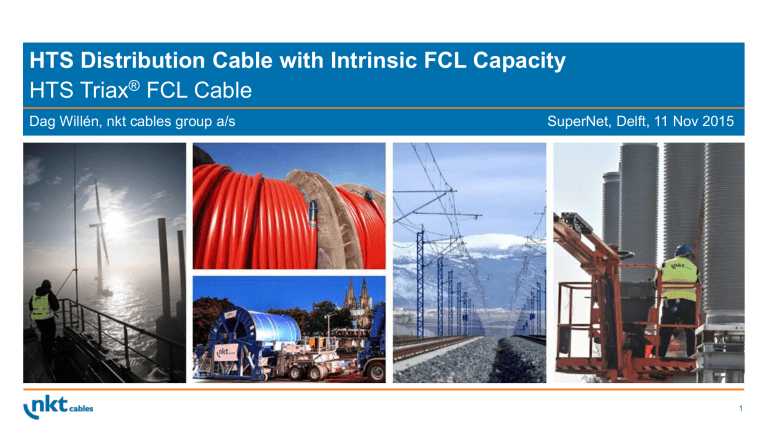

HTS Distribution Cable with Intrinsic FCL Capacity

advertisement

HTS Distribution Cable with Intrinsic FCL Capacity HTS Triax® FCL Cable Dag Willén, nkt cables group a/s SuperNet, Delft, 11 Nov 2015 1 Acknowledgements Ultera® – A Southwire / nkt cables Joint Venture The Hydra Project • J. Yuan, J. Maguire, D. Folts, N. Henderson, American Superconductor • D. Knoll, Jerry Tolbert, Southwire, Carsten Thidemann, Heidi Lentge, nkt cables • M. Gouge, R. Duckworth, J. Demko, ORNL • Z. Wolff ,Consolidated Edison This material is based upon work supported by the Department of Homeland Security, Science & Technology Directorate, under contract #HSHQDC-08-9-00001. Joining forces to develop and manufacture the Resilient Electric Grid 2 Operation experience of HTS cables A total of 14 years of operation Installations Copenhagen, Denmark • • • 30 meter, 30 kV, 104 MW 2 years operation 2001 – 2003 Supplied 50,000 users Carrollton, GA • • • 30 meter, 12.5 kV, 27 MW 6 years operation 2000 – 2006 Supplied energy to Southwire’s cable factories Columbus, OH • • • 200 meter, 13 kV, 69 MW 6 years operation Aug 2006 – Oct 2012 Carried 100% of substation load New York, NY • • • • ~200 meter, 13 kV, 4kA 96 MW Qualification test compete Installation 2016 Substation MV Bus Tie We have a long experience of operating HTS cable systems 3 Lowest AC loss In collaboration with Alliander and TU Delft Cable design • Round conductor, Ø42 mm • Pitch angles • Gaps • 0.11 W/m at 3.0 kArms. 60 Hz It is possible to make very low-loss AC conductors with 2G HTS 4 Efficient Cryostat In-house development 50 m demonstrator • • • • • Optimal MLI arrangement Vacuum 10-5-10-6 mbar Warm and cold getters Low-loss spacers P=0.5 W/m in a 100/143 mm cryostat Low loss and low flow friction in a compact thermally insulating duct 5 First FCL cable tests 3 m cable in open bath Test parameters • • • • • • Voltage 32 Vpk Available fault current 60 kArms Limited fault current 30-45 kApk 140 ms fault DT ~13 K (77 → 90 K) No degradation • 7.5 kVrms/km • Immediate limitation in first-cycle front edge • Ifcl = 21 kArms The HTS wires survive the rapid heating to Tc 6 Application of FCL cable: Substation Intertie Project Hydra, New York, NY HTS Triax with Fault Current Limiting Capability • 13.8kV ● 4,000 A ● 96 MVA • Rated 40kA for 67ms • Limit Fault Current by 17% in 3 cycles • HTS Triax® Technology Increases System Reliability and Resiliency 7 Type test of FCL cables Completed at ORNL in 2011 25m HTS Triax® Cable • • • • • • • • Full Scale Terminations DC critical current test AC loss: 1PH & 3PH 3PH AC current up to 4kA (thermal stability for cable & terms) PD measurements at test voltage AC withstand up to 39 kV Impulse Withstand: 110kV BIL Fault current test up to 40+kArms (unlimited) 15 kV HTS Triax® FCL Cable qualified for installation in distribution grids 8 FCL Performance 25 m HTS Triax® FCL Cable Type Test Results Unlimited current 46 kArms (65 kApk) Limited current 25 kArms (35 kApk) Limitation within first-cycle front edge No degradation Minimal overall temperature increase Measured versus Simulated Results Symmetrical Fault 25-m Cable Ic Measured Limited Current (kA) Meas Unlimited Current Simulated Limited Current (kA) 80 9000 8500 70 8000 Critical Current (A) 60 7500 50 Phase 1 7000 Phase 2 Measured & Simulated Limited Current Phase 3 40 6500 6000 30 5500 5000 73 74 75 76 Temperature (K) 77 78 79 Current (kA) • • • • • 20 10 0 -10 -20 -30 -40 -50 -60 -70 Normal Op Fault After fault Unlimited Fault Current -80 0.0000 0.0083 0.0167 0.0250 0.0333 0.0417 0.0500 0.0583 0.0667 0.0750 0.0833 0.0917 0.1000 Time (S) Big advantage: Resistive limitation removes the asymetric fault peak 9 Heating during faults Non-limiting let-through faults (LT) and bolted faults (FC) Example: 1600 m long 3 kA, 15 kV system • • • • • • • • • Zero-load operation 3 kA normal operation Stability limit, 3 kA operation Boiling temperature 115 3 kA normal operation 10 kA LT w/o limitation 2 x LT w/o limitation (wi 20 kA limited FC LT + FC 90 105 Tboil [K] T(LT+FC) [K] 85 95 85 75 Tnom [K] Margin for 3 kA operation T(1xFC) [K] 80 T [K] T [K] Tmax [K] T(2xLT) [K] 75 T(1xLT) [K] 65 T(ZL) [K] 70 Tnom [K] 55 0 500 1000 L [m] 1500 65 0 500 1000 1500 L [m] The cable system supports one or two event with continued operation 10 HTS Cable Manufacturing Ultera®/nkt cables/Southwire HTS line in Cologne Dedicated cleanroom for HTS cable manufacturing 1 crate HTS per layer Drum Capacity 22 ton (~2 km) HTS Fab Finished HTS Triax® Cable Conductor Insulation Drum with transport cover Existing line can produce 100 km HTS cable/yr 11 Installation of HTS cables Two-step approach: Cryostat first, then the HTS cable Pull Cryostat Pull HTS Cable Joints • 1 day/unit • Conventional pulling techniques • Pull into typical duct • PE jacket lubricated during pulling • 1 day/unit • Conventional pulling techniques • Pull into cryostat • Low friction material on OD of cable • No lubricant • • • • • 1 wk/unit Soldered conductor joints Taped insulation Welded enclosure High-quality vacuum Termination • 2 wks/unit • Protective tent 12 Operation of HTS cables Cool-down, regular inspections, service of coolers PH1 PH2 Neut PH3 Utility Connections Utility Connections System overview Neut Back-up LN PH3 CA HTS Triax Termination PH2 BL E-IN -C R PH1 YO STA LN Return Supply LN Refrigerator T HTS Triax Termination Cooling System Service requirement similar to fluid-filled cables and HV transformers 13 Future applications Cost-driven acceptance Distribution Transmission, transport • First applications possible now • Partial undergrounding • Parallel lines • Long-distance transmission • More widespread use ↔ reduced volume and cost • Resilience and environment Long-term • Electric ships and avionics • Defence • Levitating ground transport and energy storage We are still on a steep development curve of performance and cost 14 Thank you for your attention! 15