OMICRON Magazine 1/2012

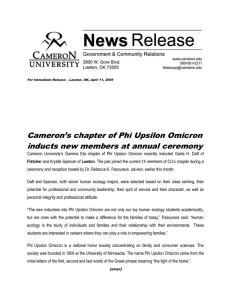

advertisement