Regulatory responses to the use of various

advertisement

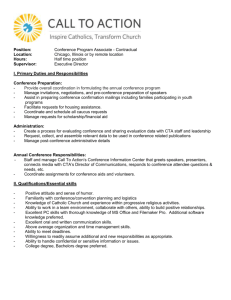

Focus – Chemistry, manufacturing & controls Regulatory responses to the use of various lean stability strategies in early drug development Authors Anita L Freed, Global Chemistry, Manufacturing & Controls; Elise Clement, Analytical Research & Development; Robert Timpano, Analytical Research & Development; Pfizer Worldwide Research & Development, Groton, CT, US. Keywords Investigational medicinal product dossier (IMPD); Investigational new drug application (INDA); Early development (ED); Phase I; Phase IIa; Drug substance (DS); Drug product (DP); Clinical trial application (CTA): Lean stability; Accelerated Stability Assessment Program (ASAP). Abstract This paper discusses drug substance (DS) and drug product (DP) lean stability strategies applied to compounds in early development (ED, Phases I and IIa) and the responses of various regulatory agencies to these approaches. Clinical stability programmes are designed to support and underwrite DS review periods and DP use period assignments at specified storage conditions and packaging configurations. Specific applications of science-based and risk-based approaches used to develop lean stability strategies in support of these assignments will be discussed. This includes the use of these approaches in the clinical dossiers in the absence of traditional (“ICH-like” – Note: ICH guidances are written for compounds to be commercially registered and not in scope for early clinical studies) stability data and the use of reduced testing designs. Specifically, a reduction in time points and/or testing and determining the necessity of placing batches on stability after manufacturing changes will be presented. The regulatory response to each of these strategies will be discussed. Introduction Many countries and regions have differing expectations of the stability information needed for clinical trial applications (CTAs) to support the proposed ED clinical trials. Most regions/ countries differentiate their expectations based on the stage of development; however, there may be subtle but important differences among the level of information expected. For example, the US guidance for Phase I studies1 states that “although stability data are required in all phases of the IND [investigational new drug] to demonstrate that the new drug substance and drug product are within acceptable chemical and physical limits for the planned duration of the proposed clinical investigations, if very short-term tests are proposed, the supporting stability data can be correspondingly very limited.” The related guidances in the www.topra.org EU2 and Canada3 likewise seem to differentiate their expectations based on stage of development, eg, Phase I versus Phases II and III. However, unlike the US Phase I and Phase II guidances,1,4 they cite that the DS review period (EU and Canada), the DP use period and stability protocol (Canada) and use period extension (EU) protocols should be included in the CTA. There are also a few countries/regions that continue to expect industry to apply ICH Q1 guidance requirements for early stage clinical programmes. This includes: (1) requiring clinical use periods to not exceed for example X + 12 M for room temperature supplies,5 and (2) new stability studies for changes in packaging configurations (eg, switching from bottles to blisters).6 Although this is a minority of the countries, it can result in challenges for the supply chain, especially when the use period is required to be included on the clinical supply label. DS and DP clinical stability programmes should be designed to ensure the quality of the material for the duration of its use. The varying countries/regions agree that a commitment to assess the stability of the clinical (or representative) supplies in parallel to the clinical studies and throughout its duration should be included in the dossiers. Science- and risk-based approaches, which consist of tailoring each case based on scientific understanding to ensure they are fit for purpose,7–12 should be considered. This application may allow the use of lean stability strategies, which reduce cost and/or lead time by minimising nonvalue added tests, conditions and pull points. Potential strategies to consider for stability studies to support early development (Phase I and IIa) programmes and the regulatory responses to each will be discussed. Examples of lean stability strategies in early development Topic A: Establishing initial review and use periods. Stress testing can provide an initial understanding of the stability of the DS and DP, as well as the need for any storage and/or package restrictions (temperature, light, humidity). As such, it can be employed to set initial DS review periods7 and DP use periods12 in lieu of traditional stability (“ICH-like” – Note: ICH guidances are applicable at registration) data (see examples 1 and 2 below) and can be described in the CTA to allow clinical programmes to start earlier. Example 1: Initial DS review period assignment of 18 months based on 70⁰C/75%RH one week stability data: The data were submitted from this stressed study in the CTA, and a commitment made to monitor a batch representative of the clinical material at the pertinent traditional conditions, eg, 5°C/60% RH, 25°C/60% RH, 40°C/75% RH, concurrent with the clinical studies for the pertinent stability related attributes, eg, appearance and purity. This approach has been filed for drug substances stored at room temperature (15–30°C) in the initial Phase I CTAs in a few instances in the US and once in Canada and in Belgium, without any queries or comments in the former two Regulatory Rapporteur – Vol 11, No 7/8, July/August 2014 5 6 Focus – Chemistry, manufacturing & controls Table 1: ASAP stability protocol. Condition Duration 5ºC/5% RH (Control) 14 days 50ºC/75% RH 14 days 60ºC/40% RH 14 days 70ºC/5% RH 14 days 70ºC/75% RH 1 day 80ºC/40% RH 2 days cases. Note, however, that the DS review period was not included in the US filing (only the related information, data and above cited commitment). The Belgian regulatory agency approved the CTA, but did comment that additional stability results should be presented in future applications for this compound. Example 2: Initial DP use period assignment of not more than (NMT) 12 months based on an Accelerated Stability Assessment Program (ASAP): The conclusions from a statistically designed 14-day stability study (ASAP) were submitted. The design of the ASAP study was based on work in the literature that demonstrates the modelling degradation observed in solid oral dosage forms using an isoconversion paradigm and a moisture corrected Arrhenius equation.13 Here, a tablet was compressed that consisted of low drug loading, eg, 1%, to represent the highest excipient to drug ratio for this product. Therefore, the possible drug–excipient interactions and thus the degradation of the DS in the formulation will be maximised. The tablets were stored in open containers to allow for equilibration of the samples with the set humidity point, thereby allowing for a better correlation on the impact of water on degradation kinetics. The stability samples were subsequently evaluated for appearance and concentration(s) of the main degradation product(s). The textual results were given, eg, “no changes in appearances…”, “RRT X.XX is the use period-limiting degradant”. The conditions and durations were presented in the CTA and are shown in Table 1. A commitment was made in the CTA to monitor representative batches of the clinical material at the pertinent traditional conditions, eg, 5°C/60% RH, 25°C/60% RH, 40°C/75% RH, in the clinical packaging configuration concurrent with the clinical studies to demonstrate that the clinical supplies meet the standards of identity, strength, quality and purity at the time of use. For CTAs submitted in the EU and pertinent emerging market (EM) countries (those that receive Section P.8 Stability), a protocol was given in tabular format. This approach has been submitted in numerous CTAs for ED studies in the US, Canada, EU and pertinent EM countries (those that require and thus received Section P.8 Stability) with various compounds. Queries have been received from South Korea, Czech Republic and Ukraine. In the case of South Korea, the Agency stated that threemonth data at the long term storage condition must be provided in order for an initial use period assignment of 12 months to be accepted. Updates in the stability expectations in this country have been experienced since this query was received; however, this expectation seems to remain. In the Czech Republic Agency, previous experiences have shown that the Agency follows ICH Q1E5 for setting DP use periods, ie, 2 X long-term stability data but not exceeding X + 12 months for 15–30°C storage conditions. As such, the sponsor enquired about the possibility of meeting with the Agency in advance of the CTA submission, but was informed that a request could not be granted. Therefore, additional technical information on ASAP was provided for the regulatory agency to review as part of the CTA package. Despite this additional information and the informal discussions, the team was unsuccessful in obtaining approval of this approach, and the use period was required to be set as per the ICH Q1E guideline. In Ukraine, previous experiences have also shown that this Agency required real-time stability data for setting DP use periods via ICH Q1E.5 As such, in advance of a CTA for an ED study, the sponsor requested the Agency via written format to consider an extrapolation approach for assignment of use period for ED products and provided supportive additional information. The Agency responded by requesting data and an extrapolation diagram of the key degradants for that specific drug product. This Table 2: ASAP protocol and data of use period limiting degradants for Compound A 0.5% compacts. Condition Duration 5°C/5% RH (Control) 14 days 0.25% 50°C/75% RH 14 days 0.31% 60°C/40% RH 14 days 0.42% 70°C/5% RH 14 days 0.52% 70°C/75% RH 1.5 day 0.36% 80°C/40% RH 2 days 0.66% Regulatory Rapporteur – Vol 11, No 7/8, July/August 2014 Amounts (%) of use period limiting degradant(s) RRT X.XX www.topra.org Focus – Chemistry, manufacturing & controls Figure 1: Graph of RRT X.XX levels with extrapolated clinical use periods for Compound A at various storage conditions. 0.600 % of total area 0.500 25C/60%RH 0.400 30C/65%RH 30C/75%RH 0.300 0.5% Spec 0.200 0.100 0.000 0 3 6 9 12 15 18 20 24 Time (months) information was provided in advance of and again with the CTA. In this instance, the Agency agreed to the proposed use period for this compound. The sponsor now routinely includes this extrapolation information and data for the key degradant in CTAs submitted in the EU, European Neighborhood Policy (ENP), European Economic Area (EEA) (see following specific example). Additional CTAs including this information have been approved in Ukraine. In a global Phase IIa CTA, Compound A included its initial use period at 12M based on ASAP and included the extrapolation information and data for key degradants (see Figure 1 and Table 1, respectively), as discussed in the above paragraph for Ukraine. No queries or comments were received from regulatory agencies in the US, Canada, Bulgaria, Hungary, India, Romania, Serbia, Slovakia, Philippines, South Africa, Taiwan, or Turkey (the latter four of which do not require this information and thus did not receive it) for its initial Phase IIa CTA. Serbia and Romania requested additional stability information to support this use period assignment. At that point, additional stability data were available and were provided. Ultimately, the proposed shelf life was accepted. Topic B: Assessing manufacturing changes. The decision to conduct stability studies after changes in the manufacturing process or packaging configurations are based on the stability knowledge of the compound, the scientific understanding of the shelf life limiting attributes and the types of changes being made.9,13 The decisions are routinely based on internal risk assessments that often use a comparison of the results from the accelerated/stressed (70°C/75%RH for DS, ASAP for DP). Examples 3 and 4 below discuss a DS manufacturing change and the implementation of a new DP container closure system, respectively. Example 3: Assess need for additional stability studies after DS process changes: The internal risk assessment typically has not been described in the CTA in early development studies unless the changes were significant (eg, new form). This approach has been filed in numerous examples of ED CTA submissions in the US, Canada, the EU and the pertinent EM countries (Section S.7 Stability is not required and thus not provided in all EM countries) with www.topra.org various compounds, and no queries or comments have been received to date. For Compound A, a different processing/workup used in steps 1 and 3 of the 3-step process for one batch, while the DS was recovered and purified from the mother liquor for a second batch. All processes were described in Section S.2 Manufacturing of the Phase IIa CTA, but the stability risk assessment was not discussed in the CTA. No queries or comments were received from the US, Canada, Bulgaria, Hungary, India, Romania, Slovakia, Philippines, Taiwan or Turkey (the latter three of which do not require this information and thus did not receive it). Example 4: Assess need for additional stability studies after implementation of a new DP container closure system: The justification has typically been included in the CTA for new container closures and the plans to support the use period are clearly defined. There are numerous examples of submissions of this approach in the US, Canada, the EU and pertinent EM countries (where Section P.8 Stability was required) with various compounds. Compound B used this approach in a Phase IIa CTA, concluding the ongoing stability study in high-density polyethylene (HDPE) bottles with desiccant to be representative, but including a commitment to run an abbreviated confirmatory stability study in the new packaging (aclar/foil blisters). Information from an ASAP assessment was included in the justification within the CTA. The only query received was in the case of South Korea for Compound B, which filed CTAs for a Phase IIa study using blisters. No queries were received from the US, Canada, Bulgaria, Hungary, India, Romania, Serbia, Slovakia, Philippines, South Africa, Taiwan or Turkey (the latter four of which do not require this information and thus did not receive it). Unfortunately, the South Korean Agency agreed in the final approval letter (no opportunity to discuss further) to our shelf life only after three-month data in the blisters was provided. This required a South Korea-specific use period to be assigned and the supplies already staged for shipment to be re-labelled. Updates in the stability expectations in this country have taken place since this query was received; however, this expectation seems to remain. Regulatory Rapporteur – Vol 11, No 7/8, July/August 2014 7 8 Focus – Chemistry, manufacturing & controls Topic C: Eliminating non-value adding testing. Example 5 discusses the removal of assay testing in the DS stability programme when the DS batch on stability and the working standard it is tested against are the same batch of material. Example 5: The exclusion of assay testing in the initial DS stability programme when the batch is the same as that of the working standard: The following justification for not testing assay was provided in the CTA: l T he DS batch currently on clinical stability is also used as reference standard in analytical testing. Therefore, performing assay at each stability checkpoint would mean that the DS would be tested against itself and variability in “assay” values obtained on stability would be reflective of method accuracy, not degradation. l R eference standards are generally stored under the same condition as clinical supplies. l T he HPLC method employed for monitoring degradation products has been developed to be stability indicating, ie, all known degradation products are resolved from the main band. Degradation products, if any, are quantified versus the main band at this stage of development, assuming the equivalent response factors. Data on appearance and purity/degradation is provided. This approach has been submitted numerous times in ED CTAs to the US, Canada, the EU and pertinent EM countries (those that require Section S.7 Stability) with various compounds. No queries or comments have been received, apart from two recent queries from Canada and one comment (not contingent on approval) from Belgium. In Canada, we presented our rationale and justification in a general (non-project related) teleconference. Additional details were provided on the practices for developing a stabilityindicating method and assuring initial DS stability. The Agency agreed “that the analytical results for assay would not be stability indicating”. However, it suggested that other options be explored to generate meaningful assay results on stability, eg, additional purification of the reference standard, storing it under more than stringent conditions, alternative analytical methods. In the case of Belgium, the Agency approved the CTA. However, it recommended assay be included in the stability testing protocol during further development of the product. It was requested that this point be taken into consideration and readdressed at the time of assessment of future applications related to the investigational medicinal product. To date, no further applications have been submitted to Belgium for this product. review period and use period assignments, respectively, and to manage regulatory risk and expectations. Acceptance of lean stability strategies, not only during clinical trials but throughout the developmental lifecycle, will require further collaboration between industry and the regulators. The authors advocate a continued dialogue at scientific conferences, through publications and on project-specific basis when these opportunities arise, as our patients will ultimately benefit. Acknowledgements Steve Colgan, Aine Kane, Julia Claus, Doug Farrand. References 1Guidance for Industry: Content and Format of Investigational New Drug Applications (INDs) for Phase 1 Studies of Drugs, Including Well-Characterized, Therapeutic, Biotechnology-Derived Products. 2CHMP/QWP/185401/2004: Guideline on the Requirements to the Chemical and Pharmaceutical Quality Documentation Concerning Investigational Medicinal Products in Clinical Trials. 3Quality (Chemistry and Manufacturing) Guidance: Clinical Trial Applications (CTAs) for Pharmaceuticals 4Guidance for Industry: INDs for Phase 2 and Phase 3 Studies; Chemistry, Manufacturing, and Controls Information. 5ICH Q1E: Evaluation of Stability Data. 6ICH Q1A: Stability Testing of New Drug Substances and Products. 7C Q Li, F Qiu, K Cohen et al. ‘Best practices for drug substance stress and stability studies during early-stage development part I – conducting drug substance solid stress to support phase Ia clinical trials’, J Pharm Innov, 2012, 7(3): 214-24. 8C Q Li, F Qiu, K Cohen et al. ‘Best practices for drug substance stress and stability studies during early-stage development part II – conducting abbreviated long-term and accelerated stability testing on the first clinical drug substance batch to confirm and adjust the drug substance retest period/powder for oral solution shelf life’, J Pharm Innov, 2013, 8(1): 56-654. 9C Q Li, F Qiu, W McWilliams et al. ‘Best practices for drug substance stress and stability studies during early stage development part III – how to make science- and risk-based stability testing decisions for drug substance batches produced after manufacturing process changes’, J Pharm Innov, 2013, 8(4): 229-39. 10W R Porter. ‘Degradation of pharmaceutical solids accelerated by changes in both relative humidity and temperature and combined storage temperature and storage relative humidity (Txh) design space for solid products’, J Valid Tech, 2014, 19(2). 11B Acken, M Alasandro, S Colgan et al. ‘Early development GMPs Conclusion for stability: an industry perspective (Part IV), Pharmaceutical The lean stability strategies described herein have been widely accepted by regulatory agencies in varying countries/regions through the standard clinical trial application filing and query response process. When this was not the case, acceptance was gained in some instances by providing further understanding and justification to the agency(ies) through additional written material and/or verbal discussion. When selecting DS and DP stability strategies for early development programmes, the sponsor should consider applying science- and risk-based strategies to support and underwrite Technology, 2012, 36(9): 64-70, E-published, page number to be Regulatory Rapporteur – Vol 11, No 7/8, July/August 2014 determined. 12S T Colgan, R J Timpano, M Roberts et al. ‘Opportunities for lean stability strategies’, In draft; to be submitted to J Pharm Innov. 13K Waterman, S T Colgan. ‘A science-based approach to setting expiry dating for solid products’, Regulatory Rapporteur, 2008, 5(7): 9-14. 14K Waterman, A Carella, M Gumkowski et al. ‘Improved protocol and data analysis for accelerated shelf-life estimation of solid dosage forms’, Pharmaceutical Research, 2007, 24(4): 780-790. www.topra.org