Manual

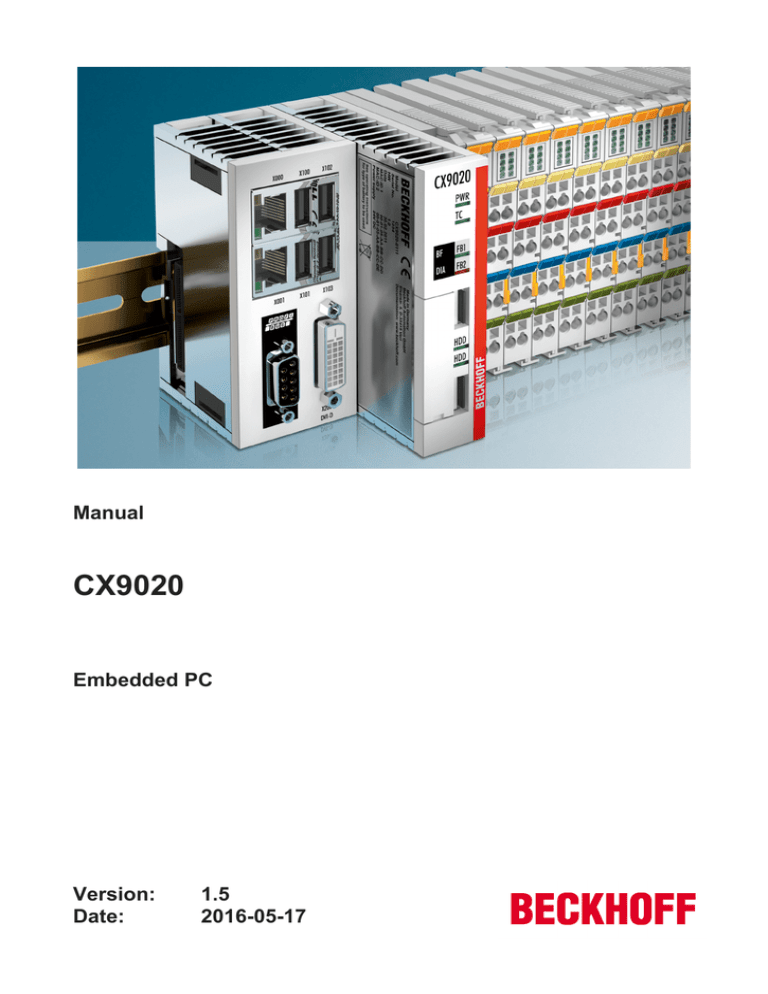

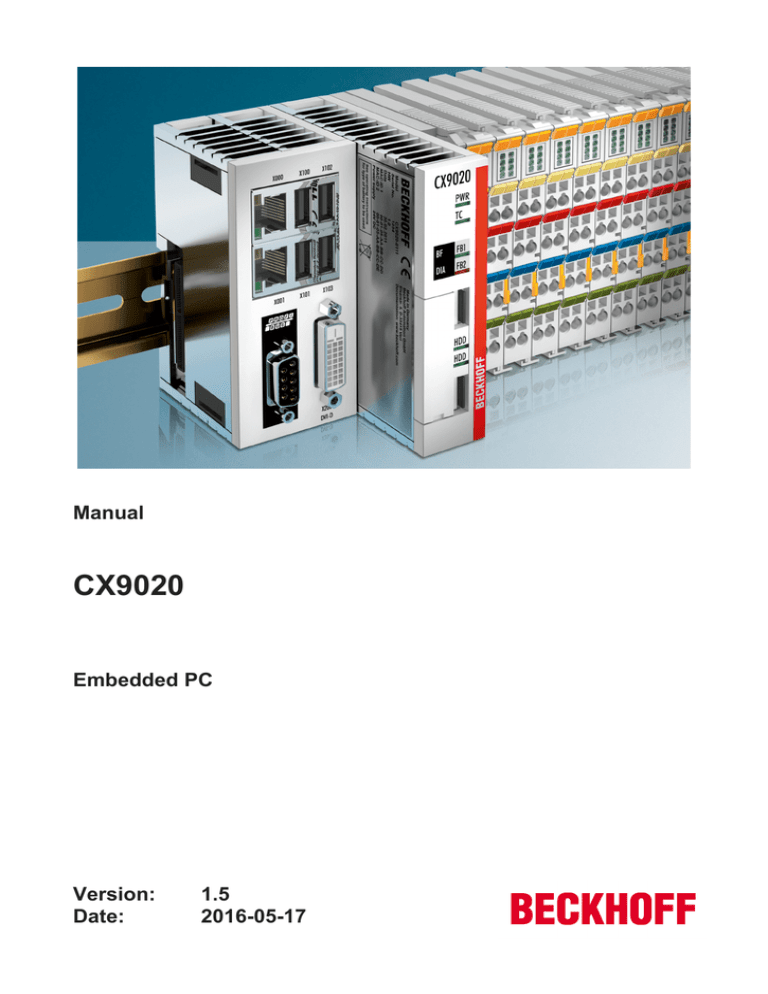

CX9020

Embedded PC

Version:

Date:

1.5

2016-05-17

Table of contents

Table of contents

1 Foreword .................................................................................................................................................... 4

1.1

Notes on the documentation............................................................................................................. 4

1.2

Safety instructions ............................................................................................................................ 5

1.3

Documentation issue status.............................................................................................................. 6

2 Product overview....................................................................................................................................... 7

2.1

Intended use ..................................................................................................................................... 7

2.2

System overview............................................................................................................................... 8

2.3

CX9020 Technical data .................................................................................................................. 10

2.4

Types .............................................................................................................................................. 11

2.5

Architecture overview ..................................................................................................................... 12

2.6

Battery compartment ...................................................................................................................... 13

2.7

Micro-SD slot .................................................................................................................................. 14

2.8

Micro SD card ................................................................................................................................. 15

2.9

S-UPS: capacitive one-second UPS............................................................................................... 16

3 Mounting and wiring ............................................................................................................................... 17

3.1

Unpacking, installation and transport.............................................................................................. 17

3.2

Dimensions ..................................................................................................................................... 18

3.3

Installation on the mounting rail ...................................................................................................... 19

3.4

Power supply .................................................................................................................................. 21

3.5

Mounting of passive terminals on the CX9020 power supply ......................................................... 23

3.6

DVI-D port....................................................................................................................................... 24

3.7

USB connections ............................................................................................................................ 26

3.8

LAN connections............................................................................................................................. 27

3.9

Audio interface (CX9020-N020)...................................................................................................... 28

3.10 RS232 connections (CX9020-N030) .............................................................................................. 30

3.11 RS422/RS485 connections (CX9020-N031) .................................................................................. 31

4 Commissioning........................................................................................................................................ 33

4.1

Switching on and off ....................................................................................................................... 33

4.2

1 Seconds UPS .............................................................................................................................. 34

4.2.1 Overview ............................................................................................................................. 34

4.2.2 Functions ............................................................................................................................ 38

4.2.3 Data Types.......................................................................................................................... 39

5 Error handling and diagnostics ............................................................................................................. 40

5.1

LEDs on the basic CPU module ..................................................................................................... 40

5.2

LEDs of the power supply in K-bus mode....................................................................................... 41

5.3

LEDs of the power supply in E-bus mode....................................................................................... 44

5.4

Faults .............................................................................................................................................. 45

6 Decommissioning.................................................................................................................................... 46

6.1

Disassembly and disposal .............................................................................................................. 46

7 Appendix .................................................................................................................................................. 48

7.1

Accessories .................................................................................................................................... 48

7.2

Support and Service ....................................................................................................................... 49

7.3

Certifications ................................................................................................................................... 50

CX9020

Version: 1.5

3

Foreword

1

Foreword

1.1

Notes on the documentation

This description is only intended for the use of trained specialists in control and automation engineering who

are familiar with the applicable national standards.

It is essential that the following notes and explanations are followed when installing and commissioning

these components.

The responsible staff must ensure that the application or use of the products described satisfy all the

requirements for safety, including all the relevant laws, regulations, guidelines and standards.

Disclaimer

The documentation has been prepared with care. The products described are, however, constantly under

development.

For that reason the documentation is not in every case checked for consistency with performance data,

standards or other characteristics.

In the event that it contains technical or editorial errors, we retain the right to make alterations at any time

and without warning.

No claims for the modification of products that have already been supplied may be made on the basis of the

data, diagrams and descriptions in this documentation.

Trademarks

Beckhoff®, TwinCAT®, EtherCAT®, Safety over EtherCAT®, TwinSAFE®, XFC®and XTS® are registered

trademarks of and licensed by Beckhoff Automation GmbH.

Other designations used in this publication may be trademarks whose use by third parties for their own

purposes could violate the rights of the owners.

Patent Pending

The EtherCAT Technology is covered, including but not limited to the following patent applications and

patents:

EP1590927, EP1789857, DE102004044764, DE102007017835

with corresponding applications or registrations in various other countries.

The TwinCAT Technology is covered, including but not limited to the following patent applications and

patents:

EP0851348, US6167425 with corresponding applications or registrations in various other countries.

EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation GmbH,

Germany

Copyright

© Beckhoff Automation GmbH & Co. KG, Germany.

The reproduction, distribution and utilization of this document as well as the communication of its contents to

others without express authorization are prohibited.

Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a

patent, utility model or design.

4

Version: 1.5

CX9020

Foreword

1.2

Safety instructions

Safety regulations

Please note the following safety instructions and explanations!

Product-specific safety instructions can be found on following pages or in the areas mounting, wiring,

commissioning etc.

Exclusion of liability

All the components are supplied in particular hardware and software configurations appropriate for the

application. Modifications to hardware or software configurations other than those described in the

documentation are not permitted, and nullify the liability of Beckhoff Automation GmbH & Co. KG.

Personnel qualification

This description is only intended for trained specialists in control, automation and drive engineering who are

familiar with the applicable national standards.

Description of symbols

In this documentation the following symbols are used with an accompanying safety instruction or note. The

safety instructions must be read carefully and followed without fail!

Serious risk of injury!

Failure to follow the safety instructions associated with this symbol directly endangers the

life and health of persons.

DANGER

Risk of injury!

Failure to follow the safety instructions associated with this symbol endangers the life and

health of persons.

WARNING

Personal injuries!

Failure to follow the safety instructions associated with this symbol can lead to injuries to

persons.

CAUTION

Damage to the environment or devices

Failure to follow the instructions associated with this symbol can lead to damage to the environment or equipment.

Attention

Tip or pointer

This symbol indicates information that contributes to better understanding.

Note

CX9020

Version: 1.5

5

Foreword

1.3

Version

0.1

1.0

1.1

1.2

1.3

1.4

1.5

6

Documentation issue status

Changes

Preliminary version

First publication

UPS chapter added

UPS notes added

Reworked images in chapter battery compartment

Chapter Technical Data reworked

Architecture overview added, Chapter Types

reworked

Version: 1.5

CX9020

Product overview

2

Product overview

2.1

Intended use

The CX9020 device series is a control system designed for DIN rail installation. The system can be installed

in the control cabinet or terminal box as required.

Only switch the PC off after closing the software

Before the Embedded PC is switched off, the software currently running on it should be stopped properly in

order to avoid data loss on the hard disk. Please read the section on “Switching off”.

Switch off all system components and uncouple the Industrial PC from the system if the PC is not used for

control purposes, e.g. during a function test. To disconnect first pull the first terminal behind the power

supply unit (optional), then pull the connectors of the fieldbus connections.

System components that have been switched off must be secured against being switched on again.

The Embedded PC’s power supply unit must be supplied with 24 VDC.

Damage to the environment or devices

Attention

Do not exchange any parts when under power! The exchange of controller parts when live

can lead to short-circuits or overvoltages. These can damage the controller itself and connected peripherals (terminals, monitors, input devices, etc.).

When components are being fitted or removed, the supply voltage must be switched off.

Software knowledge

System malfunctions

Mandatory software knowledge! Every user must be familiar with any of the functions of the

software installed on the PC that he can reach.

Attention

CX9020

Version: 1.5

7

Product overview

2.2

System overview

The system

The CX9020 is a compact, DIN rail-mountable Ethernet control system with 1 GHz ARM Cortex™ A8 CPU.

The connection for the Beckhoff I/O systems is directly integrated into the CPU module. The unit offers

automatic bus system identifi cation (K-bus or E-bus) and independently switches in the corresponding

mode. The CX9020 comprises the CPU with two microSD card slots, the internal RAM and 128 kB NOVRAM

as nonvolatile memory. The basic configuration also includes two switched Ethernet RJ 45 interfaces, four

USB-2.0 interfaces and a DVI-D interface. The RJ 45 interfaces are connected to an internal switch and offer

a simple option for creating a line topology without the need for additional Ethernet switches. The operating

system is Microsoft Windows Embedded Compact 7. TwinCAT 2 automation software transforms a CX9020

system into a powerful PLC and Motion Control system that can be operated with or without visualisation.

Optionally, the unit can be ordered with a fi eldbus, serial or audio interface.

The extended operating temperature range between -25 and +60 °C enables application in climatically

demanding situations.

EtherCAT as a fast I/O system

The CX9020 Embedded PC was developed for optimum interaction with EtherCAT.

Interestingly, EtherCAT offers several options for connecting conventional fieldbus systems to the CX9020:

As an EtherCAT device in terminal form. The PROFIBUS master is available either as a CX1500-M310 or as

a EL6731 EtherCAT terminal. In practice, this means that the PROFIBUS master can be positioned exactly

where it is required within a machine. It no longer has to be implemented as a plug-in card in the IPC or a

master controller in the control cabinet.

PLC, Motion Control, interpolation and visualisation

As a DIN rail IPC and in conjunction with the TwinCAT software from Beckhoff, the CX9020 offers the same

functionality as large Industrial PCs. In terms of PLC, up to four virtual IEC 61131 CPUs can be programmed

with up to four tasks each. All IEC 61131-3 languages can be used.

Moreover, all TwinCAT functionalities are available for Motion Control applications:

In theory, up to 256 axes can be controlled. In addition to simple point-to-point movements, more complex

multi-axis functions such as “electronic gearbox”, “cam plates” and “flying saw” can be implemented.

In addition to real-time execution of control tasks, the TwinCAT real-time kernel ensures that enough time

remains for the user interface (HMI), to communicate with the real-time components via software interfaces

such as ADS or OPC.

8

Version: 1.5

CX9020

Product overview

For CX9020 the familiar basic principle applies: it is a programming tool for all controllers.

The complete programming of PLC, Motion Control and visualisation is transferable to all PC controls from

Beckhoff, which is reassuring in cases where it becomes apparent during a project that more processing

power is required after all. In this case a system with higher performance can be used.

Optional interfaces:

The optional interfaces can be used to connect single-channel fieldbus interfaces. Operation is limited to one

interface at a time. If several fieldbus interfaces are required, they can be added as E-bus terminals

(EL67xx). The following fieldbus interfaces are available:

• CX9020-N020 = Audio, 3 x 3.5 mm jack plugs, Line-In, Mic-In, Line-Out

• CX9020-N030 = RS232, D-Sub connector, 9-pin

• CX9020-N031 = RS422/RS485,D-Sub socket, 9-pin

• CX9020-B110 = EtherCAT slave, EtherCAT IN und OUT (2 x RJ 45)

• CX9020-M310 = PROFIBUS master, D-Sub socket, 9-pin

• CX9020-B310 = PROFIBUS slave,D-Sub socket, 9-pin

• CX9020-M510 = CANopen master, D-Sub socket, 9-pin

• CX9020-B510 = CANopen slave, D-Sub socket, 9-pin

• CX9020-M930 = PROFINET RT, controller Ethernet (2 x RJ 45)

• CX9020-B930 = PROFINET RT, device, Ethernet (2 x RJ-45-Switch)

• CX9020-B950 = EtherNet/IP slave, Ethernet (2 x RJ-45-Switch)

The software

In combination with the TwinCAT automation software, the CX9020 Industrial PC becomes a powerful IEC

61131-3 PLC with up to four user tasks. Additionally, Motion Control tasks can also be executed. Depending

on the required cycle time, several servo axes can be controlled.

The CX9020 system is programmed in the same way as other bus controllers:

Remote programming via Ethernet

This option is used if the basic unit is equipped with “Windows Embedded Compact 7”. In this case, the

system is programmed via a laptop or a desktop PC, which is connected to the CX via Ethernet (network or

crossover cable). The programs are developed on the laptop with a standard TwinCAT software licence and

then loaded into the target device.

CX9020

Version: 1.5

9

Product overview

2.3

CX9020 Technical data

The basic configuration of the CX9020 includes a 256 MB µSD Flash card. The basic configuration includes

two Ethernet RJ-45 interfaces (connected via the internal switch), four USB 2.0 interfaces and a DVI-D

interface.

Process data

The process data must not exceed the maximum size of 3328 bytes. For some projects, the maximum

process data size may be lower than 3328 bytes and it depends on the project.

Technical Data

Processor

Internal Flash memory

Internal main memory

Persistent memory

UPS

Interfaces

Diagnostics LED

Clock

Operating system

Control software

Power supply

Current supply

Max. power loss

Dielectric strength

Dimensions (H x W x D)

Weight

Operating/storage temperature

Relative humidity

Vibration/shock resistant

EMC immunity/emission

Protection class

CX9020

ARM Cortex™-A8, 1 GHz

256 MB MicroSD (optional expandable), 2 x MicroSD

card slot

1 GB DDR3 RAM

128 kB NOVRAM integrated

1-Sekunden-UPS integrated (optional)

2 x RJ 45 (Ethernet, internal Switch), 10/100 MBit/s,

DVI-D, 4 x USB 2.0, 1 x optional interface

1 x power, 1 x TC status, 2 x bus status, 2 x flash

access

Internal clock with battery backup for time and date

(battery replaceable)

Microsoft Windows Embedded Compact 7

TwinCAT 2 PLC runtime or TwinCAT 2 NC PTP

runtime

24 V DC (-15 %/+20 %)

I/O terminals 2 A

5 W (including system interfaces)

500 Veff (supply/internal electronics)

84 mm x 99 mm x 91 mm

approx. 590 g

-25° C ... +60° C / -40° C ... +85° C

95 % no condensation

conforms to EN 60068-2-6/EN 60068-2-27/ 29

conforms to EN 61000-6-2 / EN 61000-6-4

IP 20

Further Information: www.beckhoff.de/CX9020

10

Version: 1.5

CX9020

Product overview

2.4

Types

The CPU module can be equipped with different software options for control software. The operating system

is limited to "Windows Embedded Compact 7". The TwinCAT automation software transforms a CX9020

system into powerful PLC and Motion Control system that can be operated with or without visualization.

Further system interfaces (pre-installed in the factory) or fieldbus connections can be added to the basic

CPU module.

The CX9020 is available in the following types:

Table 1: CX9020 (1 GHz 1 core)

Module

no

operating

system

CX9020-0100

X

CX9020-0110

CX9020-0111

CX9020-0112

CX9020-0115

Windows

Embedded

Compact 7

X

X

X

X

no

TwinCAT

X

X

-

TwinCAT 2

TwinCAT 2

PLC runtime NC runtime

X

-

TwinCAT 3

XAR

X

-

X

Software Images

A list of the different software images can be found in the Software Documentation.

Note

CX9020

Version: 1.5

11

Product overview

2.5

Architecture overview

The architecture of the CX9020 Embedded PC is described below.

The CX9020 Embedded PC is based on the ARMv7-A microarchitecture, which was developed by ARM®.

The following CPU is used in the CX9020:

• i.MX535 CortexTM-A8

For details on the CPUs please refer to ARM. The memory is connected directly to the CPU. The Embedded

PC is available in one memory configuration: with 1GB DDR3 RAM. The memory is not expandable. The

CX9020 Embedded PC has two MicroSD card slots.

The CPU provides all required interfaces:

• 2x switched Ethernet-RJ45

• 4x USB 2.0

• DVI-D

• Serial interface (CX20x0-N03x)

• 1 EMI for FPGA for K-/E-Bus and NOV-RAM

• 2x MicroSD card slots

The interfaces USB, DVI, and LAN ports are standard interfaces. They can be used for operating devices

that comply with the standard. Only digital signals can be transmitted over the DVI-D interface.

The RJ45 interfaces are connected to an internal switch, without the need for additional Ethernet switches.

Details of the individual system interfaces are described in separate sections.

12

Version: 1.5

CX9020

Product overview

2.6

Battery compartment

The battery compartment is located under the front cover of the CX20x0. The opening in which the battery

bracket is mounted can be seen when the front cover is opened. The battery is then pulled carefully out of

the holder with the help of the ejection tab and then removed.

To insert a new battery push it into the battery compartment. Ensure correct polarity. Then close the front

cover. The battery change is then complete.

The battery is a CR2032 type from Panasonic.

The correct specifications are:

Battery type

CR2032

Electrical properties

(at 20 °C)

nominal

nominal

voltage

capacity

3.0 V

225 mAh

Standard

charge

continuous

load

0.20 mA

Dimensions

diameter

height

weight

20.0 mm

3.20 mm

3.1 g

An incorrectly inserted battery may explode!

Attention

Only use the same battery type (CR2032) from Sanyo or Panasonic. Make absolutely sure

that positive and negative terminals of the battery are inserted correctly. (Positive pole on

the left) Never open the battery or throw it into a fire. The battery cannot be recharged.

Battery maintenance

The battery must be replaced every 5 years. Spare batteries can be ordered from Beckhoff

Service.

Note

CX9020

Version: 1.5

13

Product overview

2.7

Micro-SD slot

Two µSD Flash slots are located at the front, which enables the storage medium to be replaced. This allows

the storage medium to be exchanged. The card in the upper slot (Slot 1) is used for the operating system.

The lower slot (Slot 2) is used for an additional µSD card. Here data or further programs can be archvied.

The µSD Flash card can be removed from the module for maintenance. This should only be done in

switched-off state, otherwise the system may crash. In this way it is also possible to expand the system

(only operating system and program memory). MicroSD Flash cards (µSD cards) are available as accessories

[} 48] in various sizes.

The following images illustrate the handling of the µSD cards. The eject mechanism is based on the pushpush principle: The CFast Flash card is disengaged with a soft click by lightly pressing the card ( with a

screwdriver) . At the same time the card moves approx. 2-3 mm out of the housing, so that it can be pulled

out.

When the card is pushed back the eject mechanism locks again. The card is positioned correctly, if it is

located approx. 1 mm lower than the front of the housing.

14

Version: 1.5

CX9020

Product overview

2.8

Micro SD card

The micro SD Flash Card (µSD Card) is a non-volatile memory.

Data to be retained in the event of a power failure should be saved on the µSD card. The µSD card operates

like a hard disk.

Using µSD cards

Note

CX9020

We strongly recommend that only µSD cards supplied by Beckhoff Automation GmbH

should be used. These are industrial µSD cards with a higher number of write/read cycles

and an extended temperature range (+85 °C). Proper operation can only be guaranteed

with µSD cards from Beckhoff Automation GmbH!

Version: 1.5

15

Product overview

2.9

S-UPS: capacitive one-second UPS

The CX9020_U900 family features a built-in capacitive one-second UPS. It ensures a safe storage of the

persistent application data on the Compact Flash card.

Up to 1 MB of persistent data can be saved.

Integration into a PLC

TwinCAT offers special function blocks for integrating the S-UPS into a PLC program. These are described

in the chapter Commissioning>1 Second UPS. For TwinCAT 2.11R3 Build 2247 or TwinCAT 3.1 Build 4018

the required library is integrated in the installation. For older versions the library TcSUPS_CX9020_U900.lib

has to be copied into the TwinCAT library directory.

16

Version: 1.5

CX9020

Mounting and wiring

3

Mounting and wiring

3.1

Unpacking, installation and transport

The specified storage conditions must be adhered to (see "Technical data").

Dimensions and weight of the individual modules:

Dimensions (W x H x D): 144 mm x 100 mm x 91 mm

Weight: approx. 1160 g / 1165g / 1230 g (basic module)

Unpacking

Proceed as follows to unpack the unit:

1.

2.

3.

4.

5.

6.

Remove packaging.

Do not discard the original packaging. Keep it for transporting the device in the future.

Check the delivery for completeness by comparing it with your order.

Please keep the associated paperwork. It contains important information for handling the unit.

Check the contents for visible shipping damage.

If you notice any shipping damage or inconsistencies between the contents and your order, you

should notify Beckhoff Service.

Danger of damage to the device!

Attention

During transport in cold conditions, or if the device is subjected to extreme temperature differences, condensation on and inside the device must be avoided. Prior to operation, the

device must be allowed to slowly adjust to room temperature. Should condensation occur,

a delay time of approximately 12 hours must be allowed before the unit is switched on.

Installation

The devices are designed for installation in control cabinets.

Shipping and relocation

Despite the robust design of the unit, the components are sensitive to strong vibrations and impacts. During

transport, your computer should therefore be protected from excessive mechanical stress. Therefore, please

use the original packaging.

CX9020

Version: 1.5

17

Mounting and wiring

3.2

Dimensions

The following drawing shows the dimensions of the CX9020 devices.

Dimensions

18

Version: 1.5

CX9020

Mounting and wiring

3.3

Installation on the mounting rail

Snapping onto the mounting rail

The CX9020 can simply be snapped onto the mounting rail. The bar clips are inserted on the top side and

underside Then simply position the block on the mounting rail and push it slightly until it engages on the

right-hand side. This is indicated by a distinct click. The bars are then engaged again. The engagement of

the individual bars is indicated by a distinct click.

Avoid damage!

Do not force the module or apply excessive pressure!

Attention

Installation position

Comply with the permitted installation position and minimum distances!

Attention

CX9020

The maximum ambient temperature for CPU modules mounted on a top-hat rail is 60°C.

The orientation in which the device is fitted must be selected in such a way that cooling air

can flow vertically through the ventilation holes. The images below show the permitted and

two incorrect installation positions. Mounting must provide a clearance of 30 mm both

above and below a CX9020 device combination to ensure adequate ventilation of the base

CPU module and the power supply unit.

Version: 1.5

19

Mounting and wiring

Correct installation position

The high performance and the compact design of the CX9020 systems may result in increased heat

generation. The heat is dissipated via a passive ventilation system. This system requires the unit to be

mounted correctly. Ventilation openings are located at the top and bottom of the housing. The system

therefore has to be installed horizontally. This ensures optimum air flow.

Incorrect installation positions

The CX9020 system must not be operated vertically on the top-hat rail. A vertical position would lead to

insufficient CPU ventilation, since the ventilation openings are located on the top and bottom of the housing.

Installation of the system on its side would also lead to inadequate ventilation.

invalid installation position

20

invalid installation position

Version: 1.5

CX9020

Mounting and wiring

3.4

Power supply

This power supply unit is equipped with an I/O interface, which permits connection of the Beckhoff Bus

Terminals. The power is supplied via the upper spring-loaded terminals labeled “24V” and “0V”.

The supply voltage supplies the CX system ant the terminal Bus and Bus Terminal with a voltage of 24 V DC

(-15 %/+20 %). The dielectric strength of the power supply unit is 500 Vrms. Since the Terminal Bus (K- and

E-bus) only transfers data, a separate power supply is required for the Bus Terminals. This is provided by

means of the power contacts, which are not connected to the power supply.

Requirements for the 24V power supply

The power supply must be capable to supply 4A at 24 V to guarantee proper function of CPU CX9020

module and terminals.

CX9020

Version: 1.5

21

Mounting and wiring

The terminals are implemented in spring force technology. Connect the cables as follows:

1. Open a spring-loaded terminal by slightly pushing with a screwdriver or a rod into the square opening

above the terminal.

2. The wire can now be inserted into the round terminal opening without any force.

3. The terminal closes automatically when the pressure is released, holding the wire securely and

permanently.

Wire size width

Wire stripping length

0.5 ... 2.5 mm2

8 ... 9 mm

AWG 20 .. AWG 14

0.33 inch

LED

If the power supply unit is connected correctly and the power supply is switched on, the two upper LEDs in

the terminal prism are green. The left LED (Us) indicates the CPU supply. The right LED (Up) indicates the

terminal supply. The other LEDs indicate the Terminal Bus status. A detailed description of the LEDs can be

found in section "LED troubleshooting".

Power contact PE

Powerkontakt "PE"

Attention

The “PE” power contact must not be used for other potentials. "PE" und "0V" (24V CX-System supply) have to be on the same potential. (connected in the cabinet) Der Powerkontakt

"PE" darf nicht für andere Potentiale verwendet werden. "PE" und "0V" (24V Systemversorgung) müssen auf dem gleichen Potential liegen. (im Schaltschrank verbunden) The

wiring the cabinet has to follow the Norm EN EN 60204-1:2006: Safety of machinery - Electrical equipment of machines - (PELV = Protective Extra Low Voltage)EN 60204-1:2006

chapter 6.4.1:b): One side of the circuit or a point of the energy source of the circuit must

be connected to protective earth system

Interrupt power supply / switching off

Attention

22

If the power supply should be disconnected the "0V" must not be disconnected. Always disconnect the “24V” wire first. Otherwise there can be electrical current flow via the shield.

Possibly connected devices with own power supply (e.g. panel) must have the same electrical potential for "PE" and "GND" as the CX-unit. Otherwise the CX-unit and/or the connected device can be damaged.

Version: 1.5

CX9020

Mounting and wiring

3.5

Mounting of passive terminals on the CX9020 power

supply

Note on the mounting of passive terminals

Note

EtherCAT Bus Terminals (ELxxxx/ESxxxx) that do not actively participate in data exchange

within the Bus Terminal block are called passive terminals. These terminals can be recognised by their lack of power consumption from the E-Bus. In order to ensure optimal data

exchange, these may not be connected directly in-line to the power supply!

Examples of the mounting of passive terminals (coloured dark):

The following drawing shows impermissible mounting:

The following illustration shows the correct mounting of the passive terminal:

CX9020

Version: 1.5

23

Mounting and wiring

3.6

DVI-D port

DVI-D port (X200)

The DVI-D interface transfers digital data and is suitable for connecting a digital display. The resolution at the

display or the Beckhoff Control Panel depends on the distance from the display device. The maximum

distance is 5 m. Beckhoff offers various Panels with an integrated “DVI extension”. These make a cable

length of up to 50 meters possible.

DVI-D Interface

The DVI interface does not use VGA signals, so that the connection of CRT VGA monitors

to the CX9020 system using a DVI to VGA adapter is not possible.

Note

DVI-D socket

Pin

1

2

3

4

5

6

7

Assignment

TMDS Data 2TMDS Data 2+

TMDS Data 2/4 Shield

not connected

not connected

DDC Clock

DDC Data

Pin

9

10

11

12

13

14

15

8

Analog Vertical Sync

16

24

Assignment

TMDS Data 1TMDS Data 1+

TMDS Data 1/3 Shield

not connected

not connected

+ 5V Power

Ground ( +5V, Analog

H/V Sync)

Hot Plug Detect

Version: 1.5

Pin

17

18

19

20

21

22

23

Assignment

TMDS Data 0TMDS Data 0+

TMDS Data 0/5 Shield

not connected

not connected

TMDS Clock Shield

TMDS Clock +

24

TMDA Clock -

CX9020

Mounting and wiring

Resolution at the monitor

Resolution in pixels

1920 x 1200

1920 x 1080

1600 x 1200

1280 x 1024

1024 x 768

800 x 600

640 x 480

Distance of the interface from the monitor

5m

5m

5m

5m

5m

5m

5m

The Embedded PC also supports higher resolutions according to the DVI standard. A maximum resolution of

2560 x 1440 pixels can be set on the Embedded PC. Whether this resolution is achieved is dependent on

the monitor, the cable quality and cable length.

CX9020

Version: 1.5

25

Mounting and wiring

3.7

USB connections

USB interface (X100 / X101 / X102 / X103):

The CX9020 has 4 independent USB interfaces, for connecting keyboards, mice, touchscreens and other

input or data storage devices. Attention is thereby to be paid to the power consumption of the individual

devices: No more than 500 mA can be output per port.

The USB socket is a type A socket. The USB interface complies with the USB 2.0 specification.

Pin

1

2

3

4

Shell

26

Assignment

VBUS

DD+

GND

Shield

Version: 1.5

Typical assignment

Red

White

Green

Black

Drain Wire

CX9020

Mounting and wiring

3.8

LAN connections

LAN interface (X000/ X001)

The CX9020 systems have two switched LAN interfaces. Both ports are able to operate at speeds of 10 /

100 Mbit. The LEDs on the left-hand sides of the RJ45 sockets indicate the status of the LAN connection.

The upper LED indicates whether the port is connected to a network. The LED flashes if data traffic takes

place on the port (Link /Activity). The lower LED indicates the connection speed. The LED is off if the speed

is 10 Mbit. In 100 Mbit mode the LED is green.

Table 2: Configuration of the RJ45 interface, port 1 (X000) / port 2 (X001)

PIN

1

2

3

4

5

6

7

8

Signal

TD +

TD RD +

connected

Description

Transmit +

Transmit Receive +

not used

RD connected

Receive not used

Dependence of the ports

Both ports are dependent of each other. In contrast to the CX50x0 and CX20x0 systems,

one switch is integrated. For a line topology no further switch is required.

Note

CX9020

Version: 1.5

27

Mounting and wiring

3.9

Audio interface (CX9020-N020)

This system interface provides the audio interface for the CX9020 system. Two inputs, "LINE IN" (X300) and

"MIC IN" (X302), are available. The "LINE OUT" (X301) connection is used as output for audio signals. It can

also be used for connecting headphones with a maximum output of 200 mW. The audio interfaces are

accessed via the operating system.

The 3.5 mm sockets are designed for jack plugs.

Standard / stereo mode:

The audio module operates in stereo mode as standard, using stereo outputs/inputs and a single-channel

input for the microphone. The inputs should be connected as indicated. The pin assignments are described

below.

Line In / Line Out stereo jack plugs (X300 / X302):

Table 3: Pin assognment Line In /Line Out:

Signal

L

R

Ground

Description

Left channel

right channel

Ground

The left channel is transferred via the tip of the jack plug, the right channel via the first ring. The remainder of

the sleeve is used for earthing.

Mic In mono jack plug (X301):

28

Version: 1.5

CX9020

Mounting and wiring

The only existing channel is transferred via the tip, the remainder of the sleeve is used for earthing.

The audio settingsa can be done via the Beckhoff CX-Configuration Tool. Open the tool via

Startmenue -> Control Panel -> CX Configuration

Navigate to tab "Miscellaneous" to change audio settings.

The checkbox "Enable Audio Device" enables or disables the interface. With "Audio Settings" a "Mixer" can

be called. The volume for the output and input is selected with the slider. The input source can be selected

with "Input select". Only one source (LINE or MIC) can be active at once. "OK" confirms these settings.

CX9020

Version: 1.5

29

Mounting and wiring

3.10

RS232 connections (CX9020-N030)

The CX9020-N030 system interface provides an RS232 interface, COM1 (X300). It is implemented on a 9pole Sub-D pin strip. If more than one interface is required the system can be extended via the Terminal Bus

(K- or E-bus) or Bus Terminals (KL/EL6001) which provide serial interfaces. The pin assignment is shown at

the bottom of the page.

The maximum baud rate on both channels is 115 kbit. The interface parameters are set via the operating

system or from the PLC program.

RS232 COM interface (connector)

Table 4: Pin assignment of the COM interface

PIN

2

3

5

7

8

30

Signal

RxD

TxD

GND

RTS

CTS

Type

Signal in

Signal out

Ground

Signal out

Signal in

Version: 1.5

Description

Receive Data

Transmit Data

Ground

Ready to Send

Clear to Send

CX9020

Mounting and wiring

3.11

RS422/RS485 connections (CX9020-N031)

The CX9020-N030 system interface provides an RS422 or RS 485 interface, COM1 (X300). It is

implemented on a 9-pole Sub-D socket strip. If more than one interface is required the system can be

extended via the Terminal Bus (K- or E-bus) or Bus Terminals (KL/EL6021) which provide serial interfaces.

The pin assignment is shown at the bottom of the page.

The maximum baud rate on both channels is 115 kbit. The interface parameters are set via the operating

system or from the PLC program.

COM interface (socket)

Table 5: Pin assignment of the COM interface

PIN

2

3

5

6

7

8

Signal

TxD+

RxD+

GND

VCC

TxDRxD-

Type

Data-Out +

Data-In +

Ground

VCC

Data-Out Data-In -

Description

Transmit 422

Receive 422

Ground

+5V

Transmit 422

Receive 422

For RS 485 pins 2 and 3 (data +) must be connected, and pins 7 and 8 (data -).

Setting the interface parameters

The interface is parameterised as follows in the delivery condition:

Table 6: RS485 without echo, end point (terminated) standard setting

Function

Echo on

Echo off

Auto send on

Always send on

Auto receive on

Always receive on

Term on

Term on

CX9020

Status

off

on

on

off

on

off

on

on

Version: 1.5

31

Mounting and wiring

Changing the interface parameters

Note

32

If parameters other than those set should be required, please choose the right order number:

- CX9020-N031-0001 RS485 with Echo, End-Point (Terminated)

- CX9020-N031-0002 RS485 without Echo, Drop-Point (not Terminated)

- CX9020-N031-0003 RS485 with Echo, Drop-Point (not Terminated)

- CX9020-N031-0004 RS422 Full Duplex, End-Point (Terminated)

Version: 1.5

CX9020

Commissioning

4

Commissioning

4.1

Switching on and off

Switching on

The power supply for the basic CPU module comes from the power supply unit. The basic CPU module

starts automatically when the power supply unit is connected to the mains.

Switching on for the first time

When you switch on the PC for the first time, the pre-installed operating system (optional) will be started.

Switching off

The Embedded PC switches off when the power supply unit is switched off. The control software typically

running on Embedded PCs should be shut down or stopped correctly. A user who may not close software

may also not switch the Embedded PC off, since data can be lost from the hard disk by switching off while

software is running.

Once the software has been stopped, the operating system can be shut down. Only then should the power

supply be interrupted.

CX9020

Version: 1.5

33

Commissioning

4.2

1 Seconds UPS

4.2.1

Overview

The library TcSUPS_CX9020_U900.lib includes functions and function blocks required for controlling the

one-second UPS.

Function blocks

Name

FB_S_UPS_CX9020_U900

FB_NT_QuickShutdown

Description

Block for controlling the one-second UPS

Internal block for QuickShutdown, used by the

FB_S_UPS.

Functions

Name

F_GetVersionTcSUPS_CX9020_U900

Description

This function can be used to read PLC library version

information.

Component

Version

TwinCAT on the development PC and on the control TwinCAT 2.11R3 Build 2047 or higher

system

4.2.1.1

FUNCTION_BLOCK FB_S_UPS_CX9020_U900

The function block FB_S_UPS_CX9020_U900 can be used on CX devices with one-second UPS to control

the one-second UPS from the PLC. This allows the persistent data to be saved and a quick shutdown to be

performed in the event of a power failure. If possible the default values of the INPUTs of the

FB_S_UPS_CX9020_U900 should be retained.

Loss of data

Attention

The seconds UPS can be used only for a few seconds in the event of a power failure in order, to save persistent data. The data must be saved in the fast “persistent mode”

“SPDM_2PASS”, even though this can lead to real-time violations. Sufficient router memory

must be configured for the storage of the persistent data!

The second UPS does not have sufficient capacity for bridging power failures. Only the CFast card can be

used for data storage, in view of the fact that the UPS capacity is inadequate for operating a hard disk.

A QuickShutdown is performed automatically in the eSUPS_WrPersistData_Shutdown mode (standard

setting) after the storage of the persistent data.

In eSUPS_WrPersistData_NoShutdown mode only the persistent data are stored. No QuickShutdown is

executed.

In the eSUPS_ImmediateShutdown mode a QuickShutdown is executed immediately without saving data.

34

Version: 1.5

CX9020

Commissioning

In the eSUPS_CheckPowerStatus mode only a check is performed as to whether a power failure has

occurred. If this is the case, the module only switches back to the PowerOK state after the expiry of

tRecoverTime (10s).

Independent of the mode and thus independent of the saving or the shutting down of the controller, the UPS

switches the main board off after the capacitors have discharged, even if the voltage has returned in the

meantime.

Caution when using files:

If other applications or the PLC keep other files open or write to them, this can lead to faulty

files if the UPS switches off the controller.

Attention

FUNCTION_BLOCK FB_S_UPS_CX9020_U900

VAR_INPUT

VAR_INPUT

sNetID : T_AmsNetId := ''; (* '' = local netid *)

iPLCPort : UINT := AMSPORT_R0_PLC_RTS1; (* PLC Runtime System for writing persistent data *)

iUPSPort : UINT := 16#4A8; (* Port for reading Power State of UPS, dafault 16#4A8 *)

tTimeout : TIME := DEFAULT_ADS_TIMEOUT; (* ADS Timeout *)

eUpsMode : E_S_UPS_Mode := eSUPS_WrPersistData_Shutdown; (* UPS mode (w/wo writing persistent

data, w/wo shutdown) *)

ePersistentMode : E_PersistentMode := SPDM_2PASS; (* mode for writing persistent data *)

tRecoverTime : TIME := T#10s; (* ON time to recover from short power failure in mode eSUPS_WrPersistData_NoShutdown/eSUPS_CheckPowerStatus *)

END_VAR

E_S_UPS_Mode

sNetID : AmsNetID of the controller.

iPLCPort : Port number of the PLC runtime system (AMSPORT_R0_PLC_RTS1 = 801,

AMSPORT_R0_PLC_RTS2 = 811, AMSPORT_R0_PLC_RTS3 = 821, AMSPORT_R0_PLC_RTS4 = 831).

iUPSPort : Port number via which the UPS status is read (standard value is 16#4A8).

tTimeout : Timeout for the execution of the QuickShutdown.

eUpsMode : The eUpsMode defines whether persistent data are to be written and whether a

QuickShutdown is to be performed.

Standard value is eSUPS_WrPersistData_Shutdown, i.e. with writing of the persistent data and then

QuickShutdown. See E_S_UPS_Mode.

ePersistentMode : Mode for the writing of the persistent data. Standard value is SPDM_2PASS.

tRecoverTime : Time after which the UPS reverts to the PowerOK status in the case of UPS modes without

shutdown.

The tRecoverTime must be somewhat longer than the maximum holding time of the UPS, since the UPS

switches off even when the voltage returns.

VAR_OUTPUT

VAR_OUTPUT

bPowerFailDetect : BOOL; (* TRUE while powerfailure is detected *)

eState : E_S_UPS_State; (* current ups state *)

END_VAR

E_S_UPS_State

bPowerFailDetect : True during the power failure; False if the supply voltage is present.

eState : Internal state of the function block, for values see E_S_UPS_State.

CX9020

Version: 1.5

35

Commissioning

VAR_GLOBAL

VAR_GLOBAL

eGlobalSUpsState : E_S_UPS_State; (* current ups state *)

END_VAR

E_S_UPS_State

eGlobalUpsState : Internal state of the function block as a global copy of the VAR_OUTPUT eState; for

values see E_S_UPS_State.

Prerequisites

Development environment

TwinCAT v2.11R3 Build 2047 or higher

4.2.1.2

Target platform

PC (i386)

Hardware

PLC libraries to include

Seconds UPS

TcSUPS_CX9020_U900.

Lib

FUNCTION_BLOCK FB_NT_QuickShutdown

The function block FB_NT_QuickShutdown can be used to trigger an immediate reboot, without stopping

TwinCAT or the Windows operating system.

Attention:

Loss of data

Attention

The function block FB_NT_QuickShutdown is used internally by

FB_S_UPS_CX9020_U900. It must not be used independently, because this could result in

data loss!

FUNCTION_BLOCK FB_NT_QuickShutdown

VAR_INPUT

VAR_INPUT

NETID :T_AmsNetId;

START :BOOL;

TMOUT :TIME := DEFAULT_ADS_TIMEOUT;

END_VAR

NETID : AmsNetID of the controller.

START : Rising edge leads to immediate reboot of the control system.

TMOUT : Time out period.

VAR_OUTPUT

VAR_OUTPUT

BUSY :BOOL;

ERR :BOOL;

36

Version: 1.5

CX9020

Commissioning

ERRID :UDINT;

END_VAR

BUSY : QuickShutdown is executed.

ERR : Becomes TRUE, as soon as an error occurs.

ERRID : Supplies the error number when the ERR output is set.

Prerequisites

Development environment

TwinCAT v2.11R3 Build 2047 or higher

CX9020

Target platform

PC (i386)

Hardware

PLC libraries to include

One-second UPS

TcSUPS_CX9020_U900.

Lib

Version: 1.5

37

Commissioning

4.2.2

Functions

4.2.2.1

FUNCTION F_GetVersionTcSUPS_CX9020_U900

This function can be used to read PLC library version information.

FUNCTION F_GetVersionTcSUPS_CX9020_U900 : UINT

VAR_INPUT

nVersionElement : INT;

END_VAR

nVersionElement : Version element to be read. Possible parameters:

• 1 : major number

• 2 : minor number

• 3 : revision number

Prerequisites

Development environment

TwinCAT v2.11R3 Build 2047 or higher

38

Target platform

PC (i386)

Hardware

PLC libraries to include

Seconds UPS

TcSUPS_CX9020_U900.

Lib

Version: 1.5

CX9020

Commissioning

4.2.3

Data Types

4.2.3.1

TYPE E_S_UPS_Mode

eSUPS_WrPersistData_Shutdown: write persistent data and then QuickShutdown

eSUPS_WrPersistData_NoShutdown: write persistent data only (no QuickShutdown)

eSUPS_ImmediateShutdown: QuickShutdown only (no writing of persistent data)

eSUPS_CheckPowerStatus: determine status only (neither write persistent data nor QuickShutdown)

Prerequisites

Development environment

TwinCAT v2.11R3 Build 2047 or higher

4.2.3.2

Target platform

PC (i386)

Hardware

PLC libraries to include

Seconds UPS

TcSUPS_CX9020_U900.

Lib

TYPE E_S_UPS_State

eSUPS_PowerOK: in all modes: supply voltage is OK

eSUPS_PowerFailure:

in all modes: Supply voltage faulty (applied for one cycle only)

eSUPS_WritePersistentData:

in eSUPS_WrPersistData_Shutdown mode: writing of the persistent data is active

in eSUPS_WrPersistData_NoShutdown mode: writing of the persistent data is active

eSUPS_QuickShutdown:

in eSUPS_WrPersistData_Shutdown mode: QuickShutdown is active

in eSUPS_ImmediateShutdown mode: QuickShutdown is active

eSUPS_WaitForRecover:

in eSUPS_WrPersistData_NoShutdown mode: wait for return of the voltage

in eSUPS_CheckPowerStatus mode: wait for return of the voltage

eSUPS_WaitForPowerOFF:

in eSUPS_WrPersistData_Shutdown mode: wait for shutdown by the UPS

in eSUPS_ImmediateShutdown mode: wait for shutdown by the UPS

Prerequisites

Development environment

TwinCAT v2.11R3 Build 2047 or higher

CX9020

Target platform

PC (i386)

Hardware

PLC libraries to include

Seconds UPS

TcSUPS_CX9020_U900.

Lib

Version: 1.5

39

Error handling and diagnostics

5

Error handling and diagnostics

5.1

LEDs on the basic CPU module

Display

LED

PWR

TC

FB1

FB2

HDD 1

HDD 2

40

Meaning

Power supply The Power LED comes on when the

device is connected to a live power supply unit

(green).

The LED blinks fast (red) if there is a power failure.

The LED blinks slow (red) if there is no or an

incorrect µSD card inserted.

TwinCAT status LED TwinCAT is in Run mode

(green)

TwinCAT is in Stop mode (red)

TwinCAT is in Config mode (blue)

Status LED1 for fieldbus (function is written at the

fieldbus interface)

Status LED2 for fieldbus (function is written at the

fieldbus interface)

Indicates access to the µSD card in slot 1. LED

flashes green during read access.

LED flahes yellow during write access.

Indicates access to the µSD card in slot 2. LED

flashes green during read access.

LED flahes yellow during write access.

Version: 1.5

CX9020

Error handling and diagnostics

5.2

LEDs of the power supply in K-bus mode

After switching on, the power supply immediately checks the connected Bus Terminal configuration. Errorfree start-up is signalled by the red "I/O ERR” LED being extinguished. If the “I/O ERR” LED blinks, an error

in the area of the terminals is indicated. The error code can be determined from the frequency and number of

blinks. This permits rapid rectification of the error.

Display

LED

Us 24 V

Up 24V

K-BUS RUN

K-BUS ERR

Meaning

Power supply for the CPU module. The LED lights

green if the power supply is correct.

Power supply for terminal bus. The LED lights

green if the power supply is correct.

K-bus diagnostics. The green LED lights up in order

to indicate fault-free operation. "Fault-free" means

that the communication with the fieldbus system is

also running.

K-bus diagnostics. The red LED flashes to indicate

an error. The red LED blinks with two different

frequencies.

The I/O error LED blink code

Fast blinking

First slow sequence

Second slow sequence

CX9020

Start of the error code

Error code

Error code argument

Version: 1.5

41

Error handling and diagnostics

LEDs for K-bus diagnostics

Error code

Error code argument

Persistent, continuous

flashing

Description

Remedy

EMC problems

- Check power supply for

overvoltage or undervoltage

peaks

- Implement EMC measures

3 pulses

4 pulses

0

0

n

5 pulses

n

6 pulses

0

1

8

7 pulses

0

K-bus command error

If a K-Bus error is present, it

can be localized by a restart of

the power supply (by switching

it off and then on again)

- No Bus Terminal inserted

- One of the Bus Terminals is

defective; halve the number of

Bus Terminals attached and

check whether the error is still

present with the remaining Bus

Terminals. Repeat until the

defective Bus Terminal is

located.

K-Bus data error, break

Check whether the n+1 Bus

behind the power supply

Terminal is correctly connected;

replace if necessary.

Break behind Bus Terminal Check whether the Bus End

n

Terminal 9010 is connected.

K-bus error in register

Exchange the nth bus terminal

communication with Bus

Terminal n

Error at initialization

Exchange Bus Coupler

Internal data error

Perform a hardware reset on

the Bus Coupler (switch off and

on again)

Internal data error

Perform a hardware reset on

the Bus Coupler (switch off and

on again)

Process data lengths of the Check configuration and

set and actual

terminals for consistency

configurations do not

correspond

Error code argument

The number of pulses indicates the position of the last Bus Terminal before the fault. Passive Bus Terminals,

such as a power feed terminal, are not included in the count.

In the case of some errors, rectification does not cause the power supply to leave the blink sequence. The

power supply can only be restarted by switching its supply voltage off and on again.

The CX unit recognizes these terminals automatically on scanning, reads out the terminal types and

automatically places them in the System Manager.

42

Version: 1.5

CX9020

Error handling and diagnostics

K-bus state

The K-bus status is saved in the state byte (see fig. K-bus interface “1”). If the value is 0 the K-bus is

operating synchronously and without errors. If the value is <> ”0” there may be a fault, or it may only be an

indication that the K-bus cycle is longer than the task, in which case it would no longer by synchronous with

the task. The task time should be faster than 100 ms. We recommend a task time of less than 50 ms. The Kbus update time typically lies between one and five ms.

Bit 0 = K-Bus error

Bit 1 = terminal configuration has changed since the start

Bit 2 = process image lengths do not match

Bit 8 = no valid inputs (yet)

Bit 9 = K-bus input update not yet complete

Bit 10 = K-bus output update not yet complete

Bit 11 = watchdog

Bit 15 = acyclic K-bus function active (e.g. K-bus reset)

If there is a K-bus error, this can be reset via the IOF_DeviceReset function block (in the TcIoFunctions.lib).

CX9020

Version: 1.5

43

Error handling and diagnostics

5.3

LEDs of the power supply in E-bus mode

After switching on, the power supply immediately checks the connected Bus Terminal configuration. In the EBus mode the “L/A” led lights up. It starts blinking when there is traffic on the bus.

Display

LED

Us 24 V

Up 24 V

L/A

44

off

on

flashing

Version: 1.5

Meaning

Power supply for the CPU module

The LED lights green if the power

supply is correct.

Power supply for terminal bus. The

LED lights green if the power supply

is correct.

E-bus not connected

E-bus connected / no data traffic

E-bus connected / data traffic on the

E-bus.

CX9020

Error handling and diagnostics

5.4

Faults

Please also refer to the Safety instructions section.

Possible faults and their correction

Fault

Cause

no function after the Embedded PC no power supply for the Embedded

has been switched on

PC

other causes

Embedded PC does not boot fully

Computer boots, software starts,

but control does not operate

correctly

µSD card access error

Hard disk damaged (e.g. due to

switching off while software is

running), incorrect setup,other

causes

Cause of the fault is either in the

software or in parts of the plant

outside the Embedded PC

Faulty µSD card, faulty card slot

Embedded PC only works partially Defective components in the

or temporarily

Embedded PC

Measures

1. Check fuse

2. Measure voltage at connection,

check plug wiring

Call Beckhoff support

Check setup Call Beckhoff support

Call the manufacturer of the

machine or the software.

Use a different µSD card to check

the card slot Call Beckhoff support

Call Beckhoff support

Please make a note of the following information before contacting Beckhoff service or support:

1.

2.

3.

4.

5.

6.

Precise device ID: CXxxxx-xxxx

Serial number

Hardware version

Any interfaces (N030, N031, B110, ...)

TwinCAT version used

Any components / software used

The quickest response will come from support / service in your country. Therefore please contact your

regional contact. For details please refer to our website at www.beckhoff.de or ask your distribution partner.

CX9020

Version: 1.5

45

Decommissioning

6

Decommissioning

6.1

Disassembly and disposal

A CX9020 hardware configuration is dismantled in 2 stages:

1. Switching off and disconnecting the power supply

Before a CX9020 system can be dismantled, the system should be switched off, and the power supply

should be disconnected.

2. Removing from the top-hat rail:

Before the individual modules are disconnected, the whole CX9020 hardware block should be removed from

the top-hat rail. Proceed as follows:

2.1. Release and remove the first Terminal next to the power supply unit on the tophat rail.

First remove any wiring from power supply unit and then from the first terminal on the top-hat rail next to the

power supply unit. If the wiring is to be reused for another system, it is advisable to make a note of the

connections. Then pull the orange terminal release (see arrow) to release the terminal and pull it out.

2.2. Releasing the CX9020 systems

To release the CX9020 block, release the orange DIN rail bracket on the left-hand side of the device. Push

back the lower hook. An audible click indicates that the device is released.

46

Version: 1.5

CX9020

Decommissioning

After pulling the terminal release of the power supply unit, the block can be removed carefully from the tophat rail.

Do not use force to open the device!

Opening the module housing by force would destroy it. The devices may only be opened by

Beckhoff service personnel.

Attention

Disposal

The device must be fully dismantled in order to dispose of it.

Electronic parts must be disposed of in accordance with national electronics scrap regulations.

CX9020

Version: 1.5

47

Appendix

7

Appendix

7.1

Accessories

MicroSD cards

instead of the 512 MB microSD card

oder number

CX1900-0123

Description

1 GByte microSD card, instead of 512 MB microSD

card

2 GByte microSD card, instead of 512 MB microSD

card

4 GByte microSD card, instead of 512 MB microSD

card

8 GByte microSD card, instead of 512 MB microSD

card

CX1900-0125

CX1900-0127

CX1900-0129

spare microSD cards

oder number

CX1900-0122

CX1900-0124

CX1900-0126

CX1900-0128

CX1900-0130

Description

512 MByte microSD card

1 GByte microSD card

2 GByte microSD card

4 GByte microSD card

8 GByte microSD card

Passive DVI-to-VGA adaptor

Order number

CX1900-0101

Description

Passive DVI-to-VGA adaptor for the connection of standard VGA monitors to the

CX system

– feeds out the VGA signals of the DVI-I interface of the CX module

– DVI-A plug, 29-pin (bottom), socket, 15-pin (top)

– Weight: approx. 40 g

– Dimensions (W x H x D): 40 x 42 x 15 mm

Spare battery for CX-Systems

oder number

CX1900-0102

48

Description

Battery for the CX-Systems

- original product description: Panasonic type

CR2032 3V/225mAh

Version: 1.5

CX9020

Appendix

7.2

Support and Service

Beckhoff and their partners around the world offer comprehensive support and service, making available fast

and competent assistance with all questions related to Beckhoff products and system solutions.

Beckhoff's branch offices and representatives

Please contact your Beckhoff branch office or representative for local support and service on Beckhoff

products!

The addresses of Beckhoff's branch offices and representatives round the world can be found on her internet

pages:

http://www.beckhoff.com

You will also find further documentation for Beckhoff components there.

Beckhoff Headquarters

Beckhoff Automation GmbH & Co. KG

Huelshorstweg 20

33415 Verl

Germany

Phone:

Fax:

e-mail:

+49(0)5246/963-0

+49(0)5246/963-198

info@beckhoff.com

Beckhoff Support

Support offers you comprehensive technical assistance, helping you not only with the application of

individual Beckhoff products, but also with other, wide-ranging services:

• support

• design, programming and commissioning of complex automation systems

• and extensive training program for Beckhoff system components

Hotline:

Fax:

e-mail:

+49(0)5246/963-157

+49(0)5246/963-9157

support@beckhoff.com

Beckhoff Service

The Beckhoff Service Center supports you in all matters of after-sales service:

• on-site service

• repair service

• spare parts service

• hotline service

Hotline:

Fax:

e-mail:

CX9020

+49(0)5246/963-460

+49(0)5246/963-479

service@beckhoff.com

Version: 1.5

49

Appendix

7.3

Certifications

All products of the Embedded PC family are CE, UL and GOST-R certified. Since the product family is

continuously developed further, we are unable to provide a full listing here. The current list of certified

products can be found at www.beckhoff.com.

FCC Approvals for the United States of America

FCC: Federal Communications Commission Radio Frequency Interference

Statement

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates, uses,

and can radiate radio frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user will be required to correct the

interference at his own expense.

FCC Approval for Canada

FCC: Canadian Notice

This equipment does not exceed the Class A limits for radiated emissions as described in the Radio

Interference Regulations of the Canadian Department of Communications.

50

Version: 1.5

CX9020