eddy current testing

NEW SOUTH WALES

TECHNICAL AND FURTHER EDUCATION COMMISSION

______________________

EDDY CURRENT TESTING

______________________

NSW Module Number: 6161C

Implementation Date: 01-Jan-1998

National Module Code: EA605

MANUFACTURING AND ENGINEERING

MECHANICAL & MATERIALS PROGRAM AREA

A. Module information

Eddy Current Testing - 6161C

1. MODULE DETAILS:

1.1 Module Name:

Eddy Current Testing

1.2 Nominal Student Hours: 72 hours

This module is equivalent to two standard modules and so will normally require

72 hours for delivery.

1.3 Module Codes:

NSW Module Number: 6161C

National Module Code: EA605

1.4 Field of Education Code: 030301 Chemical Engineering

1.5 Copyright Information:

(c)Commonwealth of Australia

1.6 Licensing and Franchise Arrangements:

Licensing and franchising arrangements are to be negotiated with the

Australian National Training Authority (ANTA) (03)9630 9825.

2. MODULE PURPOSE

The purpose of this module is to enable students to operate eddy current equipment and interpret signals indicated by the equipment, and to use eddy current test procedures in industrial applications.

This module meets the training requirements of AS 3998-1992 "Non-destructive

Testing and Qualification and Certification of Personnel - General Engineering" for Level 2 certification in eddy current testing.

3. PREREQUISITES

Nil

4. RELATIONSHIP TO COMPETENCY STANDARDS:

Implementation Date: 1-Jan-1998 Status:Approved

Manufacturing and Engineering - Mechanical & Materials (c) 2002 The State of NSW,

Department of Education and Training unless otherwise stated in the Copyright section of the document.

Date Printed: 6/02/2003

2

A. Module information

Eddy Current Testing - 6161C

This module fully addresses the National Metal and Engineering Competency

Standards Unit MEM24.6AA Perform eddy current testing in developing generic skills.

To achieve full workplace competence for Competency Standards Unit MEM24.6AA, the learner will need to have undertaken relevant on the job skill practice. This can be as either part of the module learning process, after completion of the module or through previous experience.

5. CONTENT:

1. Basic principles

Electricity

Direct current

Amperage

Voltage

Ohms law and resistance

Conductivity and resistivity

Alternating current

Amplitude

Phase

Impedance

Vectorial representation

Electromagnetic induction

Field generated by a current

Filed/induction relationship

Flux of induction vector

EMF of induction

Self-inductance - coefficient of

Mutual inductance - coefficient of

Coupling coefficient

Impedance of circuit in presence of another circuit

Representation of impedance plane

Effect of fill factor

Normalised impedance plane

Effect of frequency

Influence of magnetic field

Resonant frequency

Magnetism

Magnetic data

Induction and magnetic fields

Magnetic permeability

Iron magnetisation

Induced magnetic flux

Lines of force and force fields

Flux conservation, residual magnetism

Magnetic Ohm law

Magnetomotive force

Reluctance

Magnetic circuits

Electromagnetism

Magnetic field produced by a current

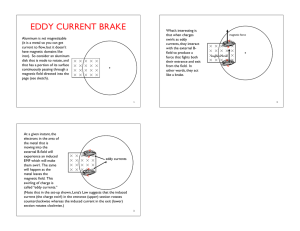

Inductive current - eddy current

Reactance - field made by eddy current

Biot and Savant law

Definition

Implementation Date: 1-Jan-1998 Status:Approved

Manufacturing and Engineering - Mechanical & Materials (c) 2002 The State of NSW,

Department of Education and Training unless otherwise stated in the Copyright section of the document.

Date Printed: 6/02/2003

3

A. Module information

Practical (right hand) rules

Amperes law

Eddy Current Testing - 6161C

Definition

Applications (toroid, infinite coil, flat coil)

Lenz law

Definition

Auto-induction factor

Mutual induction factor

Coupling factor

Induced currents

Short circuit coil

Metallic mass

Skin effect

Reactance

2. Theory of eddy currents

Distribution of eddy currents

Plane conductors

Effect of amplitude and phase

Depth of standard penetration

Defect reaction according to its position

Cylindrical bars

Similarity law

Characteristical frequency

Variation of amplitude and currents

Depth of standard penetration

Defect reaction according to its position

Tubes

Characteristical frequencies

Variations in amplitude and phase of currents

Depth of standard penetration

Defect reaction according to its position

Geometric defect characterisation

Hypothesis of interrupted current

Point defects

Large defects

Multiple defects

Impedance diagrams

Encircling coil with bar, tube or sphere

Operating points, choice

Use of impedance diagrams

3. Characteristics of eddy current probes

Induction and reception functions

Absolute and differential measure

Types of probes - Encircling, internal, surface, hybrid

Means of focussing

Field from an empty coil, divergence between theory and practice

Effect of coupling

EC distribution related to coil position

Field generated by non-load inductor

EC path in product according to its position towards inductor coil

Distance influence on coupling in various shapes

Probe reactance to small, long and continuous defects

Design technology, manufacturing technology, electric parameters

Implementation Date: 1-Jan-1998 Status:Approved

Manufacturing and Engineering - Mechanical & Materials (c) 2002 The State of NSW,

Department of Education and Training unless otherwise stated in the Copyright section of the document.

Date Printed: 6/02/2003

4

A. Module information

maintenance

Remote field techniques

Eddy Current Testing - 6161C

Magneto-optical imaging

4. Eddy current equipment

Working principles

Transmission

Reception

Data presentation

Equipment controls

Oscillator - frequency control

Energising devices and measure-ment

Balancing the system

Amplifier, filter, modulation/demodulation

Phase rotation

Display - ellipse, A-scan, vector point

Gain control

Types of equipment

Mono-parameter, mono-channel

Multi-parameter, multi-channel

Auxiliary devices

Signal acquisition

Saturation magnetiser/demagnetiser

Signal storage

Recorders

Memories

Data processing

5. Properties of materials

Physical properties

Electrical conductivity

Effect of chemical analysis

Temperature

Grain size

Texture

Cold work

Structure

Magnetic permeability

Effect of chemical analysis

Temperature

Grain size

Texture

Cold work

Structure

Hysteresis loop

Rayleigh area

Saturation

Weiss area

Curie point

Anomalies relating to manufacture and service

Applications of eddy curry testing

6. Influence of various parameters on eddy current measurement

Defect position and orientation

EC path

Implementation Date: 1-Jan-1998 Status:Approved

Manufacturing and Engineering - Mechanical & Materials (c) 2002 The State of NSW,

Department of Education and Training unless otherwise stated in the Copyright section of the document.

Date Printed: 6/02/2003

5

A. Module information

Penetration depth

Zone of probe action

Eddy Current Testing - 6161C

Material temperature

Heating

Deviations

Compensation

Structure and geometry of test part

Choice of frequency

Phase discrimination

Noise filtering

Magnetic saturation

Coupling influence

Vibrations

Centering

Fill factor

Sensitivity

Compensation

Relative speed

Testing frequencies according to speed

Band width of apparatus according to test speed

6. ASSESSMENT STRATEGY

The assessment of this module is holistic in nature and requires the demonstration of the knowledge and skills identified in the module content, and the integration of that knowledge with those skills. To be successful in this module, the student must show evidence of achievement of the module purpose.

Additionally, the module is graded and so allows the student to demonstrate greater depth and/or breadth of achievement. The assessment scheme is designed to assess essential knowledge and skills in a variety of ways throughout the module's assessment events.

7. LEARNING OUTCOME DETAILS

7.1 Learning Outcome 1:

Describe the basic principles of eddy current testing.

Assessment criteria Explain the physics of electricity and magnetism

as it applies to eddy current testing.

Explain the physics of electromagnetism.

Discuss the relevant laws of electromagnetism and

electromagnetic induction in relation to the

production of eddy currents.

Conditions Suitable eddy current laboratory

Assessment method Written test to include multi-choice, short answer and

essay questions to cover the theory and practical work.

Students will also be assessed on the reports submitted

on practical assignments.

Implementation Date: 1-Jan-1998 Status:Approved

Manufacturing and Engineering - Mechanical & Materials (c) 2002 The State of NSW,

Department of Education and Training unless otherwise stated in the Copyright section of the document.

Date Printed: 6/02/2003

6

A. Module information

7.2 Learning Outcome 2:

Describe the theory of eddy currents.

Eddy Current Testing - 6161C

Assessment criteria Describe how eddy currents are distributed in

sheet, plate, bars and tubes.

Describe how defects may be characterised for

eddy current determination.

Explain the use of impedance diagrams in eddy

current testing.

Conditions Suitable eddy current laboratory

Assessment method Written test to include multi-choice, short answer

and essay questions to cover the theory and practical

work.

Students will also be assessed on the reports

submitted on practical assignments.

7.3 Learning Outcome 3:

Describe the characteristics of eddy current probes.

Assessment criteria Describe the induction and reception functions of

eddy current probes.

Discuss the features and applications of absolute

and differential probes.

Illustrate the design technology and manufacturing

technology of eddy current probes.

Conditions Suitable eddy current laboratory

Assessment method Written test to include multi-choice, short answer and

essay questions to cover the theory and practical work.

Students will also be assessed on the reports submitted

on practical assignments.

7.4 Learning Outcome 4:

Describe the principles underlying the use of eddy current test equipment for the inspection of materials and components, and set up the equipment.

Assessment criteria Describe the principles of the operation of eddy

current equipment.

Set up and calibrate the various types of eddy

current equipment.

Use eddy current equipment for inspection of

materials and components for thickness gauging,

Implementation Date: 1-Jan-1998 Status:Approved

Manufacturing and Engineering - Mechanical & Materials (c) 2002 The State of NSW,

Department of Education and Training unless otherwise stated in the Copyright section of the document.

Date Printed: 6/02/2003

7

A. Module information

flaw detection, and conductivity.

Eddy Current Testing - 6161C

Conditions Suitable eddy current laboratory

Assessment method Written test to include multi-choice, short answer

and essay questions to cover the theory and practical

work.

Students will also be assessed on the reports

submitted on practical assignments.

7.5 Learning Outcome 5:

Describe the applications for eddy current testing, including the materials and products that may be tested by this method and the nature of the defects that may be detected.

Assessment criteria Describe the electromagnetic properties of

materials that affect their suitability to eddy

current testing and the effect of variations in

electromagnetic properties on the test outcomes.

Describe and identify the main types of defects

and discontinuities that may be detected by eddy

current testing.

Describe the discontinuities in materials that

may result from methods of manufacture or service.

Conditions Suitable eddy current laboratory

Assessment method Written test to include multi-choice, short answer and

essay questions to cover the theory and practical work.

Students will also be assessed on the reports

submitted on practical assignments.

7.6 Learning Outcome 6:

Discuss and assess the influence of various parameters on the eddy current test.

Assessment criteria Describe how parameters such as defect orientation

and position, structure, shape, coupling and test

speed may influence the technique and outcome of

eddy current testing.

Assess and report on the effect of various

parameters on the test outcomes.

Conditions Suitable eddy current laboratory

Assessment method Written test to include multi-choice, short answer and

essay questions to cover the theory and practical work.

Students will also be assessed on the reports submitted

on practical assignments.

Implementation Date: 1-Jan-1998 Status:Approved

Manufacturing and Engineering - Mechanical & Materials (c) 2002 The State of NSW,

Department of Education and Training unless otherwise stated in the Copyright section of the document.

Date Printed: 6/02/2003

8

A. Module information

Eddy Current Testing - 6161C

8. DELIVERY

DELIVERY STRATEGY

This module may be delivered either in an off-the -job environment or, where suitable resources are available, in an on-the-job environment. It would be expected that all learners should be exposed to the testing that make up the module even in those cases where the learning outcome requires only that they should be able to verify, understand, assess results and recommend action.

RESOURCE REQUIREMENTS

Suitable physical resources should be available to carry out each of the tests that are included in the module.

OCCUPATIONAL HEALTH AND SAFETY REQUIREMENTS

Learners should be made aware of the occupational health and safety implications at all times.

Implementation Date: 1-Jan-1998 Status:Approved

Manufacturing and Engineering - Mechanical & Materials (c) 2002 The State of NSW,

Department of Education and Training unless otherwise stated in the Copyright section of the document.

Date Printed: 6/02/2003

9

B. TAFE NSW implementation requirements

1. Module(s) replaced by this module:

2.1 TAFE Advanced Standings:

Eddy Current Testing - 6161C

Arrangements

No : 501820

Start : 01-01-1993

End :

Sponsor:

Target Modules

6161C Eddy Current Testing

Manufacturing and Engineering

3. Standard Exemptions:

EA605

Source Modules

6132A Eddy Current Testing

A student is eligible for an exemption in this TAFE NSW module if they provide documentary evidence from a Recognised Training Organisation that they have successfully completed the national module/s with the specified national module code/s.

4. Recognition of Prior Learning:

Students who have completed formal training or who have relevant life/work experience and consider they are able to meet the module purpose, may seek recognition of their prior learning.

Applicants will be required to present evidence of their relevant skills and knowledge in an interview with specialist staff. This evidence will be validated either through satisfactory supporting documentation or support from a recognised industry or workplace representative or a challenge test, or other appropriate assessment practice.

5. Module Included in the following Courses:

Number Ver Course Name

1741

1742

1 Manufacturing Technology

1 Manufacturing Technology

1743

1744

1745

1746

3441

1

1

1

1

1

Manufacturing Systems

Manufacturing Systems

Quality Systems

Quality Systems

Metal and Engineering Competency Standards

Units

3453

4242

4242

4267

4277

4278

1

1

2

Engineering - Higher Engineering Trade

Non-Destructive Testing

Non-Destructive Testing

Sponsor

Manufacturing and Engineering

Manufacturing and Engineering

Manufacturing and Engineering

Manufacturing and Engineering

Manufacturing and Engineering

Manufacturing and Engineering

Manufacturing and Engineering

Manufacturing and Engineering

Manufacturing and Engineering

Manufacturing and Engineering

3 Engineering - Higher Engineering Trade Manufacturing and Engineering

1 Mechanical Engineering Manufacturing and Engineering

1 Naval Architecture Manufacturing and Engineering

4285

4286

4293

4294

1 Mechanical Engineering

1 Naval Architecture

1 Mechanical Technology

1 Naval Architecture Technology

Manufacturing and Engineering

Manufacturing and Engineering

Manufacturing and Engineering

Manufacturing and Engineering

Implementation Date: 1-Jan-1998 Status:Approved

Manufacturing and Engineering - Mechanical & Materials (c) 2002 The State of NSW,

Department of Education and Training unless otherwise stated in the Copyright section of the document.

Date Printed: 6/02/2003

10

9325

9885

9886

9887

9891

9975

32000

6076

6161

6182

6793

6794

6795

6796

6797

6798

6799

6800

6899

9231

B. TAFE NSW implementation requirements

6075 1 Engineering

9240

9322

9323

9324

Eddy Current Testing - 6161C

1

1

1

Engineering

Non-Destructive Testing

Materials Technology

1 Manufacturing Technology

1 Manufacturing Technology

1 Manufacturing Systems

1 Manufacturing Systems

1 Quality Systems

1 Quality Systems

1 Materials Technology

1 Materials Technology

1 Engineering - Technician

Manufacturing and Engineering

Manufacturing and Engineering

Manufacturing and Engineering

Manufacturing and Engineering

Manufacturing and Engineering

Manufacturing and Engineering

Manufacturing and Engineering

Manufacturing and Engineering

Manufacturing and Engineering

Manufacturing and Engineering

Manufacturing and Engineering

Manufacturing and Engineering

Manufacturing and Engineering

Manufacturing and Engineering 2 Metal & Engineering Competency Standard

Units

1 Mechatronics

1 Non-Destructive Testing

1 Non-Destructive Testing

1 Engineering - Higher Engineering Trade

Manufacturing and Engineering

Manufacturing and Engineering

Manufacturing and Engineering

Manufacturing and Engineering

(N.D.T.)

1 Engineering (Non-Destructive Testing) Manufacturing and Engineering

1 Manufacturing Technology Manufacturing and Engineering

1 Mechanical and Manufacturing Engineering Manufacturing and Engineering

1 Mechanical and Manufacturing Engineering Manufacturing and Engineering

1 Manufacturing Technology Manufacturing and Engineering

1 Engineering

1 Selected Study

Manufacturing and Engineering

Selected Study Program Sponsor

Implementation Date: 1-Jan-1998 Status:Approved

Manufacturing and Engineering - Mechanical & Materials (c) 2002 The State of NSW,

Department of Education and Training unless otherwise stated in the Copyright section of the document.

Date Printed: 6/02/2003

11