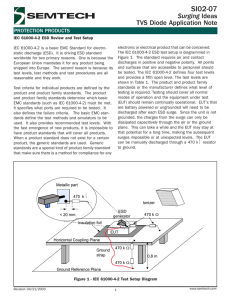

MIL-STD-461E

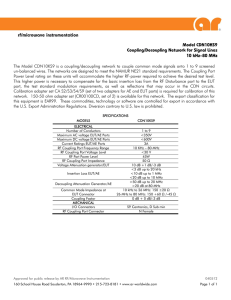

advertisement