LEP 5.3.10- 00 Plasma physics: Surface treatment

advertisement

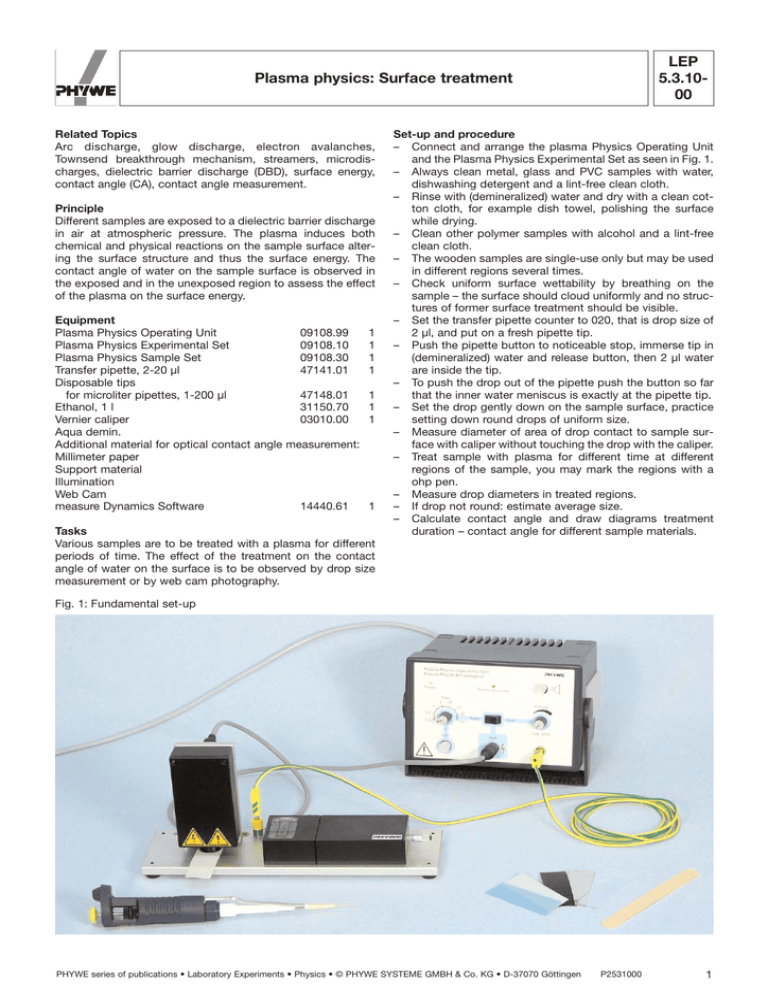

LEP 5.3.1000 Plasma physics: Surface treatment Related Topics Arc discharge, glow discharge, electron avalanches, Townsend breakthrough mechanism, streamers, microdischarges, dielectric barrier discharge (DBD), surface energy, contact angle (CA), contact angle measurement. Principle Different samples are exposed to a dielectric barrier discharge in air at atmospheric pressure. The plasma induces both chemical and physical reactions on the sample surface altering the surface structure and thus the surface energy. The contact angle of water on the sample surface is observed in the exposed and in the unexposed region to assess the effect of the plasma on the surface energy. Equipment Plasma Physics Operating Unit 09108.99 1 Plasma Physics Experimental Set 09108.10 1 Plasma Physics Sample Set 09108.30 1 Transfer pipette, 2-20 µl 47141.01 1 Disposable tips for microliter pipettes, 1-200 µl 47148.01 1 Ethanol, 1 l 31150.70 1 Vernier caliper 03010.00 1 Aqua demin. Additional material for optical contact angle measurement: Millimeter paper Support material Illumination Web Cam measure Dynamics Software 14440.61 1 Tasks Various samples are to be treated with a plasma for different periods of time. The effect of the treatment on the contact angle of water on the surface is to be observed by drop size measurement or by web cam photography. Set-up and procedure – Connect and arrange the plasma Physics Operating Unit and the Plasma Physics Experimental Set as seen in Fig. 1. – Always clean metal, glass and PVC samples with water, dishwashing detergent and a lint-free clean cloth. – Rinse with (demineralized) water and dry with a clean cotton cloth, for example dish towel, polishing the surface while drying. – Clean other polymer samples with alcohol and a lint-free clean cloth. – The wooden samples are single-use only but may be used in different regions several times. – Check uniform surface wettability by breathing on the sample – the surface should cloud uniformly and no structures of former surface treatment should be visible. – Set the transfer pipette counter to 020, that is drop size of 2 µl, and put on a fresh pipette tip. – Push the pipette button to noticeable stop, immerse tip in (demineralized) water and release button, then 2 µl water are inside the tip. – To push the drop out of the pipette push the button so far that the inner water meniscus is exactly at the pipette tip. – Set the drop gently down on the sample surface, practice setting down round drops of uniform size. – Measure diameter of area of drop contact to sample surface with caliper without touching the drop with the caliper. – Treat sample with plasma for different time at different regions of the sample, you may mark the regions with a ohp pen. – Measure drop diameters in treated regions. – If drop not round: estimate average size. – Calculate contact angle and draw diagrams treatment duration – contact angle for different sample materials. Fig. 1: Fundamental set-up PHYWE series of publications • Laboratory Experiments • Physics • © PHYWE SYSTEME GMBH & Co. KG • D-37070 Göttingen P2531000 1 LEP 5.3.1000 Plasma physics: Surface treatment Alternative 1: Area of contact drop to sample surface measurement with web cam – Mount the web cam that it views top-down (Fig. 2). – All-sided diffuse illumination is advisable for contrast of the drop's edge. – Place sample with drop and a cut-out strip of millimeter paper into the focus under the camera. – Camera settings: maximal contrast and black and white operation. – Save pictures as *.jpg. – Start measure dynamics software, select "File" > "Open picture…". – Select in the drop-down menu file type "JPeg picture (*.jpg)" and open the desired file. – Select "Measure" > "Calibration". – Fit the calibration line with the mouse over the picture of the millimeter paper, see Fig. 4. – Click on the legend and enter distance and unit. Fig. 4: Calibration line Fig. 5: Circle to fit the drop picture Fig. 2: Alternative 1 Fig. 6: "Display/Paint objects" window – – – Fig. 3: Alternative 2 2 P2531000 – Select "Display" > "Paint" and use the circle button (Fig. 6). Adjust the properties of the circle with the upper right button from the "Display/Paint objects" window right of the "Play" button. Set "Width" to 1 pixel, select a well visible color and no filling, see Fig. 7. Note down circle diameter and area. PHYWE series of publications • Laboratory Experiments • Physics • © PHYWE SYSTEME GMBH & Co. KG • D-37070 Göttingen LEP 5.3.1000 Plasma physics: Surface treatment – – – Use "Display" > "Paint" to do so. Adjust the properties of the circle with the upper right button from the "Display/Paint objects" window right of the "Play" button (see Figs. 6 and 7). Set "Width" to 1 pixel, select a well visible color, no filling and a partly translucent "Alpha channel" slide bar setting with the slide bar near the middle. Fig. 8: Angle measurement Fig. 7: Window to adjust properties Alternative 2: Direct contact angle measurement with web cam – Place the sample with drop on it right in front of the web cam and focus well on the drop, drop centered in the field of view. – Tilt the camera only few degrees downwards. – Illuminate a spot on a plane well behind the sample, the spot size at most the field of view of the camera (Fig. 3). – Keep the rest of the room dark so the drop appears dark in front of an illuminated background to minimize picture misinterpretation through glare and reflexes. – Best camera settings are black and white, maximal contrast, high brightness and exposure. – Save pictures as *.jpg. – Start measure dynamics software, select "File" > "Open picture…". – Select in the drop-down menu file type "JPeg picture (*.jpg)" and open the desired file. – Select "Measure" > "Measure angle". – Move the yellow marks with the mouse to desired positions and read out the contact angle, see Fig. 8. – To improve accuracy you may draw circles to fit the profile of the drop and its reflection on the sample surface – the tangent of a circle is better visible than that of the drop, the intersection of the circles defining the horizon – and you may evaluate two tangents to each side (Fig. 9). Fig. 9: Angle measurement with help of circles PHYWE series of publications • Laboratory Experiments • Physics • © PHYWE SYSTEME GMBH & Co. KG • D-37070 Göttingen P2531000 3 LEP 5.3.1000 Plasma physics: Surface treatment Theory Plasma, the fourth state of matter Plasma is often referred to as the fourth state of matter after solid, liquid and gaseous. A plasma is a gaseous state of matter in which part or all of the species (atoms or molecules) are ionized. The plasma may consist of neutrals, free electrons and positively charged ions. In the presence of electronegative gas particles the electrons may get captured by them so that negative ions may also be present and the number of free electrons reduced. A plasma can be characterized by it's degree of ionization. The degree of ionization X is defined as X = ni / (ni + na) where ni is the number density of ions and na is the number density of neutral atoms. Also particle density (or pressure) and temperature play main roles in the description of plasma behavior. Ionizing processes as heat, chemical reactions, ionizing radiation or electrical fields may lead to plasma formation. Some plasmas are named according to the process that generate them, for example "low pressure radio frequency (RF) plasma". Widely known plasmas are – the photosphere of the sun exited by heat, – flames exited both by chemical reactions and heat, – the ionosphere of the earth exited by UV, soft X-ray and energetic proton irradiation, – the mercury vapor glow discharge inside a common fluorescent lamp exited by low frequency high voltage electric fields – or the lightning from a thunderstorm as an example of an electric arc. Since mobile charge carriers are present, plasma is an electric conductor and the static electric field inside the plasma is usually weak. Strong static electric fields may be present though in sheaths around electrodes, where the reactions forming the plasma take place. Non-thermal and thermal plasma Depending on pressure and mechanism of plasma generation the plasma may not be in thermal equilibrium, so different species may have strongly different mean energies, sometimes also referred to as different temperatures, though the term temperature is only precisely defined in thermal equilibrium. For example in case of weakly ionized electric plasma at low gas pressure in the hPa range as in glow discharges the gas ions have nearly ambient temperature while the electrons gain energy from the electric fields until they are able to excite or ionize the present gas particles. The excitation or ionizing energies can be in the range of several eV. According to thermodynamics in an ideal gas per degree of freedom the average energy in thermal equilibrium is E = 1/2 kB T with the Boltzmann constant kB. The energy of two eV per degree of freedom of electrons would correspond to a temperature of T = 1 eV / kB = 1.602-19 CJ / 1.38-23 J/K = 11600 K, so the electrons may be considered "hot" compared to the ions at about 300 K. Such a glow discharge is structured in regions of high field where plasma formation takes place and others of low field – different regions having different luminosities. So a glow discharge is an example of a non-thermal plasma. In contrast to that in a thermal plasma like an arc pressure and degree of ionization are high enough that electrons and ions efficiently exchange their energy and have the same temperature of a few thousand K. The arc discharge is not structured in a way like a glow discharge. 4 P2531000 Mobility, diffusion and drift The strong deviation of electron and ion behavior depends on the strong differences in mobility and momentum exchange in collisions. The mobility of particles in a gas decreases with their mass and the mass of the light H atom is already about 2000 times the mass of an electron. Also higher pressure decreases the mobility since the pressure determines the mean free path. The motion of a charged particle in a gas under influence of a static electric field is an average directed drift. The drift velocity is the mobility times the electric field strength. In gases at breakdown conditions the directed drift velocity of electrons is in the range of 105 ... 106 m/s, the velocity of ions is in the range of 50 ... 500 m/s. In a collision between a gas ion and another atom or molecule the masses of the particles are of the same order of magnitude. After the collision the probability is high that the momentum is evenly distributed between the collision partners. So if a ion gains some energy from the electric field it will loose it probably again in the next collision. This is not so for the electrons in a plasma of low ionization degree that are mainly reflected from the much heavier gas particles with few momentum transfer at each collision unless they can excite or ionize the collision partner. Only few energy is transferred due to rotational and vibrational state transitions during collision betwenn electrons and molecules. Because of their higher mobility the electrons in a glow discharge shield the electric fields while the ions spread their energy efficiently in collisions unless pressure is that low that their mean free path is as long as the dimensions of the electric field distribution. Reactions induced by non-thermal plasma In a non-thermal plasma the energetic electrons and ionized or exited gas particles can activate a lot of desired chemical and physical reactions while a sample surface exposed to the plasma is not heated to a great extent. The energy transfer from the electric source is mainly to the electrons and thus excitation and not to excessive heating so the electrical effection of chemical reactions by plasma can be very efficient. At low gas pressure use of high frequency electric fields and electrodeless configurations are possible. So non-thermal plasma is used for plasma chemical vapor deposition, etching and sputtering at low pressure and in high purity environments, especially in semiconductor or optics fabrication. Unluckily no glow discharge will establish at atmospheric pressure but electric breakdown will lead under these conditions to formation of an electric arc, a thermal plasma, if sufficient field strength of DC, AC or high frequency is applied. On the other hand it is desirable to have non-thermal plasma at atmospheric pressure at hand so no expensive and unhandy vacuum equipment is necessary for the possibility of chemical reactions or surface treatment provided by non-thermal plasma. So understanding the plasma formation process may help. Electron avalanches With electric plasma generation, that is electrical gas breakdown, charge carrier multiplication provides for the ionization. To reach a significant degree of ionization a randomly present charged particle needs to produce in average more than one other charged particle before recombining with another particle or an electrode. Otherwise the electric field will sweep away the present charge carriers and any discharge will die out. PHYWE series of publications • Laboratory Experiments • Physics • © PHYWE SYSTEME GMBH & Co. KG • D-37070 Göttingen LEP 5.3.1000 Plasma physics: Surface treatment The main starting process of charge multiplication in gases is an electron avalanche because electrons gain most energy from the electric field due to highest mobility. An initial electron may be set free by omnipresent random ionizing radiation or by a positive gas ion recombining at a surface under emission of Auger electrons. There may be a retardation time before the starting electron appears delaying discharge formation. In an electron avalanche an initial electron produces after inelastic scattering in average more than one more free electron and a positively charged ion. Such an avalanche spreads in field direction with the electron directed drift velocity and laterally with the undirected thermal electron diffusion velocity so the outer form of the avalanche is drop-shaped, a round avalanche head and a pointy tail. High and low charge density discharge behavior What happens after development of an electron avalanche depends on the gas conditions and field distribution. In the following the situation between parallel metal plates some millimeters to centimeters apart with applied AC voltage is considered. a) If the pressure is low, then the charge density of the avalanche is small enough not to significantly distort the applied field. The avalanche reaches the anode after some nanoseconds where the electrons get absorbed leaving a trace of slower ions behind which now travel to the cathode. When the ions impinge on the cathode after some microseconds they release with a certain probability secondary electrons by Auger effect when recombining with the metal's conduction band electrons. The secondary electrons seed in turn new electron avalanches. Since the reaction between ions and electrode surface determine the rate of electron creation, this type of discharge is sensitive to electrode materials. After less than a millisecond a plasma has formed between the metal plates with a positive space charge due to the slower positive ions in front of the cathode strengthening the field there and lowering it in the rest of the discharge volume. This cathode fall region contracts to a size such that avalanche multiplication becomes optimal there. This is called Townsend breakdown and the result of this process is a glow discharge. b) If the pressure is high the free paths are so small that the resulting charge densities of an avalanche generate an electric field strength in the range of the field strength that initiated the avalanche. The separating electrons and ions form a dipole that weakens the field inside the avalanche region and amplifies it to the head and tail of it. The field strength increases there to an extent that electrons set off by photons emanating from the avalanche start new avalanches with increased probability. Several avalanches connect to a streamer, a thin weakly ionized plasma channel. Once the streamer interconnects the plates after some nanoseconds, current can begin to flow between the plates heating the plasma and forming an arc. Thermal emission occurs where the arc touches the electrodes. The streamer formation propagates at least with the electron drift velocity. For long distances as in lightning the electrons in the head of interconnected streamers can be accelerated to energies above 100 eV where they have again a reduced reaction cross-section with gas molecules. They are called run-away or beam electrons and can form a leader discharge which leaves a thin highly ionized channel before connecting the electrodes. Providing low charge density discharges at atmospheric pressure So if at atmospheric pressure a non-thermal plasma is desired, arc formation has to be avoided because streamers will form if break-through conditions are reached or streamer formation has to be avoided altogether. One method is the dielectric barrier discharge (DBD) where a dielectric between the electrodes provides for an AC field strong enough for breakthrough and streamer formation but inhibits large current flow and thus arc formation. So the streamers lead to microdischarges that conduct current until there is enough charge gathered on the dielectric surface that the external field is shielded. Since the mobility of charges sideways on the dielectric surface is low, many parallel microdischarges take place until the field is lowered over the whole electrode surface. So the discharge is filamented and the filaments tend to arrange in an equidistant pattern and tend to stay located because the patterned charge distribution left on the dielectric seed new microdischarges in the same pattern after field reversal. Streamer formation may be inhibited to some extent in a DBD if after a discharge cycle enough seed electrons remain everywhere on the dielectric to initiate so many avalanches that a uniform but relatively low ionization is achieved and a so called atmospheric pressure glow discharge (APG) forms. Another method to produce non-thermal atmospheric pressure discharges is to use micro-structured electrodes (MSE). There the electrode distance is that small that breakthrough occurs with only a few hundred volt between the electrodes and the avalanche length small enough to avoid high charge densities capable of streamer formation. Technical applications of non-thermal athmospheric pressure plasmas Technically DBDs are employed to large scale in ozone generators (with glass tubes as dielectric) and also for surface treatment to improve printability or wettability for example in the textile industry. A future application might be cleaning of exhaust gases from toxic compounds. In a DBD in air at ambient pressure besides ions of air molecules neutral radicals like ozone and nitrogen oxides and their ions are produced which then can react with a sample surface. The surface itself can produce reactive radicals if bombarded with electrons and ions and the radicals from the DBD. Altogether surface compounds can be changed in a DBD leaving polar groups as bound oxygen and the like on a former unpolar surface or the surface layer structure can get disturbed by insertion of faults which may lead to deformed structures with increased dipole moment. The surface energy is altered and the changed hydrophilicity alters the wettability. Technically the trend from unpolar solvents to water-based systems for surface coating requires better wettability for unpolar surfaces so improved hydrophilicity is desired. The surface treatment experiment In the present experiment the plasma is created by a (200 ± 5) Hz AC (15000 ± 500) kV field from a source delivering maximally 2 mA. The field is applied over a 1 mm dielectric barrier consisting of alumina ceramic (Al2O3 or corundum) and a gap of 2.5 mm in air at ambient pressure. One electrode is metal powder inside the alumina tray and the other is the aluminium ground plate of the Plasma Physics Experimental Set. PHYWE series of publications • Laboratory Experiments • Physics • © PHYWE SYSTEME GMBH & Co. KG • D-37070 Göttingen P2531000 5 LEP 5.3.1000 Plasma physics: Surface treatment A sample can be placed into the space between alumina tray and ground plate and can be exposed to the usually filamentary discharge for durations between 0.2 s and 60 s. A change in the surface energy of the sample is detected by the measurement of the contact angle of a water droplet on the sample surface on the untreated surface and after different plasma treatment durations. Wetting and contact angle The cosine of the contact angle is according to Young's equation for partial wetting equal to the ratio of surface energy difference between solid-air- and solid-liquid surface to surface energy of liquid-air surface cosa sS sLS sL (1) with sL the surface energy of the liquid-air surface, sS the surface energy of the solid-air surface, and sLS the surface energy of the liquid-solid surface, the surface energy also called surface tension. This equation can be derived by considering the forces. The liquid-air-solid contact line can move on the sample surface only parallel to the surface and will move until the force tangential to the sample surface is zero, the tangential components of the forces cancel each other. See Fig. 10. The surface energy is equal to a force per length tangential to the surface at a rim of the surface. Three cases are commonly distinguished: complete, partial or no wetting. In case of complete wetting the contact angle is zero, the solid-air surface energy exceeds the sum of liquid-air and liquid-solid surface energies and a drop is spread over the whole surface. Partial wetting occurs, if the surface energy of the solid-air interface is less than the sum of liquid-air and solid-liquid surface energies but greater than the solid-liquid surface energy. A defined contact angle below 90° occurs. In these two cases the surface energies of both drop and solid are lowered by adhesion of the drop. Fig. 10: Forces on the meeting line of the phases, cos a | FL | = | FS | – | FLS | 6 P2531000 | FL II | = If the solid-air surface energy is less than the solid-liquid surface energy the contact angle will exceed 90° and the surface is called unwettable by the liquid. A drop will roll off the surface then when the surface has a slope. Contact angles exceeding 90° can be observed though and the liquid-solid surface energy is always positive and less than the liquid-air surface energy, since adhesion to something is always better than to vacuum due to always present London forces or vacuum radiation pressure. The surface energy of the solid is raised with the presence of the drop, only the drop's surface energy is lowered so the whole system can be still thermodynamically stable. The interaction between condensed matter and air is assumed to be negligible and the same as to vacuum. The wettability of a surface can be raised by plasma treatment. The plasma leaves polar groups on the surface raising the dipole and hydrogen bond interactions between surface compounds thus raising the surface energy and strengthening the surface-water interactions lowering the liquid-solid surface energy. Evaluation In case of drop size measurement the contact angle can be determined from the drop size and the known volume of the drop. Let the drop volume V on the pipette be set to 2 µl = 2 mm3. In case the drop is small enough so gravitational distortion of the drop form plays no role and the surface is uniform enough so the drop is round then the drop will form a spherical segment on the sample surface with a specific contact angle between sphere surface and sample surface (Fig. 11). The segment of a sphere with sphere radius R has segment radius a and height h and the volume V = π h (3a2 + h2)/6 = π h2 (R – h /3 ) (2) and the contact angle a = arcsin(a / R) (3) Fig. 11: Drop with contact angle a, height h, sphere radius R and diameter 2a PHYWE series of publications • Laboratory Experiments • Physics • © PHYWE SYSTEME GMBH & Co. KG • D-37070 Göttingen LEP 5.3.1000 Plasma physics: Surface treatment In the experiment the drop diameter 2a is observed so the dependence of a on a is of interest. The left part of eq. (2) delivers for h the cubic equation h3 + 3a2h – 6V/π = 0 with the solution 3 2 u a2 3 2 u with u 2 3 3 V a6 a V b p p B and from the theorem of Pythagoras R a2 h2 . 2h Since the formulas are unhandy and the achievable accuracy low, the value of the contact angle a may be read out of the graph of Fig. 12. The data were created using spreadsheet calculation to evaluate the formulas. Fig. 13 shows typical measurement results for the drop size method after plasma treatment of the samples for time t. The absolute volume of a drop from the pipette is not so precisely defined and for a drop radius near the value for 90 ° is the relative angle error greatest so that falsely angles above 90 ° appear. For example some of the drop volume may have rested on the tip resulting in a falsely too high angle value. The behavior of a water drop on wood is changed in the way that after plasma treatment the drop gets soaked into the wood more quickly the longer the plasma was applied. The wetting seems to be completely and directed along the fibers. In case of the polymers the method is too inaccurate to really order the polymers according to their surface energy without using at least a second test fluid. It can be seen that plasma treatment raises the surface energy but not to such an extend that complete wetting with water occurs. From the literature value of their surface energy one would expect complete wetting with water both for glass and aluminium, which is always covered with it's oxide in air. But both have chemisorbed water already on their surface after contact with normal room atmosphere. SiO2 in glass and Al2O3 form links to hydroxyl groups during contact with water which in turn form hydrogen bonds to water molecules. So these surfaces pick up water immediately after production and their surface energy is in turn already lowered. Plasma treatment seems to exchange some of the hydroxyl groups and complete wettability is the result. The filamentary structure of the discharge over aluminium leads to not uniform surface energy in the treated region and the drops spread not to a circle. This may reduce the reliability of the evaluation with the drop diameter method. Fig. 12: Contact angle in dependence on drop radius PHYWE series of publications • Laboratory Experiments • Physics • © PHYWE SYSTEME GMBH & Co. KG • D-37070 Göttingen P2531000 7 LEP 5.3.1000 Plasma physics: Surface treatment Table 1 shows literature values for the surface energy at 20 °C. Table 1: Surface energy values Material surface energy [mJ/m2] dispersive contribution to surface energy [mJ/m2] polar contribution to surface energy [mJ/m2] Al2O3 5900 - 7300 n. a. n. a. Glass 560 n. a. n. a. Water 72.8 n. a. n. a. PVC 41.5 39.5 2.0 PE 35.7 35.7 0.0 Polyester (PC) 34.2 27.7 6.5 PP 30.1 30.2 0.0 PTFE 20.0 18.4 1.6 Fig. 13: Measurement results for the contact angle of water on different sample surfaces after plasma exposure of duration t 8 P2531000 PHYWE series of publications • Laboratory Experiments • Physics • © PHYWE SYSTEME GMBH & Co. KG • D-37070 Göttingen