350351_IMAPS.qxp

2/14/2007

8:42 PM

Page 1

MARCH/APRIL 2007

Vol. 34 No.2

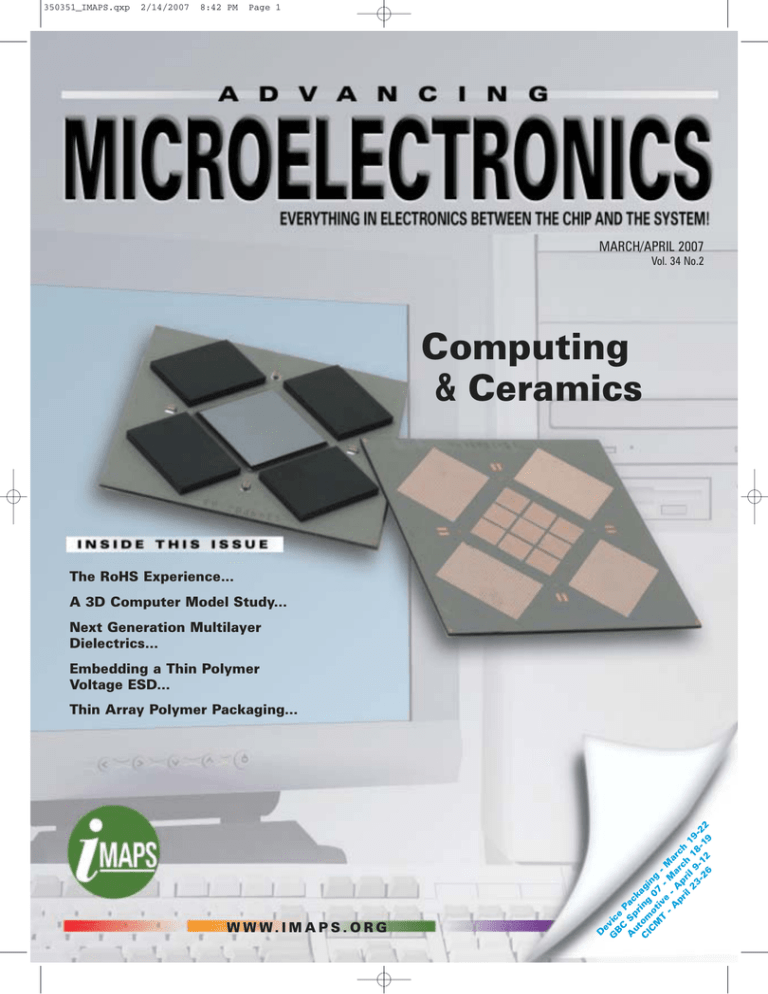

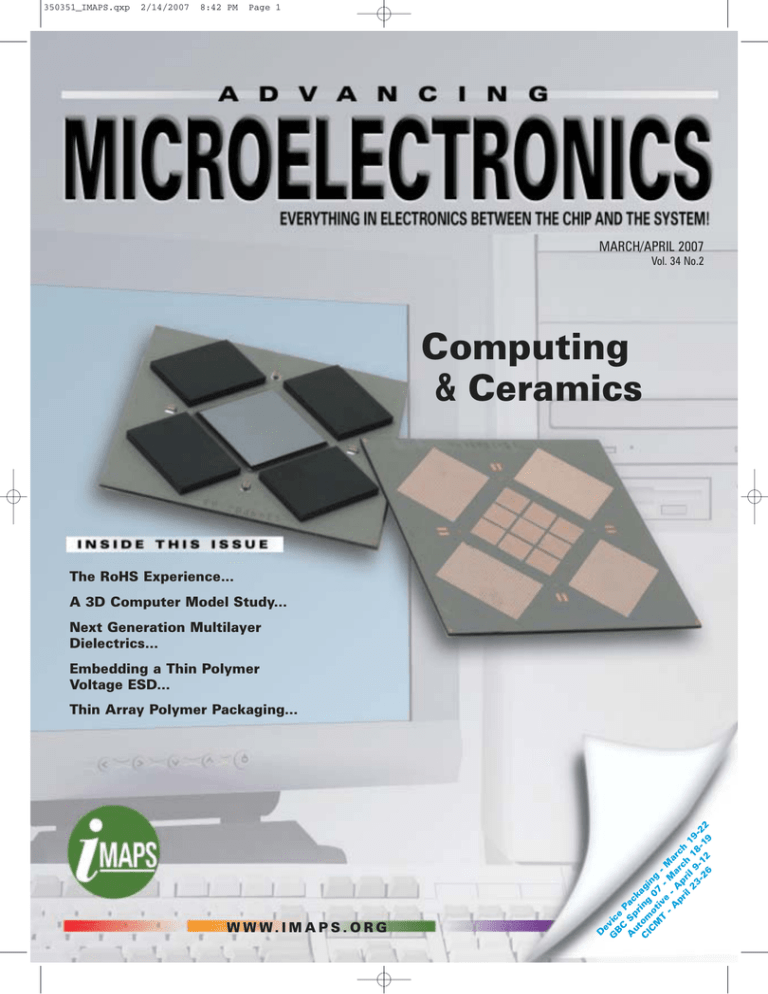

Computing

& Ceramics

The RoHS Experience...

A 3D Computer Model Study...

Next Generation Multilayer

Dielectrics...

Embedding a Thin Polymer

Voltage ESD...

W W W. I M A P S . O R G

D

e

G vic

B e

C P

A Sp ac

ut r k

C om ing agi

IC o 0 n

M ti 7 g

T ve - - M

M

A - A a ar

pr p rc ch

il ri h

23 l 9 18 19

-2 -1 -1 -22

6 2 9

Thin Array Polymer Packaging...

350351_IMAPS.qxp

2/14/2007

8:42 PM

Page 2

350351_IMAPS.qxp

2/14/2007

8:42 PM

Page 1

MARCH/APRIL

2007

Features

The RoHS Experience at

NCR Corporation

Paul Rostek

10

L

A 3-D Computer Module

Study

Don Hayashigawa

20

L

Next Generation

Multilayer Dielectrics for

High Reliability

Multilayer

Hybrid Circuits

Stefan Flick, Annette Kipka

and David Malanga

Embedding a Thin

Polymer Voltage ESD

Suppressing Core in a

Chip Package Offers

and Alternative to on

Chip ESD Protection

of Sensitive High

Performance ICs Used

in Today’s Cell Phones

and Computers

Karen Shrier and

Greg Caswell

Thin Array Polymer

Packaging (TAPP®)

Leo M. Higgins III, Ph.D.

On the cover:

9 layer, Z interconnect,

PTFE System in Package

Courtesy of Endicott Interconnect

Technologies, Inc.

24

L

28

L

34

L

350351_IMAPS.qxp

2/14/2007

8:42 PM

Page 2

A DVA N C I N G

MICROELECTRONICS

CONTENTS

D E PA R T M E N T S

IMAPS 4-TIER

PARTICIPATION

4

5

From the Publications

Committee Chair:

Spreading the Word

6

From the European Editor:

SIP, MCM, Flip Chips, Wirebond,

QFN, Surface Mount...?

7

Industry

49

Metro Chapter Meeting

Draws Large Audience

54

Welcome New Members

54

First Time Renewals

Sales and Marketing Corner:

Don’t Shoot ‘til You See the

Whites of Their Eyes!

MEMBER TOOLS

48

Chapter Contacts

33

MASH 2007 Editorial

(Military, Aerospace, Space, and

Homeland Security Conference)

50

Exhibitor Products

& Services

56

Advertiser Hotline

56

Who to Call at IMAPS HQ

U P D AT E S

from IMAPS

38

2

European News

Foundation Focus

Design

IMAPS - International

Microelectronics And

Packaging Society

611 2nd Street, NE

Washington, DC 20002

Tel: (202) 548-4001

Fax: (202) 548-6115

E-mail:

IMAPS@imaps.org

See us on IMAPS’s Home Page:

www.imaps.org

42

23

Systems &

Applications

Materials &

Process

From the President

Reflections on a Reflection

CHAPTER and

INDUSTRY NEWS

Device Packaging

Program-at-a-Glance

Inside Back Cover

Calendar of Events

39

IMAPS 2007 –

From the Technical Program

Co-Chairs

40

IMAPS Awards –

Your Help Needed

41

CICMT Program-at-a-Glance

55

In Memoriam – Jack Rubin

COMING NEXT ISSUE

Military/Aerospace

International Technology

350351_IMAPS.qxp

2/14/2007

8:43 PM

Page 3

UPCOMING

EVENTS

Executive Council

*International Conference on Device Packaging

March 19-22, 2007 Scottsdale, AZ

(co-located with GBC Winter Meeting)

GBC Spring 2007 Meeting

March 18 & 19, 2007 Scottsdale, AZ

(co-located with Device Packaging)

Automotive ATW

April 9-12, 2007 Dearborn, MI

*International Conference on Ceramic Interconnect and

Ceramic Microsystems Technologies

April 23-26, 2007 Denver, CO

Co-sponsored by IMAPS and ACerS

*Military, Aerospace, Space & Homeland Security

(MASH 2007)

May 8-10, 2007 Baltimore, MD

IMAPS 2007

*The 40th International Symposium on Microelectronics

November 11-15, 2007 San Jose, CA

Integrated/Embedded Passives

November 15 – 17, 2007 San Jose, CA

*Exhibit Space Available

President

Michael R. Ehlert, Barry Industries, Inc.

President-Elect

Stephen J. Adamson, Asymtek

First Past President

James R. Drehle, Robert Lloyd & Associates

Vice President of Technology

Andrew Strandjord, FlipChip International

Vice President of Membership

Michael P. O’Neill, Heraeus – Thick Film

Division

Secretary

Susan Trulli, Raytheon

Treasurer

Steve Capp, Laserage Technology Corp.

Northwest Regional Director

John Zhang, Finisar

Southwest Regional Director

Hossein Ahmad, Applied Reliability IME

Southeast Regional Director

Kinzy Jones, Jr., Motorola

North Central Regional Director

Adam Schubring, Kyocera America, Inc.

Northeast Regional Director

Michael Salloum, R&D Assembly, Inc.

Publications Committee

Publications Committee Chair

Jeffrey C. Demmin, Tessera

Technologies, Inc.

Editor-in-Chief, Advancing Microelectronics

Jerry Sergent, Fairfield University

Editor - The Americas,

Advancing Microelectronics

Greg Caswell, Virtex Assembly, Inc.

Editor - Europe, Advancing Microelectronics

Søren Nørlyng, Micronsult

Editor - Asia, Advancing Microelectronics

Dr. Hironori Asai, Toshiba Corporation

Editor, Journal of Microelectronics

and Electronic Packaging

Dr. Fred Barlow, University of Idaho

Directors

Executive Director

Michael O’Donoghue

Director, Program Development & Technology

Brian Schieman

Managing Editor and Advertising Sales

Ann Carter Bell, Manager

Marketing & Communications

Visit www.imaps.org for links to all

upcoming events including:

L

full event descriptions

L

abstract submissions

L

exhibition information

L

event updates

Advancing Microelectronics (formerly Inside ISHM), is

published six times a year and is a benefit of IMAPS

membership. The annual subscription price is $75; $15

for a single copy. Copyright 2007 by IMAPS—

International Microelectronics And Packaging Society.

All rights reserved. Except as defined in 17 USC, Sec.

107, permision to republish any materials in this publication must be obtained from IMAPS, 611 2nd Street,

NE, Washington, DC 20002. Telephone (202) 548-4001.

3

350351_IMAPS.qxp

2/14/2007

8:43 PM

Page 4

A DVA N C I N G

MICROELECTRONICS

FROM

THE

PRESIDENT

Reflections on a Reflection

Mike Ehlert, Irvine, CA

and Attleboro, MA USA

IMAPS 2007 President

Have a look

in the mirror

and see the

reflection.

People, specifically the

technological packaging

experts – IMAPS members –

made it work.

The realities of a production schedule mean that

although you are reading this at the change of seasons,

it is written in mid winter. I am spending my winter

vacation in Fairbanks, Alaska visiting family. Fairbanks

is located in central Alaska on the Chena River some

130 miles south of the Artic Circle. It is just after the

winter solstice and although blessed with 4 hours and 7

minutes of sun-up time, the low sun angle, high mountains to the south and the near-constant clouds mean it

only gets to twilight conditions and the sun is never

seen. The airport sign greets you “Welcome to

Fairbanks, -22F at 3:57 PM.” Today is unseasonably

warm at +2F while our members of IMAPS-Brazil in São

Paulo are blessed with 72F. This is nothing new for our

members from IMAPS-Nordic and IMAPS-Russia, but

the rest of us may learn a little.

In these conditions the human body and mind must

be protected from frostbite and cabin fever, respectively,

but life goes on pretty normally otherwise. People get

up, eat breakfast and go to work in the morning, come

home in the evening to dinner. The kids go to school,

learn their lessons and play in the streets. People drive

around in cars, chat on cell phones, snap pictures with

digital cameras and generally do the same things everyone else does. What makes this significant is that no

one worries about the electronics. The cars are plugged

in at night so the battery stays warm and the oil stays

fluid enough to crank but that is about it. MP3 players

are left laying on the dash, electronic ignitions and

stereos work fine and everything is okay as long as the

battery is kept warm enough for the chemistry to work.

Fur traders using dog sleds settled interior Alaska in

the 1800s. At that time the only things that worked in

this weather were self-heating: dogs, people, coal-oil

lanterns, wood stoves. Why is it that things have

changed so much? As part of the Industrial Revolution

someone worried about all the packaging problems –

“everything between the chip and the system” – and

made it all work. Have a look in the mirror and see the

reflection. People, specifically the technological packaging experts – IMAPS members – made it work.

Some of the first steps were halting. Portable transistor radios, if left in the sun, melted into single frequency devices. We had LCD watches that stopped

working if you bumped them. Progress has been continuous and fast. Now everything everywhere is electronic and it all works pretty much. Modern life with

oil heat, electricity and indoor plumbing is the result of

decades of good work by people like you. So the next

time you look in the mirror, consider the effect on the

world that person has. What will you invent next?

IMAPS has three conferences directly on this point

coming up.

International Conference and Exhibition on

Device Packaging

Doubletree Hotel - Scottsdale, Arizona USA

March 19-22, 2007

Advanced Technology Workshop on

Automotive Packaging

Hyatt Regency - Dearborn, Michigan - USA

April 9-12, 2007

IMAPS/ACerS 3rd International Conference

and Exhibition on

Ceramic Interconnect and Ceramic

Microsystems Technologies (CICMT)

April 23-26, 2007

Grand Hyatt Hotel - 1750 Welton Street Denver, Colorado USA

If you are interested in some of the world’s best work

in packaging I suggest you come to one or all of these.

The world’s best people in packaging “everything

between the chip and the system” will be there, and in

your mirror.

IMAPS 2007

San Jose

Classic Trolley

photo courtesy of the San Jose Convention & Visitors Bureau

4

350351_IMAPS.qxp

2/14/2007

8:43 PM

Page 5

MARCH/APRIL

2007

PUBLICATIONS

COMMITTEE

Spreading the Word

I hope that you have noticed – and taken advantage

of – the updates to the various IMAPS information

sources. This is the second issue of the re-designed

Advancing Microelectronics, with broader coverage and

upgrades to details that should make the information

more accessible. And, hey, it just looks a lot nicer, too.

On the electronic front, the IMAPS website

(www.imaps.org) has had a major overhaul, with the

new version going live at the beginning of 2007. This

was probably an even bigger upgrade than the magazine. The Internet has continued to evolve of course,

so the IMAPS website had some catching up to do. The

homepage has been reorganized to make everything

clearer, for example, and features like the event calendar are easier to use. We are also planning further

upgrades to make more IMAPS information available to

members.

One interesting outcome of these improvements is

that we have looked more closely at the IMAPS membership to understand better who you are and what

information you might want. All of those boxes that

you check describing your job, company, interests, etc.,

have been put to use! For example, one out of six

IMAPS members is a vice president or higher in their

organization. It isn’t just wishful thinking that the

industry leaders are part of IMAPS. Also, the membership really is heavy on technical people – at the “manager/director” level, people with technical roles outnumber sales and marketing professionals by almost

two to one. It’s good to have some of each, but IMAPS

intentionally emphasizes the technical part of the

industry. Along with all of that technical management

horsepower, more than a quarter of the members put

themselves in the “engineer / research / scientist” category.

The geographic scope of the membership is thoroughly international, too, with more than one-third of

the members residing outside of North America. We

are hoping for that fraction to grow, too, as the importance of international supply chains and partnerships

continues to increase. Finally, the industry coverage of

the membership reflects the four tiers of IMAPS (materials and process, design, systems and applications, and

industry). There are many of the traditional material

and equipment companies on the rolls, like K&S, DEK,

Heraeus, Cookson, and Dow, and the large OEMs

downstream are there, too, with companies like

Agilent, Cisco, Nokia, and Sony participating in

IMAPS.

It has been useful for the IMAPS staff and volunteers

to take a closer look at the membership, since that

helps us to understand your needs better. I thought

that I would highlight some of that data here, so that

the members also have some more insight into our

IMAPS colleagues. As always, please let us know if you

have suggestions on what other information IMAPS

could gather and transmit to the members, or about

how we accomplish that. The website and Advancing

Microelectronics have been upgraded, but there is

always room for improvement.

Thanks for reading,

Jeff Demmin

IMAPS Publications

Committee Chair

One interesting

outcome

of these

improvements

is that we

have looked

more closely

at the IMAPS membership

to understand better

who you are and what

information you

might want.

For exhibiting opportunities at

IMAPS 2007, visit

www.imaps40th.org:

L

Exhibitor Prospectus and booth application

L

Exhibitor Benefits

L

Previous Exhibitors

L

and more!

5

350351_IMAPS.qxp

2/14/2007

8:43 PM

Page 6

A DVA N C I N G

MICROELECTRONICS

EUROPEAN

EDITOR

SIP, MCM, Flip Chips, Wirebond,

QFN, Surface Mount...?

Søren Nørlyng

noerlyng@micronsult.dk

I imagine that

quite often an

OEM has the

challenge

to find the

optimum

solution

for a new packaging

concept with more

components on a

restricted area.

Of course the headline should be: System cost.

I imagine that quite often an OEM has the challenge

to find the optimum solution for a new packaging concept with more components on a restricted area. What

is the optimum solution?

If you ask the strategic buyers, you should do what

you always have done, no new exotic solutions, no new

suppliers to be qualified and audited. If you ask the

technical nerds, you will be told to use the latest technology that would be suitable. If you ask other engineers, you will most likely get as many different

answers as available options.

Why? Because it actually is a very difficult task to

suggest the optimum, as it requires multiple skills,

experience and insight.

You have to know so many details. Volume and timing, motherboard complexity vs. price for on-board

solution or module solution – and for wirebond and

flip chip solutions, the requirements to pad termination

materials and eventual fine-line needs. In the case of

flip chips, then you need to know chip design, pitch,

metallization, bump type, requested or preferred joining technology, underfills, pastes or films. Test strategy,

repairability, reliability, needs for second sourcing. All

possibilities have to be overviewed before a final choice

is made – it also has to be known if we talk in-house or

outsourced production to a preferred EMS or packaging

house – and therefore about their capabilities and preferences regarding technologies and the necessary

equipment. In order to succeed cooperation and

involvement of all partners are required as early as possible before the requirements and specs are “frozen.”

And don’t forget, the engineers have to know as

much as possible about this broad span of technologies

in order to have fruitful discussions with suppliers and

subcontractors.

IMAPS is a tremendous source. IMAPS NA last year

introduced almost the answer to these multidisciplinary needs by their Device Packaging Conference in

Scottsdale.

Here we had parallel tracks like flip chip – wafer

bumping, flip chips – future directions, flip chip –

underfill & materials, flip chip – packaging, flip chip –

copper/low-K, 3D – wafer bonding, 3D – stacked die,

3D – device applications, 3D – assembly and manufacturing – and many more.

The number of delegates demonstrated the need for

this kind of conference.

I am sure this year’s event in March will be an equally big success!

Also in Europe the IMAPS chapters organize very

broad conferences covering the many areas of interest

with focused sessions.

You can definitely expect that this year’s European

event will cover all needs from advanced PCBs and flex

to interconnection, advanced packaging, 3D-SIP, manufacturing technologies to thermal management and

design.

EMPC2007, the 16th European Microelectronics

and Packaging Conference and Exhibition, will be held

in Oulu, Finland, June 17-20. Plan to come to the technical capital of Finland and also take the opportunity to

visit the many companies there.

Please read more on http://www.empc2007.org.

See you in Oulu!

Søren Nørlyng

noerlyng@micronsult.dk

IMAPS 2007

San Jose

Cezar Chavez Park

photo courtesy of the San Jose Convention & Visitors Bureau

6

350351_IMAPS.qxp

2/16/2007

8:12 PM

Page 7

MARCH/APRIL

2007

SALES

and

MARKETING

CORNER

Don’t Shoot ‘til You See the

Whites of Their Eyes!

“Don’t shoot ‘til you see the whites of their eyes!”

General George Prescott uttered these famous words to

his Revolutionary War troops as the British marched

upon them from Boston Harbor in 1775 in the colonial

US. Why start out the inaugural Sales and Marketing

Corner of Advancing Microelectronics with such a statement? Eye-to-eye contact is one of the most important

means of human communication. And communication

is probably the single most important factor in the

success of any sales and marketing initiative.

Fast forward to today. The incorporation of the

Internet as an information-gathering tool has revolutionized the way we do business. Emails, e-shopping,

newsletters, blogs, and other readable electronic media

supply information and transaction opportunities at

our fingertips, and in a fraction of the time that the

IMAPS founding fathers searched for microelectronics

information 40 years ago. But what advantage – yes,

advantage – did General Prescott’s troops or the IMAPS

founding fathers have without the multitude of communication choices at our disposal today? They had to

rely primarily on face-to-face interactions to get things

done. There were no misunderstood emails and no

spam. When we purchased something, a handshake

closed the deal, not “proceed to secure checkout.” Yes,

all these tools allow transactions to happen faster and

more efficiently. But e-commerce cannot replace the following scenarios:

•

The look on the face of a person when they are

covering up (lying) about something.

•

The clear confidence beaming from someone who

has and can deliver the “killer” product or service

to someone who needs it.

•

Satisfying an individual’s or organization’s need for

a trusting personal relationship before they make a

purchase decision or a change to a new vendor.

•

Interacting with a person to discover the real need

in an inquiry.

•

The positive energy in a room when a customer

and supplier have arrived at a win-win agreement.

•

The negative energy in a room when a salesperson

sells at someone, with little regard to what the

client really needs.

In Daniel Coleman’s Social Intelligence, he discusses

the actual biochemical reactions in our brain that occur

when we interact with other people – what he calls

“Neural WiFi.” For example, when two people are sitting across from each other in deep conversation and

the body language is mimicked by both persons – the

nodding, smiling, shifting of the body, frowning. When

sensors are actually connected to certain portions of

their brains, it is proven that the individuals are biochemically “in synch.” Yet in another example,

Coleman sent off several pairs of college students to an

online chat room to get acquainted. The online interaction became quite aggressive and sexual. The researcher

was astounded as there were no signs of such behavior

in interviews before and after the online activity –

behavior likely never to be played out face-to-face. A

major theme in Coleman’s book is that we are social

beings, and like it or not we gravitate to face to face

social interaction for meaning, accomplishment, and

harmony. If you have ever spent any time in Japan, you

will certainly understand that this thinking is a way of

life.

In business, understanding how to create harmonious communications with our customers, co-workers, or industry colleagues is highly desirable. I want to

have that interaction that creates the positive body language making it clear my counterpart is in synch with

what I am saying and I am also in synch with his or her

thoughts. This is only accomplished when I can see the

whites of someone’s eyes. Hurling email back and forth

or relying on Internet searches exclusively to make

major purchase decisions only gets a fraction of the

story. I know from my own experiences it is tough,

because email and the Internet are easy. But the idea

here is to become more effective in our professional

(and home) interactions.

Why is all of this relevant in a column in this magazine? The mission of IMAPS, right out of the 20062009 Strategic Plan and posted front and center on the

IMAPS home page www.imaps.org is this: IMAPS leads

the Microelectronics Packaging, Interconnect and

Assembly Community, providing means of communicating, educating, and interacting at all levels.

Collaborating face to face at symposiums, workshops

and local meetings is arguably the best way for us to get

a complete picture of the information we desire to

obtain and develop. Electronic media certainly supplies

us as much information as we desire to be fully prepared for those person-to-person interactions. This is

why we strive to provide information content in this

magazine, in the Journal of Microelectronics, and via the

IMAPS website (new and improved I might add!).

In summary, today’s electronic media provides an

efficient means for information gathering, but it simply cannot replace the face-to-face interactions needed to fully process and get the complete picture.

Stephen M. R. Covey relates in The Speed of Trust that the

“Internet is a good example of both transparency and

illusion. At the same time as it engenders extraordinary

transparency, allowing people to get information and

access truth wherever they live, it also creates a place

where people can make up pseudonyms and interact

with others inside an illusion – where nobody knows

their true identity or intent.” It is no mistake that the

latest trends in electronic communications are video

related (video conferencing, web casts, YouTube, etc.),

facilitating more face-to-face interaction. For technologists, presenting or listening to papers at symposiums

allows you to get the full story – ideally we know if a

paper is really a good paper after we listen to the pres-

Michael P. O’Neill

Vice President of

Membership

Heraeus Inc.,

Thick Film Division

continued page 8

7

350351_IMAPS.qxp

2/14/2007

8:43 PM

Page 8

A DVA N C I N G

MICROELECTRONICS

continued from page 7

entation – don’t we? It’s never the same if we just read

the Proceedings. For salespeople – it is simple: get out

in front of your customers and communicate – understand what they need. Read the interactions and body

language. Listen. The cold blank stares and uncomfortable jostling in the chair really mean something. Look

into the whites of their eyes before shooting – get in

synch!

8

Was this column interesting to you? Please send any

comments or suggestions to the author at

moneill@imaps.org.

350351_IMAPS.qxp

2/14/2007

8:43 PM

Page 9

MARCH/APRIL

2007

9

350351_IMAPS.qxp

2/14/2007

8:43 PM

Page 10

FEATURE

ARTICLE

T

he RoHS

Experience at

NCR Corporation

Paul Rostek, Teradata Division, of NCR Corporation, 17095 Via Del Campo,

San Diego, CA 92027, Phone: 858-485-2860, Fax: 213-337-5432

Email: paul.rostek@ncr.com www.ncr.com

Abstract

This is a story of the RoHS journey at NCR Corporation starting in January 2003 with the passing of the European RoHS

(Restriction of Hazardous Substances) Directive 2002/95/EC. NCR realized the need to comply with all relevant environmental legislation in order to avoid the risks, costs and the consequences of non-compliant products in the EU. This paper

discusses all the issues NCR encountered preparing for the implementation of the EU directive for a unified company-wide

approach to RoHS. This paper addresses:

•

Overview of the NCR Policy for RoHS and Environmental Intentions

•

The “DfE” Design for Environment Landscape – the regulations impacting the industry today

•

Organizing NCR for the RoHS effort and the impact on NCR Business

•

Coordinating the Corporation RoHS team and the individual Business Unit teams

•

Defining the EU legal interpretation of RoHS Terms and Conditions

•

Developing a strategy to manage the transition from non-compliance to compliance

•

Developing a logistics model for the transition for spare parts, old inventory, refurbished units, etc.

•

Evaluating and selecting tools to assist in the transition to compliance

•

Evaluating technical issues associated with RoHS – such as the “tin whisker” problem

•

Developing RoHS processes, audit preparations and assessing on-going compliance

•

Future considerations – Lessons learned and how to be proactive next time

Key words: Restriction of Hazardous Substances (RoHS), RoHS Directive, toxic materials, DfE, compliance, NCR

1.0 Introduction

This paper reveals the problems that NCR had to

deal with and understand when transitioning its products for RoHS compliance, such as managing the supply chain, using up existing inventory, and managing

outsourced manufacturing vendors. The paper looks at

the investigation into a potential problem hidden in the

parts that are soldered with tin only, known as the

growth of “tin whiskers” which may cause a short circuit between devices. Some of the internal NCR issues

discussed included the handling of spare parts, the

repairing of equipment, refurbishing units, upgrading

and resales of customer equipment “put on the market”

before July 1, 2006. Just understanding terms like the

meaning of “put on the market” took a lot of time and

resources to research and clarify.

NCR developed a strategy for gathering and managing supplier information on all electronic components

for RoHS compliance, reviewing and evaluating company databases, and anticipating future environmental

compliance initiatives. NCR had to look at all the

options to identify their parts, modules and products

for RoHS compliance. A material data management

process is discussed including part number modifications and new vendor documentation such as material

10

declaration sheets, product identifications, and certificates of compliance. How NCR identified parts and

products as part of a documented “due diligence” initiative is discussed as well as the research and understanding of the legal requirements, enforcement and

exemptions of this new Directive.

2.0 Overview of NCR Policy

and Intentions

It is NCR’s intention to be fully compliant with the

new European Union Directive on the Restriction of

Hazardous Substances (RoHS) introduced on July 1,

2006. RoHS restricts the use of certain hazardous substances in electrical and electronic equipment that

could be considered harmful to future environment.

Many of the actions taken by NCR required significant

investment, time and effort. Customers are assured that

all products and services purchased from NCR are environmentally safe and comply with the European Union

RoHS Directive.

NCR is working with its suppliers to ensure only

compliant parts are provided. NCR suppliers’ processes

were modified to ensure all Teradata products “put on

the market” after July 1 were totally compliant in the

EU. NCR maintenance processes are being modified to

350351_IMAPS.qxp

2/14/2007

8:43 PM

Page 11

MARCH/APRIL

2007

ensure RoHS compliant units are serviced using only

RoHS compliant spare parts.

NCR has a documented and auditable process to

ensure that its products are shipped and maintained as

compliant. One of the important effects of this process

was that all NCR Teradata Product ID numbers were

changed to denote they are compliant to easily differentiate them from existing products.

3.0 The Design for the

Environmental Landscape

NCR products shipped to the EU after July 1, 2006

will not contain banned substances and will be serviced

and maintained as RoHS compliant. The RoHS

Directive 2002/95/EC was passed in 2003 and became

effective July 1, 2006 for all Electrical and Electronic

Equipment as defined in the Directive. Table 1 shows a

glimpse of the upcoming regulations facing the industry for the next 2.5 years.

Other future environmental requirements are forthcoming which will need to be incorporated into this

DfE Landscape, such as (Energy using Products) EuP

Directive 2005/32/EC as they become available. DfE

(Design for Environment) is a set of engineering principles to incorporate environmental attributes into

Table 1 Future Environmental Legislations

continued page 12

11

350351_IMAPS.qxp

2/14/2007

8:43 PM

Page 12

A DVA N C I N G

MICROELECTRONICS

continued from page 11

product design, manufacture, use, service and return.

There are two goals to the DfE program. The first goal

is to comply with all environmental regulations that

apply to energy using products. The second goal is to

increase the number of environmentally preferable

attributes in the products through innovative design

and by promoting responsible environmental management by the suppliers.

4.0 Understanding the Impact on the

Business

NCR realized that it could not sell its non-compliant

products in the EU after July 1 2006, but the full impact

of RoHS on the business units was underestimated in

terms of manpower, time and cost. A cost of $2.6M

solely for Teradata was totaled for the past 18 months

ending July 1. A Teradata retiree was brought back from

retirement to help with the unexpected workload. This

total of $2.6M was only for one business unit of the six

divisions within NCR.

In early January 2005, a major supplier presented a

comprehensive RoHS picture and plan to scrub every

component in our products, and stated the necessity of

contacting every supplier to determine if they had any

of the six toxic materials in each part. The supplier submitted a $500K bid to perform the RoHS work solely to

scrub the Teradata PWBA (Printed Wired Board

Assembly) boards.

Due to the cost, Teradata Engineering decided to do

the work itself and worked on more than 1000 parts for

RoHS compliance. Also, supplier processes in manufacturing had to be modified to implement the new RoHS

transition. The Teradata RoHS Team decided that RoHS

compliant products will be identified by new class

numbers with all new part and assembly numbers. In

order to use up all the remaining inventory, non-RoHS

numbers will continue to be orderable in the rest of the

world.

5.0 How NCR Organized for the

RoHS Effort and the Impact on

the NCR Business

In early 2003, an NCR task force from all six NCR

divisions was formed to work on the WEEE Directive

which was completed in August 2005. Soon afterward

another task force team was formed to work on the

RoHS Directive. A new team leader was appointed in

early 2005 to guide the divisions toward achieving

RoHS compliance. NCR employs less than 30,000 people and is organized into six business units. Five of the

six units were directly impacted by RoHS.

Representatives from each of the business units were

chosen and team meetings were scheduled to work on

this new environmental directive from Europe. Each of

the business units in turn developed its own cross functional RoHS team comprised of members from all

affected departments.

The corporate team leader quickly set up teleconference meetings every two weeks to address RoHS concerns and issues. He wrote up the list of action items

with the selected persons to work the issues. He prioritized and tracked the action items until they were

closed. It was not obvious in late 2004 what resources,

time and work effort was necessary for this RoHS project. In early 2005, the full impact of the RoHS Directive

12

was realized after a major supplier presented its view

and perspective on the RoHS Directive.

6.0 Developing the NCR Processes

for RoHS

From the biweekly teleconferences emerged the corporate RoHS compliance process consisting of the following four main functional areas, which were incorporated into each business unit’s product development

and release processes:

1 – Engineering Design and Documentation

2 – Supplier Management

3 – Product Order Ability

4 – QA and Compliance

Development of Products is performed using the

Teradata development process. This process now incorporates the RoHS Directive which begins with the

Engineering and relevant design documentation, and

the product specification describing the product design

parameters. The Engineering documentation is then

used by SLM (Supply Line Management) to select or

approve a RoHS-compliant supplier that can deliver

RoHS-compliant components and compliance certifications for their parts to NCR. All evidence of compliance, supplier compliance certificates, audit reports,

web sites, etc. is stored in a central repository database

for ease of access, logistics, recordkeeping and audit

trails. As product compliance progresses, its product

features are defined and entered into GSDB (Global

Services Data Base) by Product Management. Features

are flagged compliant when all its components are

RoHS compliant. Otherwise it is flagged as non-compliant. Once all the product’s features are compliant,

the product is marked as compliant in GSDB, and

released to the EU countries. The released product, as

part of its release documentation, will have a formal

Product Declaration of Conformance certificate that

certifies that the product also adheres to the RoHS

Directive, as well as other EU directives for EMI and

Product Safety.

Teradata engineering added the RoHS procedures to

the existing Engineering Compliance process for EMI

and Product Safety as illustrated in Table 2.

7.0 Defining RoHS Terms and Conditions

A representative from the NCR Law Department, a

part of the corporate team, researched the terms and

conditions of the RoHS Directive. A good example of

the extensive research is illustrated in the questions

below, where the legal definition for “put on the market” was researched for interpretation and clarity.

Q What does the term “put on the market” mean? The

RoHS term “put on the market” refers to each individual product, not a product type or class. This term

refers to the initial action of making a product available

for the first time on the Community market.

Q When is a product made available for the first time?

A product is made available when it is transferred from

the stage of manufacture with the intention of distribution/use in the EC market.

Q When is a product transferred from the stage of manufacture? A product is transferred when a physical handover or transfer of ownership has taken place from the

manufacturer to an EU importer or distributor or from

the manufacturer to the final EU consumer or end user.

350351_IMAPS.qxp

2/14/2007

8:43 PM

Page 13

MARCH/APRIL

2007

Transfer can be for payment, free of charge, sale, loan,

hire, leasing, gift or the result of any other kind of legal

instrument.

Q When does physical transfer occur? Physical handover or transfer of ownership takes place in any of the

following scenarios: a) when title and risk of loss has

passed from NCR to the distributor or end user customer (typically upon delivery to customer); b) in bill

and hold sales where title and risk of loss pass upon

delivery to warehouse; c) upon delivery to a distributor

or end user customer; d) where physical handover has

occurred, but title and risk of loss have not yet passed;

e) for NCR-branded products, the physical handover or

transfer of ownership generally takes place from the

applicable NCR country/sales subsidiary to the distributor or end user customer.

Q When is a product not “put on the market”? A product is “not” put on the market for the following reasons: a) transferred to a manufacturer for further measures (assembling, packaging, processing, labeling); b)

not yet granted release for free circulation by customs;

c) has been placed under another customs procedure

(transit, warehousing or temporary importation); d) is

in a free zone; e) manufactured in a Member State with

a view to exporting it to a non EC-country; f) displayed

at trade fairs, exhibitions or demonstrations; g) is in the

Table 2 Engineering Compliance Process

stocks of the manufacturer; h) is with the authorized

representative in the community.

When title passes from one NCR entity to another

NCR EU entity (distributor), the product may be con-

continued page 14

13

350351_IMAPS.qxp

2/14/2007

8:43 PM

Page 14

continued from page 13

sidered “put on the market” when it can be demonstrated that the receiving NCR EU entity is genuinely

distributing the goods. Physical handover does not take

place merely because a product is shipped. There must

be a legal instrument for transfer of a product to be

deemed “put on the market” upon shipment.

Otherwise, the physical handover will occur upon

delivery.

In regard to third party products NCR is reselling,

physical handover or transfer of ownership will take

place in the following scenarios: a) when title and risk

of loss has passed from the third party supplier to NCR;

b) upon delivery to NCR, physical handover has

occurred but title and risk of loss have not yet passed.

In all cases, products must be granted release for free

circulation in the EU by customs to be “put on the market.” Imported products cannot be “put on the market”

prior to the time they clear customs.

8.0 Developing the Strategy to Manage

the Transition from Non-compliance to

Compliance

NCR had to review all parts, components, assemblies, PWBAs, sheet metal and cabinet designs that

were in production and also new designs in development to insure compliance to the RoHS Directive. It

was decided by the Teradata RoHS Team to change part

numbers to quickly identify RoHS-compliant parts,

making it easier to find RoHS parts, by visually seeing

them in the BoM (Bill of Material). The following table

illustrates how the unique RoHS part numbers were

assigned according to this special Teradata procedure to

clearly identify all RoHS compliant parts.

Table 3 NCR Progress Chart of Business Units

14

Parts (components, single items, etc.)

Fully RoHS Compliant —-> 007-998xxxx

Compliant / Exempt —-> 007-997xxxx

Non-Compliant —-> 007-996xxxx or others

Assemblies (modules, PWBAs, sub-assemblies)

Fully RoHS Compliant —-> 315-060xxxx

Compliant / Exempt —-> 315-059xxxx

Non-Compliant —-> 315-058xxxx or lower

All parts and assemblies were verified conforming to

the RoHS Directive by engineers and special RoHS part

numbers assigned after they were confirmed. Product

Engineering reviewed designs in their development

cycle. The manager of Product Engineering reviewed,

approved, and released the engineering bill of materials

verifying that engineering had selected all RoHS parts.

The progress of each of the business units was measured monthly for the past year. Since a single component can hold back a product from being RoHS compliant, it was only in March 2005 that real progress could

be seen as illustrated in Table 3.

Teradata had a few major suppliers that were not

RoHS compliant until the very last month of June.

Teradata worked with several major suppliers on their

RoHS products. Some suppliers came out with entirely

new lines of RoHS products in June 2006 that replaced

their old products. To meet the schedules, Teradata

held biweekly meetings with suppliers, like the UPS

vendor, to track their RoHS progress in converting their

UPS components.

All Teradata products follow the Corporate Process

which requires issuing a NCR RoHS CoC for each NCR

system product, and also requires obtaining a

Certificate of Conformity or equivalent evidence from

all NCR suppliers. Suppliers must provide RoHS-compliant parts and provide documentation of their RoHS

compliance by a CoC or equivalent proof. In early

2005, NCR developed its own supplier RoHS survey

form and questionnaire complete with CoC to be filled

out by suppliers. NCR now uses the Industry’s forms:

IPC 1751/2 standard forms for Material Declaration and

ERA audit forms. On a periodic time basis, the list of

suppliers must be reviewed and verification obtained to

confirm RoHS compliance. Supplier audits are to be

performed by NCR Business Operations to verify suppliers’ RoHS compliance. The intent is for SLM to

ensure that suppliers are delivering compliant parts and

assemblies on an ongoing, continuous basis.

In addition, a central repository for all supplier documentation and CoC has been set up at the corporate

level to contain all RoHS documentation and to eliminate needless duplication of suppliers from the

Business units.

In Teradata, the Engineering Compliance Process is

the document that provides the high level guidance to

ensure products designed and released by Teradata are

RoHS compliant. This Compliance Process and the

other process documents provide the “paper trail” for

defining RoHS compliance as a requirement. At issue is

whether there are enough controls in place to ensure

that those requirements will be met. On a day-to-day

basis, engineers do not refer to process documents

when performing their jobs. They use specific tools,

forms and templates to design, develop and release

products. The question is whether those tools, forms

350351_IMAPS.qxp

2/14/2007

8:44 PM

Page 15

MARCH/APRIL

2007

and templates have enough safeguards built in to

ensure products will be compliant. Table 4 is a summary of the Control Plan Overview for Teradata Process

Control.

9.0 Developing a Logistics Model to

Support the Transition for Spare Parts,

Old Inventory, Refurbished Units, and

Outsourced Products

The RoHS Directive applies to Electrical and

Electronic Equipment and covers the products engineered and/or marketed by the Teradata Business Unit.

This Directive applies to the design of new products as

well as equipment purchased from Original Equipment

Manufacturers and Third Party Products for incorporation in new products or redesign of existing products

for sale by NCR.

To simplify the RoHS identification of Teradata

products, the team decided to change the Class numbers and not the model numbers of all Teradata products. The class number is like a family of similar products, whereas the model number represents the actual

configuration, the exact hardware BoM for the product.

Teradata products are typically large Data Warehouse

computer cabinets as shown in Figure 1.

Table 4 Overview of the Process Control Plan

continued page 16

15

350351_IMAPS.qxp

2/14/2007

8:44 PM

Page 16

A DVA N C I N G

MICROELECTRONICS

continued from page 15

non-compliant parts and assemblies. Non-compliant

spare parts may be used to expand the capacity or

upgrade products “put on the market” before July 1,

only if the concerned equipment is not subsequently

“put on the market” as a new product.

Q How do third-party parts or kits installed after shipment but prior to or during installation affect the “put on

the market” determination? If the physical handover or

transfer of ownership of a finished product has taken

place prior to July 1, 2006, then that unit should be

considered “put on the market.” Servicing and/or

upgrade of the product can be made with non-RoHS

compliant parts or assemblies. If the unit cannot be

considered a “finished product” without incorporation

of the third-party part or kit, then the unit will not be

“put on the market” until such time that the product is

complete and a physical handover or transfer has

occurred.

10.0 Evaluating and Selecting Tools to

Assist in the Transition to Compliance

Figure 1 NCR Teradata Data Warehouse System

In order to be assigned a RoHS Class number, every

part, component, subassembly, module, sheet metal

must first have been verified as being RoHS compliant.

All existing NCR equipment in the EU before July 1,

2006 is non-RoHS, but can still be repaired, serviced,

and upgraded with non-RoHS parts. The Teradata global strategy is to use up all the inventory of non-RoHS

parts and phase in all new RoHS parts as cost and logistics allow with the goal of shipping only RoHS-compliant products to the world market. New RoHS “finished

products” will be shipped to EU countries. Whereas

non-RoHS service parts will be shipped to non-EU

countries and to only non-RoHS systems in the EU

until all the non-RoHS inventory of service parts is used

up.

The following questions and answers are good illustrative examples of the topics that surfaced during the

biweekly meetings:

Q Can used and/or refurbished products be resold after

July 1, 2006 if they are not RoHS compliant? The RoHS

Directive does not apply to the reuse of products put on

the EU market before July 1, 2006. A product first put

on the market in the EU before July 1, 2006 can be

resold “as is” or refurbished with non-compliant parts

and resold after July 1, 2006, provided that the unit is

being sold only as used or refurbished equipment. Used

or refurbished products imported into the EU for the

first time after July 1, 2006 must be RoHS compliant.

Q Must spare parts used to service and/or repair units

after July 1, 2006 be RoHS compliant? It depends when

the unit being serviced or repaired was first put on the

market. Products put on the market after July 1, may

only be serviced, repaired, and/or upgraded with RoHS

compliant parts and assemblies.

Products “put on the market” before July 1, may be

serviced, repaired, and/or upgraded with compliant or

16

The first rough cut of totaling the number of

Teradata parts impacted by RoHS was approximately

46,000 parts. Many parts were duplications as they

were used in other similar products. Microsoft Excel

was used to total up all the parts and components, but

Excel proved to be too slow. The in-house Teradata

database programs: PCMS (Purchased Commodity

Management System) and EPIC (Engineering Product

Information Center) were the sources used to extract

the data and Excel was used to massage the data for

tracking part compliance. This showed that a new software database tool will be necessary to flag and store

the required RoHS designators. To track progress, each

of the business units was monitored by the corporate

team using a tracking tool as shown in table 5 that was

updated monthly. A master chart combined all these

business unit tables for a PowerPoint presentation each

month.

11.0 Evaluating Technical concerns

Associated with RoHS – such as “Tin

Whiskers”

Early in the RoHS transition there was a real concern about the reliability of the solder joints without

using lead. The military had investigated lead-free solder and found the growth of “tin whiskers” could cause

a short between adjacent conductors on a PWBA board.

The industry had evaluated many alternatives and has

found a number of options to mitigate the problem of

long term reliability concerns in the commercial world.

The EU has granted an exemption for the next four

years for “lead in solder” in certain applications, such

as servers and storage. This was an important exemption for NCR and some of the suppliers in meeting the

July 1milestone.

12.0 Developing RoHS Process

Preparations for Audits and On-going

Supplier Compliance

In order to ensure on-going supplier compliance,

suppliers must provide RoHS-compliant parts and documentation of their RoHS compliance by a CoC

(Certificate of Compliance) or equivalent proof. RoHS

compliance for a supplier requires the following: a)

350351_IMAPS.qxp

2/14/2007

8:44 PM

Page 17

MARCH/APRIL

2007

develop manufacturing and material handling processes and procedures that are compliant with the EU

Directive RoHS 2002/95/EC; b) ensure that process

materials and chemicals used in the controlled manufacturing processes are compliant with the RoHS

Directive.

To verify internal compliance to RoHS, as well as

EMI, Product Safety regulations and/or agency accreditations, internal audits are held periodically by the

Quality Analyst within Teradata. ISO audits are performed by an external service contracted by the

Teradata Quality group. In some cases it may be necessary to test and/or verify the impact of manufacturing

variations on product compliance and assure continued

compliance over the product’s lifetime. RoHS-compliance audits for suppliers are performed by Business

Operations as defined under the Supplier Management

section in the NCR Corporate Process document on a

periodic time basis. The process controls are periodically audited to assure the original process quality and

integrity.

Conformance is more than simply testing one product during development or early production, and

declaring all subsequent production units compliant.

Most regulatory agencies require retest or verification

as part of an ongoing conformance program. This

requirement can be met by testing new production

samples as products are enhanced and upgraded. The

engineering processes must be audited by the Quality

Analyst to verify that the proper procedures are being

followed to ensure the quality and integrity of the

processes and conformance to the global regulations

and requirements. In order to check and/or verify compliance, there are several Teradata on-line databases

that list the part numbers including parameters and

designations in the Teradata PCMS and EPIC databases, and the Product Identification “PID” in the corporate GSDB database.

In preparation for a RoHS audit, the Teradata engineering process documents are being updated to provide a paper trail to support the massive one-time work

effort, to scrub the parts lists and BoM to ensure new

products being sold to the EU contain RoHS-compliant

materials. However, this is different from what is collected on an ongoing basis to show that products have

been designed, developed and released in compliance

with the RoHS Directive. A major requirement of an

ongoing audit trail is the collection of evidence to show

“due diligence” that the supplier is continuously verifying compliance on a periodic basis as documented in

the process.

A DoC (Declaration of Compliance) certificate that

is used for EMI and Product Safety certification has

been modified to include the RoHS certification.

Certificates relative to existing products have been

updated and signed by an officer of the company. This

shows that management has confirmed that processes

are in place to ensure RoHS compliance.

In the NCR Corporate GSDB (Global Services Data

Base), the following are some of the symbols used to

flag and indicate the various RoHS levels:

CMP ==> (Compliant)

NCE ==> (Non-Compliant with Exemption)

TRN ==> (Transitioned)

NA ==> (Not Applicable)

Table 5 Tracking Tool for Teradata Compliance

NCM ==> (Non-Compliant)

UPG ==> (Kit or Cable) with Conditionally

Orderable Reason Code of “RO”

In addition, a Central Repository for all supplier

documentation and Certificates of Conformity is set up

at the corporate level to contain all the RoHS documentation and to eliminate duplicate suppliers from all

the Business units.

In July, an internal audit on the Teradata business

unit revealed some “gaps” in the RoHS compliance

process. These gaps were solely within the internal

Teradata process and steps being taken to eliminate

them. Figure 2 shows page 1 of the internal assessment

cover.

13.0 RoHS Training Course Available

In order to make new people aware of the RoHS

requirements and to properly train and prepare personnel, appropriate RoHS training was necessary. This

course provides an overview and describes the detailed

implementation impacts of the Restriction on

Hazardous Substances (RoHS) Directive put into effect

in the European Union as of July 1, 2006. It is designed

to provide NCR Field Service and all support personnel

with the knowledge and information required in their

job responsibilities to be aware of and adhere to these

new legal requirements.

14.0 Future Considerations –

Lessons Learned and How to be

Proactive Next Time

One of the lessons learned was that better database

tools are needed to capture and massage the data and

scope the magnitude of the problem. The first estimate

of parts impacted was approximately 46,000 parts, but

there were many obsolete parts, end-of-life parts, nonapplicable parts, and duplications used in similar products. Microsoft Excel was used to total all parts, but

proved to be so slow that it was unusable on very large

databases. The other in-house database programs EPIC

and PCMS were not set up to capture the appropriate

parts data and massage it, or attach and store all the

supplier verification data.

continued page 18

17

350351_IMAPS.qxp

2/14/2007

8:44 PM

Page 18

A DVA N C I N G

MICROELECTRONICS

continued from page 17

Therefore, a new software database tool will be necessary to capture large blocks of data and massage it. It

may also be necessary to flag and store the necessary

designators for countries and/or States in the United

States, and to anticipate the impact of future environmental compliance laws and initiatives, such as shown

in table 1. A database program called “Merlin” looks

promising and could be implemented in the future to

supplement or replace the existing EPIC and PCMS

database programs.

As a side observation, it was interesting to find that

transitioning the Teradata products to RoHS did not

impact the EMI test certifications, probably because the

engineering designs were not impacted.

References

1. Fleming, J., “RoHS Compliance Status – Teradata,” NCR

Corporation, June 26, 2006.

2. Mahsoub, M., “NCR Corporate Product Compliance Process,” July

14, 2006.

3. Jonathan J., “Put on the Market,” NCR Corporation, February 2,

2006.

4. Celio, J., “NCR Assessment Report,” NCR Corporation, July 10,

2006.

5. Rostek, P., “Engineering Compliance Process,” NCR Corporation,

June 30, 2006.

Figure 2 Cover Sheet of Internal Audit Report

IMAPS 2007

San Jose

Historic

Winchester House

photo courtesy of the San Jose Convention & Visitors Bureau

18

350351_IMAPS.qxp

2/14/2007

8:44 PM

Page 19

MARCH/APRIL

2007

19

350351_IMAPS.qxp

2/14/2007

8:44 PM

Page 20

FEATURE

ARTICLE

A

3-D Computer

Module Study

Don Hayashigawa, NxGEN Electronics Inc., 9771 Clairemont Mesa Blvd.,

San Diego, CA 92124, donh@NxGENelectronics.com, 858-309-6610 ext 3014

Introduction

The current trend in military space electronics is to

utilize the latest COTS (Commercial-Off-The-Shelf)

technology in such a way that they can still meet the

demanding requirements of the target application,

including low cost, small form factor, conduction cooling, high reliability and functional performance. A

major building block in a missile application is the

microcomputer, whose “main purpose is to accept the

digitized spectral information from the sensors, process

the information so that the ‘target’ can be discriminated

from ‘non-targets’ and generate signals for the missile

control and payload systems to turn towards the target…” 1. The subject of this paper is the development

of the preliminary package design for a 3-D microcomputer module intended for this purpose.

The preliminary requirements and specifications for

the module were determined with the customer. A

block diagram was initially generated and subsequently modified by the customer, as shown in figure 1

below.

Abstract

This paper outlines a study for the development of a small

form-factor 3D-Microcomputer Module for a military

application, based on COTS devices. The process, from

establishing the module functional requirements to the

development and analysis of a preliminary package

design, will be examined. The main discussion will center

on how the mechanical, electrical and thermal requirements can be met by adopting different packaging strategies, including CSP stacking, rigid-flex PCB, embedded

passives, low profile components and a novel heat sink

design. Finally, the results of the analyses done to validate

this system-in-package design will be presented.

• Dual Core 8641D CPU Up to 1.5 GHz

w/Altivek

• 466 MHz DDR2 SDRAM Up to 1 GB

• Dual Core version has 2 DDR Interfaces 64MB

to 512MB

• 4X 2.5 GHz PCI Express (PCIe) Interfaces

• 4X 3.125 GHz Serial Rapid IO (SRIO)

Interfaces

• 4X GBE Interfaces

• Up to 512 MB (NAND) Flash Boot Memory

• FPGA based Quad 3.125 GHz Rocket I/O

Interfaces

• Two Local Bus Interfaces to CPLD and FPGA

• Dual DS 1772 Thermal Sensors

Some of the environmental requirements include

the following:

• Operating Temperature Range: -40 to +85ºC

• Non-operating Temperature Range: -55 to

+105ºC

• Vibration: VITA 47 Level V3

• Shock: 40g, 11 millisecond half-sine

Package Design

Figure 1. Block Diagram

The key features required to meet the computing

and communications requirements and specifications

of the target application included the following:

• Size: 2.4 “ x 2.4” x .35”

• Weight: .2 LBS

• ~1080 ball outs

20

The package design developed for the above

requirements is depicted in the 3-dimensional view of

figures 3. and the side view of figure 4. Standard packaging for the CPU and the FPGA was selected due to

the high cost and unavailability of fully tested bare die.

In order to maintain the footprint size, it was necessary

that the CPU and the FPGA be in some way mounted

one over the other. One method for doing so is through

the use of a flex substrate on which the FPGA and CPU

are mounted on separate rigid substrates. Because the

CPU dissipates the most power, it was located on the

upper substrate in direct contact with the coldplate,

while the FPGA was mounted below. For reasons of

minimizing real estate and minimizing trace lengths,

the CPLD and memory were placed on the same rigid

substrate as the CPU. The CPLD is again assumed to be

a COTS packaged device and placed on top, while the

flash and DRAM are located on the opposite side of the

CPU. The package I/O are implemented as an array of

solder balls on 1 mm pitch.

350351_IMAPS.qxp

2/14/2007

8:44 PM

Page 21

MARCH/APRIL

2007

Figure 2: Model of 3-D Microcomputer Module

Figure 3: Side View of Model of 3-D Microcomputer Module

(Heat sink removed for visibility)

One unique feature of this package is the folded

copper heatsink which wraps around the upper substrate and is used to conduct heat from the top surface

of the FPGA to the coldplate. In many military space

applications, there is no available airflow and the motherboard is usually running at a fairly-elevated temperature, so the coldplate was assumed to be the only

source for cooling of the module.

The side view of figure 4 shows the DRAM and flash

memory implemented as Tessera µZ-ball Stacks TM.2 A

more detailed view of such a stack with its basic construction is shown in figure 5. In this technology,

wafers are obtained from various DRAM manufacturers

and thinned down from 150 microns to as low as 75

microns. The die are then placed face down and

attached to a flex substrate using a compliant adhesive.

The compliant adhesive acts to mechanically decouple

the low-CTE die from the higher-CTE PCB on which

the stack is mounted and provides inherent reliability

to the stack.

The substrate has a slot running down the middle of

it, which reveals the center row of bond pads of the

attached DRAM die. The assembly is then flipped over

and DRAM bond pads are wirebonded through the slot

up to the substrate bond pads. The bond pads are then

connected via traces to rows of solder ball pads on each

side of the substrate. The wirebonds are encapsulated

and solder balls are then reflowed onto the solder pads.

The layers can then be stacked and reflowed to create

the final assembly.

Wafer probed memory die are becoming available

through manufacturers such as Micron, Samsung and

others. In addition, each stack layer can be further tested as an individual CSP prior to final assembly. This

greatly enhances the overall yield of the stack. Thus,

although not strictly COTS, memory stacks are inherently cost-effective, reliable and small-form factor components, which are ideally suited for applications such

as this.

With regard to the rigid-flex substrate, it is assumed

that as many as 16 layers might be required. The side

view in figure 4, shows flex connections on either side

of the substrate. On the right side, two flex cables are

shown connecting the upper and lower sections, but up

to 4 is possible. The maximum allowable number of

flex connections between rigid sections is critical to

assuring not only sufficient signal interconnect, but

also power ground plane integrity. On the left side of

figure 4 is another flex connection, which would be

achieved after the assembly is folded. This connection

could be achieved through a spot soldering operation

or an ACA (anisotropic conductive adhesive) attachment.

There are clearly many passive components which

would be required for a functional microcomputer

including high-frequency and low-frequency bypass

capacitors, bias and termination resistors and frequency control capacitors. Termination resistors can be

embedded into the substrate using Ohmega-PlyTM

resistors, while high-frequency bypass capacitance can

be achieved through buried capacitive layers. Low frequency bypass capacitors tend to have a large footprint

as well as being high-profile. However, some capacitors

have recently become available which have fairly high

capacitances (10ufd) and low profile (~.5 mm).

Other key issues are shock and vibration requirements. The component as designed does appear to meet

the weight specifications, however, to meet the vibration and shock requirements, it appears that some form

of mechanical restraint would be required. The simplest

approach would be to bolt the heatsink to the PCB

through holes drilled in the heatsink.

Thermal Analysis:

From the 3-D model, a FEM thermal analysis was

conducted using SolidWorks COSMOS. The following

power assumptions were made for the various components.

Table 1: Component Power Dissipations

Figure 4: Detailed View of 2-Layer ìZ-ball Stack TM

The cold plate was set arbitrarily at 25ºC and it was

assumed that it was in direct contact with the FPGA

die. If the maximum junction temperature is assumed

to be 115 ºC, then the maximum allowable delta

between junction and the cold plate would be 30 ºC,

continued page 22

21

350351_IMAPS.qxp

2/14/2007

8:44 PM

Page 22

A DVA N C I N G

MICROELECTRONICS

continued from page 21

given the maximum cold plate temperature of 85 ºC.

The results from the thermal analysis indicates a temperature rise of 6 ºC, which is probably a little overly

optimistic as the die was assumed to be the same size as

the FPGA package. Still, a temperature rise over 10 ºC

would not be expected. The lower DRAM die on the

stack packages runs the hottest with a cold-plate-tojunction temperature of 20 ºC. It should be noted that

the stacks were modeled with a thermally conductive

material bonding the stacks together. The assumptions

for the DRAM die dissipation were given by the customer, however, it is likely that the DDR2 die will run

significantly cooler.

Conclusion:

A preliminary package design for a 3D microcomputer module targeted for a demanding military space

application was completed. This design incorporates a

novel heatsink design, a rigid-flex substrate, buried/low

profile passive components and µZ-ball Stacks TM components. A simplified thermal analysis indicates that

the module should meet the thermal requirements. To

the extent possible, it appears that all the other specifications and requirements for this device are being met.

The other tasks required to complete the development include: rad- hard design, electrical analysis, preliminary layout, final analyses, final design and development of a functional prototype.

References

1. R. Czajkowski, SBIR Final Report (Contract HQ0006-05-C7-190),

“3D Computer Module, NxGen Electronics Inc.,” 2006.

2. Vern Solberg, Ignacio Osorio, and Jeffrey Demmin, Tessera, “Ball

Stack Packaging for High Performance Memory,” Tessera Inc.,

SMTA International, September, 2003.

Figure 5

22

350351_IMAPS.qxp

2/14/2007

8:44 PM

Page 23

MARCH/APRIL

2007

Foundation Focus

Focus and Initiatives of The

Microelectronics Foundation

Talent and innovation are critical to the industry’s

and Foundation’s success. New programs and innovative projects including research will drive the

Foundation. Collaboration is always better than competition, whether within an industrial context or with

several universities. The Foundation can offer not only

human capital resources but funding resources for

those projects.

What is the Goal?

The goal is to attract the best and brightest to the

Microelectronics industry by making Microelectronics

a visible and exciting field of endeavor. Programs to

accomplish this goal are designed to create greater

awareness, develop future industry leaders and create a

funding source to support their education.

Developing Future Leaders

•

•

•

Train teachers of gifted and talented students with

an emphasis on increasing exposure to and appreciation of microelectronics, blended classroom

learning strategies, plus web-based learning tools,

and conventional teacher presentations.

A high school outreach program is starting,

focused on microelectronics careers/jobs, with

direction given by IMAPS retirees, interested volunteers and retired executives. If you have the

time, the interest and the passion to help, we need

you.

A high school curriculum or enhancement to the

curriculum program — a comprehensive, integrated view of what comprises a microelectronics program — is now in formation with ASU and

University of Kentucky.

•

Begin a university intern work program to achieve

goals of greater awareness of microelectronics and

collaboration with corporate donors. Does your

company have an intern program? Contact us and

we will help you set one up.

Creating a Funding Source Named Awards

The Microelectronics Foundation is setting up new

grants, awards and scholarships to fund and develop

the talent we find. The Foundation is eager to work

with your company and its philanthropic department

on exciting new programs that will enhance the

Microelectronics industry. In nearly all cases, the company or group of contributors that fund the award will

name the award, such as the Sidney J. Stein Award for

Graduate Studies or the Motorola Innovation & Design

Competition.

Awards and Grants are conferred annually to

encourage the study of theory and application of microelectronics and microelectronic packaging by university and college students and practitioners.

Scholarships are conferred annually to encourage

the study of Microelectronics and Microelectronics

Packaging. Multiple-year scholarships for the innovators that industry needs will be designed to provide

funding through college into graduate school.

To get involved, contact Jim Drehle, jdrehle@microelectronicsfoundation.org

James R. Drehle,

Robert Lloyd & Associates

23

350351_IMAPS.qxp

2/14/2007

8:44 PM

Page 24

FEATURE

ARTICLE

N

ext Generation

Multilayer

Dielectrics for

High Reliability

Multilayer

Hybrid Circuits

Stefan Flick, Annette Kipka, Heraeus TFD, Hanau, Germany,

stefan.flick@heraeus.com, +49-6181-354935

David Malanga, Heraeus TFD, West Conshohocken, PA

david.malanga@heraeus.com, +1-610-825-6050

Abstract

As the core in a multilayer build-up the dielectric plays an

important role in preventing resistors from cracking or

chipping provoked by the heat of the laser beam. State-ofthe-art dielectrics must be able to handle the stringent

requirements of wirebond and solder pads. Cost is also

paramount in the electronics industry so a new dielectric

must be cost effective. A dielectric that uses only a 2layer-build-up and low total thickness but still provides

high insulation and high breakdown voltage is a cost effective solution.

These requirements are extremely important in automotive, medical, and power electronic applications which

require cost effective alternatives with ever increasing

stringent demands. An environmentally-friendly dielectric

has been developed which addresses actual and future

expectations in terms of RoHS and ELV legislation. This

paper will present a new lead, cadmium and phthalatefree dielectric which meets the strict requirements of

today’s multilayer hybrid circuits. Performance data will

be presented on electrical and mechanical performance, as

well as compatibility with resistors and other RoHS-compliant conductors.

Key words: Hybrid, Dielectric, Break Down Voltage,

Adhesion, Chip-Off, 2 Layer, Battery Effect

1. Motivation

Hybrid thick film circuits are comprised of conductive and dielectric layers on top of a substrate which is

typically 96% alumina. The chemical inertness at higher working temperatures, high frequency properties

and a remarkable insulation resistance of Al2O3 (~1012

to 1015 Ohm*cm), supplemented by good thermal conductivity offers a safe and flat platform for electronic

circuits. High batch-to-batch consistency in smoothness and geometry ensures a high yield during build-up

of circuitry, population and mounting which balances

out higher material costs compared to PCB.

Highly integrated double-sided circuits with buried

power tracks and thermo-mechanical shock stability

are typical requirements of harsh environments like

under-the-hood applications for car components.

To achieve a higher level of integration, multilayer

hybrid circuits use dielectric layers to insulate stacked

conductor tracks. Conductors, via fills, resistors and

dielectric layers are applied by screen printing, drying

and firing at 500 – 850°C of each consecutive layer.

Thick film resistors can be realized between 0.1Ohm to

100Mohm, and high precision and reliability can be

achieved by laser trimming [1],[2]. Through holes

(conductor through the substrate to connect the front

with the back side) and multilayer build-up offer a freedom in design and high integration density for population with passive and active components.

Typical fields of application are motor and gearbox

management, air flow meters, airbag igniters, as well as

high frequency, wireless communication devices.

Production of hybrid circuits is an inexpensive

process due to the time of development and undedicated equipment enabling short term modifications.

Hybrid technology offers the advantage of high reliabil-

24