safety with acrylic

advertisement

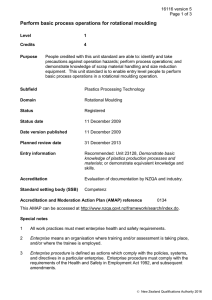

~@ ®@[Ji])® W@[f[k®~@[P) ~mlclli(!J]®~~~®~ [P)~®©~~©®® [p)[f@©®®®®® Acknowledgments This document was produced in collaboration with the Education Liaison Group and other leI staff on Teeside, who assisted with the technical details and provided support. for printing and the teachers involved. Out of print Ifll and ESPI booklets provided a framework of information which was built upon by the working party. The cover photographs were supplied by leI. Members of the Working Party Don Raspin - Education Liaison, ICI Keith Waugh - Development Officer, Design and Technology, Cleveland L.E.A. Polly Brettle - Advisory Teacher, Design and Technology, Cleveland L.E.A. Paul Bennington -Head of Technology, Ormesby School, Cleveland David Barrass - Head of Technology, Hartlepool Sixth Form College, Cleveland Editor Alan Stan cliffe Polymer Industry Education Centre Department of Chemistry University of York Heslington York Y015DD Telephone (0904) 432523 © Jointly held by ICI and the University of York Published 1994 ISBN: 185342700 4 The copyright holders waive the copyright on the material which follows to the extent that teachers may reproduce this material for use with their pupils in the establishment for which the material was purchased, but for all other purposes permission to reproduce any of this material in any form must be obtained from leI orthe University of York. The material may not be duplicated for lending, hire or sale. CONTENTS Page Introduction SECTION1 SCHOOLBASEDPROCESSES 1.1 WORKSHOP PRACTICE 1.1.1 Storage 1.1.2 Protective masking 1.1.3 Static electricity 1 1 1 1 1.2 SAFETY WITH ACRYLIC 1.2.1 Handling and machining 1.2.2 Flammability 1.2.3 Pressure shaping 2 2 2 2 1.3 FABRICATIONPROCESSES 1.3.1 Safety 1.3.2 Perspex acrylic sheet 1.3.3 Marking out 1.3.4 Edge treatment 1.3.5 Cutting straight lines 1.3.6 Cementing 1.3.7 Machining 3 3 3 3 3 4 5 7 1.4 SIMPLE THERMOFORMING TECHNIQUES 1.4.1 Effect of moisture 1.4.2 Oven heating 1.4.3 Single curvature forming 1.4.4 Double curvature forming 8 8 8 9 11 1.5 VACUUM FORMING 1.5.1 Equipment 1.5.2 Moulds 1.5.3 Heating times 1.5.4 Cooling times 13 13 14 15 16 1.6 FLUID BED COATING 17 SECTION2 INDUSTRIALBASED PROCESSES 2.1 PROCESSINGMETHODS 2.1.1 Extrusion 2.1.2 Balloon blowing 2.1.3 Calendering 2.1.4 Injection moulding 2.1.5 Thermoforming by pressure 2.1.6 Thermoforming by vacuum 2.1.7 Biaxial stretching of film 2.1.8 Glass Reinforced Plastics Lay-up and Moulding 2.1.9 Plastic laminates 2.1.10 Compression moulding 2.1.11 Rotational moulding 2.1.12 Extrusion blow moulding 2.1.13 Injection stretch blow moulding 2.1.14 Dip moulding 2.1.15 Structural foam moulding 18 18 19 20 21 22 23 24 25 27 28 29 30 31 33 34 1 APPENDICES Appendix 1 Properties and applications - Thermoplastics Appendix 2 Properties and applications - Thermosets Appendix 3 Physical properties of some thermoplastics Appendix 4 Chemical resistance of some thermoplastics Appendix 5 Summary of main industrial processes Appendix 6 Equipment and materials suppliers Appendix 7 Other resources 35 36 37 38 39 40 41 Trade names and abbreviations associated with different materials are included in the tables listed above. 11 Introduction This booklet has been produced in response to enquiries from teachers of Design and Technology seeking information on working practices in industry and schools relating to thermoplastics. It is not an exhaustive reference guide but does provide an introduction to basic techniques suitable for schools and the more common processes found in industry. The booklet is intended as a resource for the teacher but could also be used as a source of information for students engaged in Design and Technology project work for National Curriculum Key Stage 4 and for 16+ courses. Some of the practical working methods outlined will also be relevant to Design and Technology projects at Key Stage 3 of the National Curriculum. Teachers involved with the Scottish Curriculum for Technical Education, particularly with the 11-18yrs age group, will find the information relevant. Section one considers storage and safety procedures to be observed in schools and colleges in respect of plastics materials. It then goes on to outline some practical processes which can be undertaken using equipment normally found in school/college Design and Technology departments. Practical workshop processes have been outlined using acrylic as a sample material since this is one of the most commonly used in schools. However, most of the techniques described will be suitable for other thermoplastic sheet materials (e.g. polystyrene, PVC, ABS) providing consideration is given to differences in softening temperatures and appropriate categories of adhesives. Some techniques previously used in schools are now restricted as a result of regulations relating to Control of Substances Hazardous to Health (COSHH) and are not included in this document. It is common for all acrylic materials to be incorrectly described as Perspex. In fact Perspex is an ICI trade name for their own acrylic products. When referring to the material in general terms the correct title is Acrylic . .~ection two describes some of the more common industrial In use. processes currently Appendices 1 to 5 provide extensive tables of properties, applications and processes which will be useful for both teachers and older students studying at sixth form and FE levels. Appendix 6 lists equipment and material suppliers; appendix 7 lists locations of other resources. iii SECTION 1 SCHOOL BASED PROCESSES 1~1 ACRYLIC: WORKSHOP PRACTICE 1.1.1 Storage Acrylic and other thermoplastic sheet is best stored on its edge in storage racks having a backboard at a slight angle to the vertical (an A-Frame). The protective masking is left in position and the material should not be allowed to bow. Such storage provides adequate support and permits sheets to be withdrawn without danger of damage. Horizontal storage is not recommended as sheets are difficult to withdraw, and any dirt, swarf or grit trapped between them may damage their surfaces. Store rooms should be well ventilated, cool and dry. The masking on extruded acrylic sheet helps to protect against moisture absorption but cannot eliminate it. For this reason, acrylic should be stored in a dry area. 1.1.2 Protective masking The paper/adhesive masking system used for many years on acrylic is being replaced. ICI Acrylics has introduced a polyethylene film masking with a pressure-sensitive adhesive backing for the protection of cast 'Perspex' sheets. Sheets masked with a pressure-sensitive adhesive polyethylene film (PSPE) offer the end user several advantages. The film will not fall off, is more stable to climatic variations and can be cut or machined in place. PSPE masking can be kept in place for local bending applications provided heaters are not in direct contact with the film, but PSPE masking cannot be otherwise thermoformed. The masking must be removed prior to heating the acrylic for thermoforming, normalising or annealing. The surface of sheet masked with PSPE will not now need to be washed prior to cementing or thermoforming. However, for all surface decoration requirements, it is recommended that after removing the masking the surface of the sheet be rinsed with clean water (to remove particles of dust and neutralise any residual static charge) and dried with a soft dry cloth. Whenever possible the protective masking should be left attached to acrylic to avoid surface damage. It is also useful for marking out shapes before machining. 1.1.3 Static electricity To eliminate static on a finished article, use Acrylic Anti-static Cleaner or other approved products. However, if cementing, screen printing or spray painting, only use warm soapy water, rinse well and dry. 1.2 SAFETY WITH ACRYLIC 1.2.1 Handling and Acrylic is a hard material. damage eyes. Recommended machining Sharp edges could cause cuts, and flying chips could practice • Sharp corners and edges should always be removed (see page 3) before handling with bare hands. • Goggles should always be worn when machining it, as protection against flying swarf particles. • When it is being machined, the material should be held firmly and cutting tools, particularly drills (given a negative rake), should be sharpened correctly. • The manufacturer's recommendations should be followed when coolants are used during machining operations. • The area should be well ventilated with extraction of both fumes and dust. 1.2.2 Flam mabi Iity When acrylic is heated, it softens and can be shaped readily. At normal shaping temperatures of 140 to 170°C, acrylic does not evolve any noticeable amount of vapour. However, it is dangerous to subject acrylic to flames or prolonged heating because it creates highly flammable and irritant fumes. The flash ignition temperature of acrylic is 280°C. Recommended practice Care should be taken when thermoforming acrylic and teachers should refer to existing Health & Safety Regulations. 1.2.3 Pressure shaping Heated acrylic is often thermoformed by air pressure without a complete mould, either by free blowing or by the use of a skeleton mould. It is possible for the acrylic to burst during forming by air pressure. The possible causes are: • • • • Excessive air pressure A faul t in the blank Damage to the surface of the blank Contamination of the blank with foreign matter Safety shields should be provided when acrylic is being blown, to protect the operator from fragments of acrylic in the event of a burst thermoform. This is not necessary if a complete mould is being used. Blanks for thermoforming should be handled and stored carefully so as to avoid damage or contaminating the surface. Whenever possible, the protective paper should not be removed until just before the blank is placed in the oven. 2 1.3 ACRYLIC: 1.3.1 FABRICATION PROCESSES Safety Normal codes of practice must be observed in the workshop. The following documents offer further guidance: • • • • • • • COSSH*: Guidance for schools (from HMSO) Risk Assessment for Technology in Secondary Schools (from CLEAPSS) Topics in Safety (from ASE) Safeguards in the School Laboratory (from ASE) Be Safe! - Some Aspects of Safety in School Science and Technology (ASE) Make It Safe (from NAAIDT) Managing Health and Safety in Design and Technology Workshops (from NAAIDT) Addresses for the above documents are listed in appendix 7 Appropriate protective clothing must be worn at all times (e.g. gloves/aprons/dust masks etc.) 1.3.2 Perspex acrylic sheet Perspex acrylic sheet is produced in two common standard forms. These are cast Perspex and extruded Perspextx. Extruded Perspex tx is particularly suitable for vacuum forming whereas cast Perspex is more suited to fabrication processes. 1.3.3 Marking out The use of fine line permanent markers, chinagraph pencils, scribers and masking tape is recommended with normal marking out procedures. 1.3.4 Edge treatment Sanding Sanding discs and finishing machines can be used with care for trimming and smoothing very rough edges, but avoid overheating. Goggles and dust masks should always be worn when abrading any plastics materials. Abrasive paper A fine grade 'wet or dry' abrasive paper will produce a smooth surface suitable for polishing. Polishing The machined surfaces of acrylic may be brought to a high surface gloss by careful buffing or hand polishing with 'Perspex' polishes or conventional metal polishes. Usually an intermediate smoothing operation is required to avoid extended polishing times. * COSSH - Control of Substances Hazardous to Health 3 1.3.5 Cutting straight lines Scribe-breaking Acrylic up to 4.0 mm thick may be cut in a straight line by deeply scoring one surface with a sharp metal scribing knife, clamping the sheet with the scribed line uppermost and aligned with the edge of a bench, and breaking the sheet by pressing steadily downwards on the free part. A suitable blade is the Stanley Knife Scriber blade No. 5194. IF CUTTING LONG LENGTHS. CLAMP THE STRAIGHT EDGE DURING BREAKING. PRESS STEADILY DOWNWARDS. Scribe breaking acrylic Hand sawing When cutting irregular shapes, acrylic may be cut using a hacksaw or fretsaw provided they are sharp and have fine teeth. Coarse tooth saws and heavy pressures will cause chipping. Preferably clamp the acrylic close to the line of the cut when hand sawing to prevent cracking of the sheet. Power sawing Band saws and fretsaws can be used in production work but always ensure that the pitch of the teeth is less than the thickness of the material being cut. Material should not be forced through the saw. Strips of sellotape over the line of cut will help to dissipate heat produced by friction from the saw blade and prevent the saw cut from 'welding up' behind the blade. 4 1.3.6 Cementing Acrylic can be cemented to acrylic with 'Tensol' cements. 'Tensol' cements can also be used to cement acrylic to some non-acrylic materials. 'Tensol' adhesives The most useful 'Tensol' adhesives for joining acrylic are 'Tensol' Cement 12 - a solvent based adhesive and 'Tensol' Cement 70 - a polymerising adhesive. 'Tensol' Cement 12 is supplied ready for use. Care should be taken not to shake or drop the bottle, which might cause air bubbles in the liquid. (Ideally, 'Tensol' Cement 12 should be stored in a refrigerator with other similar chemical materials). 'Tensol' Cement 70 is a two part adhesive, prepared by mixing twenty parts of Component A to one part of Component B. The mixture should be stirred thoroughly and left to stand for a few minutes until any air bubbles have dispersed. The mixture must be used within 20 minutes of mixing. Room temperature must be above 15°C. 'Tensol' Cement 70 (A + B) should be stored in a cool dark place. At very low temperatures, crystals of component B may appear in the mixture. It is important that any crystals be dissolved before use. The film of 'Ten sol' is normally applied to one surface only. If there is a glossy surface and one which has been machined, the cement should be applied to the machined surface. When using 'Tensol' cement 70, always ensure excess cement is applied as the cement will shrink 20% during reaction. Only apply light pressure. Application Ensure all surfaces to be glued are perfectly clean and grease free. Assemble the joint when the cement has been in contact with the surface for about 30 seconds. If left for a longer period a skin will form over the cement which can prevent the joint from being bonded successfully. Care Current safety procedures should be followed at all times. Use 'Tensol' and other solvent cements in a well ventilated room, ideally equiped with appropriate fume extraction facilities, and away from sources of ignition. Other adhesives There are a range of adhesives available for joining plastics materials. Some have a permanent rubbery quality for use with flexible plastics and in joining plastics to other materials. There are also hot melt adhesives available which rely on heat to melt a plastics pellet or film to produce a join. Some adhesives rely on evaporation of a solvent while others involve the mixing of two liquids or pastes which then cure by chemical reaction. There are a range of commercial liquid solvent cements available for use with thermoplastics. Some solvent cements will work on several plastics (e.g. acrylic, ABS, butyrate, styrene) while others will only work on one particular plastic material. Reference should be made to manufacturers instructions and guidelines. Special dispensers and applicators are also available. Various Bostik, Epoxy Resin (Araldite) and Cyanoacrylate (Super Glues) preparations are suitable for joining plastics but their use is subject to safety legislation and current local authority regulations and practice. 5 Suggestions for cementing techniques WIRE PACKI TO ASSISTCAPILLARY ACTION: REMOVE BEFORE GEL STAGE. MASKING REMOVED AT GEL STAGE. ANGLE JOINT. USE PLENTY OF CEMENT. REINFORCING FILLET. Note - When using solvent cement to join two dissimilar plastics, the harder material should have its joint surface softened by applying a light coat of solvent prior to bringing the two surfaces together. 6 1.3.7 Machining The machining characteristics of acrylic sheet (cast or extruded) are similar to those of brass or hard aluminium, but there is one very important difference. This is that acrylic will start to deform if it is heated to temperatures in excess of 80°C. Therefore the heat generated by the cutting tool must be kept to a minimum. This will minimise any stress being produced in the machined area and reduce the possibility of causing any alteration to the machining characteristics of the material. Where possible, acrylic should always be machined with the polyethylene masking film left in place. NB. Acrylic is a notch sensitive (brittle) material and care must be taken to ensure that no notched areas are introduced during machining. Sharp cutting tools will help to avoid this. Cutting tools These must be kept sharp not only to produce a good surface finish but to minimise the amount of heat generated. Dri II ing Standard twist drills up to 5 mm are quite suitable for drilling acrylic, as also are many of the drills specially developed for plastics such as step drills and cone drills. It is recommended that standard twist drills above 5 mm be sharpened with a negative rake to prevent 'grabbing' during the drilling process. Always clamp the acrylic sheet firmly against a piece of wood or other soft material before drilling and never use a centre punch to mark the position of the hole, as this will crack the acrylic. Typical drilling speeds are shown in the table below: Dr ill Diameter (m m) Approximate Drill Speed (rev/min) 1 .5 7000 5.0 1800 12.0 900 Turning Acrylic can be turned to engineering tolerances on metal-working lathes and many of the techniques used for metal can be applied. Tool bits made from highspeed steel are preferable. Speeds and feeds are similar to those for brass. Milling Care must be taken when milling acrylic because cutter rotation is usually slower than for other machining operations. The feed and depth of cut should be matched to the cutter. 7 1.4 SIMPLE THERMOFORMING TECHNIQUES When acrylic cast sheet is heated to 150-170°C it becomes rubber-like and can be stretched into complicated shapes. After cooling to 90°C, or below, the acrylic will retain the shape imposed on it. If re-heating takes place the acrylic will return to its original flat sheet form. Cast acrylic sheet should not be heated to temperatures above 170°C as this will produce highly flammable, irritant fumes. When extruded acrylic sheet is heated to 140-150°C it behaves in a soft and rubberlike way. In this state it can be thermoformed in a similar manner to acrylic cast sheet. When the material is heated to 170-200°C it behaves in a thermoplastic manner and can be thermoformed into complex shapes using very little pressure. It is this characteristic which makes Perspex tx an excellent vacuum forming material. 1.4.1 Effect of moisture Extruded acrylic sheet materials will absorb moisture when exposed to a humid atmosphere. Absorbed moisture can seriously affect the thermoforming performance of acrylics and causes blisters of about 2-3 mm diameter to appear during heating. If this occurs the sheet can be dried out by 'heat soaking' at a temperature of 85-95°C for 24 hours (with the protective masking removed from both sides). When cool, the 'dried' sheet should be protected against any further moisture absorption by wrapping in polyethylene film. 1.4.2 Oven heating Heating is normally done in a small oven. Ideally an air circulated oven should be used. Heating times Thickness mm 2 2.5 3 4 5 6 in an air oven Heatlnc At 150°C At Perspex tx Times 160°C At min 12 13 14 16 18 21 min 16 17 19 22 25 28 for 170°C min 8 8 9 11 12 14 It is most important not to exceed these times because of material elongation in vertical ovens or shelf marking where the material is heated horizontally. 8 1.4.3 Single curvature thermoforming This means that, in general, the heated sheet is not stretched but allowed to bend or fold along a single axis. Drape forming For items with a shallow single curvature, the heated acrylic sheet is placed in a concave mould and allowed to settle under its own weight until it rests on the surface of the mould. For convex moulds - light pressure will be needed until the sheet is cool. Both methods are illustrated in the diagrams below. For convex moulds some pressure will be needed until sheet is cool. CLOTH FORMER. Simple Making a tube from acrylic drape forming sheet A suitable length of polyvinyl chloride (PVC) tube (e.g. plastic drain pipe) can be used as a mould to form a tube from flat acrylic sheet. The plastic pipe is cut longitudinally down one central axis to create two halves. These are then held together along one edge by use of a tape/cloth style hinge. One edge dimension of the acrylic sheet should be cut to match the internal circumference of the PVC tube when closed. The two halves of the PVC tube mould are laid open and the heated flexible acrylic sheet placed in position over them, taking care to match the correct edge of the acrylic with the curved circumference profile of the mould. The mould is then closed allowing the acrylic sheet to take on the shape of the internal curvature. The closed mould can be held in a simple jig as shown below until the acrylic cools down. Forming a cylindrical tube 9 from acrylic sheet Simple scrolling for letters or curves Simple jigs can be made to form scrolled curve shapes similar to wrought iron work. Strips of acrylic are cut to size, heated and formed around the jigs when flexible. An example of a simple arrangement is illustrated below. Acrylic Local strip formed into a scroll shape on a simple jig bending Angled bends along straight lines can be obtained by heating the acrylic locally on both sides using a strip heater. Simple jigs can be constructed to hold the acrylic in position during the cooling period as illustrated below. 'Perspex' heated locally along line of bend Acrylic shapes held in a simple 10 jig while cooling 1.4.4 Double curvature thermoforming This requires force to be applied to the sheet by using either air pressure, vacuum, a press with a male and female mould, or a combination of these techniques. The acrylic sheet has to be firmly clamped before stretching or shaping takes place. This should be done quickly to avoid undue loss of temperature after heating, which could cause excessively strained shapings. Toggle clamps are the most convenient for this process. It is advisable to heat the clamping frame to 60-70°C before positioning the acrylic sheet. Toggle clamp Free-blowing In this process heated acrylic sheet is shaped by use of direct air pressure or vacuum without the use of a mould. The outer edges of the acrylic sheet are held by a clamping ring and the heated sheet is then subjected to pressure or vacuum to create a natural bubble shape. The pressure or vacuum is set and the setting is maintained throughout the cooling period. Pressures of up to 10 N/cm2 are sufficient for most school work. A simple arrangement is illustrated below. Controlled heIght Heated 'Perspex' tnrnrnrnq lines Free Compressed blowing air an acrylic 11 bubble shape Simple press forming (plug and yoke) A simple male and female mould (plug and yoke) which can be constructed from Medium Density Fibre Board (MDF) is illustrated below. The heated acrylic sheet is sandwiched between the plug and yoke of the mould which are then forced together under pressure causing the acrylic to take on the shape of the mould. By placing the mould on the table of a pillar drill, the drill press can be used to apply the required force. Dowel location pins Constructed ~ from M.D.F. Simple plug and yoke arrangement 12 1.5 VACUUM FORMING A variety of related techniques are included in the description vacuum forming. Their common feature is the shaping of a hot sheet of thermoplastic material by removing the air from one side of the sheet and thus, in effect, 'sucking' it into or over a mould. Perspex tx is ideally suited to the technique of vacuum forming on machines which are designed for this purpose. Perspex tx can be formed with the clear protective masking in place on the upper surface of the sheet if required but any imperfections in the masking film such as cuts, holes and blisters may leave slight impressions on the surface of the sheet. 1.5.1 Equipment Machines used for commercial production are designed so that they will operate with the minimum of attention and for some specialised applications they have been designed to function completely automatically. Such complexity is not needed for school applications, and is indeed undesirable. Simple and relatively inexpensive machines suitable for school use are now available from manufacturers (see Appendix 6). A simple vacuum forming machine consists of 4 main parts: A A A A heater vacuum box clamping system for the thermoplastics vacuum system sheet The clamping system must hold the sheet firmly in place to form a vacuum tight seal with the box. A frame made from small-section angle iron, and held down with quick-acting clamps is usually used for the clamping system. The vacuum system must remove the air quickly from the vacuum box - this is more important than achieving a high vacuum. Thermoplastic sheet " Rubber seal Oamping frame---4~Clamp Mould Perforated mould support A typical vacuum former arrangement With a simple vacuum forming machine as described above articles can be formed using female or male moulds. 13 Working sequence: Thermoplastic clamped above the mould Heat applied to make the plastic pliable Soft Thermoplastic sucked into mould Vacuum formed sheet allowed to cool Plastic moulding removed from former 1.5.2 Vacuum release valve opened to withdraw air Vacuum release valve closed when plastic set Repeat the cycle Moulds Moulds for vacuum forming are simple to construct. Although for commercial production aluminium moulds are frequently used, wood, plaster, medium densityfibre board (MDF), and papier mache are suitable, and even clay has been used, but a mould must be designed carefully. Vents must be provided to ensure the rapid evacuation of all the air trapped between the mould and the material being formed. The vents may conveniently take the form of a series of small holes, about Irnm in diameter where they emerge from the working surface, drilled in the lowest part of the mould and in any local depressions or cavities within the mould area. These small holes should be counter bored to about 6 mm in diameter for the greater part of their length (from the back of the mould to within about 3 mm of the mould face), and connect with the holes in the mould support. ~. ;I ~ /: Air passages Typical :: . Bottom of mould rebated or resting on thin 'spacers' to allow air passage mould features It is important to allow some degree of taper on the vertical faces of a mould in order to allow for shrinkage of the material as it sets and to enable the moulding to be removed from the mould. Recommended tapers are 0.50 to 10 for female moulds and 2-100 for male moulds, depending on the depth of draw (i.e. the distance from the plane of the clamping frame to the deepest part of the mould) and on the material being used. All internal and external corners of moulds should be radiused (rounded) and the surface made as smooth as possible, to reduce the risk of imperfections being transmitted through the thickness of the sheet. Marks on moulds can spoil the appearance of the finished article, particularly when clear sheet is used. Good separation can be achieved by use of a release agent such as talcum powder. 14 The distribution of material thickness in articles which are vacuum formed differs according to whether a male or female mould has been used. This is illustrated in the diagrams below: .,-. b I \~ .1 Typical material ., 1f cl material Heating I r \ Thickness a a b c d e f g at: - 1.02 1.02 0.65 0.50 0.50 0.65 mm mm mm mm mm mm mould female • - 1.27 0.65 0.25 0.40 0.50 1.27 1.27 mm mm mm mm mm mm mm a male from distribution thickness a b c d e f at: from distribution thickness IV dl Typical 1.5.3 fl If ••• Thickness mould times Heating times will depend on individual circumstances. In average conditions a time of 20 seconds per millimetre of thickness can be used as a guide for clear sheet; for opals 10% longer should be allowed. Comparison of the vacuum forming of extruded and cast acrylic Heating time (seconds) Approximate surface temperature (OC) 100 210 90 Perspex tx (extruded) 3 mm Clear performances sheet Standard Perspex (cast) 3 mm Clear Surface degradation 200 Maximum heating timet definition Good definition 80 185 Good definition Maximum definition obtainable with standard Perspex 70 170 Good definition Fall-off 60 160 Slight fall-off 50 140 Continued 40 120 Definition equal to that of standard Perspex at 80 seconds in definition fall-off Surface degradation in definition Continued fall-off in definition Too cold Too cold These results were achieved on a laboratory vacuum forming machine with a lower rate of heating than the average quoted earlier. 15 1.5.4 Cooling times The cooling time for extruded acrylic sheet is more critical than its heating time. The exact time is dependent on mould temperature, sheet thickness, ambient temperature and type of forced air cooling (if employed). Cooling times can be expected to be fairly short, i.e. less than 60 seconds for 3 mm thick sheet under average conditions. Extended cooling will allow the material to shrink back on to the mould to a point where the forming will crack from a weak spot or notch sensitive area. If not cooled for long enough, the forming will distort. Ideal conditions must be found by trial and error. It is preferable to remove thermoformings from the mould while they are still hot (surface temperature 95°C) as this procedure eliminates most of the locked-in stress which can cause stress-cracking to develop in service. Always wear protective gloves when doing this. 16 1.6 FLUID BED COATING Fabricated metal articles can be covered with a thermoplastics polyethylene) by use ofa fluidised bed of powder. coating (eg The construction of a fluidised bed is illustrated below. Air at low pressure is passed through the porous base of a container into which the thermoplastics powder has been placed. Care should be taken to use a sufficient quantity of thermoplastic material in order to achieve steady fluidisation without 'boiling' of the powder. The metal article to be coated is first cleaned of oil and grease, and then heated in an oven, before being plunged in to the fluidised bed. Some powder will fuse and stick to the hot metal; the coated article is then removed from the bed and returned to the oven to completely fuse the coating. The temperature to which the article needs to be heated before coating will depend on the thermal capacity of the article. A thin wire construction, for example, will require a higher temperature than will a solid rod of steel. When low density polyethylene is used for the coating, a temperature of about 180°C is suitable for most articles. Temperatures above this may result in degradation of the polymer, producing harmful fumes. --1------ Fluidised bed Porous base Air in Typical fluidised 17 bed arrangement SECTION INDUSTRIAL 2 BASED PROCESSES 2.1 PROCESSING METHODS 2.1.1 Extrusion Products • drain pipe and guttering • window frames and curtain rails • roofing sheet • plastic hose • wire insulation • flat sheet can also be made by extrusion. Containers and bottles can be produced from extruded tube by a blowing process. Process Extrusion is a method of moulding thermoplastic material into continuous lengths of profiles. These may be solid or hollow. Pipe and tube are examples of the latter. In extrusion, a thermoplastic in the form of granules is fed from a hopper into an extrusion machine. The material is softened under the action of heat and pressure and then extruded to the required form (e.g. window frame profiles) from a die fixed to the nozzle of the machine. This method can be used to produce all types of polyvinyl chloride (PVC), polyethylene (PE) and polypropylene (PP) thermoplastic pipe and tube. Various shapes and sizes of extrusion can be produced using different dies. Two exam ples are shown below: tube/pipe Two typical extrusion shapes Large screw forces heated plastic along the chamber and through the die extrusion Hopper containing plastics granules / Cooled chamber base interchangeable steel die Spool for flexible extrusions A typical extruder 18 arrangement electric motor 2.1.2 Balloon blowing Products • dustbin liners and carrier bags • more luxurious uses where attractive tinting or surface finish is involved Polythene films will, after suitable treatment, take printing inks and this allows information about a polythene-wrapped product to be printed on the pack. Process In balloon blowing, a plastic melt is extruded and then a different die and air blower are used to produce a balloon of plastic which can be nipped or pressed into a double film called layflat tubing. This can be made into bags by cutting the material into lengths and heat sealing one end. A gusseting device is sometimes used to fold a triangular section along the sides of the layflat tubing so that when it is made into bags the gusset can open to increase the volume inside the bag. Balloon extrusion is very rapid and the film produced can range in thickness from 2 mm to 0.1 mm. gusseting device wind-up _ guide board layflat tubing with gussets layflat tubing without gussets plastic balloon compressed air supply Typical balloon extrusion system The air ring at the base of the balloon serves to cool the molten plastics material 19 2.1.3 Calendering Products • protective sheet • shower curtains • stretch wrap film Process Suitable thermoplastic compositions are passed through heated metal rollers with progressively smaller gaps to produce continuous film and precision thin sheet. This method is used to produce polyvinyl chloride (PVC) flexible film in widths of up to 4 metres, and thin PVC and polystyrene (PS) rigid foils for use in thermoforming processes or making sheet material. Embossing techniques can also be incorporated into the rolling process. Hopper Extruder Compressor Wind up Cooling jets of compressed air A typical calender 20 system 2.1.4 Injection moulding Products • buckets and washing up bowls • agricultural produce boxes - high density polyethylene (HDPE) and polypropylene (PP) • growing pots - polystyrene (PS) • TV and hi-fi cabinets - high impact polystyrene • telephones and gear wheels Process Injection moulding is probably the most widely used process for making thermoplastic items in large numbers. However, it is not economic for making small numbers of a particular moulding because of the initial set-up costs and expense involved in producing the moulds for the machine. With injection moulding, thermoplastic material (in granular form) is fed from a hopper into the heated barrel of the machine. The barrel contains a revolving screw which carries the granules along to where they are softened to a liquid state. The molten thermoplastic is then forced under high pressure through a small nozzle into a split mould where the material rapidly solidifies, taking on the shape of the mould. When the material is set, the mould is opened and the moulding ejected. Sophisticated complex moulds can be pre-heated by built in systems to assist material flow prior to cooling. Injection moulding is suitable for moulding all thermoplastics and a wide variety of domestic and agricultural items are produced by this method. Hopper Thermoplastic pellets Mould o o 000000 Controls A typical injection 21 o 0 moulding machine 2.1.5 Thermoforming by pressure Products - thin -walled growing trays and seed boxes -Tight-weight disposable trays - corrugated polyvinyl chloride (PVC) sheet for growing frames Process The process of thermoforming consists of heating a thermoplastic foil or sheet (usually polystyrene or PVC) until it is soft, then placing it over a former or mould onto which it is pressed mechanically into shape. The sheet takes on the shape of the former or mould and on cooling sets to the shape. The cooled shape is then removed and excess material trimmed off. This is a fairly simple process for speed in mass production where precision is not too critical. \,-_~r I Moulding Mould The pressure thermoforming 22 process 2.1.6 by Thermoforming vacuum Products • yoghurt pots and vending machine cups • point-of-sale display • fridge linings • equipment housings Process In this process, plastic sheet is heated until it is soft and then sucked into a mould or former by withdrawing air from the mould cavity, thus creating a vacuum. To assist the forming process, the mould table is sometimes raised, pressing the mould lightly into the softened plastic sheet just before activating the vacuum. Moulds and formers can be male or female for this process. Slide to p!ace heater .. . Heater ;fJ over thermoplastic sheet omoT06 000 0 olOo0ID00OO"OOIDm "'-------111-: Vent holes Evacuation Vacuum Pump Tank A vacuum forming machine 23 arrangement 2.1.7 Biaxial Product stretching of film • polypropylene (PP) and polyester (PE) films Process Biaxial stretching is the process of stretching semi-molten film in two directions (normally on two axis at 90° to each other) as it leaves the heated die of an extruder. ~ •• ~.... ~.... ~.... ~.... ~.... ~.... ~.... ~.... ~" ~. ~ ~.,~........ ~ ~.... ~,HOT,~.... ~.... ~~ ~~.... ~ ~"FILM'~.... ~.... , .... ,, ~, .... ~.... ~.... ~.... ~.... ~.... ~.... ~.... ~.... ~.... ~.... ~.... ~.... ~.... "" ~ Biaxially •• •• ~ stretching polymer film In the case of polypropylene and polyester films, crystallisation occurs on stretching, increasing the mechanical strength of the material and decreasing the water vapour permeability. One production method for biaxially stretched polyester film is illustrated below. extrusion chilling of extrudate setting of film using heat stretching across width using heat coiled film A typical production system for biaxially stretched film The molten plastic is extruded through the slit of a metal die, producing a hot molten ribbon of film. The hot ribbon then drops on to a chilled metal roller to solidify it and pull it away from the die. The cooled ribon of film then passes through an oven where it is reheated and stretched first along its length and then across its width (biaxial stretching). The film is then held in the stretched condition and allowed to cool (set) before being wound into large rolls for despatch to the customer. 24 2.1.8 Glass Reinforced Plastics (GRP) Lay-up and Moulding Products • canoes • boat and car bodies • chemical plant • architectural claddings Process (GRP lay-up) The lay-up technique for Glass Reinforced Plastics (GRP) involves a comparatively simple profile mould of metal, wood or plaster and the following processes: 1. Liquid polyester resin, mixed with a catalyst (or hardener), is applied to the mould to form a pre-gelled coat. 2. Glass fibre in mat or woven fabric form is laid on the first gelcoat and liquid polyester resin/catalyst mix is sprayed on until the fibre layer is saturated. 3. When the resin mix has hardened, the moulding is removed from the mould. Curing (setting) can take place in the cold or can be speeded up by heating. Glass fibra \~... I I PregeJled ['t:::~.J1--.... Lay-up /resin coat technique for Glass Fibres __ Catalysed Resin __ Moulding GRP DETAIL OF SPRAYGUN GRP LAY-UP TECHNIQUE Accelerated Resin _ Spraygun --. Separate spraygun nozzles Roller for compacting GRP fibre glass rovings Pressurised resin tank of male mould Catalysed resin Mobile trolley Automatic fibre dispenser 25 and resin spraygun Process (GRP moulding) Two other technique used with Glass Reinforced Plastics (GRP) are the rubber-bag and matched-die moulding methods in which pressure is applied to the top surface of the moulding during processing. Various compositions of polyester resin/catalyst/glass fibre are used to produce mouldings in both these pressurised processes. By heating, comparatively fast hardening of the resin is possible. The two methods are illustrated below. Air-tight seal / inflated with air Uncured GRP layup Pressure bag method of moulding GRP Dowel Pins to Pad regulating moulding thickness locate male and female mould halves 1 \ Mould Cavity in which GRP is placed Matched mould method 26 for GRP 2.1.9 Plastic laminates Products • decorative work top surfaces Process Decorative thermosetting plastic laminates have become commonly known as 'Formica', 'Warerite', 'Arborite', etc. but these are just trade names belonging to products of individual companies. The dark underside of the laminate consists of layers of brown paper impregnated with a thermosetting resin, phenol-formaldehyde (PF). The outer surface of the laminate consists of a decorative paper bonded to the underlayer of phenol-formaldehyde resin. This decorative paper is covered with a thin paper skin impregnated with melamine-formaldehyde resin (MF) and bonded to the underlayers using heat and pressure in a hydraulic press. The process of producing thermosetting decorative laminate is illustrated below. hot air paper impregnated paper I a) Paper impregnation MF ( --------resin impregnated _thin -- resin i::'egnated J-- ========::::1 _ ( overlay paper decorative printed paper heavy white underlay paper brown base papers b) Impregnated paper assembly ~~~~--..:rrr:--..=== stripping plates from laminate cut impregnated paper assembly decorative laminate pressing c} Pressing and finishing Thermosetting decorative laminate making The paper sheets are impregnated with a liquid thermosetting resin. These sheets are then dried, laid up in a loose stack and pressed between specially surfaced metal sheets in a multi-platen press under conditions of high pressure and temperature (1000 N/cm2and 150°C). Under these conditions, the resin flows between the sheets and cures (hardens) to give the final laminate. 27 2.1.10 Compression moulding Products • 'hard' electrical plugs and sockets • fuse boxes • lamp holders • saucepan handles • insulators Process Compression moulding is used mainly to process thermosetting plastics. The correct amount of plastics material, usually in powder form, is measured into a two part matched die mould. The mould is closed under pressure and heated, causing the material to soften and flow into the shape of the mould before setting hard. Moulding powders for use in compression moulding are made up from various blends of resins with cellulose and mineral fillers. The traditional thermosetting resins are ureaformaldehyde (UF), melamine-formaldehyde (MF) and phenol-formaldehyde (PF). The press for compression moulding has a central ram which applies force hydraulically to a heated mould. ~- __ +---:...' THERMOSETTING POWDER IN THE MOULD PRESS HYDRAULIC ELECTRIC MOTOR PUMP A typical compression 28 moulding system 2.1.11 Rotational moulding Products • litter bins and dustbins • storage tanks (water, etc.) • traffic bollards Process Rotational moulding is used to make large hollow articles (e.g. containers) usually in low density polyethylene (LDPE). The LDPE material in powder form is fed into a hollow sheet metal mould in the shape of the item to be produced. The mould is then heated whilst rotating about two axes so that the plastic melts and flows to form a skin over the inner surface of the mould. The mould is then cooled, opened and the hollow moulding removed. For open-top tanks (e.g. water cisterns) simple large hollow mouldings may be cut in half to provide two such products. For closed tanks (e.g. liquid fertiliser spray equipment) pipe inlets and valves can be fitted after moulding. Rotator arm ~ Remove moulding ~ Mould with molten plastic adhering to all Mould filled with thermoplastic powder (PVC/polythene) then heated by gas flame whilst rotating inside surfaces is taken from gas flame and cooled by water jet whilst rotating moulding Rotational 29 2.1.12 Extrusion blow moulding Products • bottles • drums • car fuel tanks • heater ducting Process A length of hot plastic tube is first produced by extrusion and then lowered into an open two part hollow mould of the final product shape. The mould is then closed and sealed so that the tube can be inflated, to take on the internal shape of the mould, using compressed air. When cool, the mould is opened and the product removed. Precision hollow mouldings can be produced by this method. The cycle for blow moulding a bottle shape is illustrated below. extruder knife Plastics bottles of all shapes and sizes can be made in this way. ~:~ screw make a continuous tube. turns all <h. time to hot plastics parison or When the length of tube is correct. it is surrounded by the mould and cut oH with a knife attached to the machine. With the moulding removed. the mould is now ready for another cycl •. air blower Blow moulding sequence 30 of operations 2.1.13 Injection stretch blow moulding Products • fizzy drink bottles - carbonated soft drinks (C.S.D.) • jars and non carbonated bottles • toiletries and cosmetics containers The average 'fizzy drink' bottle contains a liquid pressurised to 14 atmospheres by carbon dioxide. Polyethylene terephthalate (PET) has a sufficiently low permeability to prevent carbon dioxide seeping through it and this makes it a suitable plastics material for fizzy drink bottles. The strength of PET can be improved by the process of biorientation during production of the container (bottle) in a similar manner to principle of biaxial stretching of polymer film (see p24). This produces containers with improved stacking strength and resistance to stress-cracking, which will also withstand the pressure of normal gaseous drinks. The design of fizzy drink bottles also makes maximum use of designs for pressurized containers in that they are curved on as many areas as possible, including the base. Most bases are now of the petaloid design (see diagram on adjacent page). Process The method of blow moulding bottles for gaseous contents is mostly a two part process in order to incorporate the biorientation of the material mentioned above. The first stage is to produce a hollow cylinder, domed at one end, by injection moulding. This shape is known as a 'parison'. The parison is then removed from the injection moulder, re-heated to make sure it is pliable enough and transferred to a bottle mould for the second stage of blow moulding in to the final shape. The second stage causes the material to be stretched (oriented) in two directions at right angles to each .other (axial along the length of the cylinder and diametral across its diameter) thus giving the required strength properties. Stage 1 mould clamping and opening mechanism plastic moulding pallets mould Injection Parison moulding ready to for 31 produce blow parisons moulding Stage 2 Mould open with PET parison in position ready for blow moulding into bottle shape The pets/aid design with Mould closed blown bottle completed ready for removal of most pop bottle 32 bases 2.1.14 Dip moulding Products • protective gloves • balloons • handle grips Process Temperature controlled mandrels of the product shape are dipped into a bath of plastic paste or fluidised powder. The paste/powder softens and forms a skin around the mandrel shape which when cool can be peeled off. Alternatively, products of other materials (e.g. metals) can be dipped and the plastic material then forms a fixed durable coating on the outer surface of the product. Coated mandrel after dipping Glove mandrel to be dipped Producing rubber gloves 33 by dip moulding 2.1.15 Structural polyurethane (PU) foam moulding Products • computer housings • tool handles • casings/cabinets • furniture shells • decorative simulated wood effects for wall panelling Process A two part pre-mix of polyurethane foam is poured rapidly into a split cavity mould. The chemical reaction of the mix causes the foam to expand rapidly and take on the cavity form of the mould. The foam sets within a few minutes to produce strong, lightweight mouldings. A development of this process is used to make integrally skinned PU foams; a combination of a foam interior with a hard solid skin or surface which can be finished with lacquers. Two part mix into mould :-...~---- Mix expands into shape of mould Compression moulding 34 process Split cavity mould APPENDICES Appendix 1 THERMO PLASTICS ACRYLICS PMMA Perspex Acrylonitrile Butadiene Styrene ABS APPLICATIONS PROPERTIES Rigid. glass-clear. glossy. extremely weather resistant. excellent for vacuum forming. casting and fabricattng Rigid opague, glossy/textured. tough. colourful. excellent for injection moulding and thermoforming Signs. lenses. inspection windows. taillight lenses. synthetic fibres. lighting diffusers. leaflet dispensers. hi-f dust covers Telephone handsets. rigid luggage. domestic appliance housings (food mixers). margarine tubs. car facia panels Rigid. transparent. tough (even at low temperatures. low electrostatic pick up. easily injection moulded. relatively low coat Flexible (rubbery). transparent. glossy. excellent low temperature flexibility (-70°C). good chemical resistance. high friction coefficient Semi rigid. translucent. exceptional anti stick/low friction characteristics. superior chemical resistance. impervious to fungi or bacteria. high temperature stability (260°C). low temperature toughness (-160°C) Rigid. translucent. tough. hard wearing. fatigue and creep resistant. resistant to fuels. oils. fats and most solvents. steam steriltzable Spectacle frames. toothbrushes: tool handles. transparent wrapping. metaltzed parts (reflectors etc) pen barrels. typewriter keys Teats. inflatable toys. handle grips. flexible tubing. record turntable mats. ice cube trays. beer tubing. vacuum cleaner hose. freezer doors Non-stick coatings. gaskets. packings. bearings. high and low temperature electrical and medical applications Cyclolac Cellulosics CA. CAB. CAP. CN Cellophane Ethylene Vinyl Acetate EVA Fluoroplastics PlFE. FEP Teflon Nylons PA (Polyamides) Maranyl. Zytel Polyacetals POM Delinn, Kemetal Polycarbonate PC Lexan, Makrolon Polyesters (Thermoplastic) PETP. PBTP. (PETj Rigid. translucent. very tough. spring-like qualities. good stress relaxation resistance. good friction and wear and electrical properties Rigid. transparent. outstanding impact resistance (to -150°C) and weather resistance. good dimensional stability. very good dielectric properties Rigid. clear. extremely tough. good creep and fatigue resistance. wide range temperature resistance (-40° to 200°C) Melinex. Terqlene, Dacron Polybutylene PB Polyethylene (HIgh Density) HDPE. HMWPE Rfgidex Polyethylene (Low Density) LDPE. LLDPE Alkathene Polypropylene PP.OPP Propathene Polystyrene (General Purpose) GPPS Polystyrene (HIgh impact) HIPS Polysulphone (family) PES. PEEK. Udel, Victrex Polyphenylene PPO Oxide Noryl Styrene-Acrylonitrile San Polyvinyl Chlorlde PBC Polymethylpentene PMP TPX Polyurethane (thermoplastic) PUR(PU) Semi rigid. translucent. tough. chemical and heat resistant. good barrier properties. environmental and mechanical stress crack resistant. good electrical insulation Semi rigid. translucent. very tough. high impact resistance. weatherproof. excellent chemical resistance. low water absorption. non-toxic. easy processtng bv most methods. low cost Flexible. translucent/waxy. durable. weatherproof. good low temperature toughness (to -60°C). easy to process by most methods. low cost. excellent chemical resistance Semi rigid. translucent (Integral hinge property). excellent chemical resistance. extremely tough. exceptional fatigue resistance. steam steriltzable. high surface gloss/texture Brittle/hard. metallic transparent/opague, glossy. low cost. unsuitable for outdoor use. excellent X-ray resistance. free from odour and taste. easy processing Hard/rigid. opague/translucent. satin surface finish. impact strength up to 7 x GPPS. other properties similar Outstanding oxidative stability at high temperature (-200°C to +300°C) transparent/opaque. rigid/flexible. high cost. specialised processtna Rigid. opague, glossy. outstanding dimensional stability (particularly under stress at high temperature and humidity conditions). difficult to process (blended to ease injection mouldtngl Rigid. transparent. tough. resistant to oils and greases. resistant to stress cracking and crazing. good processability Rigid/flexible. clear/opague, durable. weatherproof. non flammable. good impact strength. excellent electrical insulation properties. limited low temperature performance Rigid. clear. tough. lightweight (density 0.83 gm/em 3). chemical resistant. additives required for outdoor use Flexible. clear. elastic. wear resistant Impermeable 35 Gear wheels. bushings. zips. pressure tubing. synthetic fibres. bearings (particularly for food processing machinery). curtain runners. carburettor parts Business m/c parts. small pressure vessels. aerosol valves. coil formers. clock and watch parts. nuclear engtneering components Crash helmet visors. riot shields. vandal-proof glazing. baby feeding bottles. safety helmets. greenhouse double glazing. miners' phones and battery cases. film/slide casettes Carbonated drink bottles. business m/c parts. synthetic fibres. parts for 1V tuners and transformers. fire alarm parts. coffee makers and toasters Boil-in-bag food packaging films. industrial pipes. high temperature tubing (500 psi @ 85°C). central heating systems Chemical drums. jerricans, carboys. quality kitchen ware. collanders, bins. toys. picnic ware. household and hospital ware. cable insulation Squeeze bottles. toys. wrapping films. utility kitchen ware. carrier bags. high frequency insulation. garment bags. chemical tank linings Sterilizable laboratory and hospital ware. containers and snap fit closures ropes. moulded hinges. packaging film. car accelerator pedals. heater ducting. door handles. washing m/c parts. suitcases. electric kettles. children's plates Toys and novelties rigid packaging. refrigerator trays and boxes. cosmetic packs and costume jewellery. ligh ting diffusers Yoghurt pots. refrigerator linings. vending cups. kitchen and bathroom cabinets. toilet seats and tanks. closures. instrument control knobs. radio and 1V cabinets High/low temperature. high technology. e.g. microwave grills. chemotherapy devices. electro/cryo surgical tools. radornes, fuel cells. aerospace batteries. nuclear reactor components Business m/c and 1V housings. automotive instrument casings. coffee pot and washing machine parts (where high temperature and moisture critical) replacement for die castings Drinking tumblers. ht-fl covers. lenses. water jugs and toothbrush handles. kitchen and picnic ware Drainpipes and guttering and roofing sheets. cable and wire insulation. floortng/hoseptpe, stationery covers. fashion footwear. "cling film" "imitation leather" fabrics Laboratory ware. syringes. lamp covers (good heat resistance) radar and microwave applications. encapsulation. printed circuit boards. microwaveable. food packa~n~ Soles and heels for sports shoes. football boots. hammer heads. seals. gaskets. Ovrtngs, rollers. skate board wheels. synthetic leather fabrics. silent running gears and sprockets for office machines Appendix 2 THERMOSETS Phenolics PF Bakelite Epoxies EP Ara/dite Polyurethanes (cast elastomers) PUR Polyesters (unsaturated) SMC, DMC, GRP (when reinforced) Alkyds NVC Allylics DAP, DAIP, ADC Polyamidesl Aramids PI Kev/ar Aminos (Melaminesl Ureas) MF, UF Furan Vinyl Esters PROPERTIES Brittle, opaque, excellent electrical and heat resistance, outstanding resistance to deformation under load, low cost Rigid, clear, very tough, chemical resistant, excellent adhesion properties, high resistance to cracking, low curing shrinkage Elastic abrasion and chemical resistant, impervious to gases, can be produced in wide range of hardnesses Rigid, clear/opaque, tough, chemical resistant, fire resistant, high strength, low creep, good electrical properties and low temperature impact resistance, low cost Rigid, opaque, tough, heat resistant, excellent arc and tracking resistance, excellent long term dimensional stability, fungus resistant, good colour stability Hard, transparent, exceptional abrasion resistance and electrical insulation properties (even under humid conditions), outstanding combination of mechanical/ chemical properties Rigid, opaque, high strength, exceptional thermal and electrical properties (up to 480°C), excellent dry bearing properties when filled with PTFE, excellent resistance to ionizing radiation, high cost Rigid, opaque, tough, very hard and scratch resistant, self extinguishing, free from taste and odour, wide colour range Rigid, opaque, high strength at elevated temperatures, excellent chemical resistance, self extinguishing, low smoke emission, resistant to carbon disulphide Rigid, translucent, good corrosion resistance, low viscosity 36 APPLICATIONS Ashtrays, fuseboxes, lampholders, bottle closures, saucepan handles, toilet seats, thrust washers Adhesives, coatings, embedding, potting, electrical components, chemical pump components, cardiac pacemakers Printing and industrial rollers, solid tyres, die pads, wheels, shoe heels (particularly suited to low quantity production runs) car bumpers Boat hulls, building panels, car bodies, lorry cabs, tanks and ducting, compressor housings, also embedding and coatings Automotive distributor caps, circuit breakers, switch gear, coloured appliance housings Optical coatings, face shields, sealants for metal castings, critical long-term high reliability electrical applications (e.g. radomes) Aerospace components, reinforcing fibres, high temperature resistant foams chemical filters, arc welding torches Decorative laminates, clock cases, lighting fixtures, dinnerware, heavy duty electrical equipment, also adhesives, bonding and laminating resins, and surface coatings Chemical plant (competitive with stainless steel), laboratory floors, foundry cases and moulds, specialised insulating foam Chemical tanks, ducts, piping, process equipment (particularly in corrosive chemical environments) Appendix 3 PHYSICAL THERMOPLASTICS Acrylics PMMA Perspex, Oroglas Butadiene Acrylonitrile Styrene ASS Cyclolac, Lustran, Novodur Cellulosics CA, CAB, CAP, CN Cellophane, Dexel Acetate Vinyl Ethylene EVA Fluoropla stics PTFE,FEB Tef/on, Kvner Nylons PA (Polyamides) Maranyl, Zytel Polyacetals FUJI Delrin, Kematal Polycarbonate Fe Lexan, Makrolon (Thermoplastic) Polyesters PETP, PBTP (PET) Melinar Polybutylene PB Polyethylene Density) (High HDPE, HMWPE Rialdex Polyethylene Density) (Low LDPE, LLDPE No vex Polypropylene PP,OPP Propathene, Hostalen PP, AJ)J)ryl (General Polystyrene Purpose) GPPS (High Impact) Polystyrene HIPS (family) Polysulphone PES,PEEK Udel, Victrex Sulphide Polyphenylene PPS Ryton, SUJ)ec Oxide Polyphenylene PPO Norvl, Pre vex Sty re ne- Ac ry I on i tri I e SAN Lustran A, Luran, Tyril Chloride Polyvinyl PVC Hostalit PROPERTIES Linear Coefficient of Expansion per °C x 106 Maximum use Temp °C Density g/cm3 1.5-3.0 60-90 70-80 1.18 1,8-2.9 14-55 65-90 75-95 1.04-1.07 0.5-4.0 2.0-60 80-180 45-70 1.15-1.35 0.05-0.2 no break 160-200 55-65 0.926-0.950 0.35-0.7 13-no break 120 205-280 1.17 2.0-3.4 4.0-5.0 70 80-110 1.13 3.4 5.5-12 110 80 1.41 2.4 15-80 70 130 1.20 2.5 1.5-3.5 65 70 1.36 0.24 no break 130 N/A 0.91 0.60-1.3 3.0-nobreak 100 80 0.944-0.965 0.2-0.4 no break 100-220 65 0.917-0.930 0.95-1.30 5-20 70-95 80 0.902 2.3-3.35 2.0-2.5 80 65-85 1.05 2.2-2.7 10-20 80 60-80 1.03-1.06 2.1-2.4 60-no break 20-65 160 1.13-1.17 0.5 <2.5 50 240 1.30 2.1-2.5 20-25 60-70 110 1.06 3.4-3.9 2.5-3.0 75 85 1.07 2.6 2.0-45 80 60 1.38 Tensile Modulus N/mm2 Impact Strength kJ/m2 2.9-3.3 37 Appendix 4 THERMOPLASTICS Acrylics PMMA Perspex, Drog/as Acrylonitrile Butadiene Styrene ABS Cyelolae, Lustran, Novodur Cellulosics CA, CAB, CAP, CN Cellophane, Dexel Ethylene Vinyl Acetate EVA Fluoroplastics PTFE,FEB Teflon, Kynar Nylons PA (Polyamides) Maranyl, Zyte! Polyacetals FG\1 Delrin, Kematal Polycarbonate Fe Lexan, Makr%n (Thermoplastic) Polyesters PETP, PBTP (PET) Melinar Polybutylene A3 Polyethylene (High Density) HOPE, HMWPE Rigidex Polyethylene (Low Density) LOPE, LLOPE No vex Polypropylene PP,OPP Propathene, Hostalen PP, Appryl (General Polystyrene Purpose) GJPS (High Impact) Polystyrene HIPS (family) Polysulphone PES, PEEK Udel, Vietrex Sulphide Polyphenylene PPS Ryton, Supee Polyphenylene Oxide PPO Noryl, Pre vex Styren e-Acry 10 n i tri Ie SAN Lustran A, Luran, Tyril Chloride Polyvinyl PVC Hostalit v - Variable RESISTANCE TO CHEMICALS Dilute Acids Dilute Alkalis Oils and Greases Aliphatic Hydrocarbons Aromatic Hydrocarbons Halogenated Hydrocarbons Alcohols vg vg vg m p p vg vg vg vg m p p p/v m p vg vg p p p vg vg 9 vg P P vg vg vg vg vg vg p/v vg p 9 vg vg vg g/v p p vg g/v vg 9I P vg 9 9 vg m P p N/A vg m vg vg p p vg vg vg N/A N/A P P N/A vg vg m Iv p m Iv m Iv vg vg vg m Iv p P P vg vg vg m Iv p P P vg g/v vg m Iv vg P p m Iv m vg m vg p p p/v vg vg vg m Iv p P vg vg vg vg vg vg vg N/A vg vg vg m p p m/v vg vg vg m p p m Iv vg vg vg p m Iv g/v vg - Very Good g/v 9 - Good 38 m - Moderate V p - Poor Appendix 5 SUMMARY PROCESS OF MAIN INDUSTRIAL COMMON MATERIALS APPLICATION BLOW MOULDING LOPE PET PVC INJECTION MOULDING Nylon ABS/PS HDPE/PP, Bottles Drums Car fuel tanks Heater ducting Buckets Telephones and Gears TV & Hi-fi cabinets ROTATIONAL MOULDING LOPE PVC Litter bins Storage tanks Traffic bollards EXTRUSION Nylon HDPE/PP L1)PE PVC Drain pipe/Guttering HoselWire insulation Roofing sheet Window frame COMPRESSION MOULDING Epoxy Phenolics VACUUM FORMING Acrylic PS DIP MOULDING L1)PE PVC CALENDERING L1)PE PVC PS GAP LAMINATING Epoxy Polyester resin STRUCTURAL FOAM MOULDING (PU) PS PU BAUOON BLOWING L1)PE HOPE THERMOFORMING BY PRESSURE BIAXIAL STRETCHED FILM PLASTIC LAMINATE Fuse boxeslInsulators Lamp holders Saucepan handles Yoghurt pots Vending cups Fridge linings+housings Point of sale display Protective gloves Balloons Handle grips Protective sheet Shower curtains Stretch wrap film Boats/Car bodies Chemical plant Architectural claddings Computer housings Casings Tool handles Simulated wood effect Dustbin bags Carrier bags Luxury applications with attractive finishes PP/PS Polyester Growing trays Seed boxes Disposable trays Corrugated PVC sheet Polypropylene film Polyester film PF/MF resins Decorative work top surfaces (e.g. Formica) Acrylic ABS/PVC PS PET - Polyethylene terephthalate PF - Phenol-formaldehyde ABS - Acrylonitrile butadiene styrene PROCESSES DESCRIPTION A hot thermoplastic tube is inflated by compressed air into a cooled, split-cavity mould to produce a precision hollow moulding. Molten plastic is injected under high pressure into a cooled, split mould to produce a high precision moulding. Thermoplastic powder is tumbled, heated and cooled in a split, hollow mould to produce simple shaped, hollow mouldings Molten thermoplastic is extruded under high pressure through a shaped die to produce a continuous precision section Thermosetting plastic powder is compressed and heated in a matched dieset to mould a precision product Thermoplastic sheet is heated and forced under vacuum into contact with a cooled form-mould to produce simple shaped mouldings Temperature controlled mandrels are dipped into a bath of plastic paste or fluidised powder to produce a peelable skin (or durable coating) Hot thermoplastic is passed through a series of temperature controlled rolls with progressively smaller gaps to produce continuous, precision thin sheet (also embossed if required) Layers of glass fibre matt are laid-up and wetted with a thermosetting resin into a simple mould form to produce large, strong structural mouldings A two-part premix is introduced into a split cavity mould where it expands to produce strong, lightweight mouldings An extruded plastic melt is passed through a die and air blown into a long balloon of plastic film. This is pressed into double film, cut and heat sealed at one end to make bags. A thermoplastic foil or sheet is heated until soft and then mechanically pressed into a former or mould to produce the product shape. Semi-molten film is stretched along two axes at 90° to one another to increase the mechanical strength. Brown paper sheets are impregnated with resin and laid up in a multi-platen press. Pressure and heat are then applied to produce the final laminate. PP - Polypropylene PU - Polyurethane MF - Melamine-formaldehyde PS - Polystyrene LOPE/HOPE - Low/High density polyethylene 39 Appendlxs EQUIPMENT AND MATERIAL SUPPLIES Equipment Brochures/catalogues following: of equipment for schools plastics work can be obtained from the C R Clarke & Company (UK) Ltd Unit 3 Betws Industrial Park Foundry Road Ammanford Dyfed SA182LS Formech Vacuum Forming 72 West End Road High Wycombe Bucks HPl12QQ Machines Material One of the major problems which face schools is obtaining supplies of plastics materials in appropriate quantities and sizes, at a reasonable cost. The following offer various packs of materials to meet school budgets: EMA Model Supplies Ltd 58-60 The Centre Feltham Middlesex TW13 4BH Trylon Ltd Thrift Street Wollaston Northants NN97QJ 40 K&M, Unit24 Lion Park Holbrook Ind. Estate New Street, Halfway Sheffield S195GH Appendix 7 OTHER RESOURCES ICI, in conjunction with the Technology in Context project, has produced a resource for dealing with needs and opportunities in the context of using plastics. It consists of teachers notes and student activity sheets housed in a ring binder and includes a video cassette. From: SCSST 76 Portland Place London WIN 4AA The Polymer Industry Education Centre (PIEC) can supply a list of resources about plastics, activity packs, fact sheets, information booklets, posters, slides and videos which can be obtained from a variety of industrial and other sources. The list is available free from: Polymer Industry Education Centre Department of Chemistry University of York Heslington York YOI 5DD Recommended further reading: "Design and Plastics" by Mike Hall (ISBN 0-340-40528-7) Safety publications: NAAIDT Publications 16 Kingsway Gardens Chandler's Ford Hampshire S051FE Tel: 0703 254440 CLEAPSS School Science Service BruneI University Uxbridge UB83PH Tel: 0895 251496 ASE Publications Section College Lane Hatfield Hertfordshi re ALI09AA Tel: 0707 267411 HMSO Publications Centre (Telephone Orders) Tel: 01 873 9090 NAAIDT National Association of Advisors and Inspectors for Design and Technology CLEAPSS Consortium of Local Education Authorities for the Provision of Science Services ASE Association for Science Education 41