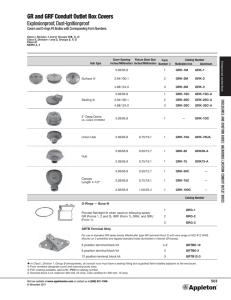

enclosures and junction boxes

advertisement