How to Choose a Right Driver - Melux Control Gears Pvt. Ltd.

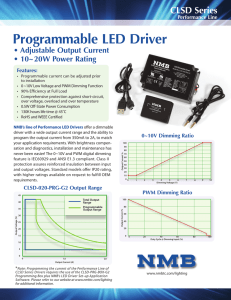

advertisement

MELCON HOW TO CHOOSE A RIGHT DRIVER… In today’s fast-paced and rapidly-changing LED arena, the complex and subtle choices involved in choosing an LED or LED array can be difficult enough. Add to this the confusion of selecting an LED driver in a solid state lighting (SSL) industry marked by obscure terminology where even the experts still debate definitions and standards, and the task can be overwhelming. As part of the LED driver selection process, it behooves a lighting product developer, or even a professional lighting designer/specifier, to understand concepts such as the choice of currentand voltage-based drive, the process of matching drivers to LED circuit topologies, dimming and flicker considerations, when and why to opt for multiple outputs, and other issues. This article will serve as a guide to help you navigate and simplify the sophisticated process of LED driver selection, understand and apply the appropriate features to the application at hand, and ask the right questions of your LED driver suppliers. Constant voltage or current? The first question developers face is almost always the choice of constant-current or -voltage supply. There are two fundamental types of LED arrays — those which run off a constant voltage (CV) and those which run off a constant current (CC) — and they’ rematerially different inside. A constant voltage array will contain devices to limit the current from going too high when the LEDs get hot, such as resistors or constant current resistors (CCRs) or even a switching DC-DC regulator of some kind. By contrast, a constant current LED array will have LEDs connected in series and perhaps several of these strings connected in parallel. You’ll want to choose a constant voltage array under two circumstances: 1) You have yet to determine your LED array and the application is one where you don’t know exactly how many LED strings will be hung on that supply or what the current draw will be (i.e., cove lighting). 2) The LED array is of the constant voltage variety and therefore has a fixed range of current for that fixed output voltage. In this instance, you’ll need to ensure that the driver you select is the right voltage and that the allowable output current range is higher than the gross estimated current draw of your LED loads. If you are aware of the current draw needed to match application light-level requirements, you’d probably choose a constant current array because it’s usually the most efficient arrangement. If your LED array requires a constant current, then you’ll need a CC LED driver. This type of driver will only have a certain range of voltages which it can drive; there will be a minimum voltage and a maximum voltage permissible. You need to ensure that your LED array has a voltage requirement that falls inside this permissible range. The table reviews AC-to-DC driver topologies and their pros, cons, and applications. There is no wrong or right approach to driver selection. Instead, you need to match topology to the application requirements. Now let’s address some specific issues. The importance of dimming another early decision will consider the importance of dimming and that can involve human visual perception and / or energy conservation issues. In order to select the right features, it helps to understand the characteristics of human perception. The human eye notices light changes on a scale which relates to what it’s already seeing and the light output of an LED lamp is roughly proportional to the current going through it. As a result, dimming to 50% is hardly noticeable to most people and 10% is perceived as just a few degrees dimmer than that. Therefore, to have a discernable visual dimming effect, you need to be able to dim down to 1%. By comparison, movie theaters require dimming in the range of 0.1%. MELCON The lack of sensitivity doesn’t mean that dimming to above 1% is not useful. In fact, the situation is quite the contrary. If you dim an LED light down to 10%, you’ve just saved 90% of its energy consumption, which is very significant. Dimming by any degree is worthwhile for energy-saving purposes, but if you want to have a dimly-lit room or theater, you must have drivers capable of dimming down below 1%, and down to 0.1% for full-range dimming. The bottom line is that while the benefits of dimming in increments above the 1% range are often not perceived by the human eye, the energy benefits generated by dimming even a few degrees can have a tremendous impact on energy savings. The flicker controversy with dimming come flicker issues and the question of how much flicker is too much. In the lighting community, flicker is defined as the percentage fluctuation of the light (or LED current) at twice the line frequency, expressed as a fraction of the steady light (or DC current) through the LED. Twenty years ago, magnetic ballasts drove fluorescent tubes, which produced an intense flash near the peak of the power-line voltage cycle such that the entire light output consisted of a series of light flashes at twice the frequency of the power line. It was found that even though most people couldn’t detect this fluctuation, some developed headaches and other stress symptoms when exposed to it. In response to the dissatisfaction with magnetic ballast flicker, electronic ballasts were developed that were capable of less than 2% flicker, which proved effective and quickly became the industry standard for good quality light. The problem still being discussed is that f licker considerations aren’t simple. Modern LED lights that have f licker are likely to have a 120-Hz fluctuation that has a smooth alternating variation at twice the line power frequency. Even when this flicker approaches 100%, it results in a significantly less-noticeable flicker than that of magnetic ballasts. We recommend that the 120-Hz ripple in the output of a driver should be less than 10% for LED task and office lighting, while for LED decorative lighting (e.g., cove lights, sconces, outdoor lighting, etc.), as much as 100% flicker may be acceptable. Dimming methods and flicker Dimming methodologies, however, can impact f licker. In the output of an LED driver, the percentage of ripple at twice the line frequency is the parameter that corresponds to the flicker in the light output. Many LED drivers produce dimming by switching the LED light on and off at a relatively high frequency, a process called pulse-width modulation (PWM) dimming or digital dimming. The human eye is completely oblivious to these high frequencies and simply perceives less light. Dimmable LED drivers exist, however, that simply modulate the light on and off at twice the line frequency; at low dim levels, the result can be a lot like the light output of old magnetic ballasts where the flicker may be easily perceived. In addition, if used with a triac dimmer, which doesn’t dim positive and negative half-cycles equally, it may introduce a line frequency component to the PWM that will be perceptible to anyone.other LED drivers produce a uniform DC current level, which is then adjusted downward to produce dimming. This methodology is sometimes referred to as analog dimming. For task and office lighting, this approach is the most trouble-free kind of dimming to use, though it’s likely to be more expensive than digital dimming. There is also the issue of how dimming information is conveyed to drivers. In many cases, drivers must work with legacy wall dimmers. The diagrams in Figs. 1 and 2 visually contrast two legacy dimming methods used in today’s LED applications that are based on controlling the AC line. Forward phase dimming typically operates on two wires and avoids the labor associated with adding a third wire; it is commonly used in churches, auditoriums, and schools. Reverse phase dimming is considerably more expensive but minimizes electromagnetic interference (EMI-EMC) issues. The driver selected must have the ability to work with the dimmers deployed in an application, especially in retrofit scenarios. MELCON LED driver lifetime Driver lifetime should also be a major concern. If the temperature of your LED array is properly controlled, it should produce more than 70% of its initial light output after 50,000 hours. Obviously, you’d like your LED driver to last equally as long. The lifetime of an LED driver is determined by the lifetime of the individual electronic components inside. The weak link, in particular, is the electrolytic capacitors, which are like little batteries. The elec FIG. 2. Reverse-phase dimming cuts the trailing edge of each half-cycle. trolyte inside is typically a gel that graduallyevaporates over the life of the component. The evaporation rate depends upon the temperature inside the driver — which, in turn, correlates to the external temperature on the driver case. Higher operating temperatures speed evaporation and hence shorten the life of the capacitor. On the label of most LED drivers there is a small circle called the hotspot or “Tc point.” This is usually the hottest point on the can and is used to determine the can temperature. The manufacturer will supply a temperature that must not be exceeded if the UL approval of the product is to remain valid. However, be aware that if you use the driver close to this limiting temperature,its operating lifetime will typically be shorter than if operated at a lower temperature.The driver manufacturer is able to supply curves that correlate the lifetime of the driver to its hotspot temperature. Fig. 3 provides an example of the curve for a typical LED driver. To ensure that the lifetime of the electrolytic capacitors exceeds the lifetime of your LED array at the necessary temperature, you must ensure that the manufacturer has used long-life electrolytic capacitors. Measures of power line quality There are additional power quality issues that you should consider. Datasheets for LED drivers can introduce bewildering terms such as THD (total harmonic distortion), power factor FIG. 3. Driver lifetime varies with temperature. (PF), and universal input voltage. Understand these concepts when making a driver selection. THD. The distortion of the sinusoidal waveform can lead to potentially dangerous consequences, such as the overheating of electrical equipment and even fires in transformers and switching stations. Considering the growth in electrical devices with non-linear loads, THD is becoming more and more important. Today, THD below 20% is usually acceptable and a THD of less than 10% is exceptionally good. PF. This is of major concern to utilities as it represents a difference between the power actually delivered to a facility and the power detected by a meter that determines the bill to a facility. Low power factor is costly to a utility. A conventional standard for PF is 0.9 or above; anything lower may result in a penalty assessed by the utility in the form of a multiplier on your electric bill. If PF isn’t mentioned in a driver specification, the default is referred to as normal power factor and implies any PF below 0.9. The actual spec could be as low as 0.4 in some of the least expensive lighting products. While PF is generally meaningless in a residential setting, careful attention needs to be paid when installing large volumes of normal-power-factor products in industrial or commercial applications. Universal input voltage: In India most commercial and industrial lighting runs off 240VAc, while consumer and retail lighting is mostly selected in operating voltage range of 180-240VAc. An LED driver that can run off either is said to have universal input voltage capability. It’s assumed that the adaptation is completely automatic and reversible. Lighting distributors like to stock universal input voltage products so they don’t have to worry about the voltage required. MELCON Multiple output ambiguity Now let’s discuss outputs in particular and the possible ambiguity when a driver offers multiple outputs. The terms “outputs” and “channels” are often used interchangeably, but professionals need to be aware that there’s a difference between multiple outputs and multiple independent outputs. The difference can have a significant impact on the luminaire’s reliability. The easiest way of connecting a single driver to multiple outputs is to simply bring multiple wires out of the driver to handle the current load. Inside the driver, the wires are all paralleled and provide multiple paths for current to f low. While very simple, this creates some significant disadvantages. In this type of driver, for example, the faults aren’t contained and there’s poor balance of current through the multiple outputs, resulting in varied brightness of each output. In addition, if one LED load shorts, it can bring down all of the other outputs; if the LED load opens, it will cause the other loads to absorb the additional current and possibly drive them to thermal overload and early life failure. Even under normal operation, without tightly matched LED loads there will be very poor balance of current among the outputs. By contrast, a driver with independent outputs (a true multi-output driver) will regulate each channel independently of the other outputs. This architecture allows each channel to have its own current regulation or fault protection and helps answer the question of “what happens on the remaining outputs when one output (or light engine) fails?” Instead of regulating to a total output current of 1A, for example, each of four theoretical outputs are regulated to 250 mA, allowing each output to have its own control and ensuring that the brightness difference between each LED load is minimal. To help illustrate this benefit, MELCON 54W driver is an example of a driver that goes one step beyond and enables paralleling of those outputs to create different combinations. With its four outputs of 350 mA each, not only can outputs be run separately, but it’s possible to run two 700mA outputs by tying the channels together. The E54W can also be connected in many other combinations. Leaving a channel unconnected or having a channel inadvertently shorted will not cause a change in performance within the unaffected channels. Tradeoff considerations Last, you need to understand common tradeoffs in driver design and how that might impact the selection process. Cost factors may require tradeoffs in features or capabilities. Following are five potential compromises to consider. • Output ripple: It’s straightforward to make an LED driver that has essentially no output current ripple by building it with two power conversion stages; a first stage generates a stable power supply and a second stage then generates the output current. A two-stage design has two control chips and two lots of high-frequency transformers inside and is more expensive. The cost of a driver can be significantly reduced by using just one power conversion stage for both power factor correction (PFC) at the input and for controlling the output current. The tradeoff is that now either the PFC is less perfect or sometimes as much as a 50% ripple at twice the line frequency is introduced into the output. • Startup time: A compromise between cost and efficiency is introduced with startup time. A short startup time can be achieved by using high power to charge up all the capacitors quickly. However, this same high power will still be there afterwards and will decrease the efficiency of the lighting system. Components can be introduced to turn the excess power off, but the tradeoff is additional system cost. It’s worth considering whether the application requires fast startup at all for example, most HID street lights take a minute or so to start up, so there’s no need for an LED street light to start in less than a second MELCON because it makes no difference to the users of the light and only gets switched on once a day. • Dimming level and efficiency: Though advances are currently being witnessed in the area of dimming, in general, to achieve lower dimming levels the tradeoff will be lower efficiency. • Cost and efficiency: Generally, an LED driver can be made more efficient by using oversize switching transistors/Mosfets (Typical Flyback Design topology) and highfrequency transformers, which adds expense. • Universal input voltage and cost: A universal input voltage product contains the components and capability for both high input voltage operation and high input current operation. You need higher current at the low voltage. The tradeoff is that you’re paying for both and you can get better value by purchasing a single-voltage product. However, fixture OEMs don’t often know what voltage the product will need, so it’s usually worthwhile to pay for the more expensive universal input voltage feature. Evaluating and selecting an LED driver for your project doesn’t have to be a daunting task. As outlined in the previous overview, an understanding of such issues as current and voltage, LED circuit topologies, dimming and flicker considerations, and multiple/ independent outputs will help you ask the right questions of your driver supplier and help identify the important features essential to optimizing your lighting system performance. MELUX CONTROL GEARS P.LTD PUNE, INDIA