Spec Sheet JC30-JC35 - ForkliftSystems.com

S P E C I F I C A T I O N S

OPTIMUM

JC30 JC35

S E R I E S

LPG/Gasoline

Cushion Tire Models

3,000 - 3,500 lb.

• Legendary Nissan Quality

• Enhanced Comfort Through Innovative Design

• Low Total Cost of Ownership

• Powerful Performance

• C lean A ir R educed E missions Engine Options

• Outworks the Competition

JC30 3000 lb.

JC35 3500 lb.

OPTIMUM

JC30 JC35

S E R I E S

S p e c i f i c a t i o n s characteristics

1 Manufacturer

2 Model

3 Capacity

4 Load Center

5 Power Type

6 Operator Orientation dimensions weight

29 Gradeability Maximum

30

31 Truck Weight

32 Weight Distribution

33

34 Tire Size

35 chassis

Manufacturer’s name

Model designation

Rated capacity

Distance

Gas - LP

Sit or stand

15

16

17

18

19

7 Tire Type

8 Wheels

9 Mast

10

11 Forks

12 Tilt Angle

13 Overall

14 Dimensions

Front and rear

Number (x = driven) front / rear

Maximum fork height (MFH)

Standard freelift

Thickness and width

Standard mast- fwd / back

Length - to face of forks

Width - standard tires

Overall ht. lowered (OHL) - standard mast

Overall height @ MFH w/ LBR

Overhead guard height

Height standard load back rest (LBR)

Width standard carriage (with Nissan mast)

20 Grade Clearance

21 Turning Radius

22 Overhang

23

Ramp breakover angle / departure angle

Minimum outside

Front

Rear

24 Minimum Right Angle Stacking Aisle Add load length and clearance performance

25 Speeds

26

27

28 Drawbar Pull Maximum

Max travel speed - forward or reverse

Lift speed - full load / no load

Lowering speed - full load / no load

Full load / no load - gasoline

Full load / no load - lpg

Full load / no load - gasoline

Full load / no load - lpg

Standard truck, no load

Front axle (no load)

Rear axle (no load)

Front

Rear

36 Wheelbase

37 Tread-Center of Tire

38

39 Ground Clearance

40 Service Brake

41 Parking Brake drive line

42 Steering

43

44 Engine

45

46

47 Transmission

48

Distance between axles on centers

Front / rear

Front dual tires

Under mast

Type - drum & shoe

Hand or foot applied

Type

Manufacturer / Model

Rated output (SAE gross / JIS) - gasoline

Rated output (SAE gross / JIS) - lpg

Rated torque (SAE gross / JIS) - gasoline

Rated torque (SAE gross / JIS) - lpg

Displacement

Number of speeds forward / reverse

Type lbs (kgs) in (mm) in (mm) in (mm) in (mm) degree in (mm) in (mm) in (mm) in (mm) in (mm) in (mm) in (mm) tan % in (mm) in (mm) in (mm) in (mm) mph (km/h) 10.9 (17.5) fpm (mm/sec) 100.4 / 112.2 (510 / 570) fpm (mm/sec) 98.4 / 108.2 (500 / 550) lbs (kgs) 3970 / 1430 (1800 / 650) lbs (kgs) 3750 / 1430 (1705 / 650)

%

% lbs (kgs) lbs (kgs) lbs (kgs) in (mm) in (mm) in (mm) in (mm) in (mm) in (mm) hp/rpm (PS/rpm) hp/rpm (PS/rpm) ft-lb - rpm (kg-m/rpm) ft-lb - rpm (kg-m/rpm) cu in (cm 3 )

Nissan

JC30

3000 (1500)

24 (500)

Gas-LP

Sit

Cushion

2 x / 2

130 (3300)

11 (280)

1.5 x 4 (40 x 100)

5 / 10

80.4 (2045)

38.2 (970)

83.1 (2110)

179.3 (4555)

81.1 (2060)

48 (1220)

32.5 (825)

37 / 35

68.3 (1735)

14.7 (375)

18.5 (470)

83.1 (2110)

Nissan

JC35

3500 (1750)

24 (500)

Gas-LP

Sit

Cushion

2 x / 2

130 (3300)

11 (280)

1.5 x 4 (40 x 100)

5 / 10

81.8 (2080)

38.2 (970)

83.1 (2110)

179.3 (4555)

81.1 (2060)

48 (1220)

32.5 (825)

37 / 35

69.5 (1765)

14.7 (375)

17.9 (455)

84.3 (2140)

10.9 (17.5)

100.4 / 112.2 (510 / 570)

98.4 / 108.2 (500 / 550)

3970 / 1320 (1800 / 600)

3750 / 1320 (1705 / 600)

36 / 18

36 / 18

5873 (2665)

2141 (970)

36 / 16

36 / 16

6314 (2865)

1993 (905)

3732 (1695) 4321 (1960)

18 x 6 x 12-1/8 (455 x 150 x 310)

14 x 4-1/2 x 8 (355 x 115 x 205)

47.2 (1200)

32.2 / 31.5 (820 / 800)

N/A

3.0 (75)

Drum & Shoe

Hand

47.2 (1200)

32.2 / 31.5 (820 / 800)

N/A

3.0 (75)

Drum & Shoe

Hand

Hydrostatic

Nissan / H20-II

Hydrostatic

Nissan / H20-II

50 / 2400 (46 / 2400)

47 / 2400 (43 / 2400)

1 / 1

Automatic

116 / 1600 (15.5 / 1600)

110 / 1600 (14.5 / 1600)

120.94 (1982)

1 / 1

Automatic

NOTE: Performance specifications based on Nissan wide-view mast (130" MFH) unless otherwise noted.

S t a n d a r d E q u i p m e n t

Ergonomics / Safety

❖ Independent float system (IFS) greatly reduces vibration at every point of operator contact

❖

❖

❖

❖

❖

❖

❖

❖

❖

❖

❖

❖

❖

❖

Brake and inching pedals mounted to the truck frame reduce pedal vibration

Rubber mounted shock absorber within the steering column reduces steering wheel vibration

Top panel design with rubber insulated mounts, rubber seals and fiberglass insulation reduces vibration, engine heat and noise within the entire operator compartment

Full suspension seat with weight and back angle adjustment maximizes operator comfort

5" of front-to-back seat adjustment allows greater operator leg room

Hip restraints with retractable seat belts provide greater operator security

Infinitely adjustable steer column enhances operator comfort and productivity

Exclusive single lift/tilt lever allows simultaneous lifting and tilting to increase operator efficiency

Heel/toe pedal design provides efficient motion for reduced effort and fatigue

Separate inching pedal allows full RPM lifting while making precise maneuvers increasing operator efficiency

Durable welded metal assist grip and metal traction plate on the entry step allows safe and easy compartment entry and exit.

Metal diamond tread compartment floorboards provide positive footing

Hydrostatic power steering reduces operator steer effort and fatigue

Low front cowl design enhances forward visibility of fork tips for better load handling efficiency

Textured three spoke steering wheel allows excellent visibility of the dash display for greater operator awareness of truck status

Dash display visibly communicates the following truck status and warnings for operator awareness: fuel level, hour meter, water temperature, oil temperature, oil pressure, torque converter oil temperature, coolant level warning, battery charge indicator, LPG tank bracket lock warning, and air cleaner condition indicator

Audible back-up warning alarm promotes a safer work environment

Standard light package includes two front overhead guard mounted headlights with protective guards for greater operational visibility

Performance / Durability

❖ Nissan H20-II, 2.0 liter, four cylinder, in-line engine features an oversquare design which efficiently produces superior horsepower with reduced vibration and noise

❖ Nissan-designed engine and transmission system effectively utilizes all available torque to provide exceptional power and performance

❖ Dual hydraulic filtration keeps system free from contaminants increasing reliability and component life

❖ Rugged, fabricated steel I-beam steer axle construction, protects steer cylinder components while providing reliable performance

❖ High air intake system on the overhead guard pillar pulls in cool, clean air for better engine performance

❖ Cyclone air cleaner with replaceable filter keeps contaminants out for longer engine life

❖ Self-adjusting, self-energizing brakes are sealed to keep contaminants out resulting in longer component life and reliable performance

❖

❖

Contoured counterweight design enhances truck maneuverability

Rugged, unitized frame design incorporates an integral hydraulic tank for better heat dissipation, increased durability and long life

OPTIMUM

JC30 JC35

S E R I E S

Performance / Durability (continued)

❖ Piccolo exhaust system disperses exhaust without dirt and debris kick-up

❖ Corrugated fin-type radiator with engine shroud provides enhanced cooling performance

❖ Nissan’s flat face mast design features rolled steel channels, large cross sections, and thick inner rails for increased capacity retention

❖ Powder coat paint provides a durable, high gloss finish inside and out for increased scratch resistance, improved U.V. protection, and an exceptional appearance

Serviceability

❖ Clamshell hood design opens nearly 90 degrees for maximum accessibility to engine and truck components. Two gas springs assist and retain the hood in the open position

❖ Two-piece steel, diamond tread floorboard is easily removed for access to components and grease fittings

❖ One-touch radiator cover is easily removed, without the use of tools, for cooling system checks

❖ Hatch in the floorboard allows quick and easy transmission fluid level checks

❖ Opening in the dash panel allows quick and easy brake fluid level checks

❖ Five-piece reinforced overhead guard design allows easy replacement should parts become damaged; slotted design allows excellent upward visibility for load handling and placement

❖ Nissan’s exclusive swing-out LPG bracket simplifies tank change-out. A lamp on the dash display warns the operator if the bracket is not properly locked in place

❖

❖

All grease fittings are easily accessible for routine maintenance

Side thrust rollers on the fork carriage are easily accessed for carriage adjustments

O p t i o n a l E q u i p m e n t

❖

❖

❖

❖

❖

❖

❖

❖

❖

❖

❖

❖

Nissan’s exclusive three stage Optiview mast provides 50% greater visibility for increased productivity and load handling efficiency. Free lift cylinders are nested behind mast rails for a larger field of view

Choice of exclusive Optiview three stage, Wide-View, Duplex, or standard Triplex masts

Separate lift and tilt levers with pistol grip type knobs

Standard or polished and tapered forks in a variety of lengths

(36", 42", 48", 54", and 60")

Rotating beacons and strobe lights

Hydraulic accumulator in the lift system

CARB compliant C lean A ir R educed E missions engine with either gas or LPG fuel system

Auxiliary hydraulics w/internal hose reeving

Side shifter

Extra tilt

Electronic Engine Management System to provide

Throttle body fuel injection

Enhanced performance and efficiency

Engine shutdown system with limp home mode

Electronic governor

Cotton core radiator ❖ Rearview mirrors

Consult your local Nissan Forklift Representative for additional optional equipment.

JC30 3000 lb.

JC35 3500 lb.

OPTIMUM

JC30 JC35

Wide-View

Wide-View

Wide-View

Wide-View

Wide-View

Duplex

Duplex

Triplex 1

Triplex 1

Triplex 1

Triplex 1

Triplex 1

Triplex 1

Optiview 1

Optiview 1

Optiview 1

Optiview 1

Optiview 1

J C 3 0 & J C 3 5 m a s t s

Mast Type

Maximum

Overall

Height

Fork Height Lowered

(MFH) (OHL) in (mm) in (mm)

82 (2085)

106 (2690)

59.1 (1500)

71.3 (1810)

130 (3300)

146 (3710)

157 (3990)

105.5 (2680)

83.1 (2110)

93.3 (2370)

100.8 (2560)

72 (1830)

129.5 (3289)

152 (3850)

169 (4300)

187 (4750)

203 (5154)

217 (5500)

236 (6000)

161 (4090)

178.7 (4540)

194.5 (4940)

208.3 (5290)

228 (5790)

84 (2135)

71.3 (1810)

77.2 (1960)

83.1 (2110)

88.2 (2240)

93.3 (2370)

100.8 (2560)

77.2 (1960)

83.1 (2110)

88.4 (2245)

93.3 (2370)

100.8 (2560)

Freelift

(FL) in (mm)

11 (280)

11 (280)

11 (280)

11 (280)

11 (280)

48 (1220)

60 (1530)

47.6 (1210)

53.5 (1360)

59.4 (1510)

64.8 (1645)

69.7 (1770)

77.2 (1960)

52 (1320)

57.9 (1470)

63 (1600)

68.1 (1730)

75.6 (1920)

1 Wide drive tires are standard. Overall truck width is 38.2"

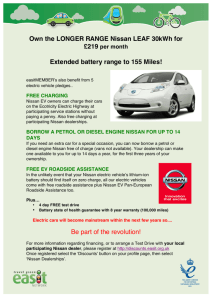

C a p a c i t y a t M F H u s i n g 1 8 7 " Tr i p l e x M a s t

8000

7000

6000

5000

4000

3000

2000

1000

0

0 24 28 32 36 40 44 48 52

Load Center (in)

JC35

JC30

240 N. Prospect Street

Marengo, IL 60152 USA

Phone (815) 568-0061

Fax (815) 568-0179 www.nissanforklift.com

5/5

5/5

5/5

5/5

5/10

5/5

5/5

5/5

Standard

Tilt

F/B Degree

5/10

5/10

5/10

5/10

5/10

5/10

5/5

5/5

5/5

5/5

MFH

14

OHL

FL

18

11

34

S E R I E S

22

12

37

24

36

13

21

43.1"

(1095 mm)

17

23

Ask your Nissan Forklift representative about our

C lean A ir R educed E missions engine options.

NOTES:

Nissan forklifts meet or exceed all ANSI B56.1 Safety Standards for Powered Industrial

Trucks and Underwriter’s Laboratories requirements as to fire hazard for gasoline, LP gas and diesel. Performance may vary as the specifications shown represent nominal values obtained under typical operating conditions.

Nissan Forklift Corporation, North America, reserves the right to make product changes relating to colors, equipment or specifications without notice. For more information, contact your Nissan Forklift representative.

SS-OPT-C1 01-02

Printed in USA

37

35

Material

Handling

and

Fleet Management

Specialist

contact@forkliftsystems.com www.forkliftsystems.com

Contact Info

MAILING ADDRESS

Forklift Systems Incorporated

884 Elm Hill Pike

Nashville, TN 37210

CONTACT INFO

Phone: 615-255-6321

Toll Free: 800-752-1882

Email: contact@forkliftsystems.

com

Web: www.forkliftsystems.com

SOCIAL MEDIA

Click Map to Open Google Map of Location

Tennessee Main Office: 884 Elm Hill Pike, Nashville, TN 37210

(615) 255-6321

Click Map to Open Google Map of Location

Alabama Main Office: 132 West Park Drive, Birmingham, AL 35211

(205) 945-1112

Other Products

Electric Pallet Trucks Large Capacity Forklifts I.C. & Electric Forklifts

Reach Truck & Order Picker Rider Sweeper & Scrubber Walkie Sweeper & Scrubber

Industrial Utility Vehicles Personnel Shuttles Burden Carriers

Scissor Lifts & Boom Lifts Rack & Storage Systems In-Plant Office - Building