As shown in Table 1, the surface potentials of PEI-MWCNTs and CTAB-MWCNTs are positive. Modification with taurine or Table 1 Material Zeta potential/mV wrap by SDBS generated negatively-charged MWCNTs. Functionallization with PEG or wrap by Tween 80 generated nearly neutrally, but little negatively charged MWCNTs, which might come from the small amount of noncovalent carboxyl groups. The different zeta potential reflects the successful surface modification of MWCNTs. Zeta potential of MWCNTs SDBS-MWCNTs CTAB-MWCNTs Tween 80-MWCNTs PEI-MWCNTs Tau-MWCNTs PEG-MWCNTs –62.9 +60.9 –1.7 +4.8 –13.2 –3.5 Then, with these six kinds of MWCNTs as the templates, the silica coated MWCNTs were synthesized. Typically, ethanol (100 mL) containing 3-aminopropyltrimethoxysilane(APTES) and tetraethoxysilane(TEOS) in a molar ratio of 1:9(typically 5 μL of APTES and 45 μL of TEOS) was added to 25 mL of an aqueous dispersion of MWCNTs(ca. 5 mg) containing citric acid(1.85 mmol/L, pH=3) under sonication. The mixture was stirred for 1 h, and sonicated every 20 min. Afterwards, a solution of NH4OH(1 mol/L) was added drop-wisely until a pH value of 8―9 was reached. Subsequently, the solution was stirred for 12 h at room temperature. After the centrifugation, the sediment was collected and washed three times with ethanol by centrifugation and redispersion cycles. Finally, the darkish product was obtained and dried at 60 °C in a vacuum oven, yielding silica-coated MWCNTs. 3 Vol.27 Results and Discussion were examined by transmission electron microscopy(TEM, JEM-200CX) and high-resolution TEM(HRTEM, JEM 2010F). As shown in Fig.1, independent of the functionallization and surface chemistry, all the MWCNTs are homogeneously coated with a uniform layer of silica with a shell thickness of ca. 15―20 nm. The result demonstrates that this method needs no specific functionallization before coating and appears to be feasible for preparing a variety of MWCNTs. Moreover, the thickness of silica shell can be controlled by the amount of APTES and TEOS(1:9, molar ratio). When 20, 30, 40 and 50 μL of APTES and TEOS were added to the system for preparing silica-coated Tau-MWCNTs, the thickness of silica shells increased from ca. 2.5 nm to 15 nm(Fig.2). Under the investigation by HRTEM, the silica coated on MWCNTs is amorphous. Furthermore, after calcination at 550 °C, the silica nanotubes with the smooth inner and outer walls were prepared [Fig.3(B)]. The morphology and structure of silica-coated MWCNTs Fig.1 TEM images of Tween 80-MWCNTs(A), SDBS-MWCNTs(B), CTAB-MWCNTs(C), Tau-MWCNTs(D), PEI-MWCNTs(E) and PEG-MWCNTs(F) after coating with silica shells Fig.2 Effect of total amount of APTES and TEOS on the thickness of silica shells As for coating Tau-MWCNTs, the thickness increases from ca. 2.5 nm(A, 20 μL), 5 nm(B, 30 μL) , 10 nm(C, 40 μL) to 15 nm(D, 50 μL). No.2 LI Ling et al. Fig.3 183 HRTEM images of silica-coated Tau-MWCNTs(A) and the silica nanotubes after calcinations(B) There were two steps in the coating procedure. Under acid-catalyzed conditions, it was likely that the sol-gel-derived silicon oxide networks yielded primarily linear or randomly branched polymers, which entangled and formed additional branches, resulting in the formation of an initial thin and uniform silica shell on MWCNTs[18]. When the pH value increased, Fig.4 leading to basic condition, more silicon alkoxides hydrolyzed on MWCNTs, which increased the total silica shell thickness[19]. However, the pH value of alkali-catalyzed condensation was perfect at 8―9. Once the pH value reached 10 or 11, part of the silicon alkoxides could form monodispersed spherical silica nanoparticles in solution(Fig.4). Effects of pH on silica coating The pH value in the step of alkali-catalyzed condensation is perfect at 8―9. PEI-MWCNTs are used as the templates. (A) pH=8; (B) pH=9; (C) pH=10; (D) pH=11. The crucial factor in the synthetic strategy is the addition of APTES. In the controlled experiment to grow silica on MWCNTs without APTES, for example, there are super thin and rough silica shells on PEI-MWCNTs(Fig.5). The result shows that APTES plays an important role in the coating process. First, since APTES easily interacts with the sidewall and functional groups of nanotubes[20], the APTES molecules may be firstly absorbed on MWCNT sidewalls for polymerization, and then the surface would become more favorable for the growth of silica by the hydrolysis of TEOS[21]. Second, APTES could also catalyze the hydrolysis of TEOS[22,23]. Riegel et al.[22] indicated that the existence of APTES accelerated the rate of hydrolysis of 3-glycidoxypropyl-trimethoxysilane. Kim et al.[23] also reported that the grafted amine groups of a silane coupling agent containing amine groups(2-aminoethyl-3-aminopropyltrimethoxysilane) on MWCNTs could activate the formation of silica shell by acid-base interaction. 4 Fig.5 TEM image of super thin and rough silica shells coated on PEI-MWCNTs without addition of APTES Conclusions In summary, a facile and general liquid process has been successfully employed to prepare silica shells on either noncovalently or covalently functionallized MWCNTs, independent of their surface chemistry. These silica-coated MWCNTs can be further calcined to form hollow silica nanotubes. This new 184 CHEM. RES. CHINESE UNIVERSITIES Vol.27 coating method is expected to prepare other inorganic core/ shell nanostructures with silica shells. [11] Fan W., Gao L., Chem. Lett., 2005, 34, 954 [12] Bottini M., Tautz L., Huynh H., Monosov E., Bottini N., Dawson References [13] Colorado R., Barron A. R., Chem. Mater., 2004, 16, 2691 [14] Deng X. Y., Wu F., Liu Z., Luo M., Li L., Ni Q. S., Jiao Z., Wu M. M., Bellucci S., Mustelin T., Chem. Commun., 2005, 758 [1] Xia Y., Yang P., Sun Y., Wu Y., Mayers B., Gates B., Yin Y., Kim H., Liu Y. F., Carbon, 2009, 47, 1421 F., Yan. H., Adv. Mater., 2003, 15, 353 [2] Rao C. N. R., Govindaraj A., Adv. Mater., 2009, 21, 4208 [3] Suh W., Suh Y., Stucky G., Nano Today, 2009, 4, 27 [4] Pastoriza-Santos I., Perez-Juste J., Liz-Marzan L. M., Chem. [15] Jiao Z., Chinese J. Inorg. Chem., 2008, 24, 98 [16] C, 2009, 113, 3150 Kim J., Lee J. E., Lee J., Yu J. H., Kim B. C., An K., Hwang Y., Shin C. H., Park J. G., Hyeon T., J. Am. Chem. Soc., 2006, 128, [17] [7] [8] Gerion D., Pinaud F., Williams S., Parak W., Zanchet D., Weiss S., [18] Iler R. K., The Chemistry of Silica, Wiley, New York, 1979 Alivisatos A., J. Phys. Chem. B, 2001, 105, 8861 [19] Tago T., Shibata Y., Hatsuta T., Miyajima K., Kishida M., Tashiro S., Wakabayashi K., J. Mater. Sci., 2002, 37, 977 Hu J., Wang Z., Zhang W., Xu Z., Wu Y., Zhu Z., Duan X., Carbon, 2006, 44, 1581 [20] Pender M., Sowards L., Hartgerink J., Stone M., Naik R., Nano [21] Yang Y., Qiu S., Cui W., Zhao Q., Cheng X., Li R., Xie X., Mai Y., [22] Li Y., Qiao X., Feng J., Zhong X., Zhang L., Qian L., Hou F., J. Mater. Chem., 2009, 19, 6137 Zhu Y., Pan Y., Xu H., Xiang C., Kou H., Guo J., Chem. Lett., Riegel B., Blittersdorf S., Kiefer W., Hofacker S., Muller M., Schottner G., J. Non-Cryst. Solids, 1998, 226, 76 J. Mater. Sci., 2009, 44, 4539 [10] Kong J., Dai H., J. Phys. Chem. B, 2001, 105, 2890 2007, 36, 1098 Lett., 2006, 6, 40 [9] Moore V., Strano M., Haroz E., Hauge R., Smalley R., Schmidt J., Talmon Y., Nano Lett., 2003, 3, 1379 688 [6] Shen M. W., Wang S. H., Shi X. Y., Chen X. S., Huang Q. G., Petersen E. J., Pinto R. A., Baker J. R., Weber W. J., J. Phys. Chem. Mater., 2006, 18, 2465 [5] Sun Y. F., Wu F., Deng X. Y., Xiong D. M., Zhao B., Wu M. H., [23] Kim M., Hong J., Lee J., Hong C., Shim S., J. Colloid Interf. Sci., 2008, 322, 321