XL-Trace - ebhdirect

advertisement

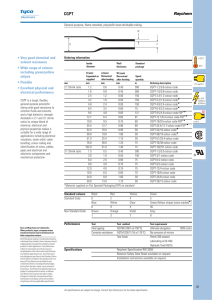

XL-Trace Self-regulating pipe freeze protection and flow maintenance system The Raychem® XL-Trace system provides freeze protection and flow maintenance of pipes in commercial applications. Typical applications include: • Buried pipes • Cooling tower lines • Sprinkler systems • Fire standpipe and drain pipes • Exposed plumbing systems • Metal and plastic pipes The heating element in the XL-Trace heating cable consists of a continuous core of conductive polymer extruded between two copper bus wires. As current flows through the core, the XL-Trace heating cable regulates its own heat output in response to pipe temperature changes. Low total operating cost Low total installed cost The same features that make an XL-Trace system easy to install the first time also simplify additions or changes to the system during building renovations. The XL-Trace heating cable’s parallel circuitry allows it to be cut to the exact length required, with no wasted cable. Its flexibility allows it to be wrapped around complex fittings and valves and overlapped without overheating plastic pipes. All of these characteristics simplify and streamline the design of a heat-tracing system. Installation is quick and simple. Building operators are assured of optimal energy efficiency and low maintenance costs when an XL-Trace system is specified. For additional information, contact your Tyco Thermal Controls representative or call Tyco Thermal Controls at (800) 545-6258. Heating cable construction Polyolefin or Fluoropolymer outer jacket Tinned-copper braid Modified polyolefin inner jacket Self-regulating conductive core Nickel-plated copper bus wire Catalog number 5XL-1-CR/CT 5XL-2-CR/CT 8XL-1-CR/CT 8XL-2-CR/CT Voltage 120 V 208–277 V 120 V 208–277 V Maximum exposure temperature 150°F (65°C) 150°F (65°C) 150°F (65°C) 150°F (65°C) Minimum installation temperature 0°F (–18°C) 0°F (–18°C) 0°F (–18°C) 0°F (–18°C) Minimum bend radius 5/8 in (16 mm) 5/8 in (16 mm) 5/8 in (16 mm) 5/8 in (16 mm) Maximum circuit length in feet (meters) 5XL-1-CR or -CT at 120 volts 8XL-1-CR or -CT at 120 volts 5XL-2-CR or -CT at 208–277 volts 8XL-2-CR or -CT at 208–277 volts * Use 40°F start-up for ambient control. Start-up temperature 40°F (0°C) 0°F (–18°C) 40°F (0°C) 0°F (–18°C) 40°F (0°C) 0°F (–18°C) 40°F (0°C) 0°F (–18°C) Circuit breaker size 15 A 20 A 165 (50) 220 (67) 110 (34) 145 (44) 120 (37) 160 (49) 85 (26) 115 (35) 285 (87) 380 (116) 190 (58) 255 (78) 205 (62) 275 (84) 150 (46) 200 (61) 30 A 250 (76) 220 (67) 190 (58) 170 (52) 450 (137) 385 (117) 350 (107) 300 (91) Technical Data Sheets: XL-Trace Nominal Power Output on Metal Pipes at 120V/208V A 5XL1-CR and 5XL1-CT 5XL2-CR and 5XL2-CT B 8XL1-CR and 8XL1-CT 8XL2-CR and 8XL2-CT Power output (w/ft) W/ft B 10 8 A 6 4 2 0 (0) 50 (10) 60 (15) 70 (21) 80 (27) 90 (32) 100 (38) 110 (43) 120 (49) 130 (54) 140 °F (60) (°C) Pipe temperature Components Raychem RayClic or FTC components must be used to terminate XL-Trace heating cables. Refer to the XL-Trace Application and Design Guide (H55838) for proper component selection. Bus wires 16 AWG nickel-plated copper Braid/outer jacket Tinned-copper braid with modified polyolefin jacket-CR or optional fluoropolymer jacket-CT Dimensions Maximum width Maximum thickness Nominal weight Approvals 92 lb/1000 ft 718K Pipe Heating Cable DESIG. 3A, 3B, 3C To minimize the danger of fire from sustained electrical arcing if the heating cable is damaged or improperly installed, and to comply with the requirements of Tyco Thermal Controls and national electrical codes, ground-fault equipment protection must be used on each heating cable branch circuit. Arcing may not be stopped by conventional circuit protection. World Wide Headquarters Tyco Thermal Controls 300 Constitution Drive Menlo Park, CA 94025-1164 USA Tel (800) 545-6258 Fax (800) 527-5703 info@tycothermal.com www.tycothermal.com Important: All information, including illustrations, is believed to be reliable. Users, however, should independently evaluate the suitability of each product for their particular application. Tyco Thermal Controls makes no warranties as to the accuracy or completeness of the information, and disclaims any liability regarding its use. Tyco Thermal Controls’ only obligations are those in the Tyco Thermal Controls Standard Terms and Conditions of Sale for this product, and in no case will Tyco Thermal Controls or its distributors be liable for any incidental, indirect, or consequential damages arising from the sale, resale, use, or misuse of the product. Specifications are subject to change without notice. In addition, Tyco Thermal Controls reserves the right to make changes—without notification to Buyer—to processing or materials that do not affect compliance with any applicable specification. © 1992, 1995, 2004 Tyco Thermal Controls LLC Tyco, RayClic, Raychem, and XL-Trace are trademarks or registered trademarks of Tyco Thermal Controls LLC or its affiliates. Printed in USA H51349 06/04 Ground-fault protection 0.75 in (19 mm) 0.38 in (10 mm)