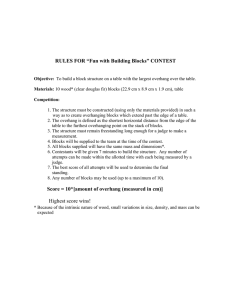

Development of BLDC Motor using Metal Powdered Core for 42V

advertisement

Proceedings of the 5th WSEAS Int. Conf. on Power Systems and Electromagnetic Compatibility, Corfu, Greece, August 23-25, 2005 (pp502-507)

Development of BLDC Motor using Metal Powdered Core for 42V Fan

Application of Hybrid Electric Vehicle

JIN HUR and HA-GYEONG SUNG

JUNG-PYO HONG

*Dept. of Electric Eng.

Intelligent Mechatronics Research Center,

Changwon National University

Korea Electronic Technology Institute (KETI))

641-773 Sarim-dong, Changwon,

203-103, 192 B/D Yakdae-dong, Wonmi-gu, Puchon,

KOREA

KOREA

http://www.keti.re.kr/premech

Abstract: - This paper aims to develop the 42V BLDC fan motor for hybrid electric vehicle using metal powdered

core. So, the influence on a motor design by metal powder is described and the powder is applied as a direct

replacement of lamination core. This point is focused upon a comparison of brushless dc motors, built with a

powdered stator and Si laminated stator, which also has been redesigned to take an advantage of the powdered core

for improving their performance on the same volume.

Key-Words: - 42V cooling fan motor, BLDC motor, Metal powdered core, Si laminated core, EMCN method

1 Introduction

The demands being placed on a car’s electrical

system today are unprecedented and so the 42V power

system will be applied to service the electrical needs of

future vehicle such as Luxury vehicle, HEV (Hybrid

Electric Vehicle) and FCEV (Fuel Cell Electrical

Vehicle) [1]. The load voltage for motors also is

recommended to be 42V because of several benefits

due to the higher voltage. The cooling fan motor is one

of main power consumed electric loads at the present

vehicle. So, the development of 42V fan motor is

needed. Generally, the 12V Brush type DC motor is

used for fan because of use of the existing

infrastructure. However, this need to be rated for

continuous operation at the highest current and the

motor lose 15 percent of their energy in the brushes

alone. So, brushless DC motor will be the choice for

most application such as fans and pumps because of its

efficiency at high voltage as well as it easy control and

high quality and reliability [2]. This paper presents the

development of BLDC motor using metal powdered

core for 42V cooling fan.

Metal powder materials as new magnetic materials

for improving the capability of magnetic circuit of

electric machine devices have been continually

developed and its applications have been expanded

according to the requirement of high performance.

That is, a magnetic material is used for all kinds of

motors converting an electromagnetic energy to a

mechanical energy and plays an important role in their

performance. So, much research is performed for

improving the performance. In such side, metal

powder materials allows improvements over the

lamination core with the respects of design freedom,

low manufacturing cost, simple manufacturing

processes, and low eddy current losses [3], [4],[5].

Since the particles of the powder are insulated by

the surface coating and adhesive used for composite

bonding, the eddy current loss is much lower than in

laminated steels, especially at higher frequencies, and

the hysteresis loss becomes the dominant component

of core loss. Motor designers can handle 3-D structure

for a more effective magnetic flux path contrary to

conventional laminated steel and expect the more

improved motor efficiency due to design trends of

smaller size, higher output in recent years [6].

In this paper, the design of BLDC motor for 42V

fan is performed first, and then the new structure of

BLDC motor with teeth overhang using the metal

powdered core, as shown in Fig. 1, are investigated to

improve the characteristics of the conventional

structure manufactured by Si laminated steel.

Fig. 1 SPM type BLDC Motor with Teeth overhang

Proceedings of the 5th WSEAS Int. Conf. on Power Systems and Electromagnetic Compatibility, Corfu, Greece, August 23-25, 2005 (pp502-507)

That is, the designed 42V conventional type BLDC

motor for cool fan has been redesigned and rebuilt

using the metal powdered core with the objective of

maximizing the performance. It must be noted that the

proposed structure using metal powder core has a

great advantage over conventional type for

maximization of the output.

2 Design of BLDC motor for 42V Fan

The fan with motor can be utilized for relatively long

operating hours in the vehicle. The BLDC motor is

especially advantages for fan application because of

their wide speed range, easy speed controllability,

high efficiency and long lifetime expectancy. The Fig.

2 shows the designed motor and their distribution of

magnetic flux density. The motor is inner-rotor type

BLDC motor with 8 poles and 12 teeth designed for

low torque ripple.

2.1 Design of Teeth overhang

In spite of many advantages of the metal powder

materials afore-mentioned, it has a disadvantage of

low permeability and high specific iron loss at low

frequencies. So, although it became very attractive for

use as magnetic core parts or for manufacturing the

stator cores of PM motor in general, it causes output

power density to be reduced [6]. In this paper, a stator

shape with teeth overhang of the BLDC motor is

designed and manufactured by the metal powder core

in the same volume as conventional type motor

laminated Si steel to maximize the effects of end

winding.

In order to analyze the effect of the teeth overhang

on the stator of BLDC motor, in this design, the

simplified magnetic equivalent circuit (MEC) model

considering the teeth overhang is developed as shown

in Fig. 3. As design variables, the overhang at the top

of stator core, Ra and Rb , is depicted.

This MEC model is applied to the initial design of

the overhang and investigation on the effect according

to the different overhang length. The advantage of this

kind of structure having teeth overhang is to be

generated the magnetic torque at the teeth overhang

region as well as at the conventional stator region,

which results in an increase of higher total torque.

However, due to their 3-D shape by the teeth overhang,

this type structure cannot be achieved by lamination of

steel sheet. This property makes the metal powder core

very attractive for producing a complex shaped stator

such as designed type. So, this structure makes up for

the weak point in the performance due to a low

permeability of metal powder.

The applied machine is a 150W BLDC motor, and

its stator has 12 slots and the rotor is built of 8 poles of

radial magnetic, Ferrite magnet. In order to compare

of the metal powder BLDC motor with lamination

core one, three BLDC motors manufactured by

conventional type Si core (Si model), conventional

type metal power core (MP model) and proposed

metal powder core with teeth overhang (OH model)

are applied to examine metal powder motor of the

same dimension as previously designed lamination

core one.

(a) Simplified MEC model for Overhang model

(b) MEC model of conventional stator yoke region

Fig.2 Distribution of magnetic flux density

(c) MEC model for Overhang model

Fig.3. MEC model

Proceedings of the 5th WSEAS Int. Conf. on Power Systems and Electromagnetic Compatibility, Corfu, Greece, August 23-25, 2005 (pp502-507)

N (i , j ,k )

(

)

The system matrix equation applied the magnetic flux

continuity condition can be obtained to all nodes as

following,

[P]n×n {U}n×1 = {F}n×1

(2)

where, n is total number of node, [P ]n× n is the

permeance coefficient matrix which is symmetric and

has a good sparsity and bandwidth, {U}n×1 is the matrix

of MSP and {F}n×1 is the forcing matrix.

The local values of flux density are calculated by

the solved MSP. Fig. 4 shows the mesh shape in x-y

plane of the designed motor. The comparison of 2D

FEA result and 3D EMCN results is shown in Fig. 5.

Fig. 6 shows also the torque characteristics according

to the rotation angle. As shown in Fig. 6, the proposed

type with a teeth overhang for using the flux leakage

of end winding have a superiority over the

conventional type in the torque point of view.

0.5

2D-FEM

3D-EMCN

0.4

Flux Density, B_y (T)

In order to accurately analyze the three models of

the BLDC with different stators, a calculation of the

magnetic field has to be performed for both models by

3-D equivalent magnetic circuit (3-D EMCN) method

[7], because 3-D analysis is required to evaluate and

design this type motor. 3-D EMCN method

supplements magnetic equivalent circuit by network

construction for getting the distribution of field

variable. In this method, the analysis model is divided

into hexahedral element and then equivalent magnetic

circuit network is constructed by connecting the node

of every elements center. The field variable of their

centroids, magnetic scalar potential (MSP), is decided

by the permeance involved with them. Thus, the

magnetic flux between two nodes (i, j, k) and (i, j-1, k)

are calculated such that

φ ( i , j ,k ) = 1

U (i , j ,k ) − U (i , j −1,k ) + F(i , j ,k )

(1)

R

0.3

0.2

0.1

0.0

-0.1

45

60

75

90

105

120

135

o

Mechincal angle ( )

Fig.5. MEC model

From these results, although the metal powder has

a disadvantage of low permeability, it can be

overcome the weakness by designing the 3D structure

using the advantage of metal powder. Also, it is noted

that the decision of overhang length is very important

and one can get a BLDC motor with the much

improved torque characteristics in the same volume.

The inductance of the proposed model (OH

model) compared conventional type (MP model)

using metal powder is described in Fig 7, which is

increased by overhang effect. From the analysis

results, more fluxes inclined into the stator, which is

due to increased linkage area as much as the area of the

teeth overhang and reduced leakages.

It means that the air gap flux becomes increased

and as the results of that the inductance is also

increased. The increased flux can be contributed

greatly to the torque characteristics of the motor.

6

Torque (kg.cm)

5

4

3

Si Model

OH Model

MP Model

2

1

60

70

80

90

100

110

120

Rotation Angle (degree)

Fig.4. MEC model

Fig. 6 Torque profile of different model according to

the rotation angle.

Proceedings of the 5th WSEAS Int. Conf. on Power Systems and Electromagnetic Compatibility, Corfu, Greece, August 23-25, 2005 (pp502-507)

5000

90

1000 Hz

80

4000

Core Loss ( W / kg )

Inductance [ mH ]

70

60

50

Developed type model

(Overhang:5.5[mm])

Conventional type model

40

30

20

3000

500 Hz

1000

10

0

700 Hz

2000

300 Hz

100 Hz

50 Hz

0

0

40

80

120

160

200

240

280

320

0.0

360

0.5

1.0

o

1.5

2.0

2.5

3.0

Peak Flux Density (T)

Electrical Angle [ ]

Fig.7 Inductance profile due to the electric angle.

Fig. 9 Core loss of metal powder

So, if the winding is redesigned to get the same

EMF, a design result of effective motor with higher

efficiency can be obtained by reducing the copper loss.

Therefore, in case of this kind of motor, if applying the

metal powder core can modify the stator, one can

dramatically increase the output characteristics in

view of toque, efficiency.

As shown in Fig. 8, the flux density at each element,

Be(t), is calculated and then analyzed by a Discrete

Fourier transform (DFT) as (3).

2.3 Analysis of Iron Loss

The flowchart for iron loss calculation is shown in Fig.

8 and the data for calculation of Iron loss, which is

interpolated using limited data, is also shown in Fig. 9.

Numerical Analysis

Spectrum

0.5

0.0

we = ∑ w(i × f )i

i =1

2

4

6

Harmonic order

8

10

30

Magnetic flux density vs.

Core loss

30

20

f = 400 (Hz)

10

f = 200 (Hz)

0

0.0

Calculation of Total Iron

loss in whole core

f = 100 (Hz)

0.5

B (T)

m

wtotal = ∑ we

e =1

1.0

∑ B p (n) e

(

j 2 πnk

N

)

(3)

n −0

Overhang (133.92AT)

Overhang (No load)

Non Overhang (133.92AT)

25

w (W/kg)

n

0

N −1

where k is the harmonic order, N is the number of the

discrete data, Bpk(k) is the peak value of the magnetic

flux density of the k-th harmonic, and Bp(n)is the

magnitude of the point n (n = 0, 1, 2, , N-1).

It is used for summation of iron loss according to

harmonics of the magnetic flux density using a curve

of magnetic flux density vs. Iron loss. So, the total iron

loss in the whole core is calculated by summation of

iron loss at the each element. Fig. 10 shows the

analysis results for iron loss in both motor,

non-overhang (MP model) and overhang model (OH

model). At 3,000[rpm] the iron loss are respectively

7.0 [%] in non-overhang model and 8.8[%] in

overhang model.

Iron loss [W]

t

Summation of Iron loss

according to harmonics

of magnetic flux density

in each element

Be(t) : DFT Analysis

1.0

Be(t)

B pk ( k ) =

20

8.8[%] of

the rated power

15

7.9[%]

10

7.0[%]

5

0

0

1000

2000

3000

4000

5000

6000

Speed [rpm]

Fig. 8 Flowchart for iron loss calculation

Fig. 10 BLDC motor for characteristic comparison

Proceedings of the 5th WSEAS Int. Conf. on Power Systems and Electromagnetic Compatibility, Corfu, Greece, August 23-25, 2005 (pp502-507)

Because the main design objective of this paper

was the increase of torque per volume using the teeth

overhang, the different amount of iron loss can be

explained by the increased core due to the teeth

overhang. So, this result is totally acceptable for using

the overhang, because the improvement of motor

performance by using the overhang is predicted by

10% and over at the rated operation.

3 Experimentation Validations

A prototype of conventional type Si-laminated

Core, metal power core and proposed type metal

power core has been realized. Fig. 11 presents the

three-type stator of BLDC motor mad of Si-core and

metal powder; Si, MP and OH model respectively.

Fig. 11 Prototype of Stator of BLDC motor

(c) OH model

Fig. 12 EMF Comparison of three-type model at

1,000(rpm)

The experimental EMF waveforms of three-type

motors are shown in Fig. 12. The distinction for EMF

waveforms is very clear from the different of the

magnitude of the EMF. The use of overhang is

increasing the total flux and EMF by 10% when

compared to the non-overhang type, MP model.

Fig. 13 presents together the experimental results

for efficiency vs. the torque characteristics and Speed

vs. the torque characteristics respectively. This result

means that the use of the teeth overhang is very helpful

scheme for improving the motor performance.

Generally the copper losses take up much portion of

total loss at the rated operation and it means that the

reduction of copper loss has been obtained by the

overhang effect.

So, even though the core loss is little increased, the

efficiency vs. torque characteristics of the proposed

type is improved as shown in Fig. 13. Also, it is noted

that the optimal design for the teeth overhang is

necessary to maximize the effects of end winding in

the motor.

90

(a) Si Model

Efficiency [%]

80

70

Si Model

MP Model

OH Model

60

0

0

1

2

3

4

5

6

7

8

9

Torque [rpm]

(b) MP model

(a) Efficiency vs. the torque characteristics

10

Proceedings of the 5th WSEAS Int. Conf. on Power Systems and Electromagnetic Compatibility, Corfu, Greece, August 23-25, 2005 (pp502-507)

5000

Speed (rpm)

4000

3000

2000

Si Model

MP Model

OH Model

1000

0

0

2

4

6

8

10

Torque (kg-cm)

(b) Speed vs. the torque characteristics

90

Efficiency [%]

80

70

Si Model

MP Model

OH Model

60

0

0

1

2

3

4

5

6

7

8

9

10

Torque [rpm]

(c) Output Power and Input power

Fig. 13 Experimental results

4 Conclusion

In order to sucessfully apply the metal powder

materials on BLDC motors, three different type BLDC

motors, conventional type Si core (Si model),

conventional type metal power core (MP model) and

proposed metal powder core with teeth overhang (OH

model), with the same dimensions are investigated.

From experimental results, the torque performance

of the lamination core motor is little higher than the

metal powder material motor on the whole. However,

the performance of the new structure of stator teeth

made of metal power core having a teeth overhang can

be much the same as the Si lamination core. So, it is

highly expected that this kind of model with teeth

overhang can be applied for mass production of

various application required high power density.

References:

[1] B. M. Baumann, G. Washington, B. C. Glen and G.

Rizzoni, "Mechatronics design and control of

hybrid electric vehicles,” IEEE/ASME Trans. on

Mechatronics, VOL. 50, NO. 1, pp.58-72, Sep.

2000.

[2] Y. G. Kim, J. P. Hong, G. H. Ha and J. Hur,

“Characteristic comparisons between iron powder

materials and lamination cores in brushless

motors,” Proc. Of ISEF2003, Maribor, Slovenia,

Sep. 2004.

[3] Jack A.G., "Experience with the use of soft

magnetic composites in electrical machines",

Proceeding,

ICEM'98,

Istanbul,

Turkey,

September, pp1441-1448, 1998.

[4] J. Cros, P. Viarouge and A. Halila, “Brush DC

motors with concentrated windings and soft

magnetic composites armatures”, in Conf. Rec.

IEEE-IAS Annual. Meeting, Chicago, IL, Oct.

2001.

[5] J. Cros, P. Viarouge, Y. Chalifour and J. Figueroa,

“A New Structure of Universal Motor Using Soft

Magnetic Composites,” IEEE Trans. on Industry

Applications, Vol. 40. No.2, March/April 2004. \

[6] Y. G. Kim, J. P. Hong and J. Hur, "Torque

Characteristics

Analysis

Considering

the

Tolerance of Electric Machine by Stochastic

Response Surface Method", IEEE Trans. on

Industry Applications. Vol. 39, No. 3, pp. 713-719,

May/June 2004.

[7] J. Hur, and D. S. Hyun, "A Method for Reduction

Cogging Torque in Brushless DC Motor

Considering the distribution of magnetizing by

3DEMCN,” IEEE Trans. on Magnetics, VOL. 34,

NO. 5, Sep. 1998.