DER-528 - Power Integrations

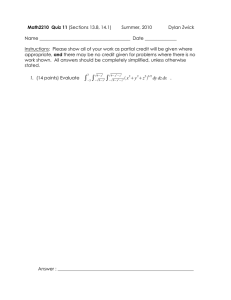

advertisement

Design Example Report Title 14 W Non-Dim m able, High Efficiency (>86% ), P ow er Factor Corrected I solated Flyback LED Driver Using LYTSw itch TM -5 LYT5226D Specification 90 VAC – 265 VAC Input; 20 VMIN – 40 VMAX, 350 mATYP Output Application Down Light Author Applications Engineering Department Document Number DER-528 Date March 09, 2016 Revision 1.0 Summary and Features • Single-stage power factor corrected, PF >0.9 • Wide output LED voltage range (20 VMIN - 40 VMAX) with accurate current regulation, ±5% • Highly energy efficient, >86% at 115 V / 230 V • Low cost and low component count for compact PCB solution • Integrated protection features • No-load and output short-circuit protection • Input and output OVP • Thermal foldback protection • Over temperature protection • No damage during line brown-out or brown-in conditions • Meets IEC 2.5 kV ring wave, 1 kV differential surge • Meets EN55015 conducted EMI with LED heat sink grounded Power Integrations 5245 Hellyer Avenue, San Jose, CA 95138 USA. Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com DER-528 14 W LED Driver Using LYT5226D 09-Mar-16 PATENT INFORMATION The products and applications illustrated herein (including transformer construction and circuits external to the products) may be covered by one or more U.S. and foreign patents, or potentially by pending U.S. and foreign patent applications assigned to Power Integrations. A complete list of Power Integrations' patents may be found at www.powerint.com. Power Integrations grants its customers a license under certain patent rights as set forth at <http://www.powerint.com/ip.htm>. Power Integrations, Inc. Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com Page 2 of 78 09-Mar-16 DER-528 14 W LED Driver Using LYT5226D Table of Contents 1 2 3 4 Introduction .........................................................................................................5 Power Supply Specification ...................................................................................8 Schematic ............................................................................................................9 Circuit Description .............................................................................................. 10 4.1 Input Stage ................................................................................................. 10 4.2 EMI Filters ................................................................................................... 10 4.3 LYTSwitch-5 Primary Control Circuit .............................................................. 10 5 PCB Layout ........................................................................................................ 12 6 Bill of Materials .................................................................................................. 13 7 Inductor Specification ......................................................................................... 14 7.1 Electrical Diagram ........................................................................................ 14 7.2 Electrical Specifications ................................................................................ 14 7.3 Material List ................................................................................................ 14 7.4 Inductor Build Diagram ................................................................................ 15 7.5 Inductor Construction .................................................................................. 15 7.6 Winding Illustrations .................................................................................... 16 8 Inductor Design Spreadsheet .............................................................................. 21 9 Performance Data .............................................................................................. 24 9.1 Efficiency .................................................................................................... 24 9.2 Line Regulation............................................................................................ 25 9.3 Power Factor ............................................................................................... 26 9.4 %ATHD ...................................................................................................... 27 9.5 Power Input Difference Between 120 V to 230 V ........................................... 28 9.6 Individual Harmonics Content ....................................................................... 29 10 Test Data ....................................................................................................... 35 10.1 Test Data, 40 V LED Load ............................................................................ 35 10.2 Test Data, 35 V LED Load ............................................................................ 35 10.3 Test Data, 30 V LED Load ............................................................................ 36 10.4 Test Data, 25 V LED Load ............................................................................ 36 10.5 Test Data, 20 V LED Load ............................................................................ 37 10.6 Test Data, Power Input Difference Between 120 V and 230 V......................... 37 10.7 Test Data, Harmonic Content at 230 VAC with 40 V LED Load ........................ 38 10.8 Test Data, Harmonic Content at 115 VAC with 40 V LED Load ........................ 39 10.9 Test Data, Harmonic Content at 230 VAC with 30 V LED Load ........................ 40 10.10 Test Data, Harmonic Content at 115 VAC with 30 V LED Load ..................... 41 10.11 Test Data, Harmonic Content at 230 VAC with 20 V LED Load ..................... 42 10.12 Test Data, Harmonic Content at 115 VAC with 20 V LED Load ..................... 43 11 Thermal Performance ...................................................................................... 44 11.1 Thermal Performance Scan – Open Frame Unit ............................................. 44 11.1.1 Thermal Scan ....................................................................................... 45 11.1.2 Thermal Scan at the Top Side ................................................................ 47 11.2 Thermal Performance at 85 ºC ..................................................................... 48 Page 3 of 78 Power Integrations Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com DER-528 14 W LED Driver Using LYT5226D 09-Mar-16 11.2.1 Thermal Performance at 230 VAC with a 40 V LED Load .......................... 49 11.2.2 Thermal Performance at 120 VAC with a 40 V LED Load .......................... 50 12 Waveforms ..................................................................................................... 51 12.1 Input Voltage and Input Current Waveforms ................................................. 51 12.2 Output Current Rise ..................................................................................... 54 12.3 Output Current Fall ...................................................................................... 58 12.4 Drain Voltage and Current in Normal Operation ............................................. 60 12.5 Drain Voltage and Current Start-up Profile..................................................... 64 12.6 Drain Voltage and Current during Output Short-Circuit Condition .................... 66 12.7 Output Diode Voltage and Current in Normal Operation ................................. 67 12.8 Output Voltage and Current – Open LED Load ............................................... 68 12.9 Output Voltage and Current – Start-up with Open Load ................................. 68 12.10 Output Ripple Current............................................................................... 69 13 AC Cycling Test ............................................................................................... 70 14 Conducted EMI ............................................................................................... 72 14.1 Test Set-up ................................................................................................. 72 14.1.1 Equipment and Load Used ..................................................................... 72 14.2 EMI Test Result ........................................................................................... 73 15 Line Surge ...................................................................................................... 75 16 Brown-in/Brown-out Test ................................................................................ 76 17 Revision History .............................................................................................. 77 Important Note: Although this board is designed to satisfy safety isolation requirements, the engineering prototype has not been agency approved. Therefore, all testing should be performed using an isolation transformer to provide the AC input to the prototype board. Power Integrations, Inc. Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com Page 4 of 78 09-Mar-16 DER-528 14 W LED Driver Using LYT5226D 1 Introduction This engineering report describes a non-dimmable, isolated flyback LED driver designed to drive a 20 V to 40 V LED voltage string at 350 mA from an input voltage range of 90 VAC to 265 VAC. The LED driver utilizes the LYT5226D from the LYTSwitch-5 family of devices. LYTSwitch-5 is a non-dimmable LED driver IC with single stage PFC function and accurate LED current control. LYTSwitch-5 incorporates a high-voltage power MOSFET and discontinuous mode, variable frequency, variable on-time controller. The controller also provides fast (cycle-by-cycle) current limit, input and output OVP, plus advanced thermal management circuitry. DER-528 provides a 350 mA nominal constant current output within 20 VMIN – 40 VMAX output LED voltage ranges. The key design goals were high efficiency and constant current regulation throughout a wide input and output voltage range. The document contains the power supply specification, schematic, bill of materials, transformer documentation, printed circuit layout, design spreadsheet and performance data. Figure 1 – Populated Circuit Board. Page 5 of 78 Power Integrations Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com DER-528 14 W LED Driver Using LYT5226D 09-Mar-16 Figure 2 – Populated Circuit Board, Top View. Power Integrations, Inc. Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com Page 6 of 78 09-Mar-16 DER-528 14 W LED Driver Using LYT5226D Figure 3 – Populated Circuit Board, Bottom View. Note: The following component locations were unstuffed (not populated): R12, R1, R5, C3, and C9 Page 7 of 78 Power Integrations Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com DER-528 14 W LED Driver Using LYT5226D 09-Mar-16 2 Power Supply Specification The table below represents the minimum acceptable performance of the design. Actual performance is listed in the results section. Description Input Voltage Frequency Output Output Voltage Output Current Total Output Power Continuous Output Power Efficiency Full Load Symbol Min Typ Max Units Comment VIN fLINE 90 115/230 60/50 265 VAC Hz 2 Wire – no P.E. VOUT IOUT 20 30 350 40 V mA POUT 14 W η 86 % 115 V / 60 Hz and 230 V / 50 Hz at 25 ºC. Environmental Conducted EMI CISPR 15B / EN55015B Safety Isolated Ring Wave (100 kHz) 2.5 kV Differential Mode (L1-L2) 1.0 kV Power Factor 0.9 Ambient Temperature TAMB Power Integrations, Inc. Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com Measured at 230 VAC / 50 Hz and 115 VAC / 60 Hz. 85 o C Free Convection, Sea Level. Page 8 of 78 09-Mar-16 DER-528 14 W LED Driver Using LYT5226D 3 Schematic Figure 4 – Schematic. Page 9 of 78 Power Integrations Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com DER-528 14 W LED Driver Using LYT5226D 09-Mar-16 4 Circuit Description The LYTSwitch-5 device (U1-LYT5226D) combines a high-voltage power MOSFET and a power supply controller in a single SO16 package. IC U1 is configured to drive a 14 W isolated flyback LED driver throughout a wide input (90 V – 265 V) and output voltage (20 VMIN – 40 VMAX) range. 4.1 I nput Stage Fuse F1 provides safety protection from component failures. Varistor RV1 acts as a voltage clamp that limits the voltage spike on the primary during line transient voltage surge events. A 275 VAC rated part was selected, being slightly above the maximum specified operating voltage (265 VAC). The AC input is full wave rectified by BR1 to achieve good power factor and low THD. 4.2 EM I Filters The differential choke L2, together with the input filter capacitor C8 and C4 work as an EMI π filter. The π filter together with common mode choke L1, Y-capacitor C2 and the LYTSwitch-5 frequency jittering feature ensure compliance with the EN55015 Class B emission limit. 4.3 LYTSw itch-5 P rim ary Control Circuit The topology is an isolated flyback. The primary winding finish terminal (no dot end) of the transformer (T1) is connected to the DC bus and the start (dotted end) terminal to the DRAIN (D) pin of the LYTSwitch-5 IC. During the on-time of the power MOSFET, current ramps through the primary winding, storing energy which is then delivered to the output load via output diode D3 during the power MOSFET off-time. During the power MOSFET off time RCD snubber D2, R2, R4 and C1 clamp the leakage voltage spike to a safe level. Output capacitor C5 provides output voltage filtering minimizing the output LED ripple current with R7 acting as preload. Diode D4 and C7 deliver the primary bias supply for U1 from transformer auxiliary winding. For a wide output LED voltage application, the bias voltage is set to 30 V at maximum LED output voltage. The use of an external bias supply (via R11) is recommended to give the lowest device dissipation and provide sufficient supply to U1 at low LED voltage. Resistor R8 is added to dampen the leakage ring from the bias winding that could mis-trigger the device output OVP function. Capacitor C10 provides local decoupling for the BYPASS (BP) pin of U1, which is the supply pin for the IC. During start-up, the bypass capacitor C10 is charged to ~5.25 V from IC internal high-voltage current source connected to the D pin. Power Integrations, Inc. Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com Page 10 of 78 09-Mar-16 DER-528 14 W LED Driver Using LYT5226D To provide input line voltage information to U1, the input AC voltage is sensed directly after the bridge rectifier diode through sampling resistors R6 and R10. The device input OVP function is activated when line sense current exceeds the OVP threshold. With reference to the FEEDBACK (FB) pin threshold of 300 mV, R17 and R16 senses the output LED current through U1 drain current and is then fed into the U1 DRIVER CURRENT SENSE (DS) pin via R13 to maintain the output constant current regulation. When the detected signal is above or below the preset average VFB threshold voltage, the controller will adjust the frequency and/or on-time to maintain regulation. Capacitor C12 and R18 provide voltage filtering and input line compensation to the sense resistor for a more optimized output current regulation throughout the input range. The IC U1 OUTPUT COMPENSATION (OC) pin senses the output voltage through the bias winding via R9 (ROC) for the output OVP function at open load and for an optimized LED current regulation throughout the output voltage range. When the OC pin current exceeds the OV threshold, output OVP is activated with the IC latching off. This will prevent the output voltage from rising further. An AC recycle is needed to reset this protection mode once triggered. For wide-output LED applications, the ROC resistor (value) should be centered between IOUV (output undervoltage) and IOOV (output overvoltage). Page 11 of 78 Power Integrations Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com DER-528 14 W LED Driver Using LYT5226D 09-Mar-16 5 PCB Layout Figure 5 – Top Side. Figure 6 – Bottom Side. Note: The following component locations were unstuffed (not populated): R12, R1, R5, C3, and C9. Power Integrations, Inc. Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com Page 12 of 78 09-Mar-16 DER-528 14 W LED Driver Using LYT5226D 6 Bill of Materials Item Qty 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 Ref Des BR1 C1 C2 C4 C5 C6 C7 C8 C10 C11 C12 D1 D2 D3 D4 F1 JP1 L1 L2 R2 R3 R4 R6 R7 R8 R9 R10 R11 R13 R14 R15 R16 33 1 R17 34 35 36 37 1 1 1 1 R18 RV1 T1 U1 Page 13 of 78 Description 1000 V, 0.8 A, Bridge Rectifier, SMD, MBS-1, 4-SOIC 1 nF, 1000 V, Ceramic, X7R, 0805 2.2 nF, Ceramic, Y1 220 nF, 450 V, Film 470 µF, 50 V, Electrolytic, Gen. Purpose, (12.5 x 20) 2.2 µF, 400 V, Electrolytic, (6.3 x 11) 10 µF, 50 V, Electrolytic, Gen. Purpose, (5 x 11) 100 nF, 400 V, Film CAP, CER, 1 µF, 16V, X7R, 0805 150 nF, 25 V, Ceramic, X7R, 0603 10 µF, 10 V, Ceramic, X7R, 0805 800 V, 1 A, Fast Recovery, 250 ns, SMA 800 V, 1 A, Fast Recovery, 250 ns, SMA 300 V, 2 A, Ultrafast Recovery, 50 ns, SMB Case 600 V, 1 A, Rectifier, Glass Passivated, POWERDI123 5 A, 250 V, Fast, Microfuse, Axial Wire Jumper, Non-insulated, #22 AWG, 0.5 in 5 mH, 0.3 A, Common Mode Choke 1.5 mH, 0.23 A, Ferrite Core RES, 200 kΩ, 5%, 1/4 W, Thick Film, 1206 RES, 680 kΩ, 5%, 1/4 W, Thick Film, 1206 RES, 10 Ω, 5%, 1/4 W, Thick Film, 1206 RES, 2.00 MΩ, 1%, 1/4 W, Thick Film, 1206 RES, 51 kΩ, 5%, 1/4 W, Thick Film, 1206 RES, 10 Ω, 5%, 1/8 W, Thick Film, 0805 RES, 221 kΩ, 1%, 1/16 W, Thick Film, 0603 RES, 2.00 MΩ, 1%, 1/4 W, Metal Film RES, 30.1 kΩ, 1%, 1/8 W, Thick Film, 0805 RES, 6.04 kΩ, 1%, 1/4 W, Thick Film, 1206 RES, 6.04 kΩ, 1%, 1/16 W, Thick Film, 0603 RES, 37.4 kΩ, 1%, 1/16 W, Thick Film, 0603 RES, 17.4 Ω, 1%, 1/8 W, Thick Film, 0805 RES, SMD, 3.6 Ω, 1%, 200 ppm, 1/2 W, 1206, Automotive, AEC-Q200, Current Sense RES, SMD, 4.75 Ω, 1%, 1/10 W, ±200 ppm/°C, 0603 275 V, 23 J, 7 mm, RADIAL Bobbin, EE1621, Vertical, 8 pins, 4pri, 4sec LYTSwitch-5, SO-16B, High voltage Mfg Part Number Manufacturer B10S-G C0805C102KDRACTU 440LD22-R MEXXF32204JJ UPW1H471MHD TAB2GM2R2E110 EKMG500ELL100ME11D ECQ-E4104KF GRM21BR71C105KA01K C1608X7R1E154K080AA C2012X7R1A106M RS1K-13-F RS1K-13-F ES2F-E3/52T DFLR1600-7 0263005.MXL 298 SU9V-03050 CTCH895F-152K ERJ-8GEYJ204V ERJ-8GEYJ684V ERJ-8GEYJ100V ERJ-8ENF2004V ERJ-8GEYJ513V ERJ-6GEYJ100V ERJ-3EKF2213V RNF14FTD2M00 ERJ-6ENF3012V ERJ-8ENF6041V ERJ-3EKF6041V ERJ-3EKF3742V ERJ-6ENF17R4V Comchip Kemet Vishay Duratech Nichicon Ltec Nippon Chemi-Con Panasonic Murata Electronics TDK TDK Diodes, Inc. Diodes, Inc. Vishay Diodes, Inc. Littlefuse Alpha Tokin CTParts Panasonic Panasonic Panasonic Panasonic Panasonic Panasonic Panasonic Stackpole Panasonic Panasonic Panasonic Panasonic Panasonic ERJ-8BQF3R6V Panasonic RC0603FR-074R75L V275LA4P EE-1621 LYT5226D Yageo Littlefuse Shen Zhen Xin Yu Jia Tech Power Integrations Power Integrations Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com DER-528 14 W LED Driver Using LYT5226D 09-Mar-16 7 Inductor Specification 7.1 Electrical Diagram 4 FL1 17.5T #31 AWG 8 18T #28 TIW FL2 38.5T #31 AWG 3 1 13T 2X #34 AWG 2 Figure 7 – Inductor Electrical Diagram. 7.2 Electrical Specifications Parameter Nominal Primary Inductance Tolerance Condition Measured at 1 VPK-PK, 100 kHz switching frequency, between pin 1 and pin 2, with all other windings open. Tolerance of primary inductance. Spec. 420 µH ±5% 7.3 M aterial List Item [1] [2] [3] [4] [5] [6] [7] [8] Description Core: EE1621. Bobbin, EE1621, Horizontal, 10 pins, Part no. 25-01044-00. Magnet Wire: #31 AWG. Magnet Wire: #34 AWG. Triple Insulated Wire: #28 AWG. Polyester Tape: 5.5 mm. Transformer Tape: 6 mm. Non-insulated Wire: #30 AWG. Power Integrations, Inc. Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com Page 14 of 78 09-Mar-16 DER-528 14 W LED Driver Using LYT5226D 7.4 I nductor Build Diagram Finish (P4) 17.5 Turns 1 X AWG31 Start (P8) Finish (FL2) 18 Turns 1 x TIW28 Start (FL1) Finish (P2) 13 Turns 2 x AWG34 Start (P1) Finish (P8) 38.5 Turns 1 x AWG31 Start (P3) Figure 8 – Transformer Build Diagram. 7.5 I nductor Construction Bobbin Modification Winding Directions Winding 1 Insulation Winding 2 Insulation Winding 3 Insulation Winding 4 Insulation Core Grinding Assemble Core Pins Finish Page 15 of 78 Cut the bobbin extension as shown on figure below. Bobbin placed on winder jig such that terminal pin 1-4 is in the left side. The winding direction is clockwise. Use wire item [3], start at pin 3 and wind 38.5 turns in 2 layers, then finish the winding on pin 8. Add 1 layer of tape, item [6], for insulation. Use wire item [4] in bifilar, start at pin 1 and wind 13 turns evenly from left to right, then finish the winding on pin 2. Add 1 layer of tape, item [6], for insulation. Use wire item [5], allot 25 mm length for fly lead wire no.1 (mark as FL1) then wind 18 turns from left to right, finished the winding with 25 mm length fly lead wire no. 2 (mark as FL2). Add 1 layer of tape, item [7], for insulation. Use wire item [3], start at pin 8 and wind 17.5 turns in 1 layer, then finish the winding on pin 4. Add 1 layer of tape, item [6], for insulation. Grind the center leg of one core until it meets the nominal inductance of 420 µH with ±5% inductance tolerance. Assemble the 2 cores on the bobbin with the gapped core place on top side of the bobbin and the un-gapped core at the bottom side. Wrap the cores with tin wire and terminate it to pin 4. Wrap the 2 cores with 2 layer of tape, item (6). Pull out terminal pin no. 7 Dip the transformer assembly in varnish. Power Integrations Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com DER-528 14 W LED Driver Using LYT5226D 09-Mar-16 7.6 W inding I llustrations Bobbin Modification Cut the bobbin extension as shown in the figure. Winding Directions Bobbin placed on winder jig such that terminal pin 1-4 is in the left side. The winding direction is clockwise. Pin 1 Pin 3 Winding 1 Pin 4 Use wire item [3], start at pin 3 and wind 38.5 turns in 2 layers, then finish the winding on pin 8. Insulation Add 1 layer of tape, item [6], for insulation. Power Integrations, Inc. Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com Page 16 of 78 09-Mar-16 DER-528 14 W LED Driver Using LYT5226D Winding 2 Use wire item [4] in bifilar, start at pin 1 and wind 13 turns evenly from left to right, then finish the winding on pin 2. Pin 1 Pin 2 Insulation Add 1 layer of tape, item [6], for insulation. Page 17 of 78 Power Integrations Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com DER-528 14 W LED Driver Using LYT5226D Winding 3 09-Mar-16 25 mm Use wire item [5], allot 25 mm length for fly lead wire no.1 (mark as FL1) then wind 18 turns from left to right, finish the winding with 25 mm Length fly lead wire no. 2 (mark as FL2). FL1- Start FL2-Finished FL1-Start Insulation Add 1 layer of tape, item [7], for insulation. Power Integrations, Inc. Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com Page 18 of 78 09-Mar-16 DER-528 14 W LED Driver Using LYT5226D Winding 4 Use wire item [3], start at pin 8 and wind 17.5 turns in 1 layer, then finish the winding on pin 4. Pin 8 Pin 4 Insulation Add 1 layer of tape, item [6], for insulation. Page 19 of 78 Power Integrations Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com DER-528 14 W LED Driver Using LYT5226D Assemble Core 09-Mar-16 Gapped Core Assemble the 2 cores on the bobbin with the gapped core placed on top side of the bobbin and the un-gapped core at the bottom side. Pin 4 Wrap the cores with tin wire (item 8) and terminate it to pin 4. Wrap the 2 cores with 2 layers of tape, item (7). Finish Dip the transformer assembly in 2:1 thinner and varnish solution. Power Integrations, Inc. Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com Page 20 of 78 09-Mar-16 DER-528 14 W LED Driver Using LYT5226D 8 Inductor Design Spreadsheet ACDC LYTSwitch5 IsolatedFlyback 011916; Rev.1.0; INPUT INFO Copyright Power Integrations 2016 ENTER APPLICATION VARIABLES VACMIN 90.0 VACNOM VACMAX 265.0 FL OUTPUT UNITS 90.0 177.5 265.0 50 Volts RMS Volts RMS Volts RMS Hertz 36.0 Volts DC 40.0 Volts DC VO_OVP_MIN 52.7 Volts DC IO 350.0 EFFICIENCY 0.87 Z PO LYTSwitch-5 DESIGN VARIABLES BREAKDOWN 725 VOLTAGE GENERIC DEVICE LYT52X6D ACTUAL DEVICE ILIMITMIN ILIMITTYP ILIMITMAX IP_MOSFET TON_MIN TON_MAX IAVG_MOSFET IRMS_MOSFET 350.0 0.87 0.50 14.00 m-Amperes Dimensionless Dimensionless Watts 725 Volts DC VO_MIN VO 40.0 LYT52X6D LYT5226D 1.767 1.900 2.033 1.319 1.327 3.887 0.167 0.320 Amperes Amperes Amperes Amperes u-seconds u-seconds Amperes Amperes KDP 1.123 Dimensionless VDRAIN DEVICE PROGRAMMING PARAMETERS RDO 529.8 Volts DC 6 k-ohms 6 k-ohms RDS ENTER TRANSFORMER CONSTRUCTION VARIABLES CORE TYPE EE1621 EE1621 AE 33.77 33.77 LE 29.00 29.00 AL 2600 2600 VE 980 980 AW 15.00 15.00 BW 5.00 5.00 MARGIN TRANSFORMER DESIGN PARAMETERS Primary winding parameters LP 420 LP_TOL 5 LP_MIN LP_MAX NP ALG BM BP Warning Page 21 of 78 mm^2 mm nH/T^2 mm^3 mm^2 mm 0.00 mm 420 5 399 441 56 133.93 3075 4741 u-Henrys % u-Henrys u-Henrys Turns nH/T^2 Gauss Gauss LYTSwitch-5 Isolated Flyback Design Spreadsheet Minimum AC line voltage. Nominal AC line voltage. Maximum AC line voltage. AC line frequency. Guaranteed minimum VO that maintains output regulation. Worst case normal operating output voltage. Minimum Voltage at which output voltage protection may be activated. Average output current specification. Total power supply efficiency. Loss allocation factor. Output power. Choose between 650V and 725V. Chosen LYTSwitch-5 generic device. Chosen LYTSwitch-5 device code. Minimum device current limit. Typical Current Limit. Maximum Current Limit. Worst case peak drain current of the MOSFET. Worst case minimum on-time of the MOSFET. Worst case maximum on-time of the MOSFET. Worst case average drain current of the MOSFET. Worst case maximum RMS current of the MOSFET. Ratio between off-time of the MOSFET and on-time of the secondary diode. Estimated worst case drain voltage of the MOSFET. DO pin resistor. Current sense programming resistor connected to the DS pin for the isolated flyback converter. Core type. Core effective cross sectional area. Core effective path length. Ungapped core effective inductance. Core volume. Window area of the bobbin. Bobbin physical winding width. Safety Margin Width (Half the Primary to Secondary Creepage Distance) Typical value of the primary inductance. Tolerance of the primary inductance. Minimum value of the primary inductance. Maximum value of the primary inductance. Number of primary turns. Gapped core effective inductance. Maximum flux density. The peak flux density is higher than 4200 Gauss. Power Integrations Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com DER-528 14 W LED Driver Using LYT5226D BAC LG LAYERS_PRIMARY_D ESIRED AWG_PRIMARY OD_PRIMARY_INSUL ATED 31 09-Mar-16 1538 Gauss 0.3 mm 4 Dimensionless 31 AWG 0.272 mm OD_PRIMARY_BARE 0.227 mm IRMS_PRIMARY 0.320 Amperes CMA_PRIMARY J_PRIMARY Secondary winding parameters 249 7.92 mils^2/Amperes Amperes/mm^2 VOR 125 125 Volts DC NS AWG_SECONDARY OD_SECONDARY_IN SULATED OD_SECONDARY_BA RE 18 18 27 Dimensionless Dimensionless 0.418 mm 0.361 mm IRMS_SECONDARY 0.979 Amperes CMA_SECONDARY J_SECONDARY Bias winding parameters VD_BIAS BIAS TURNS 206 9.59 mils^2/Amperes Amperes/mm^2 0.70 13 Volts DC Turns VBIAS 28.0 Volts DC PIVBS 132.4 Volts DC CBIAS 22.0 u-Farads RBP 25.00 k-Ohms 2.2 u-Farads 0.7 Volts DC IRMS_DIODE 0.979 Amperes IP_DIODE 4.103 Amperes 28.0 CBP SECONDARY DIODE PARAMETERS VF_DIODE PIV_DIODE 190.4 Volts DC FEEDBACK AND PROTECTION PARAMETERS WITH FINE TUNING RL 4.00 4.00 M-Ohms OVP_LINE 339.4 Volts RMS RDC_THEORETICAL RDC 2.40 2.43 Ohms Ohms CDC 10.0 u-Farads 30.0 Volts DC VO_MEASURED ROC IO_ACTUAL 40.0 280.0 350.0 Volts DC k-Ohms m-Amperes RFB_THEORETICAL 39.5 k-Ohms VBIAS_MEASURED 30.0 Power Integrations, Inc. Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com Increase the number of primary winding turns to avoid core saturation. Worst case AC Flux Density for Core Loss Curves (0.5 X Peak to Peak). Core gap length. Desired number of primary layers. Primary wire gauge. Outer diameter of the primary winding wire with insulation. Outer diameter of the primary winding wire without insulation. Maximum RMS current flowing through the primary winding. Primary winding CMA. Primary winding current density. Output voltage reflected to the primary winding when the MOSFET is off. Number of secondary turns. Secondary wire gauge. Outer diameter of the secondary winding wire with insulation. Outer diameter of the secondary winding wire without insulation. Maximum RMS current flowing through the secondary winding. Secondary winding CMA. Secondary winding current density. Bias winding diode forward drop voltage. Number of bias winding turns. Bias Voltage. Check performance at minimum VO and VACMAX. Output Rectifier Maximum Peak Inverse Voltage (calculated at VACMAX) Bias winding rectification capacitor. Bias supply resistor assuming 1mA current necessary to supply the BP pin. Minimum BP pin capacitance. Output diode forward voltage drop. Diode RMS current at LP_MIN, VACMIN and PO_MAX. Diode peak current at LP_MIN ,VACMAX and PO_MAX. Peak Inverse Voltage at VO_MAX on output diode. Standard (E96 / 1%) L pin resistor. Line overvoltage based on the actual L pin resistor used. Theoretical DS pin sense resistor. Standard (E96 / 1%) DS pin sense resistor. Standard capacitor connected in parallel with the DS pin sense resistor. Actual bias voltage (across the bias capacitor) measured on the bench. Actual load voltage measured on the bench. Standard (E96 / 1%) OC pin resistor. Actual output current seen on the bench. Calculated value of RFB, using standard values for RDS, ROVP, and RL Page 22 of 78 09-Mar-16 RFB CFB Page 23 of 78 DER-528 14 W LED Driver Using LYT5226D 39.2 150.0 k-Ohms n-Farads Standard (E96 / 1%) F pin resistor. Standard capacitor connected to the F pin. Power Integrations Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com DER-528 14 W LED Driver Using LYT5226D 09-Mar-16 9 Performance Data All measurements were performed at room temperature using LED load string. 1 minute soak time was applied before measurement with AC source turned-off for 5 seconds every succeeding input line measurement. 9.1 Efficiency 90 40 V LED 30 V LED 20 V LED 89 35 V LED 25 V LED Efficiency (%) 88 87 86 85 84 83 82 80 100 120 140 160 180 200 220 240 260 280 Input Voltage (VAC) Figure 9 – Efficiency vs. Line and LED Load. Power Integrations, Inc. Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com Page 24 of 78 09-Mar-16 DER-528 14 W LED Driver Using LYT5226D 9.2 Line R egulation 370 40 V LED 30 V LED 20 V LED 366 35 V LED 25 V LED 5% 4% Output Current (mA) 3% 362 2% 1% 358 0% 354 -1% -2% 350 -3% 346 -4% -5% 342 80 100 120 140 160 180 200 220 240 260 Input Voltage (VAC) Figure 10 – Regulation vs. Line and LED Load. Page 25 of 78 Power Integrations Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com 280 DER-528 14 W LED Driver Using LYT5226D 09-Mar-16 9.3 P ow er Factor 1.00 40 V LED 30 V LED 20 V LED 0.98 35 V LED 25 V LED 0.96 Power Factor 0.94 0.92 0.90 0.88 0.86 0.84 0.82 0.80 80 100 120 140 160 180 200 220 240 260 280 Input Voltage (VAC) Figure 11 – Power Factor vs. Line and LED Load. Power Integrations, Inc. Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com Page 26 of 78 09-Mar-16 DER-528 14 W LED Driver Using LYT5226D 9.4 % ATHD 36 40 V LED 30 V LED 20 V LED 32 35 V LED 25 V LED 28 ATHD (%) 24 20 16 12 8 4 0 80 100 120 140 160 180 200 220 240 260 Input Voltage (VAC) Figure 12 – %ATHD vs. Line and LED Load. Page 27 of 78 Power Integrations Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com 280 DER-528 14 W LED Driver Using LYT5226D 09-Mar-16 9.5 P ow er I nput Difference Betw een 120 V to 230 V 0.20 Input Power Difference (W) 0.18 0.16 0.14 0.12 0.10 0.08 0.06 0.04 0.02 0.00 20 22 24 26 28 30 32 34 36 38 40 Output LED Voltage (V) Figure 13 – Power Input Difference between 120 V and 230 V. Power Integrations, Inc. Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com Page 28 of 78 09-Mar-16 DER-528 14 W LED Driver Using LYT5226D 9.6 I ndividual Harm onics Content 60 Harmonic Content Class C Limit Harmonic Content (mA) 50 40 30 20 10 0 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39 Odd Harmonic Content Figure 14 – 40 V LED Load Input Current Harmonics at 230 VAC, 50 Hz. Page 29 of 78 Power Integrations Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com DER-528 14 W LED Driver Using LYT5226D 120 09-Mar-16 Harmonic Content Class C Limit Harmonic Content (mA) 100 80 60 40 20 0 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39 Odd Harmonic Content Figure 15 – 40 V LED Load Input Current Harmonics at 115 VAC, 60 Hz. Power Integrations, Inc. Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com Page 30 of 78 09-Mar-16 DER-528 14 W LED Driver Using LYT5226D 45 Harmonic Content Class C Limit 40 Harmonic Content (mA) 35 30 25 20 15 10 5 0 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39 Odd Harmonic Content Figure 16 – 30 V LED Load Input Current Harmonics at 230 VAC, 50 Hz. Page 31 of 78 Power Integrations Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com DER-528 14 W LED Driver Using LYT5226D 90 Harmonic Content Class C Limit 80 Harmonic Content (mA) 09-Mar-16 70 60 50 40 30 20 10 0 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39 Odd Harmonic Content Figure 17 – 30 V LED Load Input Current Harmonics at 115 VAC, 60 Hz. Power Integrations, Inc. Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com Page 32 of 78 09-Mar-16 DER-528 14 W LED Driver Using LYT5226D 35 Harmonic Content Class C Limit Harmonic Content (mA) 30 25 20 15 10 5 0 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39 Odd Harmonic Content Figure 18 – 20 V LED Load Input Current Harmonics at 230 VAC, 50 Hz. Page 33 of 78 Power Integrations Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com DER-528 14 W LED Driver Using LYT5226D 70 09-Mar-16 Harmonic Content Class C Limit Harmonic Content (mA) 60 50 40 30 20 10 0 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39 Odd Harmonic Content Figure 19 – 20 V LED Load Input Current Harmonics at 115 VAC, 60 Hz. Power Integrations, Inc. Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com Page 34 of 78 09-Mar-16 DER-528 14 W LED Driver Using LYT5226D 10 Test Data 10.1 Test Data, 40 V LED Load Input VAC Freq (VRMS) (Hz) 90 60 100 60 115 60 120 60 132 60 195 50 200 50 220 50 230 50 240 50 265 50 VIN (VRMS) 89.86 99.87 114.87 119.91 131.92 194.93 199.89 219.93 229.95 239.97 264.98 Input Measurement IIN PIN PF %ATHD (mARMS) (W) 186.90 16.70 0.99 6.50 165.30 16.40 0.99 5.82 144.68 16.47 0.99 6.04 137.82 16.37 0.99 5.54 125.31 16.33 0.99 5.91 86.18 16.30 0.97 8.03 84.15 16.28 0.97 8.37 77.32 16.27 0.96 9.98 74.33 16.25 0.95 11.17 71.77 16.27 0.94 12.24 66.23 16.27 0.93 15.38 LED Load Measurement VOUT IOUT POUT (VDC) (mADC) (W) 40.09 355.81 14.28 39.92 353.41 14.13 39.98 356.77 14.28 39.95 355.87 14.24 39.96 356.40 14.26 39.99 358.37 14.36 39.98 358.03 14.34 39.98 358.24 14.35 39.97 357.84 14.33 39.98 358.14 14.34 39.97 357.93 14.33 Efficiency (%) 85.52 86.11 86.74 86.99 87.33 88.12 88.09 88.19 88.18 88.16 88.08 10.2 Test Data, 35 V LED Load Input VAC Freq (VRMS) (Hz) 90 60 100 60 115 60 120 60 132 60 195 50 200 50 220 50 230 50 240 50 265 50 Page 35 of 78 VIN (VRMS) 89.81 99.83 114.89 119.94 131.92 194.93 199.90 219.93 229.95 239.97 264.98 Input Measurement IIN PIN PF %ATHD (mARMS) (W) 167.14 14.92 0.99 6.43 148.61 14.73 0.99 5.70 129.48 14.72 0.99 5.86 123.67 14.66 0.99 5.61 112.47 14.62 0.99 5.81 77.70 14.60 0.96 8.69 75.90 14.58 0.96 9.15 69.99 14.60 0.95 11.24 67.33 14.57 0.94 12.60 65.12 14.61 0.93 13.74 60.25 14.60 0.91 17.40 LED Load Measurement VOUT IOUT POUT (VDC) (mADC) (W) 35.78 356.46 12.78 35.69 355.13 12.69 35.71 357.09 12.78 35.70 356.79 12.76 35.69 356.86 12.76 35.72 358.35 12.83 35.71 358.18 12.82 35.71 358.36 12.83 35.69 357.89 12.80 35.70 358.53 12.83 35.69 358.05 12.81 Efficiency (%) Power Integrations Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com 85.65 86.19 86.78 87.00 87.28 87.88 87.92 87.85 87.87 87.82 87.73 DER-528 14 W LED Driver Using LYT5226D 09-Mar-16 10.3 Test Data, 30 V LED Load Input VAC Freq (VRMS) (Hz) 90 60 100 60 115 60 120 60 132 60 195 50 200 50 220 50 230 50 240 50 265 50 VIN (VRMS) 89.83 99.85 114.86 119.90 131.91 194.93 199.91 219.94 229.96 239.97 264.99 Input Measurement IIN PIN PF %ATHD (mARMS) (W) 143.60 12.81 0.99 5.55 127.46 12.61 0.99 5.42 110.47 12.52 0.99 5.85 105.68 12.48 0.99 5.74 95.92 12.41 0.98 6.40 66.95 12.43 0.95 10.17 65.47 12.41 0.95 10.90 60.39 12.40 0.93 13.56 58.46 12.44 0.93 15.02 56.40 12.40 0.92 16.63 52.59 12.44 0.89 20.82 LED Load Measurement VOUT IOUT POUT (VDC) (mADC) (W) 30.42 359.93 10.98 30.28 357.80 10.86 30.26 357.80 10.85 30.24 357.43 10.83 30.21 356.55 10.80 30.22 358.01 10.86 30.21 357.76 10.84 30.19 357.28 10.82 30.20 358.20 10.85 30.17 357.07 10.81 30.18 357.52 10.82 Efficiency (%) 85.71 86.13 86.69 86.79 87.03 87.34 87.38 87.27 87.25 87.17 87.00 10.4 Test Data, 25 V LED Load Input VAC Freq (VRMS) (Hz) 90 60 100 60 115 60 120 60 132 60 195 50 200 50 220 50 230 50 240 50 265 50 VIN (VRMS) 89.89 99.91 114.90 119.96 131.94 194.95 199.91 219.95 229.96 239.98 265.00 Input Measurement IIN PIN PF %ATHD (mARMS) (W) 118.21 10.53 0.99 5.15 105.90 10.45 0.99 5.41 91.85 10.36 0.98 5.75 88.09 10.35 0.98 6.27 80.24 10.30 0.97 7.02 56.80 10.36 0.94 12.48 55.66 10.37 0.93 13.36 51.67 10.37 0.91 16.73 49.95 10.36 0.90 18.51 48.53 10.39 0.89 20.30 45.39 10.40 0.86 25.18 Power Integrations, Inc. Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com LED Load Measurement VOUT IOUT POUT (VDC) (mADC) (W) 25.10 357.19 9.00 25.05 357.07 8.98 25.02 355.81 8.93 25.02 355.79 8.93 25.01 355.34 8.92 25.02 356.88 8.97 25.02 357.06 8.98 25.01 356.67 8.96 25.01 356.28 8.95 25.01 356.53 8.96 25.00 356.35 8.95 Efficiency (%) 85.48 85.91 86.24 86.33 86.55 86.58 86.56 86.42 86.38 86.19 86.03 Page 36 of 78 09-Mar-16 DER-528 14 W LED Driver Using LYT5226D 10.5 Test Data, 20 V LED Load Input VAC Freq (VRMS) (Hz) 90 60 100 60 115 60 120 60 132 60 195 50 200 50 220 50 230 50 240 50 265 50 VIN (VRMS) 89.88 99.91 114.90 119.95 131.93 194.94 199.91 219.94 229.96 239.98 264.99 Input Measurement IIN PIN PF %ATHD (mARMS) (W) 97.92 8.69 0.99 4.88 87.44 8.58 0.98 5.70 75.99 8.51 0.97 6.66 73.05 8.51 0.97 6.94 66.87 8.49 0.96 8.11 47.94 8.54 0.91 15.80 47.02 8.54 0.91 16.62 43.86 8.54 0.89 20.72 42.62 8.56 0.87 22.88 41.42 8.56 0.86 25.07 38.96 8.58 0.83 30.47 LED Load Measurement VOUT IOUT POUT (VDC) (mADC) (W) 20.44 359.07 7.38 20.36 357.62 7.32 20.34 355.82 7.28 20.33 356.13 7.28 20.33 355.82 7.27 20.33 35645 7.30 20.33 356.35 7.30 20.32 355.83 7.28 20.32 356.26 7.29 20.31 355.69 7.27 20.31 355.63 7.27 Efficiency (%) 10.6 Test Data, P ow er I nput Difference Betw een 120 V and 230 V Page 37 of 78 LED Voltage (V) Input Power Difference (W) 42.00 0.03 39.00 0.01 35.00 0.01 32.00 0.00 28.00 0.12 25.00 0.12 21.00 0.15 Power Integrations Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com 84.94 85.34 85.54 85.59 85.71 85.45 85.43 85.26 85.15 84.98 84.72 DER-528 14 W LED Driver Using LYT5226D 09-Mar-16 10.7 Test Data, Harm onic Content at 230 VAC w ith 40 V LED Load VIN (VRMS) 230 nth Order 1 2 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39 Freq 50 mA Content 73.25 0.08 3.71 3.48 3.05 2.75 2.31 1.73 1.59 1.24 0.93 0.64 1.27 0.59 0.91 0.50 1.10 1.28 0.76 0.57 0.56 IIN (mARMS) 73.24 % Content PIN (W) 15.986 mA Limit <25 W 0.11% 5.06% 4.75% 4.16% 3.75% 3.15% 2.36% 2.17% 1.69% 1.27% 0.87% 1.73% 0.81% 1.24% 0.68% 1.50% 1.75% 1.04% 0.78% 0.76% 55.25 30.88 16.25 8.13 5.69 4.81 4.17 3.68 3.29 2.98 2.72 2.50 2.32 2.16 2.02 1.90 1.79 1.69 1.60 Power Integrations, Inc. Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com %THD 11.377 Remarks Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Page 38 of 78 09-Mar-16 DER-528 14 W LED Driver Using LYT5226D 10.8 Test Data, Harm onic Content at 115 VAC w ith 40 V LED Load VIN (VRMS) 115 nth Order 1 2 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39 Page 39 of 78 Freq 60 mA Content 136.89 0.16 1.19 1.70 1.34 1.59 2.65 1.65 0.98 0.92 1.37 0.96 1.00 1.20 0.86 1.05 2.40 2.83 1.02 0.79 1.05 IIN (mARMS) 144.68 % Content PIN (W) 16.468 mA Limit <25 W 0.12% 0.87% 1.24% 0.98% 1.16% 1.94% 1.21% 0.72% 0.67% 1.00% 0.70% 0.73% 0.88% 0.63% 0.77% 1.75% 2.07% 0.75% 0.58% 0.77% 111.98 62.58 32.94 16.47 11.53 9.75 8.45 7.46 6.67 6.04 5.51 5.07 4.70 4.37 4.09 3.84 3.62 3.43 3.25 %THD 6.04 Remarks Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Power Integrations Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com DER-528 14 W LED Driver Using LYT5226D 09-Mar-16 10.9 Test Data, Harm onic Content at 230 VAC w ith 30 V LED Load VIN (VRMS) 230 nth Order 1 2 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39 Freq 50 mA Content 57.14 0.06 4.63 4.16 3.40 2.64 1.99 1.41 1.21 1.10 1.12 0.66 1.19 0.66 0.85 0.54 0.84 0.94 0.60 0.61 0.47 IIN (mARMS) 58.49 % Content PIN (W) 12.440 mA Limit <25 W 0.11% 8.10% 7.28% 5.95% 4.62% 3.48% 2.47% 2.12% 1.93% 1.96% 1.16% 2.08% 1.16% 1.49% 0.95% 1.47% 1.65% 1.05% 1.07% 0.82% 42.30 23.64 12.44 6.22 4.35 3.68 3.19 2.82 2.52 2.28 2.08 1.92 1.77 1.65 1.54 1.45 1.37 1.29 1.23 Power Integrations, Inc. Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com %THD 15.015 Remarks Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Page 40 of 78 09-Mar-16 DER-528 14 W LED Driver Using LYT5226D 10.10 Test Data, Harm onic Content at 115 VAC w ith 30 V LED Load VIN (VRMS) 115 nth Order 1 2 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39 Page 41 of 78 Freq 60 mA Content 109.34 0.19 1.25 2.11 2.03 0.84 2.09 1.22 1.80 1.56 0.90 0.83 0.45 0.61 1.04 0.32 2.25 1.77 0.84 0.48 0.28 IIN (mARMS) 110.26 % Content PIN (W) 12.498 mA Limit <25 W 0.17% 1.14% 1.93% 1.86% 0.77% 1.91% 1.12% 1.65% 1.43% 0.82% 0.76% 0.41% 0.56% 0.95% 0.29% 2.06% 1.62% 0.77% 0.44% 0.26% 84.99 47.49 25.00 12.50 8.75 7.40 6.42 5.66 5.06 4.58 4.18 3.85 3.56 3.32 3.10 2.92 2.75 2.60 2.47 %THD 5.825 Remarks Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Power Integrations Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com DER-528 14 W LED Driver Using LYT5226D 09-Mar-16 10.11 Test Data, Harm onic Content at 230 VAC w ith 20 V LED Load VIN (VRMS) 230 nth Order 1 2 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39 Freq 50 mA Content 40.70 0.04 6.10 4.83 3.23 2.05 1.73 1.26 1.57 0.94 1.18 0.71 0.96 0.81 0.67 0.74 0.51 0.92 0.40 0.67 0.39 IIN (mARMS) 42.63 % Content PIN (W) 8.560 mA Limit <25 W 0.10% 14.99% 11.87% 7.94% 5.04% 4.25% 3.10% 3.86% 2.31% 2.90% 1.74% 2.36% 1.99% 1.65% 1.82% 1.25% 2.26% 0.98% 1.65% 0.96% 29.10 16.26 8.56 4.28 3.00 2.54 2.20 1.94 1.73 1.57 1.43 1.32 1.22 1.14 1.06 1.00 0.94 0.89 0.85 Power Integrations, Inc. Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com %THD 22.82 Remarks Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Page 42 of 78 09-Mar-16 DER-528 14 W LED Driver Using LYT5226D 10.12 Test Data, Harm onic Content at 115 VAC w ith 20 V LED Load VIN (VRMS) 115 nth Order 1 2 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39 Page 43 of 78 Freq 60 mA Content 74.99 0.10 1.59 1.58 1.28 1.64 1.08 1.04 1.21 0.50 1.08 1.41 0.29 0.44 0.93 0.70 1.45 1.12 0.55 0.46 0.36 IIN (mARMS) 75.97 % Content PIN (W) 8.503 mA Limit <25 W 0.13% 2.12% 2.11% 1.71% 2.19% 1.44% 1.39% 1.61% 0.67% 1.44% 1.88% 0.39% 0.59% 1.24% 0.93% 1.93% 1.49% 0.73% 0.61% 0.48% 57.82 32.31 17.01 8.50 5.95 5.04 4.36 3.85 3.45 3.12 2.85 2.62 2.42 2.26 2.11 1.98 1.87 1.77 1.68 %THD 6.588 Remarks Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Pass Power Integrations Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com DER-528 14 W LED Driver Using LYT5226D 09-Mar-16 11 Thermal Performance 11.1 Thermal Performance Scan – Open Frame Unit Figure 20 – Test Set-up Picture - Open Frame. Unit in open frame was placed inside an acrylic enclosure to prevent airflow that might affect the thermal measurements. Temperature was measured using FLIR thermal camera. Power Integrations, Inc. Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com Page 44 of 78 09-Mar-16 DER-528 14 W LED Driver Using LYT5226D 11.1.1 Thermal Scan Figure 21 – 230 VAC, 40 V LED Load. Spot 1: LYT5226D (U1): 75.1 ºC. Figure 22 – 115 VAC, 40 V LED Load. Spot 1: LYT5226D (U1): 81.7 ºC. Figure 23 – 230 VAC, 40 V LED Load. Spot 1: Output Diode (D3): 66.4 ºC. Figure 24 – 115 VAC, 40 V LED Load. Spot 1: Output Diode (D3): 65.5 ºC. Page 45 of 78 Power Integrations Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com DER-528 14 W LED Driver Using LYT5226D 09-Mar-16 Figure 25 – 230 VAC, 40 V LED Load. Spot 1: Snubber Diode (D2): 69.9 ºC. Figure 26 – 115 VAC, 40 V LED Load. Spot 1: Snubber Diode (D2): 71.6 ºC. Figure 27 – 230 VAC, 40 V LED Load. Spot 1: Bridge Diode (BR1): 42.9 ºC. Figure 28 – 115 VAC, 40 V LED Load. Spot 1: Bridge Diode (BR1): 52.5 ºC. Power Integrations, Inc. Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com Page 46 of 78 09-Mar-16 Figure 29 – 230 VAC, 40 V LED Load. Spot 1: Bias Diode (D4): 64.1 ºC. DER-528 14 W LED Driver Using LYT5226D Figure 30 – 115 VAC, 40 V LED Load. Spot 1: Bias Diode (D4): 64.8 ºC. 11.1.2 Thermal Scan at the Top Side Figure 31 – 230 VAC, 40 V LED Load. Spot 1: Transformer (T1): 66.6 ºC. Page 47 of 78 Figure 32 –115 VAC, 40 V LED Load. Spot 1: Transformer (T1): 65.4 ºC. Power Integrations Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com DER-528 14 W LED Driver Using LYT5226D 09-Mar-16 11.2 Thermal Performance at 85 ºC Figure 33 – Test Set-up Picture Thermal at 85 ºC Ambient - Open Frame. Unit in open frame was placed inside the enclosure to prevent airflow that might affect the thermal measurements. Ambient temperature inside enclosure is 85 ºC. Temperature was measured using Type T thermocouple. Power Integrations, Inc. Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com Page 48 of 78 09-Mar-16 DER-528 14 W LED Driver Using LYT5226D Temperature (0C) 11.2.1 Thermal Performance at 230 VAC with a 40 V LED Load 150 145 140 135 130 125 120 115 110 105 100 95 90 85 80 75 70 65 60 55 50 45 40 35 30 25 LYT5 D2 T1 D3 Ambient 0 20 40 60 80 Burn-in Time (Min) Figure 34 – Component Temperature at 230 VAC, 85 ºC Ambient Page 49 of 78 Measurement Ambient D2 T1 LYTSwitch-5 D3 Maximum (ºC) 86.0 120.6 115.9 128.8 109.6 Final (ºC) 85.8 120.4 115.8 128.6 109.5 Power Integrations Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com DER-528 14 W LED Driver Using LYT5226D 09-Mar-16 11.2.2 Thermal Performance at 120 VAC with a 40 V LED Load 150 140 130 Temperature (0C) 120 110 100 90 80 70 60 50 LYT5 D2 40 T1 D3 30 Ambient 20 0 20 40 60 80 Burn-in Time (Min) Figure 35 – Component Temperature at 230VAC, 85 ºC Ambient. Measurement Ambient D2 T1 LYTSwitch-5 D3 Maximum (ºC) 85.4 120.3 116.2 128.9 109.9 Final (ºC) 85.0 120.1 116.1 128.6 109.9 Power Integrations, Inc. Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com Page 50 of 78 09-Mar-16 DER-528 14 W LED Driver Using LYT5226D 12 Waveforms 12.1 I nput Voltage and I nput Current W aveform s Figure 36 – 90 VAC, 40 V LED Load. Upper: IIN, 100 mA / div. Lower: VIN, 100 V / div., 10 ms / div. Figure 37 – 115 VAC, 40 V LED Load. Upper: IIN, 100 mA / div. Lower: VIN, 100 V / div., 10 ms / div. Figure 38 – 230 VAC, 40 V LED Load. Upper: IIN, 50 mA / div. Lower: VIN, 100 V / div., 10 ms / div. Figure 39 – 265 VAC, 40 V LED Load. Upper: IIN, 50 mA / div. Lower: VIN, 100 V / div., 10 ms / div. Page 51 of 78 Power Integrations Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com DER-528 14 W LED Driver Using LYT5226D 09-Mar-16 Figure 40 – 90 VAC, 32 V LED Load. Upper: IIN, 100 mA / div. Lower: VIN, 100 V / div., 10 ms / div. Figure 41 – 115 VAC, 32 V LED Load. Upper: IIN, 100 mA / div. Lower: VIN, 100 V / div., 10 ms / div. Figure 42 – 230 VAC, 32 V LED Load. Upper: IIN, 50 mA / div. Lower: VIN, 100 V / div., 10 ms / div. Figure 43 – 265 VAC, 32 V LED Load. Upper: IIN, 50 mA / div. Lower: VIN, 100 V / div., 10 ms / div. Power Integrations, Inc. Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com Page 52 of 78 09-Mar-16 DER-528 14 W LED Driver Using LYT5226D Figure 44 – 90 VAC, 21 V LED Load. Upper: IIN, 50 mA / div. Lower: VIN, 100 V / div., 10 ms / div. Figure 45 – 115 VAC, 21 V LED Load. Upper: IIN, 50 mA / div. Lower: VIN, 100 V / div., 10 ms / div. Figure 46 – 230 VAC, 20 V LED Load. Upper: IIN, 40 mA / div. Lower: VIN, 100 V / div., 10 ms / div. Figure 47 – 265 VAC, 20 V LED Load. Upper: IIN, 40 mA / div. Lower: VIN, 100 V / div., 10 ms / div. Page 53 of 78 Power Integrations Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com DER-528 14 W LED Driver Using LYT5226D 09-Mar-16 12.2 Output Current R ise Figure 48 – 90 VAC, 40 V LED Load, Output Rise. Upper: IOUT, 100 mA / div. Lower: VIN, 100 V / div., 500 ms / div. Figure 49 – 90 VAC, 40 V LED Load, Zoom View. Upper: IOUT, 100 mA / div. Lower: VIN, 100 V / div., 100 ms / div. Figure 50 – 115 VAC, 40 V LED Load, Output Rise. Upper: IOUT, 100 mA / div. Lower: VIN, 100 V / div., 500 ms / div. Figure 51 – 115 VAC, 40 V LED Load, Output Rise. Upper: IOUT, 100 mA / div. Lower: VIN, 100 V / div., 100 ms / div. Power Integrations, Inc. Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com Page 54 of 78 09-Mar-16 DER-528 14 W LED Driver Using LYT5226D Figure 52 – 230 VAC, 40 V LED Load, Output Rise. Upper: IOUT, 100 mA / div. Lower: VIN, 100 V / div., 500 ms / div. Figure 53 – 230 VAC, 40 V LED Load, Output Rise. Upper: IOUT, 100 mA / div. Lower: VIN, 100 V / div., 100 ms / div. Figure 54 – 265 VAC, 40 V LED Load, Output Rise. Upper: IOUT, 100 mA / div. Lower: VIN, 100 V / div., 500 ms / div. Figure 55 – 265 VAC, 40 V LED Load, Output Rise. Upper: IOUT, 100 mA / div. Lower: VIN, 100 V / div., 100 ms / div. Page 55 of 78 Power Integrations Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com DER-528 14 W LED Driver Using LYT5226D 09-Mar-16 Figure 56 – 90 VAC, 20 V LED Load, Output Rise. Upper: IOUT, 100 mA / div. Lower: VIN, 100 V / div., 500 ms / div. Figure 57 – 115 VAC, 20 V LED Load, Output Rise. Upper: IOUT, 100 mA / div. Lower: VIN, 100 V / div., 100 ms / div. Figure 58 – 115 VAC, 20 V LED Load, Output Rise. Upper: IOUT, 100 mA / div. Lower: VIN, 100 V / div., 500 ms / div. Figure 59 – 115 VAC, 20 V LED Load, Output Rise. Upper: IOUT, 100 mA / div. Lower: VIN, 100 V / div., 100 ms / div. Power Integrations, Inc. Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com Page 56 of 78 09-Mar-16 DER-528 14 W LED Driver Using LYT5226D Figure 60 – 230 VAC, 21 V LED Load, Output Rise. Upper: IOUT, 100 mA / div. Lower: VIN, 100 V / div., 500 ms / div. Figure 61 – 230 VAC, 21 V LED Load, Output Rise. Upper: IOUT, 100 mA / div. Lower: VIN, 100 V / div., 100 ms / div. Figure 62 – 265 VAC, 21 V LED Load, Output Rise. Upper: IOUT, 100 mA / div. Lower: VIN, 100 V / div., 500 ms / div. Figure 63 – 265 VAC, 21 V LED Load, Output Fall. Upper: IOUT, 100 mA / div. Lower: VIN, 100 V / div., 100 ms / div. Page 57 of 78 Power Integrations Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com DER-528 14 W LED Driver Using LYT5226D 09-Mar-16 12.3 Output Current Fall Figure 64 – 90 VAC, 40 V LED Load, Output Fall. Upper: IOUT, 100 mA / div. Lower: VIN, 100 V / div., 100 ms / div. Figure 65 – 115 VAC, 40 V LED Load, Output Fall. Upper: IOUT, 100 mA / div. Lower: VIN, 100 V / div., 100 ms / div. Figure 66 – 230 VAC, 40 V LED Load, Output Fall. Upper: IOUT, 100 mA / div. Lower: VIN, 100 V / div., 100 ms / div. Figure 67 – 265 VAC, 40 V LED Load, Output Fall. Upper: IOUT, 100 mA / div. Lower: VIN, 100 V / div., 100 ms / div. Power Integrations, Inc. Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com Page 58 of 78 09-Mar-16 DER-528 14 W LED Driver Using LYT5226D Figure 68 – 90 VAC, 21 V LED Load, Output Fall. Upper: IOUT, 100 mA / div. Lower: VIN, 100 V / div., 100 ms / div. Figure 69 – 115 VAC, 21 V LED Load, Output Fall. Upper: IOUT, 100 mA / div. Lower: VIN, 100 V / div., 100 ms / div. Figure 70 – 230 VAC, 21 V LED Load, Output Fall. Upper: IOUT, 100 mA / div. Lower: VIN, 100 V / div., 100 ms / div. Figure 71 – 265 VAC, 21 V LED Load, Output Fall. Upper: IOUT, 100 mA / div. Lower: VIN, 100 V / div., 100 ms / div. Page 59 of 78 Power Integrations Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com DER-528 14 W LED Driver Using LYT5226D 09-Mar-16 12.4 Drain Voltage and Current in Norm al Operation Figure 72 – 90 VAC, 40 V LED Load. Upper: IDRAIN, 200 mA / div. Lower: VDRAIN, 100 V / div., 4 ms / div. Figure 73 – 90 VAC, 40 V LED Load. Upper: IDRAIN, 200 mA / div. Lower: VDRAIN, 100 V / div., 4 µs / div. Figure 74 – 115 VAC, 40 V LED Load. Upper: IDRAIN, 200 mA / div. Lower: VDRAIN, 100 V / div., 4 ms / div. Figure 75 – 115 VAC, 40 V LED Load. Upper: IDRAIN, 200 mA / div. Lower: VDRAIN, 100 V / div., 4 µs / div. Power Integrations, Inc. Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com Page 60 of 78 09-Mar-16 DER-528 14 W LED Driver Using LYT5226D Figure 76 – 230 VAC, 40 V LED Load. Upper: IDRAIN, 200 mA / div. Lower: VDRAIN, 100 V / div., 4 ms / div. Figure 77 – 230 VAC, 40 V LED Load. Upper: IDRAIN, 200 mA / div. Lower: VDRAIN, 100 V / div., 4 µs / div. Figure 78 – 265 VAC, 40 V LED Load. Upper: IDRAIN, 200 mA / div. Lower: VDRAIN, 100 V / div., 4 ms / div. Figure 79 – 265 VAC, 40 V LED Load. Upper: IDRAIN, 200 mA / div. Lower: VDRAIN, 100 V / div., 4 µs / div. Page 61 of 78 Power Integrations Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com DER-528 14 W LED Driver Using LYT5226D 09-Mar-16 Figure 80 – 90 VAC, 20 V LED Load. Upper: IDRAIN, 200 mA / div. Lower: VDRAIN, 100 V / div., 4 ms / div. Figure 81 – 90 VAC, 40 V LED Load. Upper: IDRAIN, 200 mA / div. Lower: VDRAIN, 100 V / div., 4 µs / div. Figure 82 – 115 VAC, 20 V LED Load. Upper: IDRAIN, 200 mA / div. Lower: VDRAIN, 100 V / div., 4 ms / div. Figure 83 – 115 VAC, 20 V LED Load. Upper: IDRAIN, 200 mA / div. Lower: VDRAIN, 100 V / div., 4 µs / div. Power Integrations, Inc. Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com Page 62 of 78 09-Mar-16 DER-528 14 W LED Driver Using LYT5226D Figure 84 – 230 VAC, 20 V LED Load. Upper: IDRAIN, 200 mA / div. Lower: VDRAIN, 100 V / div., 4 ms / div. Figure 85 – 230 VAC, 20 V LED Load. Upper: IDRAIN, 200 mA / div. Lower: VDRAIN, 100 V / div., 4 µs / div. Figure 86 – 265 VAC, 20 V LED Load. Upper: IDRAIN, 200 mA / div. Lower: VDRAIN, 100 V / div., 4 ms / div. Figure 87 – 265 VAC, 20 V LED Load. Upper: IDRAIN, 200 mA / div. Lower: VDRAIN, 100 V / div., 4 µs / div. Page 63 of 78 Power Integrations Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com DER-528 14 W LED Driver Using LYT5226D 09-Mar-16 12.5 Drain Voltage and Current Start-up P rofile Figure 88 – 90 VAC, 40 V LED Load. Upper: IDRAIN, 200 mA / div. Lower: VDRAIN, 50 V / div., 40 ms /div. Figure 89 – 90 VAC, 40 V LED Load. Upper: IDRAIN, 200 mA / div. Lower: VDRAIN, 50 V / div., 4 µs /div. Figure 90 – 265 VAC, 40 V LED Load. Upper: IDRAIN, 400 mA / div. Lower: VDRAIN, 100 V / div., 40 ms /div. Figure 91 – 265 VAC, 40 V LED Load. Upper: IDRAIN, 400 mA / div. Lower: VDRAIN, 100 V / div., 5 µs /div. Power Integrations, Inc. Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com Page 64 of 78 09-Mar-16 DER-528 14 W LED Driver Using LYT5226D Figure 92 – 90 VAC, 20 V LED Load. Upper: IDRAIN, 200 mA / div. Lower: VDRAIN, 50 V / div., 40 ms /div. Figure 93 – 90 VAC, 20 V LED Load. Upper: IDRAIN, 200 mA / div. Lower: VDRAIN, 50 V / div., 4 µs /div. Figure 94 – 265 VAC, 20 V LED Load. Upper: IDRAIN, 400 mA / div. Lower: VDRAIN, 100 V / div., 40 ms /div. Figure 95 – 265 VAC, 20 V LED Load. Upper: IDRAIN, 400 mA / div. Lower: VDRAIN, 100 V / div., 5 µs /div. Page 65 of 78 Power Integrations Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com DER-528 14 W LED Driver Using LYT5226D 09-Mar-16 12.6 Drain Voltage and Current during Output Short-Circuit Condition Figure 96 – 90 VAC, Output Short. Upper: IDRAIN, 400 mA / div. Lower: VDRAIN, 50 V / div., 1 s / div. Figure 97 – 90 VAC, Output Short. Upper: IDRAIN, 400 mA / div. Lower: VDRAIN, 50 V / div., 1 µs / div. Figure 98 – 265 VAC, Output Short. Upper: IDRAIN, 500 mA / div. Lower: VDRAIN, 100 V / div., 1 s / div. Figure 99 – 265 VAC, Output Short. Upper: IDRAIN, 500 mA / div. Lower: VDRAIN, 100 V / div., 1 µs / div. Power Integrations, Inc. Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com Page 66 of 78 09-Mar-16 DER-528 14 W LED Driver Using LYT5226D 12.7 Output Diode Voltage and Current in Norm al Operation Figure 100 – 90 VAC, 40 V LED Load. Upper: ID3, 1 A / div. Lower: VD3, 20 V / div., 4 ms / div. Figure 101 – 90 VAC, 40 V LED Load. Upper: ID3, 1A / div. Lower: VD3, 20 V / div., 4 µs / div. Figure 102 – 265 VAC, 40 V LED Load. Upper: ID3, 1 A / div. Lower: VD3, 40 V / div., 4 ms / div. Figure 103 – 265 VAC, 40 V LED Load. Upper: IDRAIN, 1A / div. Lower: VDRAIN, 40 V / div., 4 µs / div. Page 67 of 78 Power Integrations Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com DER-528 14 W LED Driver Using LYT5226D 09-Mar-16 12.8 Output Voltage and Current – Open LED Load Figure 104 – 90 VAC, 40 V LED Load, Running Open Load. Upper: IOUT, 50 mA / div. Lower: VOUT, 10 V / div., 10 s / div. Figure 105 – 265 VAC, 40 V LED Load, Running Open Load. Upper: IOUT, 50 mA / div. Lower: VOUT, 10 V / div., 10 s / div. 12.9 Output Voltage and Current – Start-up w ith Open Load Figure 106 – 90 VAC, Open Load, Open Load Start-up. Upper: IOUT, 50 mA / div. Lower: VOUT, 10 V / div., 10 s / div. Power Integrations, Inc. Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com Figure 107 – 265 VAC, Open Load Open Load Start-up. Upper: IOUT, 50 mA / div. Lower: VOUT, 10 V / div., 10 s / div. Page 68 of 78 09-Mar-16 DER-528 14 W LED Driver Using LYT5226D 12.10 Output R ipple Current Figure 108 – 90 VAC, 50 Hz, 40 V LED Load. Upper: IOUT, 50 mA / div., 5 ms / div. Figure 109 – 115 VAC, 60 Hz, 40 V LED Load. Upper: IOUT, 50 mA / div., 5 ms / div. Figure 110 – 230 VAC, 50 Hz, 40 V LED Load. Upper: IOUT, 50 mA / div., 5 ms / div. Figure 111 – 265 VAC, 50 Hz, 40 V LED Load. Upper: IOUT, 50 mA / div., 5 ms / div. VIN IO(MAX) (mA) IO(MIN) (mA) IMEAN Ripple Ratio (IRP-P/IMEAN) 90 VAC 115 VAC 230 VAC 265 VAC 400.58 398.6 408.49 406.51 311.65 311.65 309.67 307.7 352.23 351.23 355.31 354.08 0.25 0.25 0.28 0.28 Page 69 of 78 % Flicker 100 x (IRP-P / IO(MAX)+IO(MIN)) 12.49 12.24 13.76 13.83 Power Integrations Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com DER-528 14 W LED Driver Using LYT5226D 09-Mar-16 13 AC Cycling Test No output current overshoot was observed during on - off cycling. Figure 112 – 115 VAC, 40 V LED Load. 1 s On – 1 s Off. Upper: IOUT, 50 mA / div. Lower: VIN, 50 V / div., 4 s / div. Figure 113 – 115 VAC, 40 V LED Load. 500 ms On – 500 ms Off. Upper: IOUT, 50 mA / div. Lower: VIN, 50 V / div., 2 s / div. Figure 114 – 115 VAC, 20 V LED Load. 1 s On – 1 s Off. Upper: IOUT, 50 mA / div. Lower: VIN, 50 V / div., 4 s / div. Figure 115 – 115 VAC, 20 V LED Load. 500 ms On – 500 ms Off. Upper: IOUT, 50 mA / div. Lower: VIN, 50 V / div., 2 s / div. Power Integrations, Inc. Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com Page 70 of 78 09-Mar-16 DER-528 14 W LED Driver Using LYT5226D Figure 116 – 230 VAC, 40 V LED Load. 1 s On – 1 s Off. Upper: IOUT, 50 mA / div. Lower: VIN, 100 V / div., 4 s / div. Figure 117 – 230 VAC, 40 V LED Load. 500 ms On – 500 ms Off. Upper: IOUT, 50 mA / div. Lower: VIN, 100 V / div., 2 s / div. Figure 118 – 230 VAC, 20 V LED Load. 1 s On – 1 s Off. Upper: IOUT, 50 mA / div. Lower: VIN, 100 V / div., 4 s / div. Figure 119 – 230 VAC, 20 V LED Load. 500 ms On – 500 ms Off. Upper: IOUT, 50 mA / div. Lower: VIN, 100 V / div., 2 s / div. Page 71 of 78 Power Integrations Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com DER-528 14 W LED Driver Using LYT5226D 09-Mar-16 14 Conducted EMI 14.1 Test Set-up 14.1.1 Equipment and Load Used 1. Rohde and Schwarz ENV216 two line V-network. 2. Rohde and Schwarz ESRP EMI test receiver. 3. Hioki 3322 power hitester. 4. Chroma measurement test fixture. 5. LED load string Figure 120 – Conducted EMI Test Set-up. Power Integrations, Inc. Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com Page 72 of 78 09-Mar-16 DER-528 14 W LED Driver Using LYT5226D 14.2 EM I Test R esult Figure 121 – Conducted EMI QP Scan at 40 V LED Load, 230 VAC, 50 Hz, and EN55015 B Limits. Figure 122 – Conducted EMI QP Data at 40 V LED Load, 230 V / 50 Hz. Page 73 of 78 Power Integrations Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com DER-528 14 W LED Driver Using LYT5226D 09-Mar-16 Figure 123 – Conducted EMI QP Scan at 40 V LED Load, 115 VAC, 50 Hz, and EN55015 B Limits. Figure 124 – Conducted EMI QP Data at 40 V LED Load, 115 V / 50 Hz. Power Integrations, Inc. Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com Page 74 of 78 09-Mar-16 DER-528 14 W LED Driver Using LYT5226D 15 Line Surge The unit was subjected to ±2500 V, 100 kHz ring wave and ±1000 V differential surge using 10 strikes at each condition. A test failure was defined as a non-recoverable interruption of output requiring repair or recycling of input voltage. Surge Level (V) +1000 -1000 +1000 -1000 Surge Level (V) +2500 -2500 +2500 -2500 Input Voltage (VAC) 230 230 230 230 Input Voltage (VAC) 230 230 230 230 Injection Location L L L L to to to to N N N N Injection Location L L L L to to to to N N N N Injection Phase (°) Test Result (Pass/Fail) 0 0 90 90 Pass Pass Pass Pass Injection Phase (°) Test Result (Pass/Fail) 0 0 90 90 Pass Pass Pass Pass Figure 125 – +1000 kV Differential Surge, 90º Phase Angle Lower: VDRAIN, 100 V / div., 5 µs / div. Peak VDRAIN: 671.6 V. Page 75 of 78 Power Integrations Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com DER-528 14 W LED Driver Using LYT5226D 09-Mar-16 16 Brown-in/Brown-out Test No failure of any component was seen during brownout test AC cut-in and cut-off. Figure 126 – Brown-in Test at 0.5 V / s. The Unit is Able to Operate Normally Without Any Failure and Without Flicker. Ch4: VIN, 100 V / div. Ch3: IOUT, 50 mA / div. Time Scale: 50 s / div. Figure 127 – Brown-out Test at 0.5 V / s. The Unit is Able to Operate Normally Without Any Failure and Without Flicker. Ch4: VIN, 100 V / div. Ch3: IOUT, 50 mA / div. Time Scale: 50 s / div. Figure 128 – Brown-in Test at 1 V / s. The Unit is Able to Operate Normally Without Any Failure and Without Flicker. Ch4: VIN, 100 V / div. Ch3: IOUT, 50 mA / div. Time Scale: 40 s / div. Figure 129 – Brown-out Test at 1 V / s. The Unit is Able to Operate Normally Without Any Failure and Without Flicker. Ch4: VIN, 100 V / div. Ch3: IOUT, 50 mA / div. Time Scale: 40 s / div. Power Integrations, Inc. Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com Page 76 of 78 09-Mar-16 DER-528 14 W LED Driver Using LYT5226D 17 Revision History Date 05-March-16 Page 77 of 78 Author MGM Revision 1.0 Description and Changes Initial release Reviewed Apps & Mktg Power Integrations Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com DER-528 14 W LED Driver Using LYT5226D 09-Mar-16 For the latest updates, visit our website: www.power.com Power Integrations reserves the right to make changes to its products at any time to improve reliability or manufacturability. Power Integrations does not assume any liability arising from the use of any device or circuit described herein. POWER INTEGRATIONS MAKES NO WARRANTY HEREIN AND SPECIFICALLY DISCLAIMS ALL WARRANTIES INCLUDING, WITHOUT LIMITATION, THE IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, AND NON-INFRINGEMENT OF THIRD PARTY RIGHTS. Patent Information The products and applications illustrated herein (including transformer construction and circuits’ external to the products) may be covered by one or more U.S. and foreign patents, or potentially by pending U.S. and foreign patent applications assigned to Power Integrations. A complete list of Power Integrations’ patents may be found at www.power.com. Power Integrations grants its customers a license under certain patent rights as set forth at http://www.power.com/ip.htm. The PI Logo, TOPSwitch, TinySwitch, LinkSwitch, LYTSwitch, InnoSwtich, DPA-Switch, PeakSwitch, CAPZero, SENZero, LinkZero, HiperPFS, HiperTFS, HiperLCS, Qspeed, EcoSmart, Clampless, E-Shield, Filterfuse, FluxLink, StackFET, PI Expert and PI FACTS are trademarks of Power Integrations, Inc. Other trademarks are property of their respective companies. ©Copyright 2015 Power Integrations, Inc. Power Integrations Worldwide Sales Support Locations WORLD HEADQUARTERS 5245 Hellyer Avenue San Jose, CA 95138, USA. Main: +1-408-414-9200 Customer Service: Phone: +1-408-414-9665 Fax: +1-408-414-9765 e-mail: usasales@power.com GERMANY Lindwurmstrasse 114 80337, Munich Germany Phone: +49-895-527-39110 Fax: +49-895-527-39200 e-mail: eurosales@power.com JAPAN Kosei Dai-3 Building 2-12-11, Shin-Yokohama, Kohoku-ku, Yokohama-shi, Kanagawa 222-0033 Japan Phone: +81-45-471-1021 Fax: +81-45-471-3717 e-mail: japansales@power.com TAIWAN 5F, No. 318, Nei Hu Rd., Sec. 1 Nei Hu District Taipei 11493, Taiwan R.O.C. Phone: +886-2-2659-4570 Fax: +886-2-2659-4550 e-mail: taiwansales@power.com CHINA (SHANGHAI) Rm 2410, Charity Plaza, No. 88, North Caoxi Road, Shanghai, PRC 200030 Phone: +86-21-6354-6323 Fax: +86-21-6354-6325 e-mail: chinasales@power.com INDIA #1, 14th Main Road Vasanthanagar Bangalore-560052 India Phone: +91-80-4113-8020 Fax: +91-80-4113-8023 e-mail: indiasales@power.com KOREA RM 602, 6FL Korea City Air Terminal B/D, 159-6 Samsung-Dong, Kangnam-Gu, Seoul, 135-728 Korea Phone: +82-2-2016-6610 Fax: +82-2-2016-6630 e-mail: koreasales@power.com UK Cambridge Semiconductor, a Power Integrations company Westbrook Centre, Block 5, 2nd Floor Milton Road Cambridge CB4 1YG Phone: +44 (0) 1223-446483 e-mail: eurosales@power.com CHINA (SHENZHEN) 17/F, Hivac Building, No. 2, Keji Nan 8th Road, Nanshan District, Shenzhen, China, 518057 Phone: +86-755-8672-8689 Fax: +86-755-8672-8690 e-mail: chinasales@power.com ITALY Via Milanese 20, 3rd. Fl. 20099 Sesto San Giovanni (MI) Italy Phone: +39-024-550-8701 Fax: +39-028-928-6009 e-mail: eurosales@power.com SINGAPORE 51 Newton Road, #19-01/05 Goldhill Plaza Singapore, 308900 Phone: +65-6358-2160 Fax: +65-6358-2015 e-mail: singaporesales@power.com Power Integrations, Inc. Tel: +1 408 414 9200 Fax: +1 408 414 9201 www.power.com Page 78 of 78