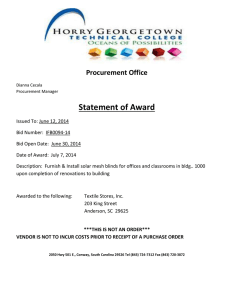

HOLLOWAY HALL AUDITORIUM RENOVATION

advertisement