RCE - Emmeti Climatic Regulator

advertisement

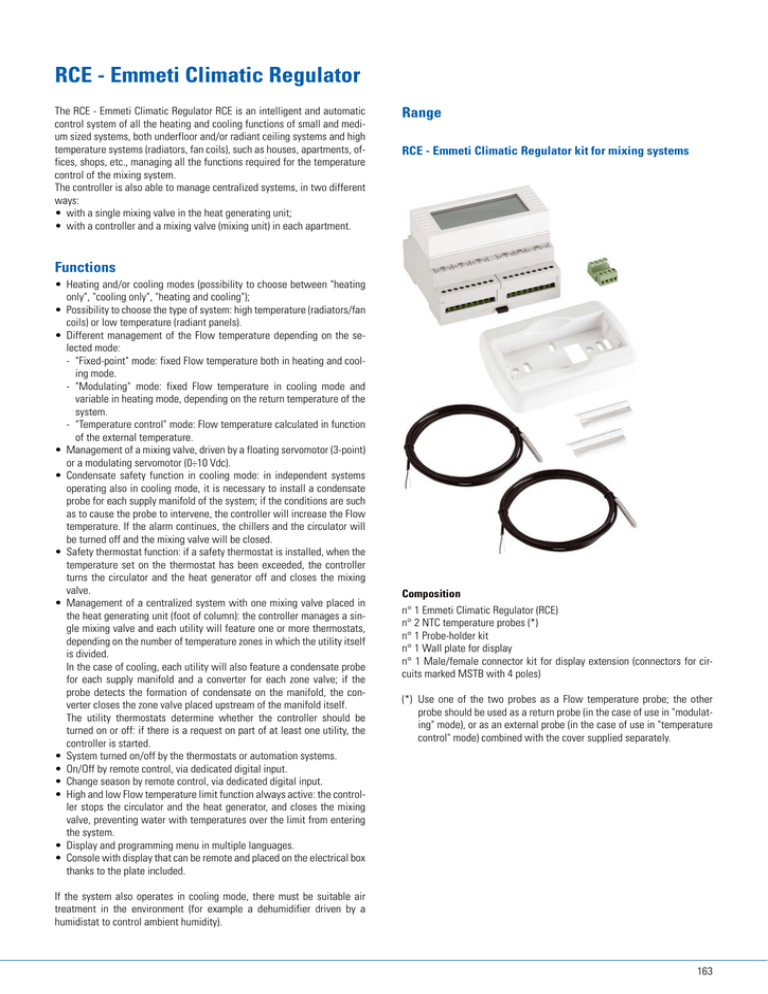

RCE - Emmeti Climatic Regulator The RCE - Emmeti Climatic Regulator RCE is an intelligent and automatic control system of all the heating and cooling functions of small and medium sized systems, both underfloor and/or radiant ceiling systems and high temperature systems (radiators, fan coils), such as houses, apartments, offices, shops, etc., managing all the functions required for the temperature control of the mixing system. The controller is also able to manage centralized systems, in two different ways: •with a single mixing valve in the heat generating unit; •with a controller and a mixing valve (mixing unit) in each apartment. Range RCE - Emmeti Climatic Regulator kit for mixing systems Functions •Heating and/or cooling modes (possibility to choose between "heating only", "cooling only", "heating and cooling"); •Possibility to choose the type of system: high temperature (radiators/fan coils) or low temperature (radiant panels). •Different management of the Flow temperature depending on the selected mode: - "Fixed-point" mode: fixed Flow temperature both in heating and cooling mode. - "Modulating" mode: fixed Flow temperature in cooling mode and variable in heating mode, depending on the return temperature of the system. - "Temperature control" mode: Flow temperature calculated in function of the external temperature. •Management of a mixing valve, driven by a floating servomotor (3-point) or a modulating servomotor (0÷10 Vdc). •Condensate safety function in cooling mode: in independent systems operating also in cooling mode, it is necessary to install a condensate probe for each supply manifold of the system; if the conditions are such as to cause the probe to intervene, the controller will increase the Flow temperature. If the alarm continues, the chillers and the circulator will be turned off and the mixing valve will be closed. •Safety thermostat function: if a safety thermostat is installed, when the temperature set on the thermostat has been exceeded, the controller turns the circulator and the heat generator off and closes the mixing valve. •Management of a centralized system with one mixing valve placed in the heat generating unit (foot of column): the controller manages a single mixing valve and each utility will feature one or more thermostats, depending on the number of temperature zones in which the utility itself is divided. In the case of cooling, each utility will also feature a condensate probe for each supply manifold and a converter for each zone valve; if the probe detects the formation of condensate on the manifold, the converter closes the zone valve placed upstream of the manifold itself. The utility thermostats determine whether the controller should be turned on or off: if there is a request on part of at least one utility, the controller is started. •System turned on/off by the thermostats or automation systems. •On/Off by remote control, via dedicated digital input. •Change season by remote control, via dedicated digital input. •High and low Flow temperature limit function always active: the controller stops the circulator and the heat generator, and closes the mixing valve, preventing water with temperatures over the limit from entering the system. •Display and programming menu in multiple languages. •Console with display that can be remote and placed on the electrical box thanks to the plate included. Composition n° 1 Emmeti Climatic Regulator (RCE) n° 2 NTC temperature probes (*) n° 1 Probe-holder kit n° 1 Wall plate for display n° 1 Male/female connector kit for display extension (connectors for circuits marked MSTB with 4 poles) (*) Use one of the two probes as a Flow temperature probe; the other probe should be used as a return probe (in the case of use in "modulating" mode), or as an external probe (in the case of use in "temperature control" mode) combined with the cover supplied separately. If the system also operates in cooling mode, there must be suitable air treatment in the environment (for example a dehumidifier driven by a humidistat to control ambient humidity). 163 Ø6 Dimensions of temperature probes 52 1500 Dimensions of probe-holder Ø 5,9 0 R2 Technical specifications of Temperature Controller Power supply: 110-230 Vac ±10%, 50/60 Hz Double insulation Capacity of contacts: 5A / 230 Vac Degree of protection: IP20 Attachable to guide DIN (EN 60715) according to DIN 43880 Material of controller: Self-extinguishing PPO Colour of controller: Grey Ral 7035 Dimensions: 6 modules DIN (95 x 105 x 82 mm) Material of display: PC/ABS Colour of display: white Delegated Regulation (UE) n. 811/2013; attachment IV-3: – Class of the temperature control device: Class 3; Class III – Contribution of the temperature control device to the seasonal energy efficiency of environment heating in %: 1.5% 67,2 Description of inputs and outputs of controller 2 analogue inputs for the NTC temperature probes (supply, return/external); 4 clean digital inputs (approval of heating/cooling/dehumidification, change season, on/off from remote, alarms). 1 digital output for the activation of the circulator; 1 digital output for the approval to the generator; 1 output for the control of a 3-point floating servomotor; (*) 1 analogue output for the control of a 0-10 V modulating servomotor; (*) 30,3 (*) the RCE controller can manage only 1 servomotor. Technical specifications of the temperature probes Type: NTC, 10KΩ at 25°C, IP68; Length of cable: 3 m; Length of probe 50 mm; Diameter of probe 6 mm. Technical specifications of wall plate for display Attachment to standard 503 box Condensate probe Technical specifications of wall plate for display Attachment to standard 503 box Dimensions of RCE controller 105 Technical specifications Power supply: 15 Vdc ±10%; RH% of intervention: 90-95%. 82 95 To be used in the case of operation also in cooling mode. Install a condensate probe for each supply manifold in the system. 10 Dimensions Dimensions of wall plate Length 1,5 Lunghezza 1,5mm 15 50 90 Length 1,5 1,5 m m Lunghezza 127 164 26 Converter Transformer 230/24 Vac, 10 VA Technical specifications Power supply: 24 Vac ±10%, 50/60 Hz; Max. absorption: 4.5 W; Capacity of contact: 5A / 230 Vac; Degree of protection: IP20; Attachable to guide DIN (EN 60715) according to DIN 43880; Material of converter: Self-extinguishing PPO; Colour of converter: Grey Ral 7035; Dimensions: 2 modules DIN (95 x 35 x 58 mm). Technical specifications 230/24 V; P=10 VA; F=50/60 Hz. Dimensions of transformer 64,8 To be used in the case of a centralized system with a single mixing valve operating also in cooling mode. Use a converter for each zone valve installed in the apartment, to allow or prevent the flow of heat transfer fluid within the apartment. To be used to power a maximum of two converters per condensate probe or to power 0-10V servomotors at 24 Vac (the number of servomotors that can be powered depends on the load required). Dimensions 35 58 Socket for immersion NTC temperature probe Technical specifications Threaded connection: G ¼” male; Length: 83 mm. Dimensions of socket 1/4” GAS Ø6,5 60 CH17 Ø7,5 95 35 9 3 11 165 50x50 mm box with cable gland for external probe Recessed electronic humidistat Technical specifications Material: Self-extinguishing ABS; Colour: white; Cover includes cable gland; Dimensions: 80x80x25 mm Note: for characteristics and models refer to the section dedicated to the humidistat. General description diagram - A RCE temperature controller. Output for the control of one mixing valve only (1-10 Vdc modulating servomotor or 3-point floating servomotor) Digital input for the connection in parallel of the ambient thermostats and of the humidistats, if present. In alternative, the micro contacts of the electrothermic heads driven by the corresponding thermostats and/or humidistats can be connected to the input. In the case of centralized systems with one mixing valve only in the heat generating unit, the micro contacts of the zone valves installed in the different utilities should be connected to this input. Digital output for the wiring of the circulator of the low temperature circuits, located upstream of the mixing valve. Analogue input for the connection of the Flow temperature probe. Analogue input for the connection of the return temperature probe (modulating operation) or of the external temperature probe (temperature control mode). If the controller is set to fixed-point mode, no probes are connected to this input. Digital alarm input for the connection in parallel of the safety thermostat and of the condensate probe/s (max 3). 166 Digital output for the approval to the generator. If the system is centralized, where each utility features a controller and a mixing valve (or mixing unit), the opening phase of the valve of the utility zone must be connected to this contact. In the case of a system with heating only, the contact will be used for the approval to the boiler, or a heat pump. In the case of a system with cooling only, the contact will be used for the approval to the chiller. In the case of a heating and cooling system with a chiller/heat pump only, the contact will manage this generator. In the case of a heating and cooling system, with a boiler intended for heating and a chiller intended for cooling, a relay controlled by a diverter (e.g. a summer/winter switch) will be connected to the contact, which will give the approval to the boiler during winter and the chiller during summer. Example of installation in a single system, operating in heating and cooling mode, with fixed-point control Remote display with wall plate Summer/Winter switch RCE controller TS Electrical box with safety thermostat E I Boiler Niña S HE Floor Control Unit Open manifold Humidistat Smarty 230 V Programmable thermostat Smarty 230 V Programmable thermostat Dehumidifier Dumy Floor Heat pump Mirai SMI* Emmeti Clima Floor underfloor circuits *In this example, the heat pump Mirai SMI operates in cooling mode only. Note 1: the volume of the open manifold/accumulator is defined in function of the potentiality of the chiller. Note 4: by installing also the external temperature probe it is possible to perform a temperature control. Note 2: the Summer/Winter switch E/I diverts the approval to the generator during winter and to the boiler during summer. Note 5: by installing also a temperature probe on the return manifold, it is possible to perform a modulating control. Note 3: it is possible, by means of the Summer/Winter switch, to change the season of all ambient thermostats (if equipped with an input contact for season change, e.g. Smarty with power supply 230 Vac). 167 Example of installation of a centralized system with a single mixing valve in the heat generating unit, operating in heating and cooling mode, with temperature control Converter Convertitore Smarty Smarty Cronotermostato Chrono-thermostat Humidistat Umidostato Emmeti Floor CircuitiClima a pavimento underfloor circuitsFloor Emmeti Clima Topway Collettore manifold Topway Dehumidifier Dumy Floor Dumy Floor Deumidificatore E I Summer/Winter Commutatore switch Estate/Inverno Converter Convertitore Remote remoto display Display wall a plate conwith placca muro External Sonda probe esterna RCE Regolatore RCE controller Smarty Smarty Chrono-thermostat Cronotermostato Humidistat Umidostato Emmeti Floor CircuitiClima a pavimento Emmeti Clima underfloor circuitsFloor Topway Collettore manifold Topway Electrical box Scatola elettrica with con termostato safety thermostat di sicurezza TS Dehumidifier Dumy Floor Dumy Floor Deumidificatore Boilers Caldaie Circolatore Circulator Motorised mixing valve Valvola miscelatrice motorizzata Open manifold Collettore aperto Heat pump Chiller Mirai SMI* *In this example, the heat pump Mirai SMI operates in cooling mode only. Note 1: the volume of the open manifold/accumulator is defined in function of the potentiality of the chiller. Note 4: by eliminating the external temperature probe it is possible to perform a fixed-point control. Note 2: the Summer/Winter switch E/I diverts the approval to the generator during winter and to the boiler during summer. Note 5: by replacing the external temperature probe with a temperature probe on the return column, it is possible to perform a modulating control. Note 3: it is possible, by means of the Summer/Winter switch, to change the season of all ambient thermostats (if equipped with an input contact for season change, e.g. Smarty with power supply 230 Vac). 168 Guide for the choice of components Single system Two-story home with a single mixing valve and 2 supply manifold, one for each floor. The system operates both in heating mode and in cooling mode. Components required: •n° 1 RCE temperature controller kit RCE (cod. 28139070). Note: for "fixed point" and "modulating" modes, all the components required are included. For "temperature control" mode, add n° 1 “cover for installation of external probe” (cod. 28139076) in order to be able to install one of the probes included outdoors. •n° 2 “condensate probes” (cod. 28139072) to be installed on each supply manifold. Both probes must be connected directly to the temperature controller. Note: this must be completed by a number of thermostats and humidistats corresponding to the number of temperature and humidity zones in the system. Centralized system Centralized system for the heating and cooling of a building with 20 apartments, with a single mixing valve in a heat generating unit. In each apartment there is a zone valve for the flow of the heat transfer fluid to the supply manifold of the apartment itself. Components required: •n° 1 RCE temperature controller kit RCE (cod. 28139070). Note: for "fixed point" and "modulating" modes, all the components required are included. For "temperature control" mode, add n° 1 “cover for installation of external probe” (cod. 28139076) in order to be able to install one of the probes included outdoors. For each apartment •n° 1 “condensate probe” (cod. 28139072) to be installed on the supply manifold. (Total 20 pcs.) •n° 1 converter for condensate probe (cod. 28139074) to be connected to the condensate probe, which will control the zone valve, closing it in the event of a condensate alarm. (Total 20 pcs.) •n° 1 “transformer 230 V - 24 V, 10 VA” (cod. 28139130) to power the converter for the condensate probe. (Total 20 pcs.) Note: this must be completed by a number of thermostats and humidistats corresponding to the number of temperature and humidity zones in the system. 169