Substrate Preparation Product Primer/ Bonding Agent

advertisement

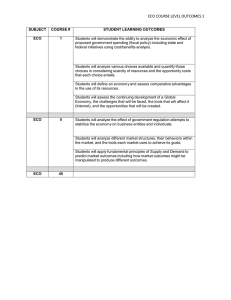

Substrate Preparation Product Concrete Skim Coating Ultra Skimcoat Planiprep FF Levelling UC Leveller Ultraplan Ultraplan ECO Ultraplan Maxi Exterior Levelling Mapecem Quickpatch/Planitop XS Please Note: All concrete surfaces must be free of contaminates that may inhibit bonding, be fully cured and free of any hydrostatic and/or moisture problems. If the Moisture exceeds 75% Relative Humidity contact Technical Services on Primer/ Bonding Agent Nil Primer G/Eco Prim T Primer G/Eco Prim T Mapeprim SP Internal Ramping & Floor Transition Differences Nivorapid Planiprep FF Primer G/Eco Moisture Vapour Barrier Biblock/Planiseal Easy Biblock Moisture Barrier Triblock P/Planiseal EMB Biblock Skim Coating Ultra Skimcoat Planiprep FF Eco Prim T Levelling Ultraplan + Mesh Latexplan Trade Mapeprim SP Hardboard Underlay Skim Coating Planiprep FF Nil Ceramic Tiles Skim Coating Ultra Skimcoat Planiprep FF Nil Steel Decks Smoothing Latexplan Trade Mapeprim SP F.C. Underlay Skim Coating Ultra Skimcoat Planiprep FF Nil Terrazzo Patching Planiprep FF Mapeprim SP Levelling Ultraplan Ultraplan ECO 1800 652666. New concrete slabs Concrete (continual rising damp or hydrostatic pressure) Timber Underlay Eg. Marine Ply Prim T Eco Prim T Mapeprim SP Please refer to respective data sheets for complete product information SURFACE PREPARATION 1. 2.0 GENERAL INSTRUCTIONS 1.1 All supporting surfaces shall be structurally sound, solid, stable, level, plumb and true to a tolerance of plane of ± 3mm in 2.4 metres for walls and ± 3mm in 3 metres for floors. They shall be clean and free of dust, oil, grease, paint, tar, wax, curing compounds, primer sealer, form release agent, alkali, loosely bonded topping, loose particles or any deleterious substance and debris which may prevent or reduce adhesion. 1.2 Mechanically sand and scarify the substrate to completely remove all paint, loosely bonded topping, loose particles and construction debris when required. 1.3 Neutralise any trace of alkali or strong acid residue. 1.4 All substrates shall be dry. The moisture content shall not exceed 75% Relative Humidity when measured in accordance to the relevant Aust STD for Vinyl/Carpet with an In-Situ Probe Meter. 1.5 Turn off all forced ventilation and radiant heating systems 48 hours prior to starting and protect work against drafts during installation and for a period of at least 72 hours after completion. Use indirect auxiliary heaters to maintain the temperature in the area at the recommended workable level. 1.6 Presswood, chipboard, flakeboard and most qualities of particleboard are not acceptable substrates for the installation of MAPEI high performance surface preparation products and adhesives. Follow the floor covering manufacturer’s recommendations regarding acceptable underlayment qualities. Do not use cement-based products directly over gypsum based floor patching compounds. CONCRETE 2.1 All concrete substrates shall be at least 28 days old, completely cured and free of any hydrostatic conditions, and/or moisture problems. 2.2 Neutralise any trace of strong acid or alkali from the substrate prior to the application of any adhesive. 2.3 On a radiant heating slab, turn off heating at least 48 hours before installation and turn it back on only 48 hours after work completion. 2.4 Do not install where hydrostatic pressure is expected. 2.5 For spot patching a substrate such as concrete, ceramic grout lines, cracks etc use PLANIPREP FF or ULTRA SKIMCOAT (refer data sheet for details). 2.6 ULTRAPLAN RANGE is a fast hardening self-levelling smoothing compound recommended for thicknesses from 3mm - 10mm (refer data sheet for details). 2.7 ULTRAPLAN/ULTRAPLAN ECO is an ultra fast hardening self-levelling compound with a very low VOC (volatile organic compound) content. Use ULTRAPLAN ECO to level a concrete floor substrate requiring a correction from 1mm to 10 mm in thickness (refer data sheet for details). 2.8 Use ULTRAPLAN to level a concrete floor substrate requiring a correction of not more than 10mm average thickness (refer data sheet for details). 2.9 Use UC LEVELLER, a self smoothing product with some leveling properties in bulk filling situations and under carpet, floating timber floors, tiles etc. 2.10 Use ULTRAPLAN MAXI to level a concrete floor substrate requiring a correction of not more than 30mm average thickness (refer data sheet for details). 2.11 Use NIVORAPID, sand and cement to build-up or level a concrete substrate requiring a topping between 12mm and 50mm average thickness (refer data sheet for details). 2.12 MAPECEM QUICK-PATCH/PLANITOP XS is a high performance, fast setting, cement based smoothing compound for exterior applications. 2.13 LATEXPLAN TRADE is a two-part self smoothing compound for use in areas such as to cut back residual adhesives, timber floors; steel decks and ceramics (refer to relevant data sheets for details). 3.0 PLYWOOD AND PARTICLEBOARD 3.1 Plywood and particleboard may contain fire retardant and/or preservatives which may be incompatible with some adhesives. Reference should be made to the adhesive manufacturer. 3.2 Panel joints, holes, splits and gaps greater than 1mm. Nail holes and knotholes should be filled with PLANIPREP FF. (Refer to technical data sheet) 3.3 The subfloor shall be inspected for dampness before sanding or other finishing operations. This is particularly important for platform constructions where exposure to the weather has occurred. The underside of the floor should also be inspected. A damp plywood floor should be left to dry until a moisture content of less than 13% is obtained throughout. 3.4 Under no circumstances shall any floor material be laid over wood or subfloors that are subject to conditions which might cause buckling or rotting of the wood. 3.5 For patching plywood and particleboard substrates, use cement based patching compounds such as PLANIPREP FF or ULTRA SKIMCOAT. (Refer to technical data sheet.) 3.6 For leveling over existing timber floors such as tongue and groove, plywood or particle board LATEXPLAN TRADE is an acceptable alternative. 3.7 All wood subfloors shall be well vented from below. 4.0 GYPSUM SURFACES 4.1 Gypsum dry wall panels and gypsum plasterboards should be primed with PRIMER G and thoroughly dry before the installation of the wall covering material. 5.0 METAL 5.1 Metal substrates shall be rigid, solidly fixed, dry, well sanded and free from dust, oil, grease, primer and all deleterious substances which may hamper adequate bonding. 5.2 LATEXPLAN TRADE can be used to smooth out any undulations or uneven areas to accept a floorcovering. (refer product data sheet for details) 5.3 Use ADESILEX G19 as the required adhesive over this type of substrate (refer data sheet for details)