Power Equipment Solutions

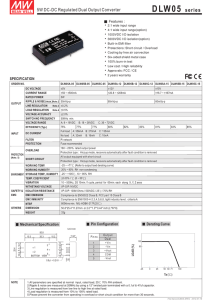

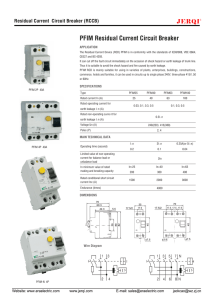

advertisement