Building a Better Coax

advertisement

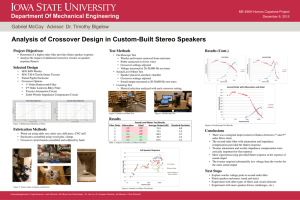

Buidling a Better Coax The coaxial approach used in the TQ install CX/DX products may look familiar, but there are a number of technical innovations which differentiate these from their predecessors. Like the legendary Altec 604 (Fig 1), the CX/DX coaxial driver uses an integrated compression driver and woofer assembly. The similarity ends here. The basic design approach of most modern, high performance coaxial drivers is to mount a compression driver to the rear of a woofer, with the exit of the compression driver firing through the center of the woofer pole-piece/voice coil. A short “horn” is used to blend the compression driver exit to the woofer cone; the woofer cone walls are used as an extension of the horn. This results in a number of problems: 1. The compression driver diaphragm and the woofer voice coil are widely separated, resulting in significant distance/time. This requires an active crossover with signal delay to properly align the two sources. 2. The excursion of the woofer modulates the high frequencies, resulting in sonic artifacts which get worse as the driver gets louder (and the woofer cone excursion increases). The sound character changes dramatically with output level. 3. The weight is excessive, due to the separate magnetic structures for the compression driver and woofer. 4. The assembly is quite deep, resulting in overly deep enclosures. Some designs (like the Altec 604) use a separate horn mounted to the pole piece. However, this causes directivity anomalies at the upper woofer frequencies, due to the shadowing of the woofer by the horn. Solving these was the first step in the CX/DX design process. The specific solutions include: Figure 1 - Classic Altec 604 coax Figure 2 - Fulcrum coax assembly 1. The new coaxial driver uses a single neodymium magnet structure, shared by the woofer and compression driver. This results in a much more compact, lightweight assembly (see Fig 2). 2. This magnet structure also keeps the compression driver diaphragm located in close proximity to the woofer voice coil. A simple passive crossover is now possible, with extremely smooth off-axis response. 3. A purpose-built high frequency horn is used for high frequency pattern control, and also to keep the HF energy off of the woofer cone. This allows the CX/ DX products to remain sonically stable at high levels. 4. The crossover overlaps the HF horn and woofer, thereby allowing the compression driver to fill in the woofer frequency range that is shadowed by the horn. A large compression driver diaphragm (3”) extends the low frequency capability of the horn. TQ processing allows the compression driver to work at these lower frequencies without sonic artifacts. 5. The woofer’s larger radiating surface works in conjunction with the HF horn to improve directional control at the bottom of the horn’s operating range. This increases directional control beyond what can be accomplished by the horn alone. 6. At the low frequency end of its range, the horn “leaks” sound back onto the woofer cone. This reflects forward, out of time, and produces tonal colorations that don’t respond to conventional EQ. TQ™ eliminates these colorations, thereby removing one of the primary shortcomings of earlier designs. The DX products use a new alignment technique for the additional woofer. To understand this, one must first realize that the DX products are not 3-way systems in the conventional sense (HF/MF/LF). Rather, they work as follows (Fig 3): 1. The woofer in the coaxial driver is operated down to approximately 50-60 Hz, depending on model. This woofer is shelved down 10 dB starting at about 300 Hz. Figure 3 - DX woofer alignment. Red = woofer; Brown = coax woofer; orange = composite. 2. The additional woofer is operates from 50-60 Hz up to approximately 300 Hz (depending on model). However, it operates at -4 dB. 3. The coax woofer output and the additional woofer output add to 0 dB, or “flat”. The benefit is that the DX has 4 dB more LF output than a conventional 3-way system using the same transducers. All of these innovations lead to a coaxial solution which overcomes the traditional shortcomings. It allows loudspeaker systems that avoid the typical performance problems associated with designs that use separate, spaced woofers and horns: 1. Separate woofers and horns can never sum coherently through crossover over a wide listening area. The physical spacing of the horn/compression driver and woofer make this impossible. A coaxial design, with closely space HF and LF elements, maintains coherence through crossover over a wide listening area. 2. When the horn and woofer are co-located, the beamwidth performance can be much smoother through crossover. In any design, both the LF and HF devices are providing output slightly above and slightly below crossover. With a separated woofer and horn, this results in extreme beamwidth irregularities in the plane in which the drivers are located. The coaxial design is free of this. 3. In CX/DX systems, the woofer and compression driver output are intentionally overlapped to allow for a very smooth beamwidth response through crossover. This cannot be done with spaced devices. Figure 4 - On- and off-axis performance – typical 12” 2-way (60° x 45°) In summary – in typical systems with offset drivers, the crossover (active or passive) attempts to orchestrate a hand-off between the two devices. An unavoidable consequence is uneven beamwidth performance. CX/DX products are a completely integrated solution. The crossover seamlessly blends the horn and woofer into a single operating unit, thereby improving directional consistency and fidelity (Fig 3 thru 6). Figure 5 - On- and off-axis performance – CX1265 (Horizontal) Figure 6 - On- and off-axis performance – CX1265 (Vertical)