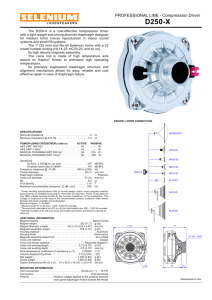

PROFESSIONAL LINE - Compression Driver

advertisement

PROFESSIONAL LINE - Compression Driver D405 LOUDSPEAKERS 2” (50 mm) exit compression driver for high sensitivity, low distortion and smooth medium frequency response applications. That leads the D405 driver to deliver high performance, high quality and high value for the pinnacle in sound reinforcement applications. Its construction features include: ® - ferrofluid (Ferrosound ) loaded gap reducing heat build-up and offering consistent results over long-term demanding concert usage; - voice coil is made of high temperature wire wound ® on Kapton former to withstand high operating temperatures; - injected plastic housing; - precisely engineered diaphragm structure and alignment mechanism allows for easy, reliable and cost effective repair in case of diaphragm failure. DRIVER x HORN CONNECTION HL47-50R HL14-50 SPECIFICATIONS Nominal impedance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 Ω Minimum impedance @ 2,900 H z . . . . . . . . . . . . . . . . . . . . . 6.8 Ω Power handling Musical Program(w/ xover 500 Hz 12 d B / oct) 1 . . . . 150 W Musical Program(w/ xover 1,000 Hz 12 dB / oct) 1. . . 200 W Sensitivity On horn,1W @ 1m, on axis2 . . . . . . . . . . . . . . . . . . . . 110 dB SPL 3 On plane-wave tube,1mW . . . . . . . . . . . . . . . . . . . . 116 dB SPL Frequency response @ -10 dB . . . . . . . . . . . . . . . 300 to 7,000 Hz Throat diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50 (2) mm (in) Diaphragm material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Phenolic Voice coil diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 (4) mm (in) Re . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.0 Ω Flux density . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.60 T Minimum recommended crossover (12 dB / oct). . . . . . . . . 500 Hz HM39-50R HM47-50R D405 HC56-50 1 Specifications to handle normal speech and music program material with 5% maximum acceptable distortion on amplifier, with the recommended passive crossover connected. Power is calculated taking into account the true RMS voltage at amplifier output along with transducer nominal impedance. Musical Program= 2 x W RMS. 2 Measured with HL47-50R horn, 500 - 3,500 Hz average. 3 The sensitivity represents the SPL in a 25 mm terminated tube, 500 - 3,500 Hz average. HC79-50 ADDITIONAL INFORMATION Magnet material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Barium ferrite Magnet weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2,640 (92) g (oz) Magnet diameter x depth . . . . . . . . . . . . 200 x 24 (7.87 x 0.95) mm (in) Magnetic assembly weight . . . . . . . . . . . . . . . . . 7,740 (17.06) g (lb) Housing material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Plastic Housing finish. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Black Magnetic assembly steel finish . . . . . . . . . . . . . . . . . . . . . . . . . . . . Zinc-plated Voice coil material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Copper ® Voice coil former material . . . . . . . . . . . . . . . . . . . . . . . . . Polyimide (Kapton ) Voice coil winding length. . . . . . . . . . . . . . . . . . . . . . . 7.0 (23.0) m (ft) Voice coil winding depth . . . . . . . . . . . . . . . . . . . . . . . 4.1 (0.16) mm (in) Wire temperature coefficient of resistance (α25) . . . . . 0.00329 1/°C 3 Volume displaced by driver. . . . . . . . . . . . . . . . . . . . 2.2 (0.078) l (ft ) Net weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8,300 (18.30) g (lb) Gross weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8,520 (18.78) g (lb) Carton dimensions (W x D x H) . . . . 23 x 22.5 x 9.7 (9.1 x 8.9 x 3.8) M6 4 x holes 86 ø 102 cm (in) MOUNTING INFORMATION Horn connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Bolt on Number of holes . . . . . . . . . . . . . . . . . . 4 (M6) equally spaced threaded holes Threaded holes diameter . . . . . . . . . . . . . . . . . . . . . . . . 102 (4) mm (in) Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Push terminals Polarity . . . . . . . . . . . . . . . . . Positive voltage applied to the positive terminal (red) gives diaphragm motion toward the throat Page: 1/2 Ed.: 00 - 08/01 ø 205 ø 50 Dimensions in mm. PROFESSIONAL LINE - Compression Driver D405 LOUDSPEAKERS RESPONSE AND IMPEDANCE CURVES W/ HL47-50R HORN INSIDE AN ANECHOIC CHAMBER, 1 W / 1 m 120 25 110 20 100 15 HARMONIC DISTORTION CURVES W / HL47-50R HORN, 10 W / 1 m. 140 120 100 90 10 80 5 80 70 60 0 200 500 1k 2k Hz 5k 10k 200 20k 500 1k 2k Hz 5k 10k 20k Response Curve. Distortion Curve, 2nd harmonic. Distortion Curve, 3rd harmonic. Response Curve. Impedance Curve. RESPONSE AND IMPEDANCE CURVES W / PLANE-WAVE TUBE, 1 m W 1W 1mW 150 120 25 140 110 20 POLAR RESPONSE CURVES 500 Hz 30° 15 120 10 1 kHz 330° -10 60° 130 100 0 -6 300° -20 dB 90° 240° 110 80 150° 70 0 200 500 1k 2k Hz 5k 10k Frequency response and impedance curves measured with 50 mm terminated plane-wave tube, with sensitivity referenced to a 25 mm tube. 330° 30° 300° 300° -20 dB 270° 240° 120° 210° 210° 0 -6 150° 180° 210° 330° -10 60° 300° -20 dB 270° 90° 240° 180° 330° 8 kHz 120° 150° 180° 0 -6 -10 60° 270° 90° 240° 150° -20 dB 90° 30° 300° 120° 210° -10 60° 20k Response Curve. Impedance Curve. 0 -6 2 kHz 330° -20 dB 4 kHz 5 30° 100 180° 0 -6 -10 60° 270° 90° 120° 90 30° D405 driver coupled to a HL47-50R horn. 270° 240° 120° 150° 180° 210° Polar Response Curve, Horizontal. Polar Response Curve, Vertical. HARMONIC DISTORTION CURVES W/ HL47-50R HORN , 1 W / 1 m. 120 HOW TO CHOOSE THE RIGHT AMPLIFIER The power amplifier must be able to supply twice the RMS driver power. This 3 dB headroom is necessary to handle the peaks that are common to musical programs. When the amplifier clips those peaks, high distortion arises and this may damage the transducer due to excessive heat. The use of compressors is a good practice to reduce music dynamics to safe levels. 100 80 FINDING VOICE COIL TEMPERATURE It is very important to avoid maximum voice coil temperature. Since moving coil resistance (RE ) varies with temperature according to a well known law, we can calculate the temperature inside the voice coil by measuring the voice coil DC resistance: 60 R 1 TB = TA + B − 1 TA − 25 + α 25 RA 40 200 500 1k 2k Hz Response Curve. Distortion Curve, 2nd harmonic. Distortion Curve, 3rd harmonic. ® Kapton : Du Pont trademark. ® Ferrosound : Ferrofluidics Corporation trademark. Specifications subject to change without prior notice. Page: 2/2 Ed.: 00 - 08/01 5k 10k 20k T A , TB= voice coil temperatures in °C. R A , RB= voice coil resistances at temperatures T A and TB, respectively. α25= voice coil wire temperature coefficient at 25 °C. EUROPE Address: BRAZIL Address: USA Address: SELENIUM EUROPE ELETRÔNICA SELENIUM S.A. SELENIUM LOUDSPEAKER USA BR 386 Km 435 / 92.480-000 St. Elisabethenstrasse 6 1701 South Park Court, Bldg 102 65396 Walluf / Ober-Walluf - Germany Chesapeake, VA 23320 - USA Nova Santa Rita - RS - Brazil Phone: +(49) 6123 601570 Phone: (757) 424-7516 / (800) 562-0510 Fax: +(55) 51 479-1120 Fax: +(49) 6123 601587 URL: www.selenium.com.br Fax: (757) 424-5246 E-mail: sales@selenium-eu.com E-mail: export@selenium-usa.com URL: www.seleniumloudspeakers.com URL: www.seleniumloudspeakers.com