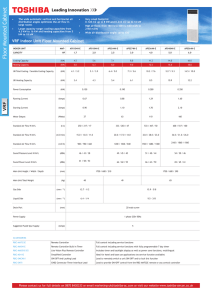

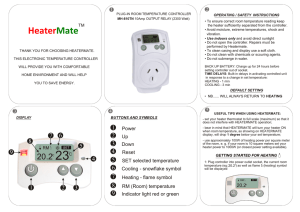

Control of ventilation and air conditioning plants

advertisement