PEM Fuel Cell Design Fabrication and Testing

advertisement

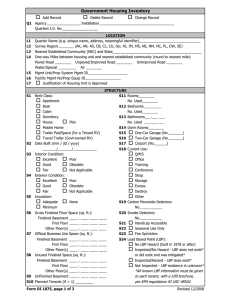

PEM Fuel Cell Design, Design Fabrication and Testing in an Undergraduate Engineering Course Denise McKayy Assistant Professor, Smith College Etta Grover Grover-Silva Silva ‘10 Smith College Fuel Cell Seminar 2009 Slide 1 of 13 Engineering Science Curriculum EGR 410D Design Clinic 300 Level Electives 3 Technical Electives required EGR 374 Fluids EGR 375 Strength of Materials EGR 220 Engineering Ci it Circuit Theory EGR 320 Signals and Systems EGR 260 Energy and M Mass Balances EGR 363 Mass and Heat Transfer EGR 270 Engineering Mechanics EGR 326 Dynamic Systems EGR 290 Engineering Th Thermo - EGR 100 Engineering For Everyone Fuel Cell Seminar 2009 Slide 2 of 13 Fuel Cell Course Overview Initial Design Concepts C (in class, no constraints) FC C Fabrication in machine shop Physical Representation (CAD or mock-up) Finalize fabrication and assembly Peer Review Design Charette Add hardware constraints Test Fuel Cells in research lab Lab report FC polarization Refine Design CAD Drawings Final Approval Dimensioned CAD Drawings Legend In class FC System Design Size a stack with polarization data Outside class Fuel Cell Seminar 2009 Slide 3 of 13 FC Design – Background Materials Initial Design Objectives: • Electrical conduction • Reactant distribution from plumbing fitting to catalyst layer • Gas sealing Fuel Cell Seminar 2009 Slide 4 of 13 FC Design – Design Ideation Given materials and dimensions • Gasketed MEA – 50cm2 active area • GDL – cloth with integrated MPL • Gaskets – Buna-N sheets • Flow Field/Current collector – metal screens or perforated metal • Endplate – acrylic/Lexan • Hardware – threaded rod, wing nuts, bolts, hose/barb fittings Fuel Cell Seminar 2009 Slide 5 of 13 FC Design – Physical Representation Fuel Cell Seminar 2009 Slide 6 of 13 FC Design – Design Charette Refine cell design directly with instructor prior to fabrication Fuel Cell Seminar 2009 Slide 7 of 13 Fabrication and Assembly Laser cut endplates Assembly Fuel Cell Seminar 2009 Water Jet Cutter Tapping endplates Final Assembly Machine Shop Slide 8 of 13 Performance Characterization – Test Cells Fuel Cell Seminar 2009 Slide 9 of 13 Application of Test Data to FC System Design Air Blowers Supply Valve Air Vent Ai Plumbing Air Pl bi Diagram Di Pressure Isolation Regulator Valve Electrical Wiring Diagram Fuel Cell Seminar 2009 Solenoid Delivery Valves Purge Valve FC Hydrogen Delivery Plumbing Diagram Slide 10 of 13 Life Cycle Cost Assessment Item Initial Costs Single Present Uniform Present Worth Year Worth Year PV Equipment FC Equipment * Installation Cost 0 0 0 Cost Present Present Worth Worth Factor Amount $4,006,030 $1,621,110 $82,800 1.0 1.0 1.0 $4,006,030 $1,621,110 $82,800 $5,520 11.5 $63,314 0.94 0.89 0.84 0 79 0.79 0.75 0.70 0.67 0.63 0.59 0.56 0 53 0.53 0.50 0.47 0.44 0.42 0.39 0.37 0 35 0.35 0.33 0.75 0.56 0.42 0.89 0.79 0 70 0.70 0.63 $76,462 $72,134 $68,051 $64 199 $64,199 $60,565 $57,137 $53,903 $50,852 $47,973 $45,258 $42 696 $42,696 $40,279 $37,999 $35,848 $33,819 $31,905 $30,099 $28 395 $28,395 $26,788 $309,365 $231,175 $172,748 $3,480 $3,097 $2 756 $2,756 $2,453 A Annual lC Costs Annual Maintenance 0 20 Repair & Replacement H2 Fuel † H2 Fuel † H2 Fuel † H2 Fuel † H2 Fuel † H2 Fuel † H2 Fuel † H2 Fuel † H2 Fuel † H2 Fuel † H2 Fuel † H2 Fuel † H2 Fuel † H2 Fuel † H2 Fuel † H2 Fuel † H2 Fuel † H2 Fuel † H2 Fuel † Inverter Replacement Inverter Replacement Inverter Replacement Water Pump Replacement Water Pump Replacement Water Pump Replacement Water Pump Replacement 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 5 10 15 2 4 6 8 $81,050 $81,050 $81,050 $81 050 $81,050 $81,050 $81,050 $81,050 Air Blower Replacement $81,050 Air Blower Replacement $81,050 Air Blower Replacement $81,050 Air Blower Replacement p $81 050 $81,050 Air Blower Replacement $81,050 $81,050 Air Blower Replacement $81,050 Air Blower Replacement $81,050 Air Blower Replacement $81,050 Air Blower Replacement $81,050 $81 050 $81,050 23 FC Stacks Replacement $81,050 23 FC Stacks Replacement $414,000 23 FC Stacks Replacement $414,000 $414,000 23 FC Stacks Replacement $3,910 23 FC Stacks Replacement $3,910 Salvage Value $3 910 $3,910 $3,910 Salvage is 10% of Initial Equipment Cost Water Pump Replacement Water Pump Replacement Water Pump Replacement Water Pump Replacement Water Pump Replacement Total Life Cycle Cost Fuel Cell Seminar 2009 10 12 14 16 18 2 4 6 8 10 12 14 16 18 3 6 9 12 18 20 $3,910 $3,910 $3 910 $3,910 $3,910 $3,910 0.56 0.50 0 44 0.44 0.39 0.35 $2,183 $1,943 $1 729 $1,729 $1,539 $1,370 $16,100 0.89 $14,329 $16,100 0.79 $12,753 $16,100 0.70 $11,350 $16,100 $ , 0.63 $10,101 $ , $16,100 0.56 $8,990 $16,100 0.50 $8,001 $16,100 0.44 $7,121 $16,100 0.39 $6,338 $16,100 0.35 $5,641 $900 000 $900,000 0 84 0.84 $755 657 $755,657 $900,000 0.70 $634,464 $900,000 0.59 $532,709 $900,000 0.50 $447,272 $900,000 0.35 $315,309 -$400,603 0.31 -$124,910 $10,181,495 Slide 11 of 13 Summary We have developed and implemented an upper division fuel cell engineering course where students: • apply fundamental science to fuel cell applications, • design, develop and fabricate their own PEM fuel cell, • test their design through polarization data, • apply single cell data in the sizing of large fuel cell stacks, and • demonstrate an integrated understanding of complex processes. As engineers are increasingly challenged to apply theoretical principles to complex and multidisciplinary problems, a curriculum that teaches knowledge integration and system level design across scales is critical to their future success. Fuel Cell Seminar 2009 Slide 12 of 13 Acknowledgements We quite graciously acknowledge: • Smith College for considering this course as a permanent offering, • Picker Engineering Program for providing tremendous financial and technical support in developing this course in the Fall 2008, • Center for Design and Rapid Prototyping for providing constant access to shop equipment and support throughout the fabrication phase Fuel Cell Seminar 2009 Slide 13 of 13 Performance Characterization – Test Systems Fuel Cell Seminar 2009 Slide 14 of 13