fans - Boldrocchi group

advertisement

Historical notes

Company profile

Interactive

table of contents

Eng. Luigi Boldrocchi

(1880-1949),

founder of the

Boldrocchi Company.

History and profile

1

Group structure

3

Heat exchangers

5

Electrical machines

cooling systems

9

Fans

13

Naval applications

16

Heavy-duty fans

17

Turbogas environmental

protections

21

Noise protection

in industry

23

Turn-key plants

25

Air pollution control

27

Cooling towers

29

Service&Revamping

30

Main customers

31

Contacts

35

n the 3rd of March 1909 LUIGI BOLDROCCHI established

the activity with the first orders for the supply of ten

centrifugal fans.

In 1911 the Officine Termo Meccaniche BOLDROCCHI

was set up in Milano with an operating area of 3000 square meters.

In 1914 the first plant for air pollution control was produced.

The company offered a wide range of products including radial and axial

fans, fire-tube boilers, coolers, dryers, ventilating and heat-exchange units

and plants.

In 1926, the licence for the manufacture of finned tubes was acquired in

the USA and the manufacture of extended surface heat-exchangers was

developed.

In the twenties and thirties the company becomes a regular supplier of the

main Italian industrial groups, the Ministry of Defence, naval yards and

State Railways.

The first air conditioning equipments for industrial and civil use were

developed; important supplies were installed in the Scala Theatre in Milan,

in the Parliament in Rome and in the first Submarines.

In the postwar period, the activity was carried on by

1

1915 - D.I. high head

centrifugal fan.

Technical drawings from the

early 20 th century.

16

1

2

GIULIANO BOLDROCCHI who progressively abandoned standard

production to concentrate on tailor made equipment for specific

industrial fields such as: power generation, the electromechanical

industry and major shipbuilders.

In 1970, a new factory was built and, with some later extensions,

forms the present site.

In 1972, under the licence of the Swedish company, BAHCO,

the production of industrial dedusting plants was increased.

In the early eighties, supplies for the nuclear sector induced the

company to introduce a Quality Assurance System.

From then on, the product range has been enlarged, particularly

for air coolers and steam condensers.

In the environmental field, two independent divisions have

been established:

Aeroto, part of the group since 1994 keeps the original

name of the company Aeroto, active since 1952 in industrial

noise protection and gas turbine ancillaries.

Ecologia, a fusion of our traditional technology with the

expertise of De Cardenas, purchased in 1997 and active since

1926 in air pollution control and industrial fans.

Completing our own structure and know-how with those ones

of De Cardenas and Marelli Ventilazione, Boldrocchi has

become the heavy-duty fan leader in Italy.

T

he Boldrocchi group now comprises various companies in

the world that can offer solutions for different production lines.

The group employs 300 people, 150 of which work in

production. The Biassono factory has a manufacturing area of

over 15,000 m2 and is equipped with thermal, acoustic and

aeraulic test facilities.

The 9,000 m2 workshop DeCardenas Ventilazione in Arcore

increased this realty in 1997.

Eighty technicians work on the four main production lines:

- Ventilation,

- Heat-exchange,

- Air pollution control,

- Industrial noise protection.

In 1993, the Quality system was certified as conforming with

ISO 9001.

1

Supplies are exclusively tailor made according to the specific

requirements of various international customers, present in all

the main industrial sectors.

The experience acquired in more than 90 years of continuous

activity and the flexibility both in designing and manufacturing

is considerable.

A wide range of materials are usually utilized: steel and copper

alloys, aluminium, titanium and plastic materials; more than

100 welding procedures have been qualified.

The products are subject to intermediate and final testing,

witnessed by the customers or delegate inspection

Authorities.

The policy of the group is always more customer

focused.

2

2

1

2

C.A.D. Stations.

View of Boldrocchi workshop,

large fans assembling area.

72

Boldrocchi Group Structure

BOLDROCCHI

Interactive

table of contents

Exchangers

Coolers

Fans

Forced draft air coolers

FOR POWER TRANSFORMERS

Air-oil coolers

Low noise air coolers

Simple and double tubes

water coolers

Axial and radial pumps

Fans

RADIAL FOR

EVERY INDUSTRIAL PURPOSE

For medium and high head

For high temperature, up to

850°C

Special steel alloys and titanium

Gas tight for toxic fluids

To compress steam

Wear and corrosion resistant

design

For boilers: combustion air and

flue gas recirculating

Process and heavy-duty fans

for chemical, steel making and

cement industries

Induced draft air coolers

History and profile

1

Surface steam condensers

Group structure

3

Vacuum air steam condensers

Heat exchangers

5

Gas heaters and coolers

Electrical machines

cooling systems

Shell and tubes heat

exchangers

9

Fans

13

Naval applications

16

Heavy-duty fans

17

Turbogas environmental

protections

21

Noise protection

in industry

23

Turn-key plants

25

Air pollution control

27

Cooling towers

29

Service&Revamping

30

Main customers

31

Contacts

35

Air preheaters (steam, oil)

Finned tubes coolers

FOR A.C. AND D.C. MOTORS

Air-air coolers

Air-water coolers

Explosion proof and special

equipments

Complete coolers with hood,

fans and filter

FOR GENERATORS

Hydrogen coolers

Air coolers

Oil bearings coolers

Axial fans

AXIAL FLOW FANS

High efficiency

Autovariable blade pitch

Carbon and stainless steels,

light alloys impeller

For trains and marine

applications

DECARDENAS

VENTILAZIONE

Heavy-duty fans for power plant

and steel making industry

Process and high head fans for

chemical, fertilizer, cement and

glass applications

Multi-stage blowers

3

AEROTO

DIVISION

Intake filter

Absorption and resonance

silencers

ECOLOGIA

DIVISION

FABRIC FILTERS:

Pulse jet bag filters

Reverse air bag filters

ELECTROSTATIC PRECIPITATORS:

Dry ESP and wet ESP

Silencers for gas exhausts of

internal - combustion engines

SCRUBBERS:

Low energy wet scrubbers

High energy venturi scrubbers

Steam exhaust silencers

MECHANICAL COLLECTORS:

Cyclones and multicyclones

Silencers/catalytic converters

GAS COOLERS:

Natural and forced air draft

Evaporative spraying towers

Noise control of gas turbine

systems

Silent cabins complete with

plants and accessories

Enviromental treatments

Diverter boxes

Exhaust stacks

Dog house and Elephant house

for E.A. Furnace

GAS REACTORS:

Dry and semidry basic reactors

Activated carbon dry reactors

Sox and nox removal systems

HOT GAS DUCTS:

Water-cooled pipe to pipe walls

Combustion chambers

DUST HANDLING:

Mechanical conveyors

Extraction valves

Ash and dust pneumatic conveying

FOREIGN

BRANCHES

BOLDROCCHI FRANCE

Air pollution control

& heavy duty fans

MB IND. GERMANY

Heavy duty and

process fans

AEROTO

BOLDROCCHI INDIA

Industrial fans

BOLDROCCHI

ECOLOGIA INDIA

Air pollution control

BOLDROCCHI

DO BRASIL

Heavy duty and process fans

BOLDROCCHI

ECOLOGIA MEXICO

Air pollution control

BAG FILTERS AND ESP REVAMPING

GAS CLEANING PLANTS

ENHANCEMENT

COMPLETE VENTILATION PLANTS

DESIGN

DIVERSIFIED

PRODUCTION

CONSULTING, AIR MEASURING,

POLLUTION SAMPLING AND

ANALYSIS

BOLDROCCHI T.E.

PLANNED MAINTENANCE SERVICES

Modular wet cooling towers

Plastic and metallic cooling

towers

Cooling towers for closedcircuits

4

heat exchangers

1

2

Interactive

table of contents

T

History and profile

1

Group structure

3

Heat exchangers

5

Electrical machines

cooling systems

9

1

he atmosphere is the cheapest and widest spread medium for cooling

in most industrial processes.

When manufacturing the first finned tubes in 1926, Boldrocchi began to

deal in extended surface heat exchangers using the air as a coolant.

After several decades of experience, the Company is today able to supply a

wide range of air cooled heat exchangers, used worldwide in utilities and

industrial applications; serving the petroleum, chemical, gas processing,

electrical, power generation, environment and steel industries.

From small coolers for endothermic engines, for compressors and dryers up

to several banks of bundles for steam condensation and for petrochemical

processes, production includes:

Fans

13

- forced and induced draft air coolers

Naval applications

16

- surface and vacuum air condensers

Heavy-duty fans

17

- gas heaters and coolers

Turbogas environmental

protections

23

Turn-key plants

25

Air pollution control

27

Cooling towers

29

Service&Revamping

30

Main customers

31

Contacts

35

Air cooled system with four

natural gas and water

bundle.

Return header cover plate

type for refinery heavy duty.

2

- air preheater and heat recuperators

21

Noise protection

in industry

3

Air cooler motoventilating

system detail.

- shell and tube heat exchangers.

1

With the help of on going research and

development, Boldrocchi continues to improve its

products. A computer aided design network

speeds up technical work and enable engineers

to examine different approaches and to reach the

best solutions.

2

Shangai (China).

Absorber pre-cooler

12130000 Kcal/h.

Submerged arc welding of

headers.

Automatic finning

machine.

5

10

All projects involve a process of:

- thermal design according to current and well

established operating techniques;

- mechanical design according to the main

standard codes such as TEMA, ASME, API;

- structural and stress analysis with finite

element method;

and, finally, the choise of the best solution

respecting the required noise level, whilst

optimizing the required power, ensuring easy

transportation, installation and maintenance

combined with competitive prices.

1

2

3

All our pressure vessels can be supplied, on customer’s request, ASME

“U” stamped.

Boldrocchi is also approved and licensed manufactures by Chinese

Autority (OBA).

3

3

6

11

heat exchangers

Interactive

table of contents

History and profile

1

Group structure

3

Heat exchangers

5

Electrical machines

cooling systems

9

Fans

13

Naval applications

16

Heavy-duty fans

17

Turbogas environmental

protections

21

Noise protection

in industry

23

Turn-key plants

25

Air pollution control

27

Cooling towers

29

Service&Revamping

30

Main customers

31

Contacts

To find the best performance for each

case ensuring high transfer coefficient

combined with low pressure drops

Boldrocchi provides several types of

helically finned tubes.

A variety of base tubes: from 1/2 inch to

2 inch diameters and different metals

such as carbon steels, stainless and

special steels, copper alloys, aluminium

and titanium can be finned with several

sizes and materials to satisfy customer

and design requirements.

Based on nine different finning machines

Boldrocchi can supply three basic

configurations on finned tubes.

- Footed fins: tension wrapped onto

the base tube. Also available: knurled

footed fins and overlapped footed

fins to ensure better heat transfer.

- Embedded fins: are tension wound in

a spiral groove, not more than

0,30 mm deep, into the base tube. A

strong joint between fin and tube is

ensured to allow excellent heat

transfer also at high operating

temperatures.

- Extruded fins: a smooth core tube is

inserted into an aluminium tube and

then fins are extruded out of the

aluminium tube.

Iffco Aonla (India) Ammonia

Plant, vacuum steam - water

surface condenser (package

unit). Heat exchanged:

4830000 Kcal/h.

Closed feed water heater.

Town central heating plant.

35

Forced draft airfin for

condensates treatment.

View of Boldrocchi workshop

tube-bundle assembling area.

7

12

3

1

2

3

4

To fit customers’ process requirements Boldrocchi designs,

manufactures, tests and assembles all the main

components: finned tubes, fans, headers and structural

elements.

A work force of skilled craftsmen combined with the best

welding techniques ensure high quality welding,

guaranteed by radiographic, ultrasonic, magnetic and

1

2

1

2

4

liquid penetrant inspections and, after assembly, by

hydrostatic and leak testing.

Air coolers may be designed to be preassembled in the

Boldrocchi factory and several options are available to

minimize power consumption, to avoid freezing and to

provide a low-noise environment.

1

2

Air-water coolers on barge.

View of Boldrocchi workshop,

air-coolers assembly area.

8

13

electrical machines cooling

Interactive

table of contents

D

History and profile

1

Group structure

3

Heat exchangers

5

Electrical machines

cooling systems

9

Fans

13

Naval applications

16

Heavy-duty fans

17

Turbogas environmental

protections

trasformers coolers

uring 1931 Boldrocchi manufactured the first oil transformer coolers

with forced ventilation and, since 1948, an engineering department has been

exclusively interested in the cooling of large electrical machines, both

rotating, such as motors and generators, and static, such as power

transformers, reactors and furnace transformers.

More than sixty years of experience in this specific field allow Boldrocchi to

offer each customer the best solutions in order to meet all requirements and

optimise reliability, performance and cost.

Specifically equipped test facilities to verify the efficency of the cooling

systems utilizing, according to the requirements, dielectric oil, water and air,

guarantee reliable know-how and performances.

In the presence of official boards and the main customers the prototypes of the

most utilized coolers have been approved with thermal and noise tests.

2

21

3

B

1

oldrocchi is one of the few companies that designs

and manufactures in-house all the main components used for

the forced cooling of power and furnace transformers.

The production range includes:

– oil-air cooler for OFAF and ODAF applications;

– water-oil coolers with simple and double wall tubes;

– axial flow and radial flow pumps;

– axial flow fans;

– control devices.

More than 10.000 air oil coolers of Boldrocchi

technology have been supplied.

The coolers essentially comprise a bundle of finned tubes of

the embedded type, to ensure complete homogeneity and

adhesion between tube and fins. Perfect conduction is

obtained without discontinuity in the passage of heat

throught the finned tubes.

Special finning machines are involved for the manufacture of

finned tubes, available in various shapes and with different

types of materials.

The coolers are equipped with low noise axial fans, selected

to meet customers most severe requirements.

Including the production of electric motors, axial and

centrifugal special pumps for the oil circulation are

manufactured.

They are of the single block type with an immerged motor,

without holding rings and therefore they are absolutely

locktight.

Series of air coolers suitable to meet the usual

requirements of each customer are designed and

furthermore the great experience and flexibility of the

company can provide special equipments for

non-standard applications.

The production range includes also different series of

oil-water coolers, designed according to different

requirements or standard rules.

Usually double wall finned tubes are employed to facilitate

leakage detection.

1

2

Noise protection

in industry

23

Turn-key plants

25

Air pollution control

27

Cooling towers

29

Service&Revamping

30

Main customers

31

Contacts

35

960 KW air-oil transformer

cooler, assembled skid with

pumps and devices.

200 KW double tube oil-water

cooler with control devices.

Joint European TorusAbington (GB).

2x150 KW - OFAF air-oil coolers.

9

14

2x500 KW special design

oil-air coolers.

3x300 KW ODAF low-noise

air-oil coolers.

1

1

2

3

2

10

15

coolers for motors

and generators

Interactive

table of contents

M

History and profile

1

Group structure

3

Heat exchangers

5

Electrical machines

cooling systems

9

Fans

13

Naval applications

16

Heavy-duty fans

17

Turbogas environmental

protections

21

Noise protection

in industry

23

Turn-key plants

25

Air pollution control

27

Cooling towers

29

Service&Revamping

30

Main customers

31

Contacts

The production range for generators includes:

– air-water coolers available in several designs and with different materials:

copper alloys, stainless steel and titanium;

ore than 7.000 heavy-duty electric motors are equipped

with Boldrocchi cooling groups. Particular attention is paid to design to meet

different requirements connected with cooling: dimensions, interface, pressure

drop, materials, vibrations, noise, consumption, reliability and maintenance.

Innumerable configurations have been designed with C.A.D., thus reducing

delivery time, even for special solutions.

The production range includes:

– cooling groups for d.c. motors.

These units, directly coupled to the motor, are usually composed of a

steel hood containing the water/air heat exchanger, an air filter and a

fan. All the components are easily removable from the case for checks

and maintenance;

– air-air cooling groups composed of two separated circuits with two fans

and exchanger, where the closed circuit air is cooled by the

external air;

– air-water cooling groups for a.c. motors, equipped with one or more

air/water exchangers, fan and noise insulating systems.

The water-air coolers are supplied both coil type or with finned tubes.

Several tube materials are available: copper, copper alloys, stainless steels

and titanium. For heavy-duty applications, such as off-shore platforms,

double tube design is suggested, with titanium internal tube.

The groups are equipped with control devices, special versions and explosionproof type are also made.

– coolers for hydrogen in closed circuits.

These units are particularly sturdy, have considerable dimensions and are

designed to operate in presence of high vibrations;

– circular coil heat-exchangers to cool the bearing lubricating oil of large

generators and turbines;

1

– medium head axial fans for cooling air circulation.

The construction and the impeller are designed to operate with high

rotating speed, up to 3.000 rpm and discontinuously.

Strict acceptance tests are carried out in excess of the overspeed

test at 75 Hz.

2

3

1

Furnace transformer 850 KW

oil-water cooler double

walled finned tubes with

floating heads.

580 KW power water-air

cooling system for W61000

electric motor.

35

Double tubes sea-water

cooling system for ABB

Derrick drilling motor on

off-shore platform.

11

16

1

4

1

2

2

3

3

3

2

4

50 KW explosion proof

air-water system with control

devices.

80 KW air-air cooler for

D.C. motors.

Generator bearings lube oil

cooler.

4x172 KW titanium made

air-water coolers for

generators.

12

17

fans

Interactive

table of contents

O

History and profile

1

Group structure

3

Heat exchangers

5

Electrical machines

cooling systems

9

Fans

13

Naval applications

16

Heavy-duty fans

17

Turbogas environmental

protections

21

Noise protection

in industry

23

Turn-key plants

25

Air pollution control

27

Cooling towers

Service&Revamping

ver thirty selected series of fans form the basis

company’s know-how and expertise thanks to the great

experience, flexibility and skill of the technicians to ensure the

best solution to customers’ needs.

Boldrocchi today is the oldest Italian manufacturer

of fans. Well over the 80% of fans produced are special

designs and almost all are for industrial applications, such as:

– Power generation and steam boiler

- forced draft fans for primary and secondary

combustion air

- flue gas induced draft fans and recirculating fans

- sealing and cooling fans.

– Chemical and petrochemical industry

- for hot, toxic and corrosive gases

- fired heaters and boilers combustion air and exhaust

flue gas fans

- process fans and steam boosters.

– Incineration plants

- high head fans for fluidized bed boilers

- acid gas fans.

– Steel and metal making industry

- for furnaces and hot gas

- for dedusting plants

- sintering plants and converter gas cleaning fans.

– Cement industry

- kiln and exhaust gas fans

- raw mill and burner fans

- clinker cooler recirculation fans.

Chlorination and rigeneration

service, detail of hot

temperature carbon rings

shaft seal with buffer gas

connections.

29

30

Main customers

31

Contacts

35

Steel industry cooling air

heavy-duty axial fan for

sinter plant.

Flow rate: 450000 m3/h.

Static head 3300 Pa.

Cement Kiln I.D. Fan

Flow rate 165 m3/s.

Head 8,4 KPa.

Installed power 2800 KW.

Impeller diam. 3800 mm.

13

18

1

1

2

1

The product range is very wide and embraces

radial fans, blowers and axial fans.

– Radial fans with flow rate exceeding

1,000,000 m3/hr.

– High speed fans with tip speeds up to

250 m/sec.

– Heavy-duty applications up to 3,000 KW

installed power.

– Static head up to 40,000 Pa single stage

blower and more with multistage.

– Axial fans with fixed, adjustable and self

variable pitch; single and multistage.

– Hot-gas circulating fans up to 850°C.

– Special blades design, such as air foil profile,

to ensure very high efficiency and low power

absorption.

– Very special designs for specific

purposes such as chlorine processing

and compressing steam.

Finite elements and stress analysis are

provided for high speed and performance

impellers and shafts.

Boldrocchi can provide a wide range of

accessories specially adapted to the

various designs and applications of

industrial fans: compensators, valves,

dampers, special drive systems, acoustic

enclosures.

2

Industrial waste incinerator.

Assembling of a Titanium

impeller for induced flue-gas

fan. Diam 2500 mm, static

head 23 KPa.

3

3

1

2

3

2

3

High pressure centrifugal

fan. Static head 37 KPa.

Installed power 400 KW.

High pressure forced

combustion air fans for solid

waste incineration fluidized

bed furnace.

Static head 18 KPa.

14

19

fans

Interactive

table of contents

naval applications

V

1

History and profile

1

Group structure

3

Heat exchangers

5

Electrical machines

cooling systems

9

Fans

13

Naval applications

16

Heavy-duty fans

17

Turbogas environmental

protections

21

entilation and heat

transfer for trains and ships were given particular attention,

right at the start. At present, special fans for speed trains,

large cruise ships and off-shore platforms form the major

part of this kind of production.

Axial and radial fans for marine service are custom designed

for every on board technical applications such as:

– engine and auxiliary room ventilation,

– main engine combustion air,

– exhaust fans for P.E.M. room,

– explosion proof and inert gas fans.

Aluminium, hot galvanized steel, stainless steel and bronze

alloys are usually employed.

Close assistance is given to shipbuilders to select the best

solution as regard suitable size and arrangement; to respect,

with the aid of our Aeroto division, the noise levels; to

choose and supply accessories such as fittings, louvers, air

filters and intake, silencers and spray removals.

Approved manufacturer in international registers such as

Lloyd’s Register and Norske Veritas, and authorized by

R.I.NA. to carry out tests, Boldrocchi today is the

Italian leader in marine fans.

Depending on the type of medium to be conveyed, the running temperature

and the impeller stress, the materials used are chosen to ensure the best

solutions:

– a range of chrome-nickel steel up to titanium is used for protection

against corrosion.

– Special low alloys steels with high yield points are supplied for stressed

applications.

– Stainless steel and special alloys such as: Inconel, Incolloy, Hastelloy and

Uranus for high temperatures.

– Rubberized, plastic and fiber glass coated, hot galvanized steel are

available.

– Very light solutions with highly resistent aluminium alloys, welded and

cast form impellers.

– Special wear resistant design with armoured impellers.

Performances, vibrations and acoustic tests including, if necessary, simulation

of service conditions such as high temperature, low pressure, sismic,

overspeed, leakage and others, are an essential part of ensuring the highest

quality of each product.

2

Noise protection

in industry

23

Turn-key plants

25

Air pollution control

27

Cooling towers

29

Service&Revamping

30

Main customers

31

Contacts

35

2

3

Assembly of flue gas induced

fan, for petrochemical

furnace. Installed power

1850 KW.

Atomization Blower

Flow rate 13,1 m3/s.

Head 62 KPa.

Installed power 1250 KW.

Steam boiler, recirculating

gas fan. Static head 9200 Pa.

Finite elements method.

Impeller stress analysis.

15

20

1

Various heavy duty axial hot

galvanized fans for naval

application.

Engine room extraction air

fans with silencer.

4

1

2

3

4

1

2

16

21

Interactive

table of contents

-

History and profile

1

Group structure

3

Heat exchangers

5

Electrical machines

cooling systems

9

Fans

13

Naval applications

16

Heavy-duty fans

17

Turbogas environmental

protections

21

Noise protection

in industry

23

Turn-key plants

ViÊ£ÇÊiÊ

>À`i>ÃÊ6iÌ>âiÊÀi«ÀiÃiÌÃÊ>

`ÀVV

Ê`«i`iÌÊ`ÛÃ]ÊÌ

>ÌÊÃÊëiV>âi`ÊÊ

`iÃ}}Ê>`Ê>Õv>VÌÕÀ}\

i>ÛÞ`ÕÌÞÊ`ÕÃÌÀ>Êv>Ã]ÊvÀÊ>ÀÊ>`Ê}>Ã

«ÀViÃÃ}Æ

ÌÕÀL}>ÃÊ>ÕÝ>ÀÞÊV«iÌÃ]ÊÊ«>ÀÌVÕ>À

ºÛiÀÌiÀ»ÆÊLÞ«>ÃÃÊÛ>ÛiÃÊvÀÊiÝ

>ÕÃÌÊ}>Ã]Ê>`Ê

ÌÊ}>ÃÊ

`ÃV

>À}iÊÃiVi`ÊÃÌVð

iÊ

>À`i>ÃÊÃÌ>ÀÌi`Ê>Õv>VÌÕÀ}Êv>ÃÊvÀÊÌ

iÊ`ÕÃÌÀÞÊ

LÕÃiÃÃÊÊ£ÓÇ°

-ViÊÌ

iÊÌ

ÕÃ>`ÃÊvÊ>V

iÃÊ

>ÛiÊLiiÊ«iÀ>Ì}Ê

Ì>ÞÊ>`ÊÜÀ`Ü`iÊÊÌ

iÊ«ÜiÀÊ«>ÌÃ]ÊÊÌ

iÊÀÊ>`Ê

ÃÌiiÊ>À}]ÊViiÌ]ÊV

iV>]Ê«ÕÌÊVÌÀÊ>`Ê

ViiÀ>ÌÊ`ÕÃÌÀiðÊÊÌ

iÊ>ÃÌÊÌÜiÌÞÊÞi>ÀÃÊÌ

iÀiÊ

>Ã

LiiÊ>ÊÀi>À>LiÊVÀi>ÃiÊÊÌ

iÊÃâiÊ>`Ê«ÜiÀÊ

>LÃÀ«ÌÊvÊÌ

iÊv>ÃÊ>`ÊÌ

iÀivÀiÊ>ÃÊvÊÌ

iÀÊ

iV

>V>ÊÃÌÀiÃð

iÊ

>À`i>ÃÊi«ÌÊÕ«ÊÜÌ

ÊÌ

ÃÊVÌÕÕÃÊÌiV

V>Ê

iÛÕÌÊ>`ÊÊ£{Ê>Ì

iÀÊ«ÀÌ>ÌÊÃÌi«ÊvÀÊÌÃ

`iÛi«iÌÊÜ>ÃÊÀi«ÀiÃiÌi`ÊLÞÊÌ

iÊ>VµÕÃÌÊvÊ>Ài

i>ÛÞÕÌÞÊÛiÌ>Ì°

25

Air pollution control

27

Cooling towers

29

Service&Revamping

30

Main customers

31

Contacts

35

"ÛiÀÊxä¯ÊvÊÌ

iÊ>ÊLiÀÊv>ÃÊÃÌ>i`ÊLÞ

iÊ>ÀiÊ>Õv>VÌÕÀi`ÊLÞÊ>ÀiÊ>`Ê

iÊ

>À`i>ð

FACTORY IN ARCORE

iÊ

>À`i>ÃÊ6iÌ>âiÊ

>ÃÊÌÃÊÜÊv>VÌÀÞÊ

V>Ìi`ÊÊÀVÀi]ÊÜV

ÊÃÊÓxÊÊÀÌ

ÊvÀÊ

>Ê>`ÊÇÊÊvÀÊÌ

iÊ`ÀVV

Ê

i>`µÕ>ÀÌiÀÊÊ>ÃÃ>°

/

iÊv>VÌÀÞÊVÛiÀÃÊ>Ê>Ài>ÊvÊÎä]äääÊõ]Êv

ÜV

Ên]äääÊVÛiÀi`ÊLÞÊÌ

iÊ«À`ÕVÌÊ

`i«>ÀÌiÌÃÊ>`ÊÓ]äääÊLÞÊÌ

iÊLÕÃiÃÃÊvvViÃ]

Ì

iÊi}iiÀ}Ê>`ÊÃiÀÛViÊÃÌÀÕVÌÕÀið

/iV

V>ÊÃÌ>vvÊÜ

ÜÊ

>ÃÊLiiÊ>V

iÛi`ÊvÀÊÊ

ÛiÀÊ>ÊViÌÕÀÞÊvÊLÕÃiÃÃÊiÝ«iÀiViÊ

>`ÊÌiÀ>Ì>ÊV«iÀ>ÌÊvÊ>Ài]

Êv>ÊLÕÃiÃÃÊÃViÊ£n£°

/

iÊÜÀÃ

«Ê`iÃ}i`Ê>`ÊLÕÌÊvÀÊv>Ê

>v>VÌÕÀ}Ê>`ÊvÀÊiV

>V>ÊV«iÌ

>ÃÃiLÞÊ

>ÃÊ>ÌiÞÊ>``i`Ê>Ài½ÃÊëiV>

iµÕ«iÌÊvÀÊ

i>ÛÞ`ÕÌÞÊv>Ê«À`ÕVÌ°

1

2

3

4

5

17

ÓÓ

-ÌiiÊ«>ÌÊÊ/>À>Ì°

>ÃÊiÝ

>ÕÃÌiÀ°

ÜÊÀ>Ìi\ÊÓÓäÊÎÉð

>VÌÀÞÊÊÀVÀi

-iÌÌ}ÊÌiÃÌÊÊÜÀÃ

«Ê >ÀÊVLÕÃÌÊv>°

ÜÊÀ>Ìi\ÊÎ{£ÊÎÉð

LÃÀLi`Ê«ÜiÀÊÓ{ÓäÊ7°

/ÜÃÌ>}iÊiÝ

>ÕÃÌiÀÊvÀÊÜ>ÃÌi

ViÀ>ÌÊ>V`Ê}>ðÊÜÊÀ>Ìi\

£ÓÊÉðÊi>`Ê£{]ÇÊ*>°

LÃÀLi`Ê«ÜiÀÊÓÇxÊ7°

Petrochemical plant.

Gas fan made in duplex and

stainless steel. Head 16 KPa.

Absorbed power 265 KW.

18

ÓÎ

1

Ê/-/Ê,

Interactive

table of contents

History and profile

1

Group structure

3

Heat exchangers

5

Electrical machines

cooling systems

/

Ê

iÊ«iÀvÀ>ViÊÌiÃÌÊÀ

vÊiÊ

>À`i>ÃÊ6iÌ>âiÊÃÊÌ`>ÞÊÌ

iÊLiÃÌÊiµÕ««i`ÊÊ

Ì>Þ°ÊÊÌÊÞÕÊV>ÊV

iVÊÌ

iÊV

>À>VÌiÀÃÌVÊVÕÀÛiÃÊÊ

iÝ«iÀiÌ>Ê«ÀÌÌÞ«iÃÊ>`Ê>ÃÊÊLÊv>ð

iÌÀvÕ}>Êv>ÃÊÜÌ

ÊÃÌ>i`Ê«ÜiÀÊ>LÛiÊÈ]äääÊ7Ê

>ÛiÊLiiÊÌiÃÌi`Ê

iÀiÊ>ÌÊÀi`ÕVi`ÊÀ°«°°

Ê£ÓääÊ7Ê`iÃiÊ}iiÀ>ÌÀÊvii`ÃÊÌ

iÊ

Û>À>LiÊëii`Ê°

°ÊÀÊ°

°Ê`ÀÛið

ÌÊÃÊ«ÀÛ`i`ÊÜÌ

\

ÊÊÊ Û>À>LiÊvÀiµÕiVÞÊ}iiÀ>ÌÀ]ÊäeÈäÊâ]Ê£äääÊ7Ê>`ÊÊ

`ÕVÌÊÌÀÃÊÜÌ

Ê«ÜiÀÊV>«>VÌÞÊÕ«ÊÌÊ£äääÊ7Æ

ÊÊÊ °

°ÊÌÀÃÊÜÌ

Ê«ÜiÀÊV>«>VÌÞÊÕ«ÊÌÊÈääÊ7]

ÊÊÊÊ ÃÕ««i`ÊÜÌ

ÊÃÌ>ÌVÊÀiVÌviÀÃÊvÀÊVÌÕÃÊëii`

ÊÊÊÊ Ài}Õ>Ì°

-iÛiÀiÊ`iÃ}}Ê>`ÊÌiÀv>V}Ê«ÀVi`ÕÀiÃ]

>Õv>VÌÕÀ}Ê>`ÊÌiÃÌ}ÊÊV«>ViÊÜÌ

ÊÌ

iÊ-"Ê

ää£Ê+Õ>ÌÞÊ-ÞÃÌiÊ

iÀÌvV>Ì]Ê>ÜÃÊiÊ

>À`i>ÃÊ

6iÌ>âiÊÌÊÃ>ÌÃvÞÊÌ

iÊÀiµÕiÃÌÃÊvÊÌ

iÊ>ÀiÌÊvÀÊv>ÃÊ

ÜÌ

ÊÌ«Êëii`ÃÊ>LÛiÊÓxäÊÉÃÊ>`Ê>LÃÀLi`ÊÕ«ÊÌÊ

£ä]äääÊ7°

9

Fans

13

Naval applications

16

Heavy-duty fans

17

Turbogas environmental

protections

21

Noise protection

in industry

23

Turn-key plants

25

Air pollution control

27

Cooling towers

29

Service&Revamping

30

Main customers

31

Contacts

35

iiÌÊÀÌ>ÀÞÊ°

-°-ÌiiÊ}>ÃÊiÝ

>ÕÃÌiÀÊ

ÀVÀiÊÌiÃÌÊÀ°

*ÜiÀÊÎÈääÊ7°

-

>vÌÊvÌÌ}Ê>Ê«iiÀÊvÀ

«ÜiÀÊ«>ÌÊiÝ

>ÕÃÌiÀ°

ÜÊÀ>Ìi\ÊÈäxÊÎÉð

LÃÀLi`Ê«ÜiÀÊÈÓääÊ7°

7`ÊÌÕiÊ>Ý>Êv>°

ÜÊÀ>Ìi\Ê£xÊÎÉð

«iiÀÊ`>iÌiÀÊÓÇ{xÊ°

/ÜÃÌ>}iÊ>Ý>Êv>ÊvÀÊ«ÜiÀ

«>ÌÊV>ÊÃ]ÊxääÊ7°

ÜÊÀ>Ìi\Ê£{{ÊÎÉð

i>`Ê£Î]ÈÊ*>°

ÃÌ>i`Ê«ÜiÀÊÓÎxäÊ7°

19

Ó{

1

2

MAIN APPLICATIONS

Ê

ÀiÊÌ

>ÊnäÊ

i>ÛÞÊ`ÕÌÞÊv>Ã]Ê>LÛiÊÓäääÊÜÊi>V

]ÊÃÕ««i`ÊÊÌ

i

>ÃÌÊÓäÊÞi>Àð

/

iÊ>Ê>««V>ÌÃÊ>Ài\

-ÌiiÊ>}\

vÀÊvÕÀ>ViÃ]ÊL>ÃÌÊvÕÀ>ViÃ]ÊV>i]ÊVÜ«iÀÃ]ÊVÛiÀÌiÀÃÊ>`ÊÃÌiÀÊið

Ê/>À>ÌÊ«>ÌÊ>ÀiÊ«iÀ>Ì}ÊÌÜÊ«ÀÌ>ÌÊiÝ

>ÕÃÌiÀÃ]Ê£]{nn]äääÊÎÉ

V>«>VÌÞ]Ê£{Ê*>Ê

i>`]Ê>`ÊÈ]xÇÇÊ7Ê>LÃÀLi`Ê«ÜiÀ°

*ÜiÀÊ«>ÌÃ\

vÀÊ`ÕVi`Ê>`ÊvÀVi`Ê`À>vÌ]Ê}>ÃÊÀiVÞV}]Ê "8ÊiÊ-"8

ÕÀÊ`ÕVi`Ê`À>vÌÊv>ÃÊÜÌ

Ê>ÊV>«>VÌÞÊ>LÛiÊÓ]äää]äääÊÎÉ

Ê>ÀiÊÃÌ>i`ÊÃVi

£Î°

iiÌÊ`ÕÃÌÀÞ\

vÀÊÃ]ÊÀÌ>ÀÞÊÃÊ>`ÊV}Ê}À>Ìið

iV>]Ê«iÌÀV

iV>]Ê>`ÊviÀÌâiÀÊ`ÕÃÌÀiÃ\

vÀÊvÕÀ>ViÃÊ>`ÊÛ>ÀÕÃÊ«ÀViÃÃÊ>««V>ÌÃÆÊëiV>ÊLÜiÀÃÊ

>ÛiÊLiiÊ>`iÊÜÌ

i>`ÊÕ«ÊÌÊÈxÊ*>Ê>`Ê>LÛiÊ£]äääÊ7Ê«ÜiÀ°

ViÀ>ÌÊ«>ÌÃ\

vÀÊÀÌ>ÀÞÊvÕÀ>ViÃ]ÊÌÀ>Ûi}Ê}À>ÌiÊ>`ÊvÕ`âi`ÊLi`°

>ÃÃÊ`ÕÃÌÀÞ\

vÀÊiÌ}ÊvÕÀ>ViÃ]Êi`ÕÊ>`Ê

}

Ê«ÀiÃÃÕÀiÊÌi«iÀ}°

ÀÊ}>ÃÊÌÕÀLiÃ\

Ì>iÊÃÞÃÌiÃÊÜÌ

Ê>ÀÊvÌiÀ}Ê>`ÊÃiÊ«ÀÌiVÌÆÊÃiVi`ÊiÝ

>ÕÃÌÊ}>ÃÊÃÌ>VÃ

>`ÊÌÕÀLiÊiVÃÕÀið

ÃÌÊvÊ>ʺÛiÀÌiÀû]ÊÃÕ««i`ÊvÀÊ/

>ÃÃi]ÊÌ>V

]ÊiiÀ>ÊiVÌÀVÊ>`

-iiÃÊÌÕÀLiÃÊ

1

£ÓääÊ6ÊÀVÀi

ÌiÃÌÊÀ°

2

/ÀÌÊÃÌiÀÊ«>ÌÊÛiÌ>Ì°

ÜÊÀ>ÌiÊÓÎÈÊÎÉð

«iiÀÊ`>iÌiÀÊ{äxäÊ°

*ÜiÀÊÎääÊ7°

3

4

20

Óx

D I V I S I O N

gas turbine

Interactive

table of contents

A

History and profile

1

Group structure

3

Heat exchangers

5

Electrical machines

cooling systems

eroto, active since 1952 specifically

in industrial noise protection, today is an

indipendent division of Boldrocchi company,

with the aim to give technical assistance to

public and private customers in solving problems

connected with industrial noise pollution.

Gas turbines are one of the most important

applications of noise protection.

Today turbogenerations are powered up to

over 200 MW and have an exhaust gas

flow of over 6 millions m3/h with sound

power value over 140 dB (A).

Aeroto solves any aspect regarding air and

noise treatment providing:

– Air intake systems with various air

filters, silencers and ducts.

– Acoustic enclosures with variuos air

ventilation, electrical and fire-fighting

plants and lifting equipment.

– Exhaust gas silencers and ducts with

operating temperature up to 600°C.

Aeroto has made more than 400

installations worldwide, satisfying our

customers’ needs.

This long time experience guarantees the

reliability of our products.

Aeroto can prove it.

9

Fans

13

Naval applications

16

Heavy-duty fans

17

Turbogas environmental

protections

21

Noise protection

in industry

23

Turn-key plants

25

Air pollution control

27

Cooling towers

29

Service&Revamping

30

Main customers

31

Contacts

35

2 Diverter Dampers for

Gas Turbine PGT 25

Ruswil Power Plant

Switzerland.

1

Power plant on barge.

Gas turbine Siemens V64.3A

Air intake and silenced

exhaust gas systems

2

Acoustic enclosure for gas

turbine.

Gas turbine MS 9001.

Central Italy Power Plant.

21

26

1

1

2

3

22

27

1

D I V I S I O N

Interactive

table of contents

History and profile

1

Group structure

3

Heat exchangers

5

Electrical machines

cooling systems

9

Fans

13

Naval applications

16

Heavy-duty fans

17

Turbogas environmental

protections

21

Noise protection

in industry

23

Turn-key plants

25

Air pollution control

27

Cooling towers

29

Service&Revamping

30

Main customers

31

Contacts

35

Silencers and acoustic enclosures for machineries

Large electrical machines

– Silencers for generator and turbines air-cooling systems

– Acoustic enclosures for electrical machines, together with internalcombustion engines or turbines, provided with inlet and outlet-silencing

systems for ventilation air.

Pumps, fans, engine-compressors, power-units,

hydraulic-joints, valves

– Acoustic enclosures for each single machine or sectioned for whole

systems, provided with silenced ventilation-systems

– Valves and pertaining ducts silencing.

Automatic tool machines, textile machines

– Acoustic enclosures, screens, baffles

– Environmental acoustic.

Silencers and acoustic enclosures for industries

Iron, Steel and metal industries

– Acoustic enclosures, screens, baffles

– Environmental acoustic

– Elephant House and Dog House

– Noise protection at work.

Petrochemical and chemical industries

– Inlet and exhaust silencers for fans

– Gas and steam vents.

Marine applications

– Inlet and exhaust silencers

– Flue-gas exhaust silencers for engine compressors units.

Power generation

– Acoustic enclosures, screens

– Acoustic ventilation

– Inlet and exhaust silencers, for turbines and motors.

2

3

3 complete by pass

systems for gas turbine

GT 13E2

Ras Abu Fontas Power

Plant.

23

28

1

2

32 air intake and exhaust

systems for gas turbine V 94.2

Iran project.

3

Air intake system for gas

Turbine V 94.3A.2

Porto Marghera.

24

29

D I V I S I O N

Interactive

table of contents

History and profile

1

Group structure

3

Heat exchangers

5

Electrical machines

cooling systems

Design

E

9

Fans

13

Naval applications

16

Heavy-duty fans

17

Turbogas environmental

protections

21

Noise protection

in industry

23

Turn-key plants

25

Air pollution control

27

Cooling towers

29

Service&Revamping

30

Main customers

31

Contacts

35

The Boldrocchi Ecologia service extends to the erection and putting into

operation of the plant complete with its automation, servicing and training

during the start-up phase and inspections and maintenance during its

operation.

ver since the foundation,

Boldrocchi has contributed with avant- Manufacturing

garde technologies to the control of

gaseous emissions from industrial plants, realizing treatement systems for

atmospheric pollutants.

From the results obtained by hundreds of systems, Boldrocchi Ecologia can

find reliable solutions for all types of polluting emissions: from the traditional

dust removal to the most highly sophisticated technologies for reducing

organic micropollutants, gaseous acids, vaporized metals, sulphur and

nitrogen oxides and all other air pollutants.

1

Application Fields

Iron and steel making

– Blast furnaces

– Sinter plant

– Coke

– Row materials

– Converters

Delivery

Boldrocchi Ecologia has all the experience required to design and construct

complete smoke extraction and dust removal systems on each part of the

production process and, as a result, is capable of purifying an entire industrial

works.

Erection

Commissioning

Testing

Service

25

30

1

Boldrocchi Ecologia is often called to restructure or expand plants that have

been in service for many years and whose efficiency is no longer in line with

the current regulations.

In these cases, we have designed special solutions that recover and make

the most of the existing plant, replacing the filtering systems with others

based on a modern design and providing an improved performance.

Even electrostatic precipitators can be repaired and made more powerful

using avant-garde internal equipment produced on the basis of a SPEIC (F)

licence.

2

Dedusting plant for 80 ton

D.C. electric arc furnace.

Treated gas flow

1.100.000 m3/h.

Heat exchanger and

bag filter on clinker

grate cooler.

2

: cast house, stock house

: sinter gas, ambient air control, sinter cooling

: coke pushing, coke grinding

: handling, grinding, mixing

: iron pouring, desulphurizing,

charging, steel tapping and refining

– Electric Arc furnaces : steel melting, oxygen blowing, gas burning,

scrap charging, steel tapping, ladle furnace

refining, AOD converters, slag handling

– Ferroalloy furnaces : Fe-Si, Fe-Cr, Fe-Mn, Si-Me electric arc furnaces

Cement and Lime

– Cement rotary kilns, ore mills, clinker coolers, clinker grinding,

cement handling

– Lime vertical and rotary kilns, lime grinding, handling, slakers

Waste to energy

– Waste selection, handling, compacting

– Municipal waste incinerators and fluized bed furnaces

– Sludge furnaces

– Hospital waste

Utility boilers

– Pulverized coal, oil, gas; fluidized bed

Industrial boilers

– Wood, biomass, R.D.F., multi-fuel

Foundry

– Iron cupolas, Induction furnaces

– Copper refining, brass casting

– Aluminium smelting and refining

– Lead, zinc, cadmium etc.

Other industries

– Chemical, ceramic, refinery, glass, mechanical, wood, food, etc.

26

31

D I V I S I O N

1

2

Interactive

table of contents

S

History and profile

1

Group structure

3

Heat exchangers

5

Electrical machines

cooling systems

9

Fans

13

Naval applications

16

Heavy-duty fans

17

Turbogas environmental

protections

21

Noise protection

in industry

23

Turn-key plants

25

Air pollution control

27

Cooling towers

29

Service&Revamping

30

Main customers

31

Contacts

teelmaking

The production of steel, whether a blast furnace or electric furnace is used,

results in the pollution of huge volumes of air which must be collected and

purified.

The in-depth knowledge of the cast iron and steel working processes enables

Boldrocchi Ecologia to make accurate forecasts about the volumes and

temperatures of the smoke with a view to identify the most suitable

design for the cleaning system.

The extraction of gases at extremely high

temperatures requires water-cooled tubular

walled ducts, while the elimination of the

heat from the smoke requires tube nest or

evaporating exchangers. Boldrocchi Ecologia

has a great deal of experience in the

construction of these devices which it

designs within the company to ensure

maximum reliability.

Smoke purification is carried out by bag

filters capable of reducing emissions to a

concentration of a few milligrams;

sometimes large electrostatic precipitators

are preferable due to their remarkable

resistance to wear over time.

Boldrocchi fans ensure that the extraction

plants operate continuously and reliably

with a maximum energy saving.

1

The dust is collected, transported and accumulated by means of mechanical

or pneumatic systems, always hermetically sealed to prevent the risk of

pollution of the environment.

The full automation of the plants is based on the use of advanced PLC’s and

is designed and implemented by our specialists according to the Customers’

requirements.

35

1

Water-cooled gas intake and

settling chamber for primary

gas from 90 ton EAF.

Temperature up to 1300°C.

2

Noise and dust control

equipment on 45 Ton

E.A.F.

27

32

3

Industrial steam generators, including those running on

unconventional fuels, are equipped with smoke purification

systems which combine extreme ease of operation with a

high degree of efficacy in eliminating ash and any acidic

pollutants.

For large thermoelectric power plants Boldrocchi Ecologia

has extremely reliable gas purification equipment, based on

electrostatic precipitator and bag filter technology.

The ash collected can be accumulated using safe and

efficient pneumatic transport systems.

Bag filter for waste to

energy plant.

3

Wood fired industrial boiler

equipped by an electrostatic

precipitator.

4

Dedusting plant for copper

refining furnaces and

continous casting in Mexico.

1

2

The production of

energy by burning waste

entails paying great attention to the

control of gaseous emission, Boldrocchi

Ecologia manufactures gas treatment

systems divided into various sections

capable of removing all the pollutants

selectively.

Electrostatic precipitators, dry and

semidry systems, bag filters,

neutralizing scrubbers, condensation

processes, together with the action of

additives such as lime, soda,

bicarbonate, activated carbon, etc. are

used to ensure an emission level that

complies with the strictest regulations.

4

Iron foundries and non-ferrous metal

founding and refining companies use

Boldrocchi Ecologia plants for purifying

the smoke emitted by all types of

smelting furnaces, both electric and

direct-fired. The great experience gained

in the cooling of dusty gases and the

filtering of highly aggresive smoke

ensures that the customer can choose

long-lasting devices and filtering means,

which comply with the emission

regulations even for the most harmful

metals.

3

2

Torpedo car deslagging

hood and bag filter.

Boldrocchi Ecologia applies newly designed bag filters and

electrostatic precipitators for purifying process smoke from

cement end lime kilns.

Many slakers, clinker coolers, screening systems, product

ensilage and loading systems have also been equipped with

high-performance dry filtration systems.

When required due to the temperature of the smoke, forcedair tube nest exchangers or water fog evaporating towers

can be supplied.

Bag filter with thermal

insulation for gas dedusting

on a large lime furnace.

3

28

33

cooling towers

Interactive

table of contents

History and profile

1

Group structure

3

Heat exchangers

5

Electrical machines

cooling systems

E

I

n order to meet the specific requirements of our customers, in 1992

Boldrocchi T. E. was founded based upon more than 25 years Boldrocchi

experience in the field of water cooling towers .

Boldrocchi T. E. manufactures exclusively industrial equipment, that

means reliable and strong product, which provides a reliable and strong

product very suitable for heavy duty works.

Boldrocchi T. E. builds axial suction fan cooling towers suitable for cooling

from a few m3/h of water up to many thousands, with impeller directly

coupled on motor shaft without spray nozzles.

The wet deck surface could be film type in PVC or P.P. type or Splash type.

The most important sectors of applications are: Metal and Steel Making,

Food Industry, Chemical, Energy, Plastic, Glass, etc.

9

Fans

13

Naval applications

16

Heavy-duty fans

17

Turbogas environmental

protections

21

Noise protection

in industry

23

Turn-key plants

25

Air pollution control

27

Cooling towers

29

Service&Revamping

30

Main customers

31

Contacts

35

8700 KW modular cooling

towers, with more cells,

installed on concrete basin.

No-clogging cooling towers,

installed on food-industry,

in order to cool 2000 m3/h

of water containing organic

matters.

Cooling tower installated on

metallurgical factory. Water

flow 300 m3/h.

13950 KW modular cooling

tower in stainless steel,

installed on an important

steel industry on continuos

cycle plant.

Heat rejection 13950 KW.

Water flow 800 m3/h.

29

34

1

2

M&S is a company, part of the Boldrocchi Group,

dedicated to the service on the Boldrocchi’s production line.

The main activity is the service on the rotating machinery

like fans, but also the other equipments like filters, heat

exchangers, industrial dampers and power plant ancillaries

are into the business activity of the Company.

1

2

In the field of the rotating machinery the following are the

typical services:

– Erection supervision.

– Ordinary and preventive maintenance.

– Mechanical problem diagnosis and solving.

– Overhauling and retrofitting of the components.

– Field and shop dynamic balancing of the rotors.

–Commissioning of the complete units including prime

movers.

PRODUCTION PROGRAMME

Cooling towers with axial suction fans that own the following

characteristics:

- for clean or dirty water;

- with film or splash filling type;

- withsafety support grid (if required);

- water distribution system without spray nozzles with distributors

no-clogging in AISI 304 stainless steel;

- with the arrangement for the partial control of wintry plume

(if required);

- with own sump or suitable for erection on concrete basin;

- with standard fans or with soundproof and oversized air outlet;

- fully assembled and tested or to be assembled on site.

This kind of towers is designed and built in

order that the erection on site results simple

and reliable.

3

The services can be done for fans manufactured by Boldrocchi

but also by the competitors.

The Company has its own shop based in Arcore (MB) (30 km

from Milan) and it’s equipped with a test rig where the final

test of the machines can be done.

3

1

2

1

2

3

Process air cooler erection and

test in a refinery

Gear coupling erection,

7 MW fan with electric motor

Booster fan erection

on FGD system

Fan Sleeve bearing check

4

In the field of dedusting plants, heat exchangers and power

plant ancillaries the activities of the Company are the

followings:

– Erection supervision.

– Commissioning of the complete units.

–Ordinary and preventive maintenance including cleaning

and consumables substitution.

– Problem diagnosis and solving.

The Company is active to send its technicians all over the

world with a brief notice.

4

3

4

4

30

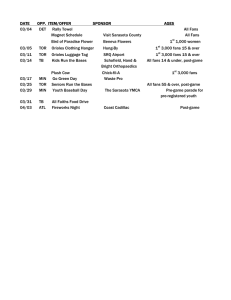

Fans

POWER AND INCINERATORS

Interactive

table of contents

History and profile

1

Group structure

3

Heat exchangers

5

Electrical machines

cooling systems

Fans

9

13

Naval applications

16

Heavy-duty fans

17

Turbogas environmental

protections

21

Noise protection

in industry

23

Turn-key plants

25

Air pollution control

27

Cooling towers

29

Service&Revamping

30

Main customers

31

Contacts

35

ABB Alstom Power

ACCAM

AEM Cremona

AEM Milano

Ambiente

Ansaldo

ASM Brescia

Aster

Babckock - Badcock Riley Power

Bono Energia

CEI

CCT

ENEL

Foster Wheeler

ISE

Larsen & Toubro

Lurgi

Macchi

Nooter

Eriksen

Nuovo Pignone

Snamprogetti

SNIA

Technimont

Technip

Heurtey

UHDE

CEMENT

Buzzi/Unicem

Calcia

CBMI

Cementir

Cementerie Merone

Ciments du Maroc

Colacem

Italcementi

LV Europe

Polcons Cement

Cementi Rossi

Sacci

Vassiliko

Vulkan

CHEMICAL & PETROCHEMICAL

APPLICATIONS

NAVAL APPLICATIONS

ABB Lummus

BHPV

Caffaro

Callidus

Chiyoda

Dow Chemicals

Enichem

Fluor

Foster Wheeler

Idrotermici

ISAB

Koch International

KTI

Larsen & Toubro

Linde

MAN Ferrostaal

SARAS

Siirtec Nigi

Atisa

Cantiere Navale F.lli Orlando

Cantieri Navali Sestri

Carnival Cruise Line

Costa Crociere

Dalian Ship Yard

Disney Cruise Line

Fincantieri

Gesco

Grimaldi Grandi Navi

Holland America

Minoan

Nuovi Cantieri Apuania

P&O Cruise

Sana

Snamprogetti

Tirrenia

Tor-Line

31

heat exchangers

METALLURGY

AFS

Danieli

Demag italimpianti

Jindal

Nuova Samim

Riva

Stein Heurtey

Techint

Tunga

Voest Alpine

SPECIAL APPLICATIONS

Hamon Research Cottrell

Lurgi

Mussi

Saint Gobain

TMC Padovan

POWER TRANSFORMERS

COOLERS

MOTOR AND GENERATOR

COOLERS

Linde

ABB Group

(Brazil,Canada,Germany,Italy,

Spain,Switzerland,Turkey,USA)

ABB Sace Vittuone

Lurgi

ABB Automation Vasteras Svezia

Man Turbo

ABB

Oy Electrical Machines Finland

Macchi

ABB

Switzerland Ltd Electrical Machines

Polimeri Europa

Acea

Aem

Areva (Brazil,United Kingdom)

Edipower

Edison

Enel

Enerco Enterprises

Ansaldo Trasporti

Firema

Marelli Trazione

Parizzi

Cantarey Reinosa S.A.U.

Laurence Scott & Electromotors LTD

Ganz Transelektro

Getra

Imefy

Jst Transformateurs

Pauwels Trafo

TRAIN

Brush HMA B.V Ridderkerk

Netherlands

Sea

Sgb

Siemens Group (Austria, Italy)

Specialtrasfo

Tamini Group

Terna

Tes

Tironi

Lummus Global

Perry Equipment

Raffineria Di Roma

Saras

Sices

Siirtec Nigi

Snamprogetti

Stogit Syrian P.E.E.

AIR COOLER

HEAT EXCHANGERS

Techint

ABB Group

Tecnimont

Agip

Agippetroli

Ansaldo Energia

Technip Coflexid

Termomeccanica

Tractebell

Uhde

Ansaldo Caldaie

Api

Burckhardt

Cct

Dresser Rand Enel

Eni

Enichem

Esso

Foster Wheeler

Howden Compressors

Ingersoll Rand

Isg

Jordan Petroleum

K.T.I.

Kuwait Nat. Petroleum Co

32

Aeroto division

Interactive

table of contents

aeroto india

ABB

Fiat Engineering

Philips Carbon Black

ABB Lummus

Jaypee Super Cement

National Fertilizer

Alcan

Fincantieri

Renco

Ansaldo

JNK Heaters Korea

PDIL

Allumina

Flowvex

Rosetti Marino

ARM Cement

JSW Stell

Punj Lloyd

Alstom Power

Foster Wheeler

Saras

BHPV

Jaiprakash Associates Limited

Raipur Alloys

Ansaldo Energia

G.E. Nuovo Pignone

Siirtec Nigi

Bangladesh Fertilizer

Jindal Steel & Power

Reliance Jamnagar Refinery

History and profile

1

Ansaldo Caldaie

Grandi Motori

SNAM

BJCIL Cement Satna

Kanoria Chemical

RCF

Group structure

3

Atlas Copco

Ingersoll Rand

Techint

BSES

Krupp Polysius

Shivam Cement Nepal

Avio

INSO

Technip Italy

Chambal Fertilizer

Kutch Chemical

Snamprogetti

Heat exchangers

5

C.M.I

Isotta Fraschini

Technip K.T.I.

Engineers India Limited

Larsen & Toubro Process

Shriram Fertilizer

Cefla

Macchi

Turbocare

Essar Refineries

Larsen & Toubro Cement

SISCOL

Edison

Mapna

Turbomach

Essar Steel

Maithan Ispat

Sterlite

Enel

Nuova SAMIM

Fouress

Mangalore Refineries

Tata Steel

Enel Power

Paul Wurth Italia

F L Smidth

Metso Power

Tata Chemical

Techint Hypertherm

Mombassa Cement

Technimont

Indo Gulf Fertilizer

MSPL Steel

Technip KT India

IFFCo

Mukund Steel

Thermax

IOCL (Haldia, Gujarat & Panipat)

Nagarjuna Fertilizer

Tororo Cement

Jacobs Netherland

National Sulphur, KSA

Uhde India

Jaypee Sidhi Cement

NTPC

Uttam Sugar

Electrical machines

cooling systems

9

Fans

13

Naval applications

16

Heavy-duty fans

17

Turbogas environmental

protections

ecologia division

21

CEMENT AND LIME

STEEL AND METALS

POWER AND INCINERATION

Buzzi Unicem

Alfa Acciai

Ansaldo

Cimprogetti

Almag

CEB

Colacem

Arcelor

Edison

27

FCB

ASO

Foster Wheeler

Cooling towers

29

Fornaci Calce Grigolin

Cogne

Snamprogetti

Halyps

Europa Metalli

Termomeccanica

Service&Revamping

30

Holcim

Ilva

Veba Oel

Italcementi

Lucchini

Von Roll

Main customers

31

Lafarge

Riva Acciai

Contacts

35

Polysius

SMS Demag

Unicalce

Valbruna

Noise protection

in industry

23

Turn-key plants

25

Air pollution control

Vicat

Villaga Calce

Vulcan

33

34

Boldrocchi Group

Viale Trento e Trieste 93 - 20853 Biassono (MB) - Italy

www.boldrocchi.eu

In Italy

Ph. +39 - 0392202.1

Fax +39 - 0392754200

E-mail: boldrocchi@boldrocchi.eu

Interactive

table of contents

History and profile

1

Group structure

3

Heat exchangers

5

Electrical machines

cooling systems

9

Fans

13

Naval applications

16

Heavy-duty fans

17

Turbogas environmental

protections

Over one century of experience and know-how in Air Pollution Control

E-mail: rath@boldrocchi.in

Ph. +39 - 039617515

Fax +39 - 0396014451

E-mail: boldrocchi@boldrocchi.eu

E-mail: boldrocchi@boldrocchi.com.br

Ph. +39 - 0392202.700

Fax +39 - 0392753498

E-mail: boldrocchi@boldrocchi.eu

E-mail: info@boldrocchi.com.mx

Ph. +39 - 0392202330

Fax +39 - 0392754188

E-mail: boldrocchi@boldrocchi.eu

Ph. +39 - 0396882411

Fax +39 - 0396882531

E-mail: btetorri@btetorri.com

in usa

E-mail: bJgallagher@msn.com

21

Noise protection

in industry

23

Turn-key plants

25

Air pollution control

27

Cooling towers

29

Service&Revamping

30

Main customers

31

Contacts

35

Ph. +39 - 0392202.1

Fax +39 - 0392754200

E-mail: saccenti@boldrocchi.eu

Foreign

branches

BLAZ JURKO

FLORIDA-USA

Air Pollution Control

E-mail: info@apolloamericas.com

Group Headquarters

ventilateurs - depoussierage

E-mail: accueil@boldrocchi.fr

E-mail: mbi.eggers@t-online.de

GERMANY

REGISTERED OFFICE AND FACTORY - Chennai

E-mail: india@boldrocchi.org

CORPORATE SALES OFFICE - Gurgaon

E-mail: nokesh@boldrocchi.org

Viale Trento e Trieste 93

20853 Biassono (MB) - Italy

Phone +39 039 2202.1

Fax +39 039 2754200

E-mail: boldrocchi@boldrocchi.eu

Indian Headquarters & Factory

B - 56 & 57, SIPCOT Industrial Area Irrungatturkottai,

Kancheepuram - 602105 (TN)

Phone +91 44 47111666

Fax +91 44 47193093

E-mail: india@boldrocchi.org