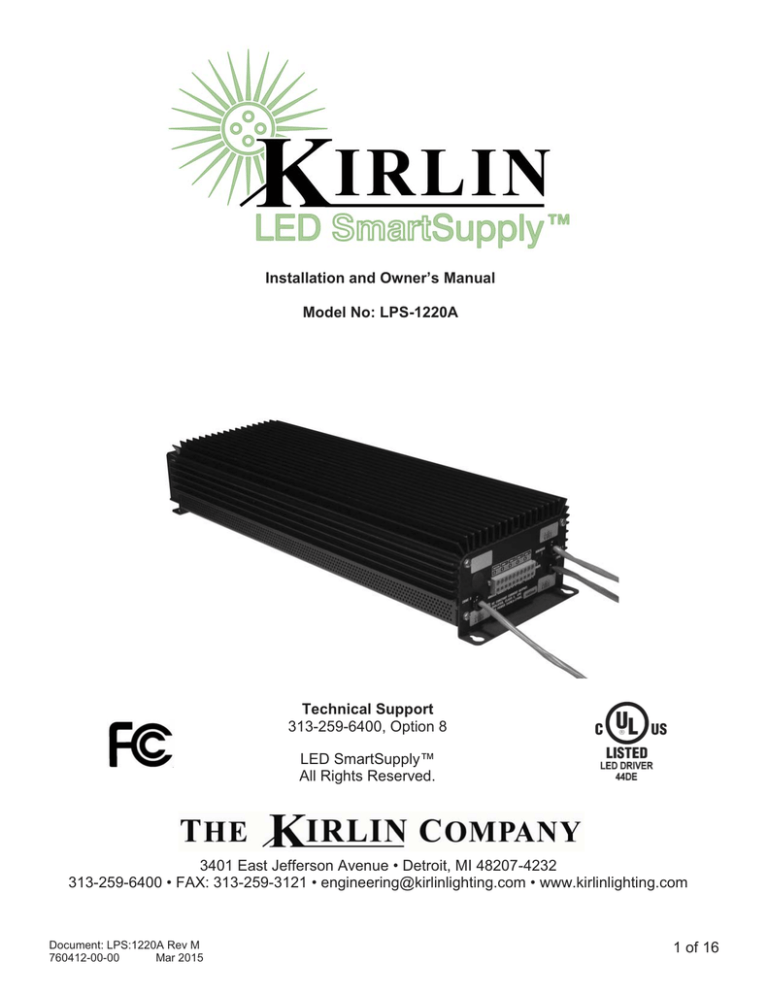

Installation and Owner’s Manual

Model No: LPS-1220A

Technical Support

313-259-6400, Option 8

LED SmartSupply™

All Rights Reserved.

3401 East Jefferson Avenue • Detroit, MI 48207-4232

313-259-6400 • FAX: 313-259-3121 • engineering@kirlinlighting.com • www.kirlinlighting.com

Document: LPS:1220A Rev M

760412-00-00

Mar 2015

1 of 16

CONTENTS

1.0 SCOPE............................................................................................................... 3

2.0 OWNER/USER RESPONSIBILITIES ................................................................. 3

3.0 EMC COMPLIANCE........................................................................................... 3

4.0 INSTALLATION GUIDELINES AND SAFETY REQUIREMENTS ...................... 4

4.1 ELECTRICAL REQUIREMENTS ....................................................................... 4

4.2 MOUNTING AND ENVIRONMENTAL REQUIREMENTS .................................. 4

5.0 MECHANICAL DETAIL ...................................................................................... 5

6.0 MOUNTING ORIENTATION .............................................................................. 6

7.0 INPUT REQUIREMENTS ................................................................................... 7

7.1 Electrical Input Specifications: ............................................................................ 7

7.2 Input Connections: ............................................................................................. 7

8.0

8.1

8.2

8.3

8.4

8.5

OUTPUT CHANNEL REQUIREMENTS ............................................................. 8

Electrical Output Specifications: ......................................................................... 8

Output Wiring Requirements .............................................................................. 8

Typical Wiring Diagram: ..................................................................................... 9

Output Zone/Channel Connections Table .........................................................10

LED Load (Fixture) Limitations ..........................................................................10

9.0

9.1

9.2

9.3

0-10 Vdc ANALOG INTERFACE .......................................................................11

LED Indicator Status .........................................................................................11

Analog Interface Specifications .........................................................................12

Analog Interface Cabling and Connections .......................................................12

10.0 INSTALLATION EXAMPLE ...............................................................................13

11.0 WIRING DIAGRAMS AND SCHEMATICS .................................................. 14-15

12.0 TROUBLESHOOTING GUIDE ..........................................................................16

2 of 16

Document: LPS:1220A Rev M

760412-00-00

Mar 2015

1.0 SCOPE

The KIRLIN LED SmartSupply™ is intended for powering and dimming Class 2 low voltage lighting

systems for permanent installations.

It is intended for installation in plenum or non-plenum locations in accordance with required local,

state, provincial, country and NEC/CEC regulations. Only Output Cables marked with “CMP” may be

installed in plenum locations.

This manual provides general installation, use and application guidelines for the KIRLIN LED

SmartSupply. It should be read in conjunction with product datasheets. Data sheets may be

downloaded at www.kirlinlighting.com.

While every effort has been made to ensure the accuracy of the contents of this manual, The Kirlin

Company cannot accept any liability for errors contained herein. Specifications are subject to

change without prior notice.

2.0 OWNER/USER RESPONSIBILITIES

It is the responsibility of the contractor, installer, buyer, owner and user to install, maintain, and

operate the KIRLIN LED SmartSupply in accordance with all applicable laws, regulations and local

Electrical Safety Authority requirements. This product is only to be installed by a qualified electrician.

There are no field serviceable parts within power unit.

3.0 EMC COMPLIANCE

This device complies with Part 15 of the FCC Rules. Operation is subject to the following conditions:

(1) this device may not cause harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

This Class A digital apparatus complies with Canadian ICES-003 requirements.

Warning: This is a Class A product. In a domestic environment this product may cause radio

interference, in which case the user may be required to take adequate measures.

Document: LPS:1220A Rev M

760412-00-00

Mar 2015

3 of 16

4.0 INSTALLATION GUIDELINES AND SAFETY REQUIREMENTS

This power unit has been evaluated to the requirements for:

UL 60950-1 2nd Edition - Information Technology Equipment-Safety Part 1: General

Requirements

CSA C22.2 No. 60950-1-03, 2nd Edition - Information Technology Equipment-Safety Part 1:

General Requirements

IEC 60950-1:2005 Second Edition

Subject 8750 Issue 3, Outline of Investigation For LED Light Sources For Use in Lighting

Products

WARNING

RISK OF FIRE OR ELECTRIC SHOCK:

x

x

x

x

x

x

x

Shut OFF power at fuse box or circuit breaker before installation

Turn power OFF before inspection or removal

Properly ground power unit to main protective earthing

Follow all NEC/CEC, local electrical code requirements for input and output wiring

Do not remove enclosure cover. No serviceable parts inside

Do not connect analog interface to class 1 circuits

To reduce the risk of fire or electric shock, do not interconnect output terminations

4.1 ELECTRICAL REQUIREMENTS

This power unit is intended for connection to a 20A branch circuit and an appropriate

disconnect device shall be provided as part of the building installation.

All secondary output circuits are SELV, limited power source (LPS) and Class 2.

4.2 MOUNTING AND ENVIRONMENTAL REQUIREMENTS

This power unit is limited to fixed plenum or non-plenum locations. Only output cables marked

with “CMP” may be installed in plenum locations.

This power unit is rated for dry locations only.

The power unit is intended for use in a nonconductive pollution environment only.

This power unit is rated for operation at a maximum ambient temperature of 40 ºC.

Allow sufficient spacing around heatsink extrusion fins for convection air flow.

Do not block ventilation openings.

4 of 16

Document: LPS:1220A Rev M

760412-00-00

Mar 2015

5.0 MECHANICAL DETAIL

Dimensions in Inches [mm]

Document: LPS:1220A Rev M

760412-00-00

Mar 2015

5 of 16

6.0 MOUNTING ORIENTATION

For sufficient cooling, the KIRLIN LED SmartSupply™ must be mounted in either a vertical or horizontal orientation as shown:

Vertical orientation provides the best cooling option

↑ UP

↑ UP

D

D

D D

D

↑ UP

Recommended mounting screw size #8 machine or self tapping screw

Acceptable mounting orientations are identified by

6 of 16

D

Document: LPS:1220A Rev M

760412-00-00

Mar 2015

7.0 INPUT REQUIREMENTS

7.1 Electrical Input Specifications (Isolated Circuit Only):

Input Specifications

Rated Input Voltage And Frequency

115 to 277

47-63

Vac

Hz

Absolute Maximum Input Voltage for

Continuous Operation

290

Vac

Rated Input Current

2.7-1.1

Power Factor EN61000-3-2

@ 115 Vac, 100%

load

0.97

Input Current Total Harmonic

Distortion

@ 115 Vac 100%

load

13

A

W/VA min

% max

7.2 Input Connections:

CAUTION

RISK OF DAMAGE:

DO NOT connect AC input of power unit to a phase cut dimmer or

dimming panel. It will cause internal damage to the power unit.

x

Remove junction box cover and connect the AC line wires (ground, line neutral) to the terminal

block as shown.

x

When installing the SmartSupply™, connect to the appropriate sized building breaker or disconnect device for line and neutral connections in accordance with local, province, state, or

country regulations.

Document: LPS:1220A Rev M

760412-00-00

Mar 2015

7 of 16

8.0

OUTPUT CHANNEL REQUIREMENTS

8.1

Electrical Output Specifications:

Output Specifications

Rated Output Power

Output Voltage

Dynamic Range

Efficiency

Turn on delay

Output Current Tolerance

@ 40 °C ambient

Under load conditions

243

6.0 to 27.0

100% load @ 115 Vac input

87

Time required for

stabilization of all outputs

2

W max

Vdc

%

sec

typical

+/-5 % of nominal

8.2 Output Wiring Requirements

x

WARNING: All output channels are isolated from each other and require a separate 2

conductor 18 AWG (minimum) twisted shielded pair for each output LED load. When

connecting LED loads to output cables observe ‘+’ and ‘-‘ polarity connections to prevent

damage to loads. To reduce the risk of fire or electric shock, do not interconnect output

terminations.

x

WARNING: Wire shields on all output cable extensions MUST be connected ONLY to the Kirlin

Symphony SmartSupply™ output cable shields for effective RFI/EMI suppression. In MRI

applications, DO NOT connect the wire/cable shields OUTSIDE of the MRI room to the room

shield grounding bar or to the RFI/EMI filters.

x

In MRI applications, all wire shields INSIDE the MRI room MUST be terminated to the interior

room shield grounding bar. See diagram on page 15.

x

A common anode or cathode wiring method for multiple LED loads cannot be used for

the SmartSupply.

x

All output wires should be connected to their respective LED loads before power up to prevent

inadvertent shorting of outputs. Shorting of outputs (+ve to –ve only) will result in hiccup mode

of operation with automatic recovery after removal of the short. Recycling of AC input will be

required to restart unit. Unused wire/channels should be capped to prevent shorting.

x

Output Class 2 circuit wiring must comply with NEC Article 725 wiring methods or to CEC

section 16-210 wiring methods.

x

Output cabling should be overall 2 conductor 18 AWG (minimum) twisted pair shielded wire to

minimize cross talk between channels and minimize Electromagnetic Interference (EMI).

Consult your local Electrical Safety Authority for acceptability in your end use

application.

x

The maximum permissible length of cable (see cable specifications above) between the Kirlin

SmartSupply™ and the LED loads is: 100 feet (30m) with (1) 20W fixture / channel. 50 feet

(15m) with (2) 20W fixtures / channel; 50 feet (15m) with (1) 42W fixture / channel.

8 of 16

Document: LPS:1220A Rev M

760412-00-00

Mar 2015

8.3 Typical Wiring Diagram

Using (1) KIRLIN LED SmartSupplyTM and (1) Wall Box Dimmer

For approved 0-10V wall box dimmers see section 9.4.

Document: LPS:1220A Rev M

760412-00-00

Mar 2015

9 of 16

8.4

Output Zone/Channel Connections Table

The 6-channel configuration provides 3 zones for dimming with 2 channels per zone.

8.5

Zone Number

Output

Channel

Belden/Alpha or

Equivalent Wire

Color/Polarity

Maximum # of

LEDs per

Channel

1

1

WHT + / GRN -

6

1

2

RED + / BLK -

6

2

3

WHT + / GRN -

6

2

4

RED + / BLK -

6

3

5

WHT + / GRN -

6

3

6

RED + / BLK -

6

LED Load (Fixture) Limitations

A maximum of (2) 20 watt fixtures or (1) 42 watt fixture is allowed per channel.

The maximum permissible length of cable (see cable specifications above) between the Kirlin

SmartSupply™ and the LED loads is:

x

100 feet (30m) with (1) 20W fixture / channel

x

50 feet (15m) with (2) 20W fixtures / channel

x

50 feet (15m) with (1) 42W fixture / channel

10 of 16

Document: LPS:1220A Rev M

760412-00-00

Mar 2015

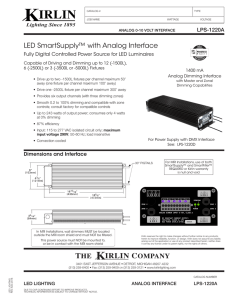

9.1

LED Indicator Status

Zone #4

No Connection

Analog Dimming

0-10 Vdc ANALOG INTERFACE

Power Indicator

9.0

Zone #1

Output

Channels 1,2

Master & Zone

Dimming Interface

Connections

Zone # 3

Output

Channels 5,6

Zone #2

Output

Channels 3,4

x

Power Indicator-Green LED will turn off if no power is detected.

x

Dimming-Green LED will flash when output master is at full on (100% light intensity). Green LED

will vary in intensity proportionally to master 0-10 Vdc control signal for

intensity levels less than 100%.

Document: LPS:1220A Rev M

760412-00-00

Mar 2015

11 of 16

9.2

Analog Interface Specifications

Analog Interface Specifications

Analog 0-10 Vdc IEC 60929

Annex E outputs 0.5mA

maximum or variable 0-10Vdc

voltage source; Class 2 outputs

Control Method

Master, Zone 1, Zone 2, Zone 3 outputs each

source 0.5 mA Maximum

Master, Zone 1, Zone 2, Zone 3 outputs

electrically isolated from earth ground

Electrical Isolation

Connection Method

UL recognized cage clamp connector

12 AWG to 28 AWG wiring

Loss of Analog

Control Signal

Outputs will go to 100% light intensity in less than 1

second

The Kirlin SmartSupply™ is compatible with commercial dimming panels and wall box dimmer products meeting IEC 60929 requirements and has been tested with a number of 0-10 Vdc Analog wall

box dimmer products. Consult Kirlin for compatibility.

9.3

Analog Interface Cabling and Connections

In the end use application, proper separation between the class 2 control wiring from the analog 010 Vdc interface and AC mains must be observed in accordance with the applicable safety standards and/or NEC/CEC requirements.

The total run length of the 0-10Vdc control wiring (purple and grey) #18 AWG should not exceed 500

feet (150 meters). In situations where the control wiring is greater than 500 feet or electrical noise is

present, shielded twisted pair cabling should be used.

9.4 0-10V Approved Wall Box Dimmers*

Brand

*

**

Model

Model Name

Hunt

PS-010

Leviton

IP710DLX

Lightolier

ZP600FAM-XXX

Sunrise

MP1500FAM-XXX

Momentum

V2000FAM-U

Vega

Lithonia

15DBC

Lutron

NSTV **

Nova

NTSTV **

Nova T

DVTV

Diva

DVSTV

Diva

VF10 w/GRX-TVI

Vareo

Others dimmers may be compatible. Please contact The Kirlin Company for compatibility.

WARNING: WHEN USING LUTRON NSTV OR NTSTV LOW-VOLTAGE 0-10V WALL DIMMERS, DO NOT

SPECIFY OR INSTALL LUTRON PP-SERIES POWER PACKS. USE OF LUTRON PP-SERIES POWER

PACKS MAY CAUSE DAMAGE TO THE SMARTSUPPLY THAT IS NOT COVERED UNDER WARRANTY.

12 of 16

Document: LPS:1220A Rev M

760412-00-00

Mar 2015

10.0

INSTALLATION EXAMPLE

(1) KIRLIN LED SmartSupplyTM, (1) COMMERCIAL DIMMING PANEL WITH (3) 0-10VDC ANALOG CONTROL SIGNALS

Note: This wiring configuration provides independent dimming control for each zone 1, 2, and 3

with a commercial dimming interface comprising (3) 0-10Vdc control signals.

See pages 14 to 15 for additional wiring diagrams.

Document: LPS:1220A Rev M

760412-00-00

Mar 2015

13 of 16

11.0

WIRING DIMMING CONTROLS TO SmartSupply™

14 of 16

Document: LPS:1220A Rev M

760412-00-00

Mar 2015

Document: LPS:1220A Rev M

760412-00-00

Mar 2015

15 of 16

12.0 TROUBLESHOOTING GUIDE

Fixtures Do Not Illuminate

1. Confirm that the wire/cable shields outside of the MRI room are NOT terminated to the room shield

2.

3.

4.

5.

6.

grounding bar. Terminating wire/cable shields on the room shield grounding bar may have damaged

the SmartSupply™ remote driver.

Confirm the installed RFI filter(s) are approved KIRLIN SmartFilters™ RFI-3100D. Use of any other

filter without factory approval is not recommended and may void the warranty.

Verify the SmartSupply is powered on. The green “POWER” indicator light, located on the top of the

unit, should illuminate continuously.

Verify the SmartSupply is dimming properly.

a. When the wall control is supplying 100% output, the green “DIMMING” indicator light should

flash.

b. When the wall control is supplying less than 100% output (dimming), the green “DIMMING”

indicator light should illuminate continuously (no longer flashing) and dim proportionally with the

light fixtures.

Check for a short circuit or incorrect wiring of fixtures or filters. Consult Wiring Diagrams in Section

11.0.

a. A short circuit will cause the SmartSupply to power off to protect itself. To reset the SmartSupply

after the short circuit condition is corrected, cycle off / on AC input power to SmartSupply.

b. Multiple 20W fixtures must be wired in series.

Disconnect the LED fixture(s) not illuminating from the output channel. Using a true RMS meter,

check output voltage of the output channel. Output voltage with no load should be 27-30V for a

properly functioning channel. Any reading below 27VDC could indicate a driver malfunction.

Lights Are Pulsing, Strobing or Flickering

1. Confirm the installed RFI filter(s) are approved KIRLIN SmartFilters™ RFI-3100D. Use of any other

filter without factory approval is not recommended and may void the warranty.

2. Verify the installed dimmer is 0-10V and approved for use with the SmartSupply. Consult Kirlin for

appropriate manufacturers’ models.

3. Verify that 18 AWG (minimum) twisted pair shielded wire is used.

4. Check all wire connections. The most common reason for one or more pulsing / strobing fixtures is a

loose wire connection. One loose wire connection can affect all luminaires on the system.

Some of the Fixtures Are Not Operating

1. Confirm the installed RFI filter(s) are approved KIRLIN SmartFilters RFI-3100D. Use of any other

filter without factory approval is not recommended and may void the warranty.

2. If there are two 20W fixtures per circuit, verify that the fixtures are wired in series. Consult Wiring

Diagrams in Section 11.0.

3. Visually inspect the LED circuit boards in the fixtures that are not operating properly. If one or more

of the LEDs are not illuminated, the LED lighthead requires replacement. Consult Kirlin.

4. Ensure each filter output channel is fed with power from the SmartSupply on the filter’s input side.

Fixtures Do Not Dim

1. Verify the installed dimmer is 0-10V and approved for use with the SmartSupply. See page 12 or

consult Kirlin for appropriate manufacturers’ models.

2. Check to make certain the gray and purple dimming control leads from the wall box dimmer have

been fully inserted into the dimming contacts located on the top of the SmartSupply.

16 of 16

Document: LPS:1220A Rev M

760412-00-00

Mar 2015