AN955

VF Control of 3-Phase Induction Motor

Using Space Vector Modulation

Author:

Rakesh Parekh

Microchip Technology Inc.

INTRODUCTION

VF control using the Sine PWM algorithm is a popular

algorithm for AC induction motor control; however, this

algorithm has certain drawbacks which affect the

overall system efficiency. A more advanced switching

algorithm, like Space Vector Modulation (SVM), overcomes the drawbacks of the Sine PWM algorithm and

increases the overall system efficiency.

This application note includes the description of the

SVM theory and its advantages over the Sine PWM. It

also discusses the SVM digital implementation for VF

control using Microchip’s PIC18FXX31 8-bit microcontrollers. See the “References” section for more

information on AC induction motors and their control.

SPACE VECTOR MODULATION (SVM)

The SVM is a sophisticated, averaging algorithm which

gives 15% more voltage output compared to the Sine

PWM algorithm, thereby increasing the VDC utilization.

It also minimizes the THD as well as switching loss.

Like Sine PWM, the SVM is also a scalar control. The

direct controlled variables are the motor voltage and

the motor frequency.

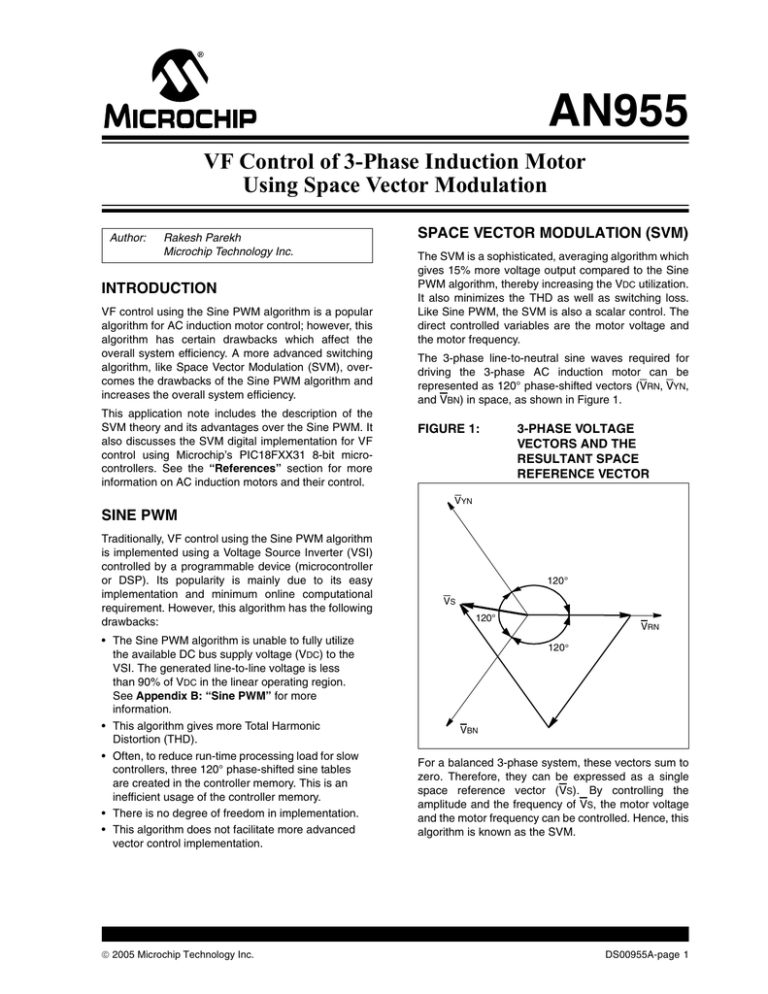

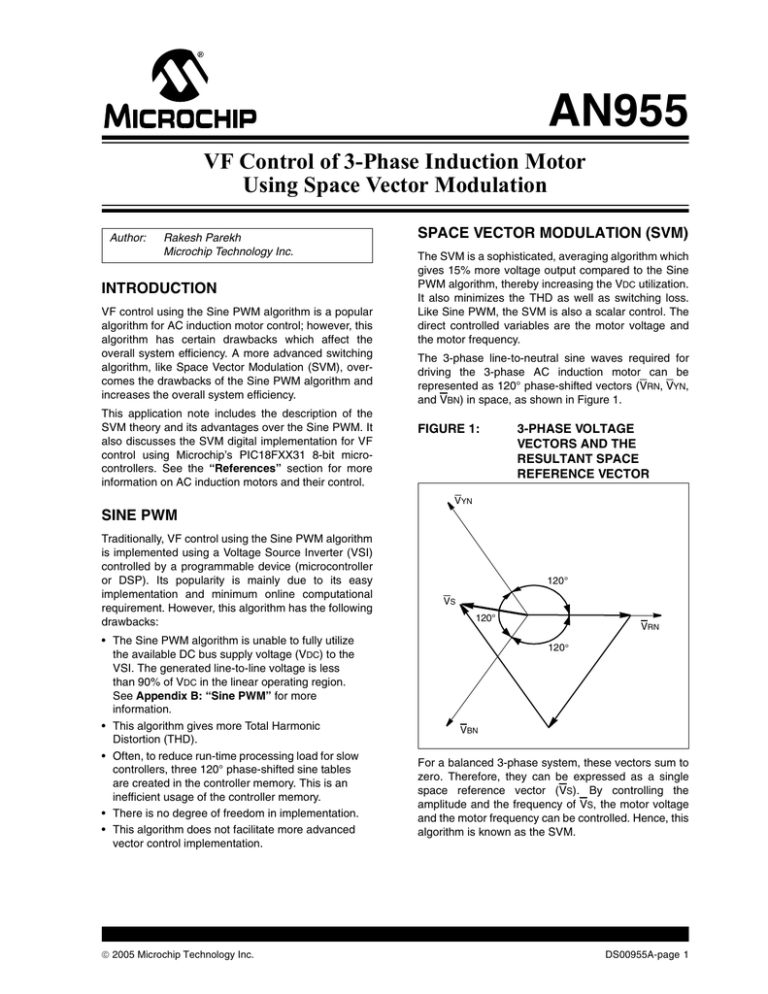

The 3-phase line-to-neutral sine waves required for

driving the 3-phase AC induction motor can be

represented as 120° phase-shifted vectors (VRN, VYN,

and VBN) in space, as shown in Figure 1.

FIGURE 1:

3-PHASE VOLTAGE

VECTORS AND THE

RESULTANT SPACE

REFERENCE VECTOR

VYN

SINE PWM

Traditionally, VF control using the Sine PWM algorithm

is implemented using a Voltage Source Inverter (VSI)

controlled by a programmable device (microcontroller

or DSP). Its popularity is mainly due to its easy

implementation and minimum online computational

requirement. However, this algorithm has the following

drawbacks:

• The Sine PWM algorithm is unable to fully utilize

the available DC bus supply voltage (VDC) to the

VSI. The generated line-to-line voltage is less

than 90% of VDC in the linear operating region.

See Appendix B: “Sine PWM” for more

information.

• This algorithm gives more Total Harmonic

Distortion (THD).

• Often, to reduce run-time processing load for slow

controllers, three 120° phase-shifted sine tables

are created in the controller memory. This is an

inefficient usage of the controller memory.

• There is no degree of freedom in implementation.

• This algorithm does not facilitate more advanced

vector control implementation.

© 2005 Microchip Technology Inc.

120°

VS

120°

VRN

120°

VBN

For a balanced 3-phase system, these vectors sum to

zero. Therefore, they can be expressed as a single

space reference vector (VS). By controlling the

amplitude and the frequency of VS, the motor voltage

and the motor frequency can be controlled. Hence, this

algorithm is known as the SVM.

DS00955A-page 1

AN955

A typical block diagram of a VSI controlled by the

PIC18FXX31, which implements SVM, is shown in

Figure 2. Point 0 is the midpoint of VDC (sometimes

called the Virtual Neutral Point). For safe operation of

the VSI, whenever one switch of a half bridge (Q1) is

on, the other switch of the same half bridge (Q0) should

be off and vice versa. This gives rise to eight distinct

switching states of the VSI. Table 1 lists all the possible

VSI switching states and respective line-to-neutral

voltages.

States 1 through 6 are called the active states, as the

energy is supplied from the supply to the motor during

these states. States 0 and 7 are called the inactive

states, as no energy is supplied from the supply to the

motor during these states. Each state can be

represented as a voltage vector in space. Figure 3

shows the space vector representation of all the

possible switching states.

BLOCK DIAGRAM OF PICmicro® MCU-CONTROLLED VSI

FIGURE 2:

Q1

Q3

Q5

3-Phase ACIM

PIC18FXX31

PWM0 (Q0)

VDC/2

PWM1 (Q1)

PWM2 (Q2)

VDC

O

B

Y

N

R

PWM3 (Q3)

PWM4 (Q4)

Rectifier

115/230 VAC

50/60 Hz

TABLE 1:

PWM5 (Q5)

VDC/2

Q0

Q2

Q4

VSI SWITCHING STATES AND RESPECTIVE LINE TO NEUTRAL VOLTAGES

Switching State

On Switches

VRN

VYN

VBN

Space Voltage Vector

0

Q0, Q2, Q4

0

0

0

V0

1

Q1, Q2, Q4

2/3 VDC

-1/3 VDC

-1/3 VDC

V1

2

Q1, Q3, Q4

1/3 VDC

1/3 VDC

-2/3 VDC

V2

3

Q0, Q3, Q4

-1/3 VDC

2/3 VDC

-1/3 VDC

V3

4

Q0, Q3, Q5

-2/3 VDC

1/3 VDC

1/3 VDC

V4

5

Q0, Q2, Q5

-1/3 VDC

-1/3 VDC

2/3 VDC

V5

6

Q1, Q2, Q5

1/3 VDC

-2/3 VDC

1/3 VDC

V6

7

Q1, Q3, Q5

0

0

0

V7

DS00955A-page 2

© 2005 Microchip Technology Inc.

AN955

As seen in Figure 3, the entire space is distinctively

divided into six equal sized sectors of 60°. Each sector

is bounded by two active vectors. V0 and V7 are the

voltage vectors with zero amplitude and are located at

the hexagon origin.

this algorithm generates maximum THD. Also, the lineto-line and the line-to-neutral waveforms are not sine

waves.

SVM Switching Rules

VS is the resultant output due to the switching states of

the VSI. For digital implementation of SVM, the VSI is

switched at a very high frequency (FPWM). This frequency is high enough (>20 kHz) so as not to generate

audible noise due to switching. FPWM decides the

sample time TS for VS, where TS = 1/FPWM. There are

various switching ways to generate VS from V0, V1...V7.

Mathematically, it can be represented as shown in

Equation 1. Variables T0, T1…T7 in Equation 1 are on

time for the corresponding VSI states and TS is the

sample time.

To implement the SVM algorithm, the following switching

rules are implemented:

•

•

•

•

These rules help in limiting the number of switching

actions and hence, there is a reduction in the switching

losses. Also, they maintain symmetry in switching

waveforms at the VSI output to achieve the lower THD.

The SVM algorithm implementation, using these

switching rules, is called Conventional SVM.

When the VSI follows the switching state pattern,

1-2-3-4-5-6-1-2..., it is called the Six-Step PWM algorithm. This algorithm is easier to implement compared

to all the other control algorithms. It can generate the

line-to-line fundamental voltage more than the VDC. But

FIGURE 3:

The trajectory of VS should be a circle.

Only one switching per state transition.

Not more than three switchings in one TS.

The final state of one sample must be the initial

state of the next sample.

SPACE VECTOR HEXAGON

Sector 2

(Q0, Q3, Q4) V3

V2 (Q1, Q3, Q4)

VS

Sector 3

Sector 1

TB

V7

0

(Q0, Q3, Q5) V4

Ψ

V1 (Q1, Q2, Q4)

TA

V0

Sector 6

Sector 4

(Q0, Q2, Q5) V5

Sector 5

V6 (Q1, Q2, Q5)

EQUATION 1:

⎛T0

⎞ ⎛T1

⎞ ⎛T2

⎞ ⎛T3

⎞ ⎛T4

⎞ ⎛T5

⎞ ⎛T6

⎞ ⎛T7

⎞

VS = ⎜ × V0⎟ + ⎜ × V1⎟ + ⎜ × V2⎟ + ⎜ × V3⎟ + ⎜ × V4⎟ + ⎜ × V5⎟ + ⎜ × V6⎟ + ⎜ × V7⎟

⎝TS

⎠ ⎝TS

⎠ ⎝TS

⎠ ⎝TS

⎠ ⎝TS

⎠ ⎝TS

⎠ ⎝TS

⎠ ⎝TS

⎠

TS = T0 + T1 + T2 + T3 + T4 + T5 + T6 + T7

© 2005 Microchip Technology Inc.

DS00955A-page 3

AN955

Different SVM Algorithms

There are various ways to implement the SVM, such as:

•

•

•

•

Conventional SVM

Basic Bus Clamping SVM

Boundary Sampling SVM

Asymmetric Zero-Changing SVM, etc.

EQUATION 3:

All SVM algorithms have the same on time for active as

well as inactive vectors. They differ mainly in the implementation of the inactive vectors, such as T0 and/or T7

distribution within TS. Discussion of the various other

SVM algorithms is beyond the scope of this application

note.

Time Calculation to Generate VS

Let us take an example where VS is in Sector 1 at a

vector angle (Ψ), as shown in Figure 4.

FIGURE 4:

VECTOR VS IN SECTOR 1

Y Axis

TS = TA + TB + T0/7

The time intervals, TA, TB and T0/7, have to be calculated such that the average volt seconds produced by

the vectors, V1, V2 and V0/7 along the X and Y axes, are

the same as those produced by the desired reference

space vector VS.

The modulation index or amplitude ratio is defined as:

m=

⎪VS⎪

VDC

where |VS| is the amplitude or the length of VS.

Resolving VS along the X and Y axes, we get:

EQUATION 4:

V2

(VDC × TA) + (VDC × cosπ/3 × TB) = ⎪VS⎪ × cosψ × TS

and

VDC × sinπ/3 × TB = ⎪VS⎪ × sinψ × TS

VS

V0/7

Equation 2 means that the VSI is in active state 1 for TA

time and it is in active state 2 for TB time. For the

remaining time of TS, no voltage is applied. This can be

achieved by applying inactive state 0 (or 7) for the

remaining time T0 (or T7).

ψ

TA

π/3

Solving for TA and TB, we get:

TB

V1

X Axis

VDC

It is assumed that during time TS, VS remains steady.

For implementing the conventional SVM using SVM

switching rules, VS is split as shown in Equation 2.

EQUATION 2:

⎛TA

⎞ ⎛TB

⎞ ⎛T0/7

⎞

VS = ⎜ × V1⎟ + ⎜ × V2⎟ + ⎜

× V0/7⎟

⎝TS

⎠ ⎝TS

⎠ ⎝ TS

⎠

DS00955A-page 4

EQUATION 5:

⎞

TA

2 × m × sin ⎛π

=

⎜3 – ψ⎟

TS

√3

⎝

⎠

TB

2 × m × sinψ

=

TS

√3

T0/7 can be found from Equation 3. For better THD, T0

(or T7) is split into two and then applied at the beginning

and at the end of the TS. The typical VSI switching

waveforms in Sector 1, as defined by Equation 2,

Equation 3 and the switching rules for the conventional

SVM using center aligned PWM, are as given in

Figure 5.

© 2005 Microchip Technology Inc.

AN955

FIGURE 5:

TYPICAL VSI SWITCHING WAVEFORMS IN SECTOR 1

TS

T0/2

TA

TS

TB

T7/2

T7/2

TB

TS

TA

T0/2

T0/2

TA

TS

TB

T7/2

T7/2

TB

TA

T0/2

Q1

Q0

Q3

Q2

Q5

Q4

Axes of Symmetry

We can observe the different axes of symmetry in all

the waveforms as shown in Figure 5. These symmetries are mainly responsible for having lower THD in

SVM compared to Sine PWM in the linear operating

region.

From Figure 3, it is clear that in the linear operating

region, the maximum line-to-line voltage amplitude can

be achieved when VS is rotated along the largest

inscribed circle in the space vector hexagon. In

mathematical terms, this is equivalent to:

EQUATION 6:

mmax =

Radius of Largest Inscribed Circle

VDC

From Figure 4 and Equation 6, it is also clear that:

By solving Equation 2, Equation 5 and Equation 7, we

get:

EQUATION 8:

Maximum Line-to-Line Voltage

=

2

× mmax × VDC

√3

=

√3

2

× VDC = VDC

×

2

√3

Equation 8 shows that it is possible to get line-to-line

voltage amplitude as high as VDC using the SVM algorithm in the linear operating range. This is the main

advantage of the SVM algorithm when compared to the

Sine PWM algorithm. Due to higher line-to-line voltage

amplitude, the torque generated by the motor is higher.

This results in better dynamic response of the motor.

EQUATION 7:

mmax =

VDC × cosπ/6

√3

= cosπ/6 =

2

VDC

© 2005 Microchip Technology Inc.

DS00955A-page 5

AN955

The reason for the higher line-to-line voltage in SVM

can be explained with the help of Figure 6. It shows the

phase voltage (line-to-virtual neutral point) generated

by Sine PWM and SVM. For clarity, only two phase

voltages (RO and YO) and their resultant line-to-line

voltage (RY) are shown in each figure.

The Sine PWM generated phase voltages are sine

waves. With 120° phase shift between them, the resultant line-to-line voltage is approximately 86.6% of VDC.

But, the SVM generated phase voltages have a third

FIGURE 6:

harmonic component superimposed on the fundamental component. The addition of this harmonic

component is due to the effective usage of inactive

states which is not possible in the Sine PWM. With

120° phase shift between them, the third harmonic

component is cancelled out in the resultant line-to-line

voltage in such a way that the resultant line-to-line

voltage is boosted to VDC (100%). Thus, SVM

generates line-to-line voltage with higher amplitude

(about 15% more) compared to Sine PWM.

GENERATED PHASE VOLTAGES AND CORRESPONDING LINE-TO-LINE

VOLTAGE IN (A) SINE PWM AND (B) SVM

A) Sine PWM Generated Waveforms

B) SVM Generated Waveforms

DS00955A-page 6

© 2005 Microchip Technology Inc.

AN955

Advantages of SVM

The advantages of SVM vis-a-vis Sine PWM are as

follows:

• Line-to-line voltage amplitude can be as high as

VDC. Thus, 100% VDC utilization is possible in the

linear operating region.

• In the linear operating range, modulation index

range is 0.0 to 1.0 in the Sine PWM; whereas in

the SVM, it is 0 to 0.866. Line-to-line voltage

amplitude is 15% more in the SVM with the

modulation index = 0.866, compared to the Sine

PWM with the modulation index = 1. Hence, it has

the better usage of the modulation index depth.

• With the increased output voltage, the user can

design the motor control system with reduced

current rating, keeping the horsepower rating the

same. The reduced current helps to reduce

inherent conduction loss of the VSI.

• Only one reference space vector is controlled to

generate 3-phase sine waves.

• Implementation of the switching rules gives less

THD and less switching loss.

• Flexibility to select inactive states and their

distribution in switching time periods gives two

degrees of freedom.

• As the reference space vector is a

two-dimensional quantity, it is feasible to

implement more advanced vector control using

SVM.

HARDWARE USED FOR SVM

IMPLEMENTATION

A PICDEM™ MC Development Board is used to

develop and test the SVM control firmware. The

PICDEM MC has a single-phase diode bridge rectifier,

converting AC input to DC and a power capacitor bank

that keeps the DC bus stable. A 3-phase IGBT-based

inverter bridge is used to control the output voltage

from the DC bus. See Appendix A: “PICDEM™ MC

Board Technical Information” for schematics of the

PICDEM™ MC Development Board.

The control circuit and power circuits are optically

isolated with respect to each other. An on-board flyback

power supply generates +5 VD, with respect to the digital ground used for powering up the control circuit,

including the PICmicro® device. The +5 VA and +15 VA

are generated with respect to the power ground

(negative of DC bus). The feedback interface circuit is

powered by the +5 VA, while the +15 VA supplies

power to the IGBT drivers located inside the Integrated

Power Module (IPM).

With optical isolation between the power and the control

circuits, the programming and debugging tools can be

plugged into the development board when main power

is connected to the board. The board communicates

with a host PC over a serial port configured with an onchip Enhanced USART (EUSART). The on-board user

interface has two toggle switches, a potentiometer and

four LEDs for indication.

In this application note, switch SW1 is used to toggle

between the motor Run and Stop and SW2 is used to

toggle the motor rotation direction. A potentiometer is

used to set the speed reference as well as the modulation index. The LEDs are used for indication of different

states of control.

© 2005 Microchip Technology Inc.

DS00955A-page 7

AN955

DIGITAL IMPLEMENTATION

To implement the SVM in the digital domain, the power

control PWM module of the PIC18FXX31 is utilized.

The module provides up to 8 PWM output channels

with the dedicated PWM timer as its time base. The

module has the capability to generate center aligned

PWM with 14-bit resolution. This is the most important

feature required for the SVM implementation.

VS needs to be created and rotated in space for SVM

implementation. To approximate the position of VS,

Equation 3, Equation 5 and the previously mentioned

switching rules are utilized. Looking at Equation 5, one

will notice that in the same sector, TA and TB are

inverted with respect to each other. Hence, only one

look-up table with time entries is needed. A look-up

table with TB entries (TABLE_TB_COUNT<MSB:LSB>)

is created. The size of the look-up table is decided by

the angle resolution used. The total sector angle is 60°

(π/3 radians). To get a good resolution with an 8-bit

microcontroller like the PIC18FXX31, the entire sector

is divided into 256 points, giving an angle resolution of

0.234°. The center aligned PWM is used for better THD

(FPWM = 1/2 * TS).

The required motor speed in Hz is decided by the rate

at which the VS is rotated. For this purpose, it is

necessary to find both the vector angle and the vector

update step size. To speed up the online calculations,

the constant, DEGREE_CONSTANT, is defined; this is

then used to calculate the vector update step size and

the vector angle as shown in Equation 9.

Looking at the definition of DEGREE_CONSTANT, one will

notice that its value, without any multiplication factor, will

result in a fractional number less than unity for

FPWM > 1.536 kHz. Almost all motor control applications

have FPWM much higher than 1.536 kHz. Handling a

fractional number with any 8-bit microcontroller will

require more CPU processing time. This requirement is

difficult to meet in the SVM implementation, where VS is

updated at every TPWM (= 1/FPWM) time interval. At the

same time, the multiplication factor value needs to be

such that its post-calculation adjustment requires the

least possible microcontroller processing time.

It is proposed that the multiplication factor be 256. This

will result in a 16-bit value for the vector update step

size and hence, 16-bit vector angle pointer

(VECTOR_ANGLE<MSB:LSB>). As an adjustment for

the multiplication factor, VECTOR_ANGLE_LSB is

discarded. VECTOR_ANGLE_MSB is used as the table

pointer for reading the value of TA and TB from the lookup table. Whenever a carry is generated due to the

Equation 9 addition, it physically means that the VS has

advanced to the next sector and hence, the sector

count (SECTOR_NO) is incremented by one. The motor

voltage is decided by the amplitude of VS (modulation

index m). To implement the same digitally, values of TA

and TB are multiplied by m. Based on TS, TA and TB, the

duty cycle values for all 3 phases (R, Y and B) are

calculated as shown in Table 2.

Equations shown in Table 2 for Sector 1 are evident in

Figure 5. Similarly, equations for other sectors are

derived with the switching rule constraints.

EQUATION 9:

DEGREE_CONSTANT =

360 × 256 × Multiplication Factor

60 × FPWM

Vector Update Step Size = DEGREE_CONSTANT × Required Motor Speed (Hz)

Vector Angle = Vector Angle + Vector Update Step Size

DUTY CYCLE VALUES FOR THE THREE MOTOR PHASES BASED ON VS LOCATION

TABLE 2:

Sector No.

Phase R Duty Cycle

Phase Y Duty Cycle

Phase B Duty Cycle

1

T0/2

T0/2 + TA

TS – T0/2

2

T0/2 + TB

T0/2

TS – T0/2

3

TS – T0/2

T0/2

T0/2 + TA

4

TS – T0/2

T0/2 + TB

T0/2

5

T0/2 + TA

TS – T0/2

T0/2

6

T0/2

TS – T0/2

T0/2 + TB

DS00955A-page 8

© 2005 Microchip Technology Inc.

AN955

SVM CONTROL FIRMWARE

The firmware is developed using PIC18F4431 and it

implements the VF control using the SVM algorithm.

Apart from the basic SVM control, the firmware incorporates various control and protection routines, such

as overcurrent protection, overvoltage protection, overtemperature protection, acceleration and deceleration

routine and rotation direction reversal.

To implement the VF control, an analog potentiometer

(R44) connected to RA1/AN1 is read. Using the

CONVERT_MANUAL_COUNT_TO_HZ routine, the potentiometer setting is converted to the required motor speed

in Hz. The potentiometer setting is also interpreted as

the modulation index, m. To get the required motor

speed, the vector update step size is calculated by

calling the CALCULATE_UPDATE_STEP_SIZE routine.

As described in the previous section, TA and TB values

are scaled with m.

All protection routines (overcurrent, overvoltage and

overtemperature) are checked at a fixed time interval

(presently, 5 ms set by overflow rate of the Timer1).

The acceleration and deceleration routine is called at

one-second intervals.

Overcurrent Protection

A shunt resistor (R110) in the negative DC bus gives a

voltage corresponding to the current flowing into the

motor winding. This voltage is amplified and compared

with a reference. The current comparison setting allows

a current up to 6.3A. If the current exceeds 6.3A, the

FAULTA pin goes low, indicating the overcurrent Fault.

The firmware is configured in the Cycle-by-Cycle Fault

mode. When the Fault persists for more than a preprogrammed count (MAX_FLTA_COUNT) in the fixed

time interval, then the motor is stopped and the Fault is

indicated by the blinking LED1.

Overvoltage Protection

The DC bus voltage is attenuated using potential dividers and compared with a fixed reference. If the jumper

JP5 is open, the reference is set for 200V on the DC

bus. If jumper JP5 is shorted, the reference is set for

400V. The FAULTB pin is used to monitor the overvoltage Fault. If the overvoltage Fault persists for more

than a preprogrammed count (MAX_FLTB_COUNT) in

the fixed time interval, then the motor is stopped and

the Fault is indicated by the blinking LED2.

Overtemperature Protection

The power module has an NTC thermal sensor, outputting 3.3V at 110°C on the junction of IGBTs. The NTC

output is connected to AN8 through an optocoupler.

The temperature is continuously measured and if it

exceeds 110°C (MAX_JUNCTION_TEMP) for more than

© 2005 Microchip Technology Inc.

a preprogrammed count (MAX_TEMP_FILT_COUNT),

then the motor is stopped and the overtemperature

Fault is indicated by the blinking LED3.

Whenever the motor is stopped due to any of the above

mentioned Faults, it can be restarted by removing the

Fault condition and then by pressing either SW1 or

SW2.

Acceleration and Deceleration

The RAMP_SPEED routine is called every 1 second to

implement the acceleration and deceleration feature.

Both the acceleration and deceleration rates are userselectable and are given in the form of Hz/s.The

acceleration and deceleration features are active only

when the motor is in run condition.

SOURCE CODE FILES

The entire source code can be downloaded from

Microchip’s web site, www.microchip.com. It includes

the following files:

• ...\SVM\ACSVM_OL.asm

This file is located in the source code folder (Main

Routine section).

• ...\SVM\ACSVM_OL_routines.asm

This file is located in the source code folder (Control

Routine section).

• ...\SVM\TIME_TABLE.asm

This file is located in the source code folder (Look-up

Table for TB).

• ...\SVM\InterfaceACSVMConstant.inc

This file is located in the source code folder (System

Parameters and User-Defined Constants section).

• ...\SVM\InterfaceACSVMVar.inc

This file is located in the source code folder

(User-Defined Variable section).

An Excel file (PARAMETERS.xls) is included in the

source code folder which has two worksheets. The

TB_TABLE worksheet calculates TB entries based on

the main oscillator frequency (FOSC), FPWM, the

required dead time, etc. The LIST worksheet creates a

table to be stored in the data EEPROM of the

PIC18FXX31 device. This table contains all userselectable compile-time parameters, such as the motor

rated speed in Hz, FPWM in kHz, the required dead time

in μs, etc. The user should make sure that the table is

entered in the ACSVM_OL.asm file as shown in the

worksheet.

An overview of the firmware’s logic flow is provided in

Figure 7 and Figure 8. A complete list of system

parameters and user-defined functions is provided in

Table 3 through Table 5.

DS00955A-page 9

AN955

FIGURE 7:

SVM IMPLEMENTATION FLOWCHART (MAIN ROUTINE)

Main Routine

START

Motor Parameters and On-Chip

Peripherals Initialization

Blink all LEDs at a Rate Set by

the Potentiometer

No

Is SW1/SW2

pressed?

Yes

Configure PCPWM Module and

Set Default Rotation Direction

Call KEY_CHECK to

Determine Pressed Key

Call PROCESS_KEY_PRESSED

to Act on the Pressed Key

Has TMR1

overflowed?

No

Yes

Call FAULT_CHECK to Check for

Fault and Display the same, if any

Call CONVERT_MANUAL_COUNT_TO_HZ to Convert the Potentiometer

Setting to the Required Motor Speed in Hz and to Set the Modulation Index

No

Is 1 sec time

interval over?

Yes

Call RAMP_SPEED to Accelerate/

Decelerate the Motor

Call CALCULATE_UPDATE_STEP_SIZE to Find

Vector Update Step Size based on the Motor Speed

DS00955A-page 10

© 2005 Microchip Technology Inc.

AN955

FIGURE 8:

SVM IMPLEMENTATION FLOWCHART (INTERRUPT SERVICE ROUTINES)

High Priority Interrupt Service Routine

ISR_HIGH

No

Is PTIF = 1?

Yes

Vector Angle = Vector Angle + Vector Update Step Size

No

Is carry

generated?

Yes

Increment Sector Number by 1

No

Is Sector

Number > 5?

Yes

Reset Sector Number to 0

Calculate TA, TB, T0/2 and

(TS – T0/2) using the Vector Angle

Load PWM Duty Cycle

Registers as per Table 2

RETFIE

Low Priority Interrupt Service Routine

ISR_LOW

No

Is ADIF = 1?

Yes

Read Phase Currents, IGBT Junction Temperature

and the Potentiometer Setting for the Motor Speed

Is TMR1IF = 1?

No

Yes

Reload TMR1 for 5 msec Overflow Rate

Increment RAMP_COUNT by 1 (used for giving 1 sec time

interval for acceleration/deceleration feature)

Yes

Is

SW1/SW2 pressed

any time?

No

Toggle LEDs

RETFIE

© 2005 Microchip Technology Inc.

DS00955A-page 11

AN955

TABLE 3:

USER-DEFINED PARAMETERS IN SVM FIRMWARE

Name

Description

CHANGE_OVER_DELAY

Defines rotation direction changeover for the motor. Its value equals the

required changeover time in ms per 39 ms.

DIRECTION_AT_POR

Defines default rotation direction at start (1 = Forward, 0 = Reverse).

CYCLE_COUNT_MAX

Defines blinking rate for Fault indication. Its value equals the required blink

time interval in ms per 5 ms.

MAX_FAULT_CHECK_COUNT

Defines time window for Fault recognition. If any Fault occurs for more than

predefined count in this time window, then the Fault is recognized and

appropriate action is taken.

MAX_FLTA_COUNT

Defines count for overcurrent Fault recognition.

MAX_FLTB_COUNT

Defines count for overvoltage Fault recognition.

MAX_JUNCTION_TEMP

Defines limit for overtemperature Fault.

MAX_TEMP_FILT_COUNT

Defines count for overtemperature Fault recognition.

TMR1L_COUNT and TMR1H_COUNT

Defines overflow rate for Timer1. In the present application, it is set for 5 ms.

PARAMETER_BUFFER_SIZE

Defines array size for storing various compile-time parameters as well as

run-time parameters. It is set at 0x35 (do not change this value).

TABLE 4:

VARIABLES IN SVM FIRMWARE

Name

Description

REQD_SPEED_REF

Stores required motor speed set by the potentiometer.

SET_SPEED_HZ

Stores actual motor speed (Hz).

RAMP_COUNT

Stores count for Timer1 overflow. It is used for generating 1s time interval as

required for acceleration/deceleration feature.

CURRENT_R

Stores either total DC bus current (when used with DC shunt current

measurement) or R phase current (when used with phase current sensor).

CURRENT_Y

Stores Y phase current (when used with phase current sensor).

CURRENT_B

Stores B phase current (when used with phase current sensor).

JUNCTION_TEMPH

Stores junction temperature of the VSI switch.

SECTOR_NO

Stores present sector location of VS.

MODULATION_INDEX

Stores required amplitude of VS.

VECTOR_ANGLE<MSB:LSB>

Stores present vector angle of VS in a sector.

TB_COUNT<MSB:LSB>

Stores TB count as pointed by the vector angle.

TA_COUNT<MSB:LSB>

Stores TA count as pointed by the vector angle.

HALF_T0_COUNT<MSB:LSB>

Stores T0/2 count.

TS_MINUS_HALF_T0<MSB:LSB>

Stores TS – T0/2 count.

TABLE_TB_COUNT<MSB:LSB>

Stores array base address for TB count.

PARAMETER_BUFFER

Stores array base address for compile-time and run-time parameters.

DS00955A-page 12

© 2005 Microchip Technology Inc.

AN955

TABLE 5:

FUNCTIONS IN SVM FIRMWARE

Name

Description

KEY_CHECK

Checks the status of Run/Stop (SW1) and Fwd/Rev (SW2) keys.

PROCESS_KEY_PRESSED

Acts on command issued by the last pressed key.

FAULT_CHECK

Checks for various Faults (overcurrent, overvoltage, overtemperature) and

acts if any Fault is recognized.

CONVERT_MANUAL_COUNT_TO_HZ

Converts the potentiometer setting into the required motor speed (Hz) and

sets the modulation index (m).

RAMP_SPEED

Implements the acceleration/deceleration feature.

CALCULATE_UPDATE_STEP_SIZE

Calculates new vector update step size depending on the motor speed.

ISR_PWM

Responds to setting of PTIF. This routine rotates by vector angle update step

size and calculates new duty cycle values for all phases (R, Y and B).

ISR_ADC

Responds to setting of ADIF. This routine reads the potentiometer setting,

phase currents and junction temperature of the VSI switch and stores them

at appropriate locations.

ISR_TMR1

Responds to setting of TMR1IF. This routine reloads Timer1 for 5 ms

overflow rate and increments RAMP_COUNT by 1 for generating a

one-second interval (required for the acceleration/deceleration feature). This

routine also blinks all LEDs at start when no key is pressed.

© 2005 Microchip Technology Inc.

DS00955A-page 13

AN955

RESOURCE USAGE

CONCLUSION

The SVM control application consumes CPU

resources, as shown in Table 6. Substantial CPU

resources, especially memory and processing time,

are still available to users for the development of their

own applications.

VF control using the SVM in the open loop is more

energy efficient compared to the Sine PWM. With an

on-chip dedicated motor control peripheral like the

power control PWM module and the rich instruction set,

the PIC18FXX31 is well suited to give a low-cost

solution, implementing the VF control using the SVM

algorithm for the 3-phase AC induction motor control. In

addition, the on-chip resources, such as the ADC and

the multiple timers, allow users to implement other control (acceleration and deceleration) and protection

(overcurrent, overvoltage, overtemperature) features.

TABLE 6:

RESOURCES USED IN THE

MOTOR CONTROL DEMO

BOARD (USING PIC18F4431)

Used

Available to User

when PIC18F4431

is Used

1942 bytes

14442 bytes

Data Memory

93 bytes

675 bytes

EEPROM

Resource Type

Program Memory

44 bytes

212 bytes

PWM Channels

6

2

CCP/Fault Input

Channels

2

0

ADC Channels

5

4

EUSART

0

1

QEI Module

0

1

Timers

1

3

External Interrupts

0

3

I/O Lines

CPU Processing

Time

(FPWM = 20 kHz,

FOSC = 40 MHz)

20

16

~27%

~63%

REFERENCES

R. Parekh, AN887, “AC Induction Motor Fundamentals”

(DS00887). Microchip Technology Inc., 2003.

P. Yedamale, AN843, “Speed Control of 3-Phase

Induction Motor Using PIC18 Microcontrollers”

(DS00843). Microchip Technology Inc., 2002.

R. Parekh, AN889, “VF Control of 3-Phase Induction

Motors

Using

PIC16F7X7

Microcontrollers”

(DS00889). Microchip Technology Inc., 2004.

“PICDEM™ MC Development Board for PIC18FXX31

User’s Guide” (DS51453). Microchip Technology Inc.,

2004.

Resource utilization, as mentioned in Table 6, is for a

general purpose, relocatable code implementing the

VF control using the SVM algorithm on PIC18F4431

with 14-bit PWM resolution. A customized solution with

only 8-bit PWM resolution can conceivably result in an

additional 10% savings in CPU processing time.

DS00955A-page 14

© 2005 Microchip Technology Inc.

AN955

APPENDIX A:

FIGURE A-1:

PICDEM™ MC BOARD TECHNICAL INFORMATION

PICDEM™ MC DEVELOPMENT BOARD FUNCTIONAL BLOCK DIAGRAM

ICD

Connector

Potentiometer

RS-232

Interface

User

Push Buttons

RS-232

Connector

Hall Sensor

Connector

PIC18FXX31

LEDs

Isolated

Control

Section

Quad Encoder

Connector

Comparator

PCPWM

Optoisolators

Voltage

Monitor

Current

Monitor

Phase Current

Monitors

Temperature

Monitor

Back EMF

Conditioner

PCPWM

Motor

Terminal Block

IRAMS10UP60A

Gate Driver and

3-Phase Inverter

Power Terminal Block

VBUS

DC

AC

© 2005 Microchip Technology Inc.

Power

Switcher

+5 VDC

+5 VAC

+15 VAC

D GND

A GND

Bridge

Rectifier

DS00955A-page 15

DS00955A-page 16

2

3

1

2

4

3

S3

+5 VD

R95

4.7K

SW1 (ON/OFF)

1

S4

4

R98

4.7K

SW2 (FWD/REV)

+5 VD

R97

4.7K

R96

4.7K

FAULTC

SW1

SW2

2

RC1

RC0

OSC2

OSC1

CF3

RE2

CF2

RA5

QEB

QEA

INDX

CF1

C52

R25

2.8K

R26

4.7K

+5 VD

RD1

RD0

INT0

FAULTB

0.1 μF 33 pF

C19

4.7K

R27

R43

100

R44

2K

+5 VD

0.1 μF VREF

2K

R42

C26

RC7/RX/DT

RD4/FLTA

RD5

RD6/PWM6

RD7/PWM7

VSS

VDD

RB0/PWM0

RB1/PWM1

RB2/PWM2

RB3/PWM3

RB4/PWM5

RB5/PWM4

RB6/PGC

RB7/PGD

0.1 μF

RC4/INT1

RC5/INT2

C17

1

U4:A

0.1 μF

MCP6002 8-DIP

4

8

+5 VD

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

3

2

1

RC1

JP1

RD2

RD3

INT1

INT2

TX

RX

RD4

SW1

SW2

PWM0

PWM1

PWM2

PWM3

PWM5

3

RB6

1

2

JP3

RB7

RD4

+5 VD

C53

33 pF

R24

1M

RD2/SDI/SDA

PIC18F4431

RD1/SDO

RD0/T0CKI/GPCKI RD3/SCK/SCL

RC3/INT0

RC2/CCP1

RC1/T1OSI/CCP2 RC6/TX/CK/SS

RC0/T1OSO/T1CKI

OSC2/CLKO/RA6

OSC1/CLKI/RA7

VSS

VDD

RE2/AN8

RE1/AN7

RE0/AN6

RA5/AN5/LVDIN

RA4/CAP3

RA3/AN3/VREF+

RA2/AN2/VREF-

RA1/AN1

RA0/AN0

U3

R40 470

MCLR/VPP

C54

33 pF

3

2

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

0.1 μF

C25

MCLR

RD5

220 μF 25V

C21

300

R34

PWM4

0.1 μF

C18

+5 VD

GND

V02

V01

VCC

GND

V02

V01

VCC

TLP2630/

SFH6326

3 CA2

4 AN2

U8

PWM1

PWM0

1 AN1

2 CA1

R39 300

R38 300

GND

V02

V01

VCC

TLP2630/

SFH6326

3 CA2

4 AN2

U7

PWM3

PWM2

1 AN1

2 CA1

R35 300

U5

PWM5

TLP2630/

SFH6326

3 CA2

4 AN2

1 AN1

2 CA1

R33 300

300

R30

5

6

7

8

5

6

7

8

5

6

7

8

R37

1K

R36

1K

R31

1K

R28

1K

LIN1

HIN1

C24

0.1 μF

LIN2

HIN2

C23

0.1 μF

+5 VA

R32

1K

LIN3

HIN3

C22

0.1 μF

+5 VA

R29

1K

+5 VA

FIGURE A-2:

C27

1

3

S2

4

R41

10K

RESET

+5 VD

AN955

BOARD SCHEMATIC, PART 1 (PIC18F4X31 MICROCONTROLLER, PCPWM

ISOLATORS, CURRENT COMPARATOR AND ASSOCIATED PARTS)

© 2005 Microchip Technology Inc.

© 2005 Microchip Technology Inc.

OSC1

OSC2

C48

33 pF

CF3

HC – 49US

INT0

FAULTB

RC1

RC0

OSC2

OSC1

QEB

Y1

14

13

12

11

10

9

8

7

6

5

QEA

4

3

3

VREF

2

1

2

1

CF1

MCLR

RC3

RC2/CCP1

RC1/CCP2

RC0

OSC2/RA6

OSC1/RA7

VSS

VDD

RA4/AN4

RA3/VREF+

RA2/VREF-

RA1/AN1

RA0/AN0

MCLR/RE3

RC6

RC7

VSS

VDD

PWM0

PWM1

PWM2

PWM3

PWM5

PWM4

RB6

RB7

C49

33 pF

RC4/INT1

RC5/INT2

U19

PIC18F2431

15

16

17

18

19

20

21

22

23

24

25

26

27

28

INT1

INT2

TX

RX

PWM0

PWM1

PWM2

PWM3

PWM5

PWM4

RB6

RB7

C41

0.1 μF

+5 VD

OPTIONAL

JP6

JP5

+5 VD

R99

100K

TX

RD1

RX

SW1

SW2

C46

1 μF

RX

TX

C47

1 μF

C44

1 μF

6

3

1

9

12

10

11

2

MCP201

LIN 6

VSS 5

4 TXD

VBAT 7

3 VDD

2 CS/WAKE

1 RXD FAULT/SLPS 8

U17

RD0

+5 VD

15

5

4

8

13

7

14

16

R100

100K

GND

C2-

C2+

A2IN

A1IN

VCC

MAX232 16-DIP

V-

C1-

C1+

A1OUT

A1OUT

T2IN

T1IN

V+

U18

D24

39V

+5 VD

R107

10 ohm

R101

1K

J14

PIN1

PIN6

PIN2

PIN7

PIN3

3 PIN8

PIN4

4 PIN9

PIN5

5

2

1

D22

1N4007

+5 VD

D23

27V

C42

0.1 μF

D21

1N4007

50

R106

C43

1 μF

C45

1 μF

9

8

7

6

3

2

1

J13

FIGURE A-3:

JP9

INDX

+5 VD

+5 VD

AN955

BOARD SCHEMATIC, PART 2 (PIC18F2X31 MICROCONTROLLER SOCKET,

USART, CLOCK OSCILLATOR NETWORK AND OPTIONAL LIN INTERFACE)

DS00955A-page 17

DS00955A-page 18

J2

5

4

3

2

1

6

5

4

3

2

1

+5 VD

+5 VD

R16

10K

R17

10K

+5 VD

R15

10K

+5 VD

QEB

RA5

CF1

VREF

INDX

QEA

INT0

INT1

INT2

J7

6

5

4

3

2

ICD 1

J3

5

4

3

2

1

J9

+5 VD

R22

10K

R21

10K

+5 VD +5 VD

RB7

RB6

MCLR

+5 VD

8

7

6

5

4

3

2

1

10K

+5 VD

1K

1K

R19

R20

1K

R18

PWM3

PWM5

PWM4

RB6

RB7

PWM0

PWM1

PWM2

QEB

QEA

INDX

J10

6

5

4

3

2

1

RD0

RD1

FAULTB

INT0

RC0

RC1

J11

10

9

8

7

6

5

4

3

2

1

RC0

RD2

RD1

RD0

470

R105

470

R104

470

R103

470

R102

RD2

RD3

INT1

INT2

TX

RX

RD4

RD5

SW1

SW2

J12

D20

D19

D18

D17

3

2

1

CF3

RE2

CF2

JP4

FIGURE A-4:

R23

J8

AN955

BOARD SCHEMATIC, PART 3 (SENSOR AND MICROCONTROLLER HEADER

CONNECTORS, MONITOR LEDS)

© 2005 Microchip Technology Inc.

© 2005 Microchip Technology Inc.

VBUS +

LEG3

LEG2

LEG1

560K

R88

560K

R90

560K

R85

R83

560K

R80

560K

R78

560K

R109

100K

560K

R91

C34

0.1 μF

560K

R86

C33

0.1 μF

560K

R81

C32

0.1 μF

560K

560K

560K

R55

100K

R76

R75

R73

C35

0.1 μF

27K

R92

R70

R69

JP2

10K

R72

22K

30K

R68

30K

R89

10K

R84

22K

R79

22K

R74

10K

R71

10K

+5 VA

22K

R87

22K

R82

22K

R77

R54

100K

R67

27K

1M

9

12

13

+IND

-IND

+INC

-INC

1M

10

R65

+INB

R64

5

6

1M

11

4

-INB

+INA

-INA

R63

3

2

C36

7

4.7K

R62

4.7K

1M

R66

U12:D

MCP6544

14

+5 VA

U12:C

MCP6544

8

+5 VA

R61

4.7K

R60

U12:B

MCP6544

+5 VA

U12:A

MCP6544

1

0.1 μF

+5 VA

300

R52

300

R49

300

R48

300

R50

R59

4.7K

+5 VA

U14

V02 6

GND 5

VCC 8

V01 7

TLP2630/

SFH6326

3 CA2

4 AN2

1 AN1

2 CA1

V02 6

GND 5

3 CA2

4 AN2

TLP2630/

SFH6326

VCC 8

V01 7

1 AN1

2 CA1

U13

R51

1K

R53

1K

R46

1K

C30

0.1 μF

+5 VD

R47

1K

FAULTB

C29

0.1 μF

+5 VD

R113

1K

QEA

3

2

1

INT1

INDX

3

2

1

INT0

QEB

3

2

1

INT2

JP10

JP11

JP8

FIGURE A-5:

0.1 μF

C31

R56

100K

AN955

BOARD SCHEMATIC, PART 4 (SIGNAL CONDITIONER FOR SENSORLESS BLDC

OPERATION)

DS00955A-page 19

DS00955A-page 20

+15 VA

HIN1

HIN2

HIN3

LIN1

LIN2

LIN3

U

V

W

R108

4.3K

VBUS+

FUSE 6.3X32

F2

C39 10 μF 16V

C38 10 μF 16V

C37 10 μF 16V

300

R93

0.05R/3W

R110

DC-

C56

33 pF

ISM

SFH618

1 +LED

COL 4

2 -LED EMT 3

U16

C57

4.7 nF

1K

R111

91K

R94

1K

+5 VD

R112

10K

R116

3

2

1K

R115

4

8

U11:A

MCP6002 8-DIP

+5 VA

1

R117

RE2

51K 1%

C55

0.1 μF

5

6

7

C58

100 pF

U11:B

MCP6002 8-DIP

R118

360

+5 VA

-LED

U20

I2

VCC2

N/C

N/C

LOC111 8-DIP

4 I1

2 +LED

3 VCCT

1

5

6

7

8

7

CF1

JP7

U4:B

MCP6002 8-DIP

5

6

R119

51K 1%

R120

470

FIGURE A-6:

VB3 1

VS3

2

NC

3

VB2

4

VS2

5

NC

6

VB1

7

VS1

8

NC

9

V+

10

NC

11

DC12

DC13

DC14

H1

15

H2

16

H3

17

L1

18

L2

19

L3

20

ITRIP

21

VCC

22

VSS

23

U15

IRAMS10UP60A

AN955

BOARD SCHEMATIC, PART 5 (3-PHASE INVERTER POWER MODULE AND SHUNT

CURRENT MEASUREMENT)

© 2005 Microchip Technology Inc.

R

Y

B

G

U

V

W

LEG1

LEG2

LEG3

4

3

2

1

C28

33 pF

FAULTC

EARTH

CF1

2.6K

R45

1K

R121

D12

1N4448

+5 VD

9 +5V

7 OUT

8 0V LTS15-NP

U6

OPTIONAL

IN6 6

IN5 5

IN4 4

3

IN3

2

IN2

1 IN1

© 2005 Microchip Technology Inc.

CF2

Load R124

0.01R, 1/2W

instead of U6

0.1 μF

C51

+5 VD

33 μF 35V

C50

1K

R122

D13

1N4448

9 +5V

7 OUT

8 0V LTS15-NP

U9

OPTIONAL

IN6 6

IN5 5

IN4 4

3

IN3

2

IN2

1 IN1

Load R125

0.01R, 1/2W

instead of U9

CF3

+5 VD

1K

R123

D14

1N4448

IN6 6

IN5 5

IN4 4

9 +5V

7 OUT

8 0V LTS15-NP

U10

OPTIONAL

Load R126

0.01R, 1/2W

instead of U10

FIGURE A-7:

3 IN3

2 IN2

1 IN1

J6

AN955

BOARD SCHEMATIC, PART 6 (MOTOR TERMINAL BLOCK AND OPTIONAL

CURRENT TRANSDUCER CIRCUITRY)

DS00955A-page 21

5

6

C16

RV1

216010

F1

C7

56 pF

R12

1.3 ohm

DC-

U1

1

2

3

4

5

DC-

1N5818

D7

S

GND

D

VCC

OCP/FB

4 AC2

3

AC1

2

1 ohm 3W

R2

R11

750 ohm

R4

150K

D8

1N4148

DC-

R3

47K

DC-

R13

2.4K

D9

1N4148

C15

R14

2.2 nF

400V

10 ohm

DC-

27 ohm

R5

D11

1N4937

C2

4.7 μF 400V

C12

220 pF

C6 1N4148

33 μF 25V

R10

4.7K

D4

470 μF 250V

C5

J17

SHORTING LINK

2

1

470 μF 250V

C1

VBUS+

C13

47 pF

DC-

DC-

D1

1

GBPC2506C

AC INPUT

R1

NTC

0.01 μF 270 VAC

DC-

4

EARTH

3

J1

G N L

2

DS00955A-page 22

1

E7

DC-

5

4

9

6

10

7

3

2

8

1

4

U2

1 3

CA 2

A 1

11DQ10

MOC8101

C

5 E

D5

R9

1K

TL431

L2

0.1 μF

C14

L1

C10

47 μF 25V

C9

47 μF 25V

10 μH

10 μH

C11

100 μF 25V

10 μH

L3

C8

100 μF 25V

D2

C3

100 μF 25V

11DQ10

D6

11DQ10

D3

6 NC

T1

TRANSFORMER TSD-877

E3

R7

4.7K

R8

4.7K

E5

D10

R6

470 ohm

+5 VD

E6

+15 VA

E4

C4

47 μF 16V

+5 VA

FIGURE A-8:

IRIS4009-HORZ

DC- DC+

AN955

BOARD SCHEMATIC, PART 7 (POWER SUPPLY)

© 2005 Microchip Technology Inc.

AN955

TABLE A-1:

SIGNALS USED IN THE PICDEM™ MC SCHEMATIC

Signal Name

Function

+15 VA

Non-isolated DC supply voltage for power components.

+5 VD

Isolated supply voltage for digital components.

CF1, CF2 or CF3

Current feedback signal from designated motor phase winding. CF can also

represent total motor current when current transducer measurement is used.

DC-

DC bus return path.

FAULTB

PCPWM Fault signal input (overvoltage).

FAULTC

Fault signal input from comparator (overcurrent).

HIN1, HIN2 or HIN3

Upper leg input for designated phase to 3-phase inverter (isolated signal).

INDX

Index position signal to QEI inputs on microcontroller.

INT0, INT1 or INT2

Hall effect sensor signal to interrupt-on-change inputs on microcontroller.

LEG1, LEG2 or LEG3

Current transducer signal for designated motor winding phase.

LIN1, LIN2 or LIN3

Lower leg input for designated phase to 3-phase inverter (isolated signal).

MCLR

Microcontroller hardware Reset.

PWM0 through PWM5

PCPWM waveform outputs from microcontroller.

QEA, QEB

Quadrature encoder sensor signals to QEI inputs on microcontroller.

RAn, RBn, RCn, RDn or REn

Bit n of the designated port of the microcontroller.

RX and TX

RS-232 serial receive and transmit.

SW1, SW2

Push button input from designated switch to microcontroller.

U, V, W

Drive level output from inverter power module to motor.

VBUS+

DC high voltage to inverter power module.

VREF

External reference voltage for overcurrent detect.

© 2005 Microchip Technology Inc.

DS00955A-page 23

AN955

APPENDIX B:

SINE PWM

APPENDIX C:

The Sine PWM is implemented using a VSI as shown

in Figure 2.

At any instant, either the top or the bottom switch of a

half bridge is on. Hence, the resultant phase-to-virtual

neutral point ‘O’ (VRO, VYO and VBO) can be

represented as:

EQUATION B-1:

Vio =

VDC × V (where = R, Y, B)

if

i

2

Vif represents the 3-phase waveforms in space with 120°

(2π/3) phase shift between them. Each phase waveform

can be represented as shown in Equation B-2:

EQUATION B-2:

MOTOR CONTROL

MADE EASY

To assist motor control developers, Microchip has

developed the PICDEM™ MC Development Board

based on the PIC18FXX31. This demo board has all

the necessary hardware for a range of motor control,

for example, AC Induction motor, BLDC motor and

Stepper motor. Various control algorithms have been

developed using the demo board to assist users in

developing motor control application. Also, a PC-based

GUI has been developed for helping users in configuring different motor control parameters and giving

real-time capability to monitor the motor speed, the

3-phase currents and temperature.

All source code and the motor control GUI are free to

use and can be downloaded from the Microchip web

site at:

www.microchip.com.

VRf = m × sinθ

VYf = m × sin(θ + 2π/3)

VBf = m × sin(θ + 4π/3)

Substituting Equation B-2 into Equation B-1, we get:

EQUATION B-3:

VDC (m × sinθ)

2

VDC (m × sin(θ + 2π/3))

VYO =

2

VDC (m × sin(θ + 4π/3))

VBO =

2

VRO =

The resultant line-to-line output voltage is given as:

EQUATION B-4:

VRY = VRO – VYO =

√3 × VDC × m × sin(θ + π/6)

2

VYB =

√3 × VDC × m × sin(θ + (5π)/6)

2

VRB =

√3 × VDC × m × sin(θ + 3π/2)

2

From Equation B-4, it is clear that the maximum line-toline voltage in the linear operating range is achieved

when m = 1.

EQUATION B-5:

Maximum line-to-line voltage =

√3 × VDC

2

This clearly shows that in Sine PWM, the VDC

utilization is less than 90% (~86.6%) in the linear

operating range.

DS00955A-page 24

© 2005 Microchip Technology Inc.

Note the following details of the code protection feature on Microchip devices:

•

Microchip products meet the specification contained in their particular Microchip Data Sheet.

•

Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

•

There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

•

Microchip is willing to work with the customer who is concerned about the integrity of their code.

•

Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device

applications and the like is provided only for your convenience

and may be superseded by updates. It is your responsibility to

ensure that your application meets with your specifications.

MICROCHIP MAKES NO REPRESENTATIONS OR WARRANTIES OF ANY KIND WHETHER EXPRESS OR IMPLIED,

WRITTEN OR ORAL, STATUTORY OR OTHERWISE,

RELATED TO THE INFORMATION, INCLUDING BUT NOT

LIMITED TO ITS CONDITION, QUALITY, PERFORMANCE,

MERCHANTABILITY OR FITNESS FOR PURPOSE.

Microchip disclaims all liability arising from this information and

its use. Use of Microchip’s products as critical components in

life support systems is not authorized except with express

written approval by Microchip. No licenses are conveyed,

implicitly or otherwise, under any Microchip intellectual property

rights.

Trademarks

The Microchip name and logo, the Microchip logo, Accuron,

dsPIC, KEELOQ, microID, MPLAB, PIC, PICmicro, PICSTART,

PRO MATE, PowerSmart, rfPIC, and SmartShunt are

registered trademarks of Microchip Technology Incorporated

in the U.S.A. and other countries.

AmpLab, FilterLab, Migratable Memory, MXDEV, MXLAB,

PICMASTER, SEEVAL, SmartSensor and The Embedded

Control Solutions Company are registered trademarks of

Microchip Technology Incorporated in the U.S.A.

Analog-for-the-Digital Age, Application Maestro, dsPICDEM,

dsPICDEM.net, dsPICworks, ECAN, ECONOMONITOR,

FanSense, FlexROM, fuzzyLAB, In-Circuit Serial

Programming, ICSP, ICEPIC, MPASM, MPLIB, MPLINK,

MPSIM, PICkit, PICDEM, PICDEM.net, PICLAB, PICtail,

PowerCal, PowerInfo, PowerMate, PowerTool, rfLAB,

rfPICDEM, Select Mode, Smart Serial, SmartTel, Total

Endurance and WiperLock are trademarks of Microchip

Technology Incorporated in the U.S.A. and other countries.

SQTP is a service mark of Microchip Technology Incorporated

in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2005, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received ISO/TS-16949:2002 quality system certification for

its worldwide headquarters, design and wafer fabrication facilities in

Chandler and Tempe, Arizona and Mountain View, California in

October 2003. The Company’s quality system processes and

procedures are for its PICmicro® 8-bit MCUs, KEELOQ® code hopping

devices, Serial EEPROMs, microperipherals, nonvolatile memory and

analog products. In addition, Microchip’s quality system for the design

and manufacture of development systems is ISO 9001:2000 certified.

© 2005 Microchip Technology Inc.

DS00955A-page 25

WORLDWIDE SALES AND SERVICE

AMERICAS

ASIA/PACIFIC

ASIA/PACIFIC

EUROPE

Corporate Office

2355 West Chandler Blvd.

Chandler, AZ 85224-6199

Tel: 480-792-7200

Fax: 480-792-7277

Technical Support:

http://support.microchip.com

Web Address:

www.microchip.com

Australia - Sydney

Tel: 61-2-9868-6733

Fax: 61-2-9868-6755

India - Bangalore

Tel: 91-80-2229-0061

Fax: 91-80-2229-0062

China - Beijing

Tel: 86-10-8528-2100

Fax: 86-10-8528-2104

India - New Delhi

Tel: 91-11-5160-8631

Fax: 91-11-5160-8632

Austria - Weis

Tel: 43-7242-2244-399

Fax: 43-7242-2244-393

Denmark - Ballerup

Tel: 45-4450-2828

Fax: 45-4485-2829

China - Chengdu

Tel: 86-28-8676-6200

Fax: 86-28-8676-6599

Japan - Kanagawa

Tel: 81-45-471- 6166

Fax: 81-45-471-6122

France - Massy

Tel: 33-1-69-53-63-20

Fax: 33-1-69-30-90-79

China - Fuzhou

Tel: 86-591-8750-3506

Fax: 86-591-8750-3521

Korea - Seoul

Tel: 82-2-554-7200

Fax: 82-2-558-5932 or

82-2-558-5934

Germany - Ismaning

Tel: 49-89-627-144-0

Fax: 49-89-627-144-44

Atlanta

Alpharetta, GA

Tel: 770-640-0034

Fax: 770-640-0307

Boston

Westborough, MA

Tel: 774-760-0087

Fax: 774-760-0088

Chicago

Itasca, IL

Tel: 630-285-0071

Fax: 630-285-0075

Dallas

Addison, TX

Tel: 972-818-7423

Fax: 972-818-2924

Detroit

Farmington Hills, MI

Tel: 248-538-2250

Fax: 248-538-2260

Kokomo

Kokomo, IN

Tel: 765-864-8360

Fax: 765-864-8387

China - Hong Kong SAR

Tel: 852-2401-1200

Fax: 852-2401-3431

China - Shanghai

Tel: 86-21-5407-5533

Fax: 86-21-5407-5066

China - Shenyang

Tel: 86-24-2334-2829

Fax: 86-24-2334-2393

China - Shenzhen

Tel: 86-755-8203-2660

Fax: 86-755-8203-1760

China - Shunde

Tel: 86-757-2839-5507

Fax: 86-757-2839-5571

Singapore

Tel: 65-6334-8870

Fax: 65-6334-8850

Taiwan - Kaohsiung

Tel: 886-7-536-4818

Fax: 886-7-536-4803

Taiwan - Taipei

Tel: 886-2-2500-6610

Fax: 886-2-2508-0102

Italy - Milan

Tel: 39-0331-742611

Fax: 39-0331-466781

Netherlands - Drunen

Tel: 31-416-690399

Fax: 31-416-690340

England - Berkshire

Tel: 44-118-921-5869

Fax: 44-118-921-5820

Taiwan - Hsinchu

Tel: 886-3-572-9526

Fax: 886-3-572-6459

China - Qingdao

Tel: 86-532-502-7355

Fax: 86-532-502-7205

Los Angeles

Mission Viejo, CA

Tel: 949-462-9523

Fax: 949-462-9608

San Jose

Mountain View, CA

Tel: 650-215-1444

Fax: 650-961-0286

Toronto

Mississauga, Ontario,

Canada

Tel: 905-673-0699

Fax: 905-673-6509

03/01/05

DS00955A-page 26

© 2005 Microchip Technology Inc.