A Comparative Anaylsis of Residential Heating Systems

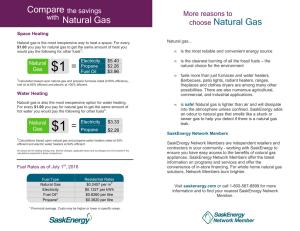

advertisement

A Comparative Analysis of Residential Heating Systems 1 LU/HSW/SD Hour AIA Best Practices The Propane Education and Research Council (PERC) sponsors this course provided by Hanley Wood, a Registered Provider with the American Institute of Architects Continuing Education Systems. Credit earned on completion of this program will be reported to CES Records for AIA members. Certificates of completion are available for non-AIA members. This program is registered with the AIA/CES for continuing professional education. As such, it does not include content that me be deemed or construed to be an approval or endorsement by the AIA of any material of construction or any method or manner of handling, using, distributing, or dealing in any material or product. Questions related to specific topics covered in this learning unit should be directed to PERC upon completion of this course. Copyright This presentation is protected by US and International copyright laws. Reproduction, distribution, display and use of the presentation without written permission from PERC is prohibited. © The Propane Education and Research Council, 2009 Learning Objectives • Describe general trends when comparing different residential heating systems and how they compare in terms of first costs, operating costs, carbon emissions, and paybacks • Describe how carbon emissions differ from various heating systems, fueled by different sources of energy, in various locations in the U.S. • Compare and contrast trade-offs involved in specifying high efficiency HVAC equipment for residential projects in terms of payback periods • Describe where certain types of HVAC system may be most appropriate to specify based on multiple factors Home Heating: Then and Now NOW: Green LATER Matters. and mechanical systems are ON: Homes Energy efficiency became more important reliable heatcarbon was theemissions. goal increasinglyTHEN: ratedCentral, for energy and Energy Carbon Images: www.thepeoplehistory.com & treehugger.com What’s at Stake? Why do residential heating systems matter? For households: • Average heating outlay is $600-$1200 annually • Heating costs represent about ~31% of household energy costs nationally, and closer to 40% in areas like the Midwest and Northeast How We Use Energy in Our Homes Source: 2007 Buildings Energy Data Book, Table 4.2.1., 2005 energy cost data What’s at Stake with Residential Heating? (cont.) What’s at Stake with Residential Heating? (cont.) At the national level: • • 113 million existing housing units Residential buildings are responsible for 22% of the nation’s total energy use each year; Residential buildings generate 21% of the nation’s carbon emissions 30.0 Millions of Housing Units • Age of Main Heating System in Residence (Years) 25.0 20.0 15.0 10.0 5.0 0.0 Less than 2 2 to 4 Years 5 to 9 Years Years 10 to 19 Years 20 Years or Don't Know More A Unique R&D Study to Find Some Answers… • A comprehensive, objective analysis of propane-based and competing residential heating systems across a variety of climates and locations. • http://www.buildwithpropane.com/?page=r esearchandinsights Background: Heating Systems Analyzed in the Study Heating Systems and Efficiency Ratings Furnaces • • • • Boilers • High Efficiency Propane with Forced-Air (water/air heat HX) • High Efficiency Fuel Oil Hydronic w/ Forced-air (water/air HX) • Standard Efficiency Propane Hydronic with Baseboard Radiant • High Efficiency Propane Hydronic with In-Floor Radiant • High Efficiency Fuel Oil Hydronic with In-Floor Radiant • 95 AFUE w/ 13 SEER A/C • 86 AFUE w/ 13 SEER A/C • 80 AFUE w/ 13 SEER A/C GSHPs • GSHP Closed Loop System with Electric Resistance Back-up • EER=14.1; COP=3.3 ASHPs • Standard Efficiency ASHP with Electric Resistance Back-up • High Efficiency ASHP with Electric Resistance Back-up • Standard Efficiency ASHP w/ High Efficiency Propane Furnace Back-up • High Efficiency ASHP with High Efficiency Propane Furnace Back-up • 13 SEER; HSPF 7.7 • 15 SEER; HSPF 8.5 • 13 SEER; HSPF 7.7; 95 AFUE • 15 SEER; HSPF 8.5; 95 AFUE Standard Efficiency Propane High Efficiency Propane Standard Efficiency Fuel Oil High Efficiency Fuel Oil • • • • 78 AFUE w/ 95 AFUE w/ 95 AFUE w/ 95 AFUE w/ 13 SEER A/C 13 SEER A/C 13 SEER A/C 13 SEER A/C • 95 AFUE w/ 13 SEER A/C • 86 AFUE w/ 13 SEER A/C Background: Heating Systems Analyzed in the Study Heating Systems and Efficiency Ratings Furnaces • • • • Boilers • High Efficiency Propane with Forced-Air (water/air heat HX) • High Efficiency Fuel Oil Hydronic w/ Forced-air (water/air HX) • Standard Efficiency Propane Hydronic with Baseboard Radiant • High Efficiency Propane Hydronic with In-Floor Radiant • High Efficiency Fuel Oil Hydronic with In-Floor Radiant • 95 AFUE w/ 13 SEER A/C • 86 AFUE w/ 13 SEER A/C • 80 AFUE w/ 13 SEER A/C GSHPs • GSHP Closed Loop System with Electric Resistance Back-up • EER=14.1; COP=3.3 ASHPs • Standard Efficiency ASHP with Electric Resistance Back-up • High Efficiency ASHP with Electric Resistance Back-up • Standard Efficiency ASHP w/ High Efficiency Propane Furnace Back-up • High Efficiency ASHP with High Efficiency Propane Furnace Back-up • 13 SEER; HSPF 7.7 • 15 SEER; HSPF 8.5 • 13 SEER; HSPF 7.7; 95 AFUE • 15 SEER; HSPF 8.5; 95 AFUE Standard Efficiency Propane High Efficiency Propane Standard Efficiency Fuel Oil High Efficiency Fuel Oil • • • • 78 AFUE w/ 95 AFUE w/ 95 AFUE w/ 95 AFUE w/ 13 SEER A/C 13 SEER A/C 13 SEER A/C 13 SEER A/C • 95 AFUE w/ 13 SEER A/C • 86 AFUE w/ 13 SEER A/C Background: Locations Where Heating Systems were Analyzed Duluth, MN Portland, OR Boise, ID Burlington, VT Madison, WI Las Vegas, NV Des Moines, IA Peoria, IL Grand Rapids, MI Buffalo, NY Mansfield, OH Baltimore, MD Indianapolis, IN Columbia, MO Nashville, TN Montgomery, AL Climate Zone Map from U.S. Department of Energy website Background: House Prototypes for New & Existing Building Characteristic Existing Home Prototype Above-Grade Square footage 1,660 SF Number of stories Foundation Type Window Area Attic R-Value Wall R-Value New Home Prototype 2,434 SF 1 or 2, depending on 1 location Slab, crawlspace, and Slab, crawlspace, and basement, depending on basement, depending on location location 15% of above-grade gross 15% of above-grade gross wall area wall area R-7 up to R-22, depending R-30 up to R-49, on location depending on location R-13 to R-21, depending R-9 on location Based on data from: U.S. Energy Information Administration’s (EIA) Residential Energy Consumption Survey (RECS) U.S. Department of Energy’s Building America Program 2006 International Energy Conservation Code (IECC) U.S. Census Bureau Background: Carbon Emissions & Emissions Factors • • CO2 emissions depend on the amount of energy used, the type of energy used to power a heating system The emissions analysis in the study accounted for different fuels, and also for electricity which comes from different types of sources Carbon Emissions by Fuels Used to Generate Electricity Fuels Used to Generate Electricity Proportions of Resulting CO2 Emissions Source: “Greenhouse Gases, Climate Change, and Energy,” US EIA, May 2008. Background: Carbon Emissions by Electricity and Other Sources Source: “Greenhouse Gases, Climate Change, and Energy,” US EIA, May 2008. Background: Estimating the First Costs of Systems Cost Estimates for New Homes – Heating and cooling unit (e.g., furnace w/ central A/C, heat pump) • Equipment cost • Installation cost – Distribution system materials (e.g. ducts, piping) • Material costs (e.g. ducts) • Installation costs – Loop field for Ground Source Heat Pump (GSHP) systems The cost of an A/C system was added to furnaces and boilers to treat heat pumps fairly • Materials & installation for drilling, pump and tubing costs Cost Estimates for Existing Homes – Heating unit (assumed that cooling unit was not being replaced) • Equipment + installation costs – Loop field for GSHP system • Materials & installation for drilling, pump and tubing costs Background: Average First Costs for New Homes System* Average First Costs A – Standard efficiency propane forced-air furnace w/ 13 SEER A/C B - High efficiency propane forced-air furnace w/ 13 SEER A/C C - High efficiency propane boiler with forced-air (water/air HX) w/ 13 SEER A/C D - Standard eff. propane boiler system with baseboard radiation w/ 13 SEER A/C $8,848 $9,108 $14,769 $14,165 E - High efficiency propane boiler system with in-floor radiant heat w/ 13 SEER A/C F – Standard efficiency fuel oil forced-air furnace w/ 13 SEER A/C G - High efficiency fuel oil forced-air furnace w/ 13 SEER A/C H - High efficiency fuel oil boiler with forced-air (water/air HX) w/ 13 SEER A/C I - High efficiency fuel oil boiler system with in-floor radiant heat w/ 13 SEER A/C J - GSHP closed loop system with electric resistance back-up $23,877 $8,985 $11,245 $12,065 $20,189 $22,378 K - Standard efficiency ASHP with electric resistance back-up L - High efficiency ASHP with electric resistance back-up M - Standard efficiency ASHP with high efficiency propane furnace back-up N - High efficiency ASHP with high efficiency propane furnace back-up $9,482 $10,337 $10,573 $11,428 Background: Average First Costs for Existing Homes System A – Standard efficiency propane forced-air furnace B - High efficiency propane forced-air furnace C - High efficiency propane boiler with forced-air (water/air HX) D - Standard eff. propane boiler system with baseboard radiation E - High efficiency propane boiler system with in-floor radiant heat F – Standard efficiency fuel oil forced-air furnace G - High efficiency fuel oil forced-air furnace H - High efficiency fuel oil boiler with forced-air (water/air HX) I - High efficiency fuel oil boiler system with in-floor radiant heat J - GSHP closed loop system with electric resistance back-up K - Standard efficiency ASHP with electric resistance back-up L - High efficiency ASHP with electric resistance back-up M - Standard efficiency ASHP with high efficiency propane furnace back-up N - High efficiency ASHP with high efficiency propane furnace back-up Average First Costs of System $882 $1,156 $4,336 $2,504 $4,336 $2,100 $4,389 $2,605 $2,605 $24,067 $4,822 $5,892 $5,978 $7,048 Background: Determining which Energy Rates to Use City State Burlington Baltimore Buffalo Des Moines Peoria Indianapolis Grand Rapids Duluth Columbia Mansfield Nashville Madison Montgomery Boise Las Vegas Portland Average VT MD NY IA IL IN MI MN MO OH TN WI AL ID NV OR Residential Propane Price ($/gal) 3.02 2.92 2.75 1.87 2.15 2.31 2.30 2.04 2.04 2.44 2.15 2.13 2.54 2.30 2.57 2.57 $2.38 Residential Residential Heating Oil Price Electricity Price ($/gal) ($/kWh) 3.61 0.15 N/A 0.14 3.54 0.19 N/A 0.10 N/A 0.11 N/A 0.09 N/A 0.11 N/A 0.10 N/A 0.08 N/A 0.10 N/A 0.09 N/A 0.12 N/A 0.10 N/A 0.07 N/A 0.12 N/A 0.09 $3.58 $0.11 Results • • • Operating costs Simple paybacks Emissions * Performance can vary greatly and is dependant on several factors Results: Operating Costs Graph provided by Newport Partners, LLC Results: Simple Payback Results: Simple Payback for a New Home with High Efficiency Heating Q: For a new home with a focus on high efficiency heating, what is they payback for a groundsource heat pump system compared to a high efficiency propane furnace with 13 SEER central A/C? A: 8.5 years for a GSHP in a cold climate 19 years for a GSHP in a very cold climate Results: Simple Payback for an Existing Home – Several Options vs. Cheapest Option Q: For an existing home in a cold climate, where the heating system needs to be replaced, what is the payback for more efficient systems relative to a standard 78% propane furnace change out? Simple Payback (years) A: A high-efficiency propane furnace is the most economical upgrade taking less than 6 months to see a return. Results: Simple Payback for an Existing Home – Comparing Alternatives to a 95% Propane Furnace Q: For an existing home in a cold climate where an existing system needs to be replaced, what is the payback for alternative heating systems assuming the default replacement will be a 95% efficient propane furnace? A: Air source Heat Pumps with propane furnace backups (standard or high-efficiency) are the most economical upgrades Results: Simple Payback for an Existing Home – Fuel Oil Furnace as the Default System Q: For an existing home in a Cold climate when a 78% standard efficiency fuel oil system needs to be replaced, what is the payback for more efficient systems? A: A high efficiency propane forced air unit costs less to install and operate than a standard efficiency fuel oil based system Results: Overall Conclusions from Simple Payback • High efficiency systems with moderate first costs are generally the most attractive options. • You may be asked by your client which system upgrade will be cost the least to operate, or the cheapest to install. – Explain the difference between first costs and long term energy savings. – Discuss the benefits of reduced carbon emissions – Explain that tax incentives or credits may be available federally or locally that can reduce costs of installation. • Visit the Database of State Incentives for Renewables & Efficiency (www.dsireusa.org) to help the homeowner locate incentives. Results: Emissions Results: Emissions Roughly three-quarters of the electricity generated in the U.S. is produced from fossil-fuels. Burning fossils like coal to produce electricity produces CO2 0.0% 1.6% 17.1% Coal Hydroelectric Other Renewables 12.5% Natural Gas 59.5% 0.4% 8.8% Petroleum Other Nuclear Results: CO2 Emissions from Heating System Operation– Midwest Locations Results: The propane back-up feature of Dual Fuel Systems drastically improves emissions compared to ASHPs 31 Results: CO2 Emissions from Heating System Operation– Midwest Locations Results: CO2 Emissions from Heating System Operation– Midwest Locations Results: Emissions – How much does it cost to save a ton of CO2? System L – High efficiency ASHP with electric resistance backup M – Standard efficiency ASHP with high efficiency propane furnace back-up Difference CO2 Emissions Heating Energy First Cost from Heating over $ per Ton Costs over Product Life Span (based on Midwest CO2 Product Life Span locations) Avoided - Midwest (Midwest) Location (tons) $10,041 $21,512 185.3 $10,356 $21,264 78.4 $315 -$248 106.9 ~ $1/ton CO2 The duel fuel system (M) has a slightly higher first cost, but saves over 7.5 tons of CO2 emissions annually. Results: Overall Conclusions from Emissions • Unless a system is powered by a carbon-free energy source (e.g. nuclear, wind) – it s operation will result in CO2 emissions. This is true regardless of whether it’s a heat pump or a furnace, whether it uses electricity, propane, or fuel oil. • Heating system efficiency and the quantity of carbon emissions do not always correlate. Lower efficiency systems can also be low emitting systems if the underlying fuel source is not carbon intensive, while high efficiency systems may also be heavy carbon emitters if the underlying fuel source is carbon intensive. • The cost to save a ton of CO2 is increasingly cited as a tool for assessing carbon saving opportunities. Heating systems which may carry higher First Costs but generate lower emissions can be assessed in terms of “$ per ton CO2 saved”. In many cases this analysis will identify cost-effective carbon-saving opportunities. Results Summary Conclusions of the Research When considering a heating system for new construction or an update, consider the following: 1. 2. 3. 4. 5. 6. First costs Operating costs and payback Resulting emissions from the system Location Energy costs Available energy sources Conclusions of the Research – Other Important Considerations Other important considerations for selecting a heating system: 1. Future shifts in energy prices 2. Comfort 3. Maturity/competition of the local market Conclusions of the Research – A Snapshot in Time Some results of this study may be valid for only a short time. Factors which may change in the near term: – Energy price changes – would alter Operating Costs and Payback findings – Carbon emission regulations – Greater recognition of not only efficiency – but carbon emissions – in building codes and green building programs Factors which should stay consistent: – Carbon emissions differences among the systems. Long-term energy supplies may shift – but it will not be a quick evolution. Thank You • This concludes the AIA portion of this learning unit. You will now take a 10-question quiz. • Please contact us with any questions regarding the results of this research or the scope of the project. • • Click here to read the full study. www.buildwithpropane.com