2015-210 Drawings

advertisement

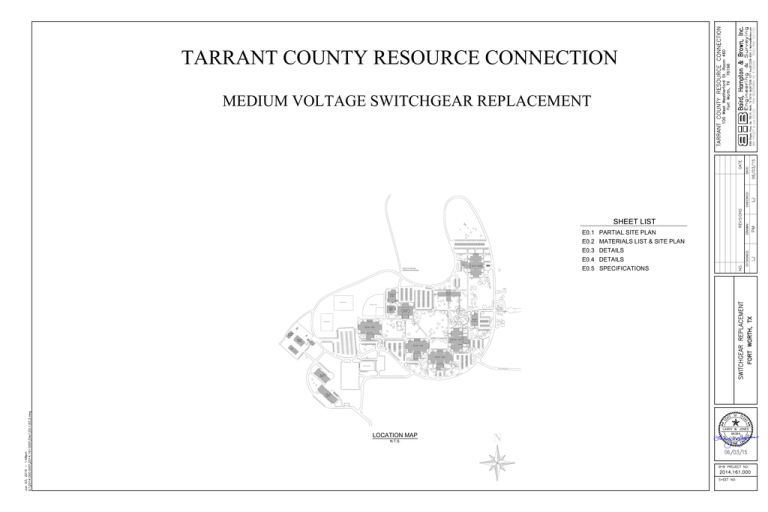

TARRANT COUNTY RESOURCE CONNECTION MEDIUM VOLTAGE SWITCHGEAR REPLACEMENT SHEET LIST E0.1 PARTIAL SITE PLAN E0.2 MATERIALS LIST & SITE PLAN E0.3 DETAILS E0.4 DETAILS BLDG. 2500 E0.5 SPECIFICATIONS STELLA ROWAN PRAIRIE ENTRANCE BLDG. 2400 BLDG. 2100 SOCCER FIELD SOFTBALL FIELD BLDG. 2200 BLDG. 2300 CIRCLE DRIVE BLDG. 1100 SOCCER FIELD BLDG. 1500 BLDG. 5010 BLDG. 5000 BLDG. 1200 BLDG. 1801 BLDG. 1400 BLDG. 5020 BLDG. 1300 STATE BUILDING JOE B. RUSHING ROAD IVE R ED CL BLDG. 5041 CIR BLDG. 5051 LOCATION MAP N.T.S. BLDG. 5000 GENERAL NOTES: BLDG. 1801 BLDG. 5020 1. THE SCOPE OF THIS PROJECT IS TO REPLACE THE EXISTING 15kV DRAWOUT TYPE METALCLAD SWITCHGEAR WITH NEW 15kV PAD MOUNTED FOUR-WAY LOAD INTERRUPTER SWITCHGEAR WITH ELECTRONIC RELAYING, REPLACE THE EXISTING RISER POLE, REPLACE THE EXISTING UNDERGROUND PRIMARY FROM THE RISER POLE TO THE MAIN GEAR, REPLACE THE EXISTING UNDERGROUND PRIMARY FROM THE MAIN GEAR TO THE FIRST DOWNSTREAM POINT OF CONNECTION, AND INSTALL A NEW POLE INLINE WITH A POLE TOP MOUNTED 900A GANG-OPERATED AIR BREAK LOAD INTERRUPTER SWITCH. 2. ALL WORK SHALL COMPLY WITH THE REQUIREMENTS OF IEEE/ANSI C2-2012, NATIONAL ELECTRICAL SAFETY CODE (NESC), APPLICABLE REQUIREMENTS OF 29 CFR 1910 (OSHA), AND APPLICABLE REQUIREMENTS OF NFPA 70 (NATIONAL ELECTRICAL CODE AS ADOPTED BY THE CITY OF FORT WORTH, TEXAS). NEW CONSTRUCTION SHALL COMPLY WITH NESC REQUIREMENTS FOR MEDIUM LOADING DISTRICT, GRADE C CONSTRUCTION. 3. DO NOT DEENERGIZE ANY PORTION OF THE SYSTEM WITHOUT PRIOR APPROVAL OF THE OWNER. ALL OUTAGES REQUIRED FOR CONSTRUCTION MUST BE SCHEDULED IN ADVANCE WITH THE OWNER. SUBMIT A WRITTEN REQUEST TO THE OWNER FOR EACH PLANNED OUTAGE. REQUESTS SHALL INCLUDE THE PROPOSED DATE OF THE OUTAGE, THE LOCATION AND EXTENT OF THE PROPOSED OUTAGE, AND THE ESTIMATED START AND STOP TIMES FOR THE OUTAGE. 4. REFER TO RECORD DRAWINGS, SHEET U18, "MARKED", IN OWNER'S POSSESSION FOR MEDIUM VOLTAGE DISTRIBUTION SYSTEM ONE-LINE DIAGRAM. EXISTING TRANSFORMER 1801 LEGEND UTILITY POLE PRIVATE POLE OOYO OVERHEAD PRIMARY, NUMBER OF " " INDICATES NUMBER OF PHASE CONDUCTORS UNDERGROUND PRIMARY PRIMARY RISER N RU 2 T EXTEND 3 #4/0 15KV INSULATED CU & 1 #2 600V INSULATED CU IN EXISTING SPARE CONDUIT FROM NEW FAULT INTERRUPTER SWITCHGEAR TO EXISTING TRANSFORMER 1801 AND CONNECT. CLEAN AND SWAB CONDUIT BEFORE PULLING IN CONDUCTORS. DISCONNECT AND REMOVE EXISTING CONDUCTORS FROM EXISTING CONDUIT. CLEAN AND SWAB CONDUIT. INSTALL NEW 1/2" BRAIDED PULL TAPE IN CONDUIT FOR FUTURE USE. 1 CK DOWNGUY NORMALLY CLOSED SWITCH O FUSED CUTOUT DISCONNECT AND REMOVE EXISTING METALCLAD SWITCHGEAR FROM PAD. SET NEW PAD MOUNTED FAULT INTERRUPTER SWITCHGEAR ON EXISTING PAD. POSITION ENCLOSURE OVER EXISTING CONDUIT STUB UPS TO ALLOW REUSE OF EXISTING CONDUITS. REFER TO SHEET E0.4. PROVIDE S&C 200 AMP QR SPEED FUSE LINK TO COORDINATE WITH UPSTREAM UTILITY BREAKER. REMOVE CABLES FROM EXISTING CONDUIT. CLEAN & SWAB CONDUIT. REUSE CONDUIT AND EXTEND 3 #4/0 15KV INSULATED CU & 1 #2 600V INSULATED CU CKT YO EXISTING ONCOR PRIMARY METER POLE OO 30 EXISTING ONCOR POLE 15 0 15 PARTIAL SITE PLAN 1 RU N 32 REPLACE EXISTING RISER POLE WITH NEW 35FT CLASS 5 POLE. REFER TO DETAIL 2, SHEET E0.3. SET NEW 40 FT CLASS 3 POLE IN LINE AND INSTALL NEW THREE-POLE 900A GANG OPERATED AIR BREAK SWITCH. REFER TO DETAIL 1, SHEET E0.3. 30 GRAPHIC SCALE EXISTING ONCOR 12.47 KV FEEDER EXTEND 3 #4/0 15KV INSULATED CU & 1 #2 600V INSULATED CU IN EXISTING SPARE CONDUIT FROM NEW FAULT INTERRUPTER SWITCHGEAR TO EXISTING J-BOX & CONNECT WITH 200A LOADBREAK TERMINATORS. CLEAN AND SWAB CONDUIT BEFORE INSTALLING CONDUCTORS. DISCONNECT AND REMOVE EXISTING CONDUCTORS FROM EXISTING CONDUIT. CLEAN AND SWAB CONDUIT. INSTALL NEW 1/2" BRAIDED PULL TAPE IN CONDUIT FOR FUTURE USE. EXISTING PRIMARY JUNCTION ENCLOSURES BLDG. 5041 BLDG. 2500 STELLA ROWAN PRAIRIE ENTRANCE BLDG. 2400 BLDG. 2100 SOCCER FIELD SOFTBALL FIELD BLDG. 2200 BLDG. 2300 CIRCLE DRIVE BLDG. 1100 SOCCER FIELD BLDG. 1500 BLDG. 5010 BLDG. 5000 BLDG. 1200 BLDG. 1801 BLDG. 1400 BLDG. 5020 BLDG. 1300 STATE BUILDING JOE B. RUSHING ROAD IVE E DR BLDG. 5041 CL CIR BLDG. 5051 CAMPUS KEY PLAN E0.1 GENERAL NOTES: 1. REPLACE ALL EXISTING TYPE "NON" 10,000 AMP INTERRUPTING RATING NON-CURRENT-LIMITING FUSES WITH NEW 200,000 AMP INTERRUPTING RATING CLASS R FUSES. USE TYPE RK1 FOR PANELS AND OTHER GENERAL LOADS. USE TYPE RK5 FOR MOTOR LOADS. REFER TO "LOW VOLTAGE SWITCHGEAR INVENTORY" ON THIS SHEET. 2. ALTERNATE 1 - PROVIDE SPARE FUSES EQUAL TO NUMBER AND SIZE OF FUSES SHOWN IN SPARE FUSE COUNT TABLE BLDG. 2500 STELLA ROWAN PRAIRIE ENTRANCE BLDG. 2400 BLDG. 2100 SOCCER FIELD SOFTBALL FIELD BLDG. 2200 BLDG. 2300 BLDG. 1100 SOCCER FIELD BLDG. 1500 BLDG. 5010 BLDG. 5000 BLDG. 1200 BLDG. 1801 BLDG. 1400 SITE PLAN & FUSE LIST BLDG. 5020 BLDG. 1300 STATE BUILDING IVE E CL CIR BLDG. 5041 DR LEGEND BLDG. 5051 EXISTING PAD MOUNTED SWITCHGEAR EXISTING PAD MOUNTED TRANSFORMER 120 60 0 120 240 GRAPHIC SCALE LOW VOLTAGE SWITCHGEAR INVENTORY E0.2 44" 44" 1 4" 10" 5" 10" 10" 4" 2 2 9" 5 13 12 42" 29" 15" 44" 12 5 2 48" 11 3 5/8" 14 4 15 55" 16 48" 6 17 6" 8 24" 18 3 9 7 19 2 7 20 10 DEAD-END POLE DETAIL GANG OPERATED AIR INTERRUPTER SWITCH DETAIL NOTES BY SYMBOL: " # " 1. INSTALLATION REQUIRES 5 FT. TALLER, CLASS 3 STABILIZED POLE. 2. REFER TO SWITCH MANUFACTURER'S INSTALLATION INSTRUCTIONS FOR THIS DIMENSION. 3. REFER TO SWITCH MANUFACTURER'S INSTALLATION INSTRUCTIONS AND ERECTION DRAWINGS FOR SWITCH OPERATOR INSTALLATION DETAILS. 4. 8 FT. HEAVY DUTY CROSS ARM. 5. PIN INSULATOR AND CROSS ARM PIN (TYPICAL). 6. SECONDARY SINGLE POINT RACK. 7. #6 COPPERWELD GROUND WIRE STAPLED TO POLE AT 24" INTERVALS. ALL POLE HARDWARE SHALL HAVE A MINIMUM CLEARANCE TO GROUND WIRE OF 2 INCHES OR SHALL BE BONDED TO GROUND. 8. BOND ALL SWITCH OPERATOR HARDWARE TO GROUND (TYPICAL). 9. BOND SWITCH OPERATOR HARDWARE TO GROUND IN ACCORDANCE WITH SWITCH MANUFACTURER'S INSTALLATION INSTRUCTIONS. 10. CONNECT POLE GROUND TO DRIVEN 5/8" x 8'-0" GROUND ROD. 11. WEDGE CONNECTOR SIZED AS REQUIRED TO ACCOMMODATE INSTALLED CONDUCTORS. DETAILS 1 2 12. 15KV POLYMER SUSPENSION INSULATOR (TYPICAL). 13. 14.4 KV, 200A, HEAVY DUTY FUSED CUTOUT WITH CROSS ARM BRACKET (TYPICAL). PROVIDE FUSE LINKS WITH AMPERE RATING AND SPEED AS SPECIFIED ELSEWHERE ON THE DRAWINGS. 14. OUTDOOR TERMINATOR SIZED FOR INSTALLED CABLE. 15. 10KV HEAVY DUTY RISER POLE CLASS ARRESTER (TYPICAL). 16. THREE-PHASE TERMINATOR AND ARRESTER MOUNTING BRACKET. 17. RISER CABLE OF SIZE AND TYPE SPECIFIED ELSEWHERE ON THE DRAWINGS (TYPICAL). 18. NEUTRAL DEAD END RACK. 19. 4" GALVANIZED RIGID METALLIC CONDUIT. 20. #6 COPPERWELD GROUND WIRE TO 5/8" x8'-0" DRIVEN GROUND ROD. E0.3 STUB OUT TWO 4" CONDUITS CAPPED AND MARKED BELOW GRADE FOR FUTURE. CONDUITS STUBBED UP BENEATH EXISTING SWITCHGEAR. VERIFY EXACT LOCATION OF CONDUIT STUBS AND LOCATE NEW PADMOUNTED SWITCHGEAR ENCLOSURE OVER CONDUIT STUB UPS (TYPICAL). TAP 3 TAP 2 TAP 1 MAIN 1 13'-0" 4-WAY VISTA SWITCHGEAR FRONT 5-WAY ENCLOSURE AND TANK ON 12" HIGH STAINLESS STEEL RISER TO FIT OVER EXISTING CONDUIT STUB UPS. EXISTING CONCRETE PAD 9'-0" FAULT INTERRUPTER SWITCHGEAR ONE-LINE DIAGRAM 200A LOADBREAK INSERT WITH CAP (TYPICAL) TAP 3 TAP 2 3 FAULT INTERRUPTER SWITCHGEAR AND PAD DETAIL 200A LOADBREAK ELBOW CONNECTORS ON TAPS (TYPICAL) TAP 1 MAIN 600A DEADBREAK ELBOW CONNECTORS ON INCOMING MAIN (TYPICAL) DETAILS 1 SPARE 30.5 TO CIRCUIT 2 2 TO CIRCUIT 1 TO RISER POLE FAULT SWITCHGEAR REAR ELEVATION 30 40 4 35 35 40 SWITCHBOARD DETAIL GENERAL NOTES: 1. ALTERNATE 2 - PROVIDE SPARE 208V, 1600 AMP, 3-PHASE, FOUR-WIRE, NEMA 3R SWITCHBOARD WITH COPPER BUSSING, SUSE LABELLING AND WITH SWITCHES AND DIMENSIONS SHOWN IN DETAIL 04, THIS SHEET. E0.4 DIVISION 16 - ELECTRICAL SPECIFICATIONS SECTION 16000 GENERAL REQUIREMENTS FOR ELECTRICAL WORK A. GENERAL CONDITIONS 1. Drawings (plans, specifications, and details) are diagrammatic and indicate the general location and intent of the electrical systems. Where drawings, existing site conditions, specifications or other trades conflict or are unclear, advise the Engineer prior to submittal of Bid. Otherwise, Engineer's interpretation of Contract Documents or conditions shall be final with no additional compensation permitted. 2.1 MATERIALS 2. The location of outlets and equipment shown on the Drawings are approximate and schematic in nature.The owner shall have the right to relocate any outlets or equipment prior to rough-in without additional cost, up to 10 feet. PART 3 - EXECUTION A. Use materials to match existing construction unless specified elsewhere in these Contract Documents. Materials shall comply with local codes, be UL listed, and be properly applied for their intended function. SECTION 16300 MEDIUM VOLTAGE MATERIALS AND EQUIPMENT A. MEDIUM VOLTAGE CABLE 1. Drawings and general provisions, including General and Supplementary Conditions and all other Specification Sections, are a part of this Contract. 2. The Contractor for this work is required to read all Specifications and review drawings for all other trades. 1. Standards: UL 1072 and ICEA S-93-639 (NEMA WC 74) 5-46 kV, type MV-105 3.1 EXISTING CONDITIONS 2. Rated Voltage: 15 kV 3. The Contractor is responsible for providing his subcontractors with a full set of bid documents including Specifications. He must also coordinate his work and inspections and the work and inspection of his subcontractors with all other trades on site to conform with the General Contractor's time schedule. 1. Two copies of Operation Manuals and Maintenance Instructions for all equipment furnished on job shall be collected and inserted in a 3" three ring binder and turned over to the Owner. END OF SECTION 16000 4. The Contractor shall visit the site prior to submitting his Bid to determine conditions affecting the work. Bids shall serve as evidence of knowledge of existing conditions and any modifications which are required to meet the intent of the drawings and specifications. Failure to visit the site does not relieve the Contractor of responsibility in performance of work. 1. The Contractor shall furnish all labor, materials, equipment, services, tools, transportation, and miscellaneous items necessary for the installation, completion and testing of all the work for the electrical systems as shown on the drawings, called for in the specifications, and as required by job conditions, to include, but not limited to the following: 1. The Contractor shall provide all labor, materials, equipment, services, tools, transportation, incidentals and details necessary to provide a complete and fully functional electrical systems as shown on the Drawings, called for in the Specifications, and as required by job conditions. Provide equipment that is rated for available fault current levels. Field verify the exact type, size, location, requirements, etc. of existing power and telephone facilities prior to submission of Bid. 3. The Drawings and Specifications are intended to supplement each other and any material or labor called for in one shall be provided even though not specifically mentioned in both. Any material or labor which is neither shown on the Drawings nor called for in the Specifications, but which is obviously necessary to complete the work or which is usually included in work of similar character, shall be provided as part of contract. 3.2 A. Access: Access to and use of the existing facilities and site will be restricted, and shall be under the direction and control of the Owner. e. B. Disruptions: Maintain existing electrical, communications, alarm, and other existing systems, and maintain existing functions in service except for scheduled disruptions. Where existing functions to remain in use are disrupted, they shall be fully restored after disruption, in full compliance with this division of the specifications for new work. Replacement of existing Class H fuses with new Class R fuses. C. Scheduling of Disruptions: Seek and obtain approval two weeks in advance of the event date. Indicate date of event, starting time, and duration of each required disruption. D. Notice of Disruption: Date, time and duration of each disruption shall be subject to the Landlord's prior approval, and shall include the following information in the form of a memorandum submitted by the Contractor to the Owner for approval: 3. Conductors shall be stranded for sizes #8 AWG and larger. 4. Aluminum conductors are not permitted. Emergency Disruptions: When circumstances preclude obtaining advance approval as specified above, make request immediately upon knowledge of the requirement, and perform work so as to cause the minimum amount of disruption, for the minimum duration. 5. All wiring shall be in conduit, unless specifically noted otherwise. 6. The contractor shall do all cutting, core drilling, chasing, or channeling and patching required for any work under this division. Cutting and patching shall have prior approval by the Owner. Patching shall match finish of surrounding area. 6. Wire connectors shall be equivalent to 3-M wire nut type with interior copper alloy thread type coils. Equivalents by Buchanan are acceptable. 7. The Electrical Contractor shall make all final electrical connections as required for a complete and operating system. F. Notification: Notify the Owner immediately by telephone and then in writing, as changes and additions to the scheduled disruption requirements become known. 7. All wiring to be color-coded as follows: 120/208 Volt System D. ELECTRICAL DEMOLITION Neutral - Gray Phase A - Black Phase B - Red Phase C - Blue 1. The Electrical Contractor shall determine the extent (if any) of demolition he is to include in his bid. Obtain accurate instruction from the General Contractor and Project Manager and inspect the site to clarify the scope of work. 2. All materials and debris removed must be removed from the site and disposed of in a timely and responsible manner. Owner shall have first right of refusal for all equipment. C. FUSES E. CODES 1. All work shall be performed in a neat and professional manner using good engineering practices. All work shall conform to the latest adopted edition of the National Electrical Code; the State's, County's, City's and local Codes and ordinances; Safety and Health Codes; NFPA Codes; Energy Codes; and all other applicable codes and requirements. This Contractor shall inquire into and comply with all applicable codes, ordinances, and regulations. This Contractor shall include any changes required by codes in the Bid. After Contract is issued, no additional cost due to Code issues shall be reimbursed to the Contractor. 2. Fuses over 600 amperes shall be Class L, bolt-on type, with time-delay and hold 500 percent rated fuse current for minimum of 4 seconds and clear 20 times rated fuse current in .01 seconds or less. Fuses shall have 'O' ring seals between end bells and glass melamine barrel, equivalent to Bussmann time delay KRP-C. 2. Working jointly with the work under other divisions of the specifications establish and mark salvage and demolition items before commencing work; report items scheduled for relocation, reinstallation or reuse, which are found to be in damaged condition; await further instructions from the Owner and/or the Engineer before commencing with work. 2. Upon completion of the work, all parts of the electrical installation shall be tested and proved free of defects. G. TRADE NAMES AND MANUFACTURERS 1. Where trade names and manufacturers are used on the Drawings or in the Specifications, the exact equipment shall be used as a minimum standard for the base bid. Manufacturers considered as an equivalent or better in all aspects to that specified will be subject to approval in writing by the Owner prior to acceptance. The use of any unauthorized equipment shall be subject to removal and replacement at the Contractor's expense. 3. All overload devices, including equipment furnished under other contracts, shall be set and adjusted to suit the load conditions. 4. Test and make corrections/adjustments for phase balancing. 5. This Contractor shall provide any necessary fittings, accessories, etc. as necessary to make a complete installation. H. SHOP DRAWINGS SALVAGE, DEMOLITION AND RELOCATION 1. Modify, remove, or relocate materials and items indicated in the Contract Documents and required by the installation of new facilities. 1. All connections at panels and switches are to be made, all splices complete, all fuses in place, and all circuits continuous from point of service connection to its final destination, and all covers and plates installed prior to the time of final inspection. 2. Furnish to the Owner all certificates of inspection and final inspection approval at completion of project. 3.3 1. Fuses shall be current-limiting, with 200,000 RMS symmetrical amperes interrupting rating and shall be UL listed. All fuses shall be of same manufacturer. D. TESTS AND ADJUSTMENTS 1. The Contractor shall obtain and pay for all licenses, permits, inspections, and fees required or related to his work. G. Duration: Complete as large a portion of the work as possible before initiating disruption and perform only that work necessary so as to minimize duration of disruption. Maintain adequate personnel, supplies, materials, equipment, tools, and other resources at job site to avoid unnecessary delay in resumption of normal service. A. General 3. Fuses 600 amperes and smaller shall be Class RK1 OR RK5, dual element. These fuses shall have separated overload and short-circuit elements. Type RK1 shall be equivalent to Bussmann dual-element LPN-RK (250 volts or less rating) and LPS-RK (600 volts or less rating). Type RK5 shall be equivalent to Bussmann dual-element FRN-R(250 volts of less rating) and FRS-R (600V or less rating). F. LICENSES, PERMITS, INSPECTIONS & FEES DISRUPTION OF EXISTING FUNCTIONS d. Final connections of all electrical work serving existing equipment furnished under this contract. 1. Conductors for feeders and branch circuits shall be COPPER and the AWG size and type as shown on Drawings. Minimum wire size shall be #12. Conductors shall have 600 volt insulation, type THWN or THHN. Wiring installed in damp locations shall be THWN, 600 volt copper. 5. All electrical work shall be installed so as to be readily accessible for operation, servicing, maintenance and repair. 5. Insulation: 220 mil ethylene propylene rubber (EPR) H. Perform splices as required to maintain circuit continuity to existing devices or equipment to remain in service. B. WIRING 4. Where the Drawings or Specifications call for items which exceed codes, the Contractor is still responsible for providing the system as designed and described on the Drawings, unless specifically noted otherwise. C. Relocate existing items as required to accommodate the new construction. Remove, relocate and reconnect equipment and accessories that are to be reused. G. Remove all conductors and exposed conduit rendered unused back to the source of supply. b. Underground medium voltage line work. c. Final connections to all electrical equipment furnished under this contract. 4. Conductor Shield: extruded semi-conducting thermosetting polymeric layer over conductor F. Refer to other divisions of the specifications and determine equipment that requires power to be disconnected, or power to be relocated and disconnect power and relocate power to this equipment. a. Overhead medium voltage line work. 2. Unless specifically noted otherwise, materials, products, and equipment, including all components thereof, shall be new, Underwriters Laboratories listed and labeled and sized in conformity with requirements of the National Electrical Code, State and Local codes, whichever is more stringent. B. Obtain data related to existing facilities from existing documents, measurements, notations, photographs, surveys and other observations at the site. E. Loads that exist and are to remain shall be connected to the new distribution system as shown on the Drawings or as required to maintain their proper operation. A. SCOPE OF WORK B. GENERAL REQUIREMENTS 3. Conductor: Class B compressed copper, size as shown on drawings D. Coordinate the Work with other divisions of the specifications. Determine which items and equipment are to remain, to be relocated or be removed, and perform all work consistent with the Scope of Work. SECTION 16050 BASIC ELECTRICAL MATERIALS AND METHODS 5. When used, the term "Provided By Contractor" shall be interpreted as meaning "Furnished and Installed by Contractor". A. Inspect the jobsite prior to bidding and be familiar with all existing conditions. Include the cost of the work required to accommodate the existing conditions in the bid proposal. 3. Owner shall have first right of refusal for all material and equipment. Deliver salvaged material accepted by the Owner to destinations on the premises as directed and remove material rejected by the Owner from the site. B. Relocations 1. Make minor relocations necessitated by the conditions at the site or as directed by the Owner, without additional cost to the Owner. 2. Repair and restore to good functional condition equipment, materials and items scheduled for relocation, which are damaged during dismantling or reassembly operations. 3. New materials and items of similar design and quality may be substituted for materials and items indicated to be relocated upon approval of shop drawings, product data, and samples. 4. Remove carefully, in reverse order to original assembly or placement, items that are to be relocated. 6. Insulation Shield: extruded semi-conducting thermosetting polymeric layer over insulation with a helically-wrapped 5-mil copper tape shield with 25% overlap 7. Jacket: overall black sunlight resistant no lead pvc jacket conforming to icea requirements. 8. Manufacturer: equivalent to Southwire Simpull EFC CT1-13ET 9. Follow cable manufacturer's recommended installation instructions. Do not exceed maximum pulling tension or maximum sidewall pressure specified by cable manufacturer. Do not train cable with a bending radius less than minimum bending radii. B. MEDIUM VOLTAGE CABLE TERMINATIONS 1. Outdoor terminations at transformers and riser poles a. Provide 15kV class, one-piece, skirted silicone rubber terminators equivalent to 3M cold shrink QT-III meeting IEEE standard 48 class 1 requirements for outdoor weather-exposed applications. 2. Padmounted Switchgear and Junction Enclosures C. Provide 200 amp, 15 kV class, loadbreak elbow connectors equivalent to Cooper Power Systems series 500-10 for termination of cables at junction enclosures and at taps of padmounted switchgear. Size terminators for cable sizes and types noted on drawings. D. Provide 600 amp, 15 kV class, deadbreak elbow connectors equivalent to Cooper Power Systems series 600-10 for termination of cables at mains of padmounted switchgear. Size terminators for cable sizes and types noted on drawings. E. MEDIUM VOLTAGE FUSED CUTOUTS 1. Provide 200 amp, 14.4 kV nominal, 110 kV BIL, 12,000 asym-amps interrupting, ultra-heavy duty fused cutouts equivalent to MacLean Power Systems Type 89071R11-D. Provide fuse links of the amp rating and speed noted on drawings. D. MEDIUM VOLTAGE PADMOUNTED SWITCHGEAR 1. Provide 15kV class, 95 kV BIL, 12.5 kA symmetrical short circuit current rated, outdoor padmounted switchgear with 600 amp mains and 200 amp lateral taps. 2. Switchgear to have manually operated three-position (closed-open-grounded) load interrupter switches on main circuits and microprocessor controlled fault interrupters in series with manually operated three-position (closed-open-grounded) disconnect switch for isolation and grounding on each tap circuit. 3. Switches and fault interrupters to be enclosed in a SF6-insulated welded stainless steel tank completely protected from the environment. 4. Connections to mains and taps to be made with elbow connectors. 5. Provide viewing windows to allow operator to confirm position of load-interrupter switches and fault interrupter disconnects without exposing operator to energized components or requiring operation of elbow connectors. 6. Fault interrupter operation to be controlled by a programmable microprocessor C37.112-1996. Program settings as shown on drawings. Power and input signals to be provided by integral transformers. 7. Provide switchgear with the number of mains and taps as shown on the drawings. 8. Furnish switchgear assembly in a mild-steel pad-mounted enclosure complying with the requirements of ANSI C57.12.28 (enclosure integrity). Provide larger enclosure than standard for specified switch when noted on drawings. 9. Provide matching stainless steel subbase of the height shown when noted on drawings. 10. Switchgear shall be S&C manual Vista underground distribution switchgear, 934132R1-S-R2 series. 5. Protect items until relocation is complete. E. MEDIUM VOLTAGE GANG-OPERATED LOAD INTERRUPTER SWITCHES E. CLEANING 1. Submit six copies of material lists and shop drawings for ALL EQUIPMENT to the Owner for approval prior to ordering equipment. Submissions shall be made early enough in project to allow eight working days for Engineer's to review submittal without causing delays or conflicts to the job's progress. Submittals shall be in accordance with General Conditions and the manufacturer's listed on the drawings. Shop drawings shall include all data that pertains to the requirements set forth on the drawings and in the specifications. Submittals shall bear the stamp of the Contractor and Subcontractor showing that he has reviewed and confirmed that they are in conformance with the contract drawings and specifications. Any exceptions to specifications or drawings shall be indicated to the Owner. Lack of such Contractor's review and approval will be cause for rejection without review by the Engineer. 1. At the end of the project, this Contractor shall clean all equipment, including light fixtures, to the satisfaction of the Architect. All dust, dirt, debris, and foreign matter shall be removed from all equipment. 2. Remove all dirt, oil or grease from light fixtures. Clean all glass, lenses, etc. and polish fixtures and trim. 1. All switch gear, circuit breakers and disconnects in switch gear, panel boards, transformers, time clocks, thermal overload fan switches, equipment control switches, safety switches, motor starters, and similar items shall be identified by name, function, and/or control. Nameplates shall be at least 1" x 3" with characters not less than 1/4". They shall be made up of plastic-laminated tags and characters engraved to engraver's standard thickness and letter style with white core and black background. Nameplates shall be fastened to equipment with pop rivets or screws. 1. The Contractor shall guarantee all materials and work under his contract and shall make good, repair or replace at his own expense, any defective work, material, or equipment which may be discovered within a period of 12 months from the date of acceptance (in writing) of the installation. 2. Provide typed directories for new panel boards to depict actual equipment connected to individual breakers/switches J. RECORD DRAWINGS 1. The Contractor shall maintain one copy of Drawings and Specifications on the job site to record deviations from Contract Drawings, such as: 2. At completion of project and before final approval, the Contractor shall make any final corrections to Drawings and certify the accuracy of each print by signature thereon and turn over to the Engineer. K. DISCREPANCIES IN DOCUMENTS 7. Perform the relocation work in accordance with applicable sections of these specifications, utilizing skilled workers. END OF SECTION 16011 1. Provide 29 kV, 150 kV BIL, 900 amp continuous rated, 900 amp interrupting rating, three-pole, group-operated, side-break, upright delta configuration switch suitable for pole mounting. 2. Switch to have steel base, polymer insulators, fiberglass crossarm, pole mounting bracket, vertical pipe operating mechanism, and all associated mounting hardware required to attach switch and operator to pole. F. IDENTIFICATION H. GUARANTEE a. Location of junction boxes and receptacles. b. Revisions, addendum, and change orders. c. Significant deviations made necessary by field conditions, approved equipment substitutions, and Contractor's coordination with other trades. d. Routing of any underground or under slab conduits. 6. Clean and repair items to be relocated, and provide new materials, fittings, and appurtenances required to complete the relocations and to restore items to good operating order. SPECIFICATIONS L. OPERATING MANUALS AND MAINTENANCE INSTRUCTIONS SECTION 16011 WORK IN EXISTING BUILDING PART 1 - GENERAL 1.1 DESCRIPTION 3. Switch shall be Hubbell Type AR144FFLX0015 to match Oncor custom spacing and height requirements. F. LINE CONSTRUCTION MATERIALS 1. Materials shall conform to the Rural Utilities Services list of materials, RUS 202-1 (July, 2014 with September, 2014 supplement), unless otherwise noted. G. FIELD TESTING OF MEDIUM VOLTAGE CABLE 1. Retain services of a NETA accredited testing agency to perform direct current high-potential acceptance testing of medium voltage cables. 2. Testing shall be performed by NETA certified technicians and shall comply with ANSI/NETA testing standards and procedures in effect at the time of testing. 3. Maximum test voltage shall not exceed cable manufacturer's recommendation for the installed cable type. A. Refer to Section 16000: General Requirements for Electrical Work. B. Furnish all labor, materials, services, equipment, and appliances required in conjunction with the work in existing buildings as indicated in the Contract Documents. 4. Provide three copies of the certified test report to the Owner. END OF SECTION 16300 PART 2 - PRODUCTS E0.5