Addendum #1

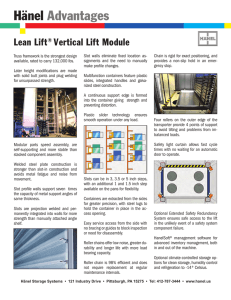

advertisement

EHRESMAN ASSOCIATES, INC. GROSSE POINTE PUBLIC SCHOOL SYSTEM PIERCE MIDDLE SCHOOL AUDITORIUM SEATING REPLACEMENT 14 440 VERTICAL PLATFORM LIFT PROJECT NO. 10313 PAGE 1 ADDENDUM #1 PART 1 – GENERAL DESCRIPTION WORK INCLUDED: Perform all work required to complete the platform lift installation. 1. MACHINE TOWER with lifting platform. 2. ACCESS GATES 3. CONTROLS 4. RAMP 5. ACCESSORIES QUALITY ASSURANCE MANUFACTURER: Company with not less than five (5) years of experience in the design and fabrication of vertical platform lifts. REFERENCE STANDARDS – Conform to following: 1. CONFORM to ICC A117.1, NEC, ASME A17.1, and ASME A18.1 2. MICHIGAN BARRIER FREE CODE 3. STATE LIFT CODE 4. FEDERAL ADA CODE JOB CONDITIONS OBTAIN ALL INFORMATION affecting work at job site. 1. VERIFY field dimensions VERIFY VOLTAGES and outlets on electrical drawings with electrical contractor before ordering motor and controls. SUBMITTALS PRODUCT DATA: Manufacturer's literature. 1. SUBMIT DRAWINGS SHOP DRAWINGS: Show dimensions, field verified measurements and wiring requirements. TESTING LOAD THE VERTICAL lift to rated capacity and test for several cycles to insure proper operation. No mechanical failures shall occur and no wear that would effect the reliability of the unit shall be detected. WARRANTY ONE YEAR: Written guarantee. TWO YEARS: On drive components PART 2 – PRODUCT PERFORMANCE RATED LOAD: 750 pound capacity TRAVEL SPEED: 10 feet per minute LIFTING HEIGHT: Approximately 3’-7” (field verify) PLATFORM SIZE: Standard: 36 inches by 48-7/8 inches clear platform dimensions PLATFORM RAMP: Stationary MANUFACTURERS ACCEPTABLE MANUFACTURERS – Subject to compliance with project requirements. 1. GARAVENTA CO., Product – Genesis Opal Model; GVL-OP-60 2. THYSSEN-KRUPP CO 3. THE NATIONAL WHEEL-O-VATOR CO., INC. 4. APPROVED SUBSTITUTE. EHRESMAN ASSOCIATES, INC. GROSSE POINTE PUBLIC SCHOOL SYSTEM PIERCE MIDDLE SCHOOL AUDITORIUM SEATING REPLACEMENT 14 440 VERTICAL PLATFORM LIFT PROJECT NO. 10313 PAGE 2 ADDENDUM #1 FABRICATION PLATFORM 12 gauge minimum zinc clad steel. 1. STATIONARY RAMP extend under the lower landing gate/door. 2. SIZE: 36 inches by 48-7/8 inches clear platform dimensions 3. CONFIGURATION: Straight Through exit/entry. PLATFORM SIDE PANELS: 42-1/8 inches high mounted on platform. 1. FRAMEWORK: Minimum 1" x 1-1/2" x. 065 tubing. MAIN FRAME SUPPORT: Square and rectangular tubing with a minimum .120 wall thickness CARRIAGE ARMS: Minimum of ½" wide steel flatbar along with ½" x 3-1/2" steel flatbar uprights. 1. CAM ROLLERS for axial carriage guidance. 2. COMBINATION of cam rollers and wear pads for horizontal stability. MACHINE TOWER SIDES: 12 gauge galv. steel, 18 gauge zinc clad steel minimum. 1. FRONT AND BACK LEADSCREW DRIVE: With manual platform emergency lowering hand wheel. ENCLOSURE: 1-1/2” min. steel tube supports, 18 ga galv. panels, with interlock UPPER LANDING GATE: 42” high, steel tube, 18 ga galv. panels, with interlock PLATFORM GATE: 42” high LOWER LANDING GATE: 42” high, with interlock CONTROL: Combination mechanical lock with electrical contact. FINISH: Electrostatically applied powder coating oven baked to cure. 1. COLOR: Selected from manufacturer's standard colors or optional colors. GRAB RAIL on the platform. MOTOR and CONTROLS MOTOR instant reversing, minimum of 2 HP capacity. POWER SUPPLY: 120 VAC single phase; 60 Hz on a dedicated 20 amp circuit. UPPER FINAL LIMIT SWITCH to cut off all power and stop the platform in the event of the upper limit switch failure. KEYLOCKED CONSTANT PRESSURE up/down control switch installed at the landing levels and on the platform. EMERGENCY STOP/ILLUMINATED ALARM SWITCH: On the car as a means of signaling for assistance in the event of an emergency. HANDCRANK: As a means of manually raising and lowering the platform in the event of a power of component failure. ELECTRIC STRIKE: Fail secure. To assure that door is both closed and locked. 1. LOCATION: Upper and lower landing doors. 2. VOLTAGE: 24 volt 3. COORDINATE: With hardware and door frame supplier/installer. PART 3 – INSTALLATION INSTALLATION ELECTRICAL CONNECTION A dedicated electrical circuit with a lockable service disconnect switch. COORDINATE work with general contractor and electrical contractor. INSTALLATION OF THE VERTICAL PLATFORM lift shall be made in accordance with the approved plans and specifications and the manufacturers installation instructions, applicable code requirements. Meet ADA and Michigan Barrier Free Code, Michigan Building Code, Life Safety Code, Michigan Elevator Code. INSTALL LIFT according to manufacturer’s recommendations. INSTALL PER 1. 1CC/A117.1 2. NEC 3. ASME A18.1 Guidelines EHRESMAN ASSOCIATES, INC. GROSSE POINTE PUBLIC SCHOOL SYSTEM PIERCE MIDDLE SCHOOL AUDITORIUM SEATING REPLACEMENT 14 440 VERTICAL PLATFORM LIFT PROJECT NO. 10313 PAGE 3 ADDENDUM #1 MAINTENANCE MAINTAIN the platform lift unit with regular cleaning of the unit and regular inspection for a period of 12 months after substantial completion. ADJUSTMENT ADJUST unit for proper operation. Secure any required state approvals. TEST Load to rated capacity and test for several cycles. END OF SECTION