ieee transactions on plasma

advertisement

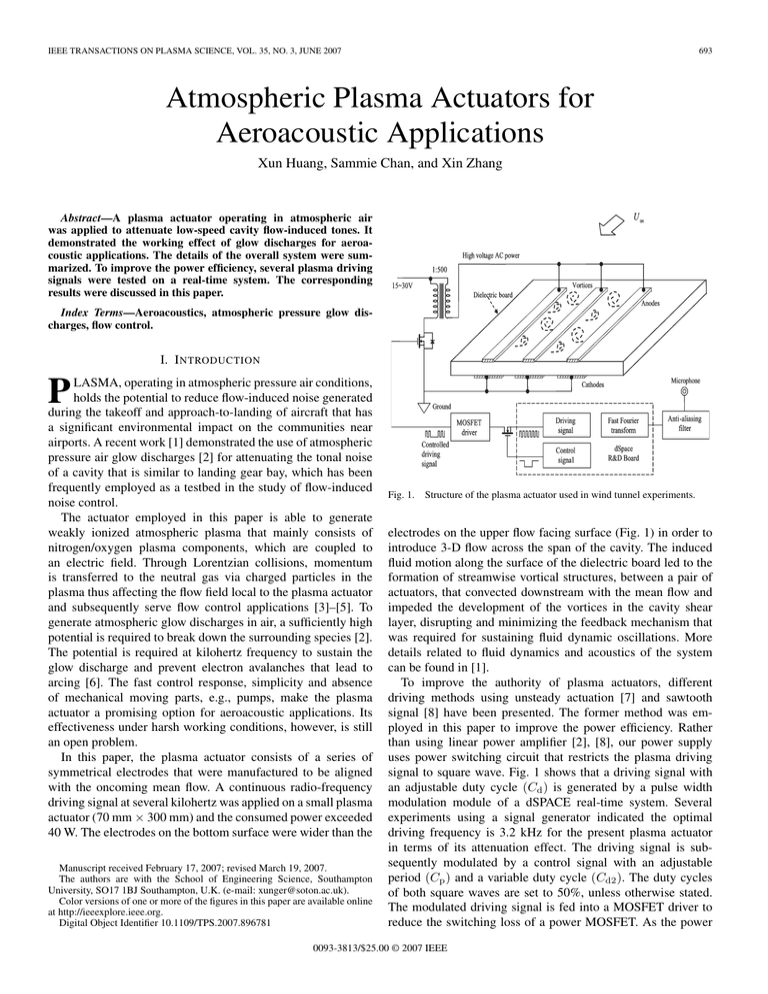

IEEE TRANSACTIONS ON PLASMA SCIENCE, VOL. 35, NO. 3, JUNE 2007 693 Atmospheric Plasma Actuators for Aeroacoustic Applications Xun Huang, Sammie Chan, and Xin Zhang Abstract—A plasma actuator operating in atmospheric air was applied to attenuate low-speed cavity flow-induced tones. It demonstrated the working effect of glow discharges for aeroacoustic applications. The details of the overall system were summarized. To improve the power efficiency, several plasma driving signals were tested on a real-time system. The corresponding results were discussed in this paper. Index Terms—Aeroacoustics, atmospheric pressure glow discharges, flow control. I. I NTRODUCTION P LASMA, operating in atmospheric pressure air conditions, holds the potential to reduce flow-induced noise generated during the takeoff and approach-to-landing of aircraft that has a significant environmental impact on the communities near airports. A recent work [1] demonstrated the use of atmospheric pressure air glow discharges [2] for attenuating the tonal noise of a cavity that is similar to landing gear bay, which has been frequently employed as a testbed in the study of flow-induced noise control. The actuator employed in this paper is able to generate weakly ionized atmospheric plasma that mainly consists of nitrogen/oxygen plasma components, which are coupled to an electric field. Through Lorentzian collisions, momentum is transferred to the neutral gas via charged particles in the plasma thus affecting the flow field local to the plasma actuator and subsequently serve flow control applications [3]–[5]. To generate atmospheric glow discharges in air, a sufficiently high potential is required to break down the surrounding species [2]. The potential is required at kilohertz frequency to sustain the glow discharge and prevent electron avalanches that lead to arcing [6]. The fast control response, simplicity and absence of mechanical moving parts, e.g., pumps, make the plasma actuator a promising option for aeroacoustic applications. Its effectiveness under harsh working conditions, however, is still an open problem. In this paper, the plasma actuator consists of a series of symmetrical electrodes that were manufactured to be aligned with the oncoming mean flow. A continuous radio-frequency driving signal at several kilohertz was applied on a small plasma actuator (70 mm × 300 mm) and the consumed power exceeded 40 W. The electrodes on the bottom surface were wider than the Manuscript received February 17, 2007; revised March 19, 2007. The authors are with the School of Engineering Science, Southampton University, SO17 1BJ Southampton, U.K. (e-mail: xunger@soton.ac.uk). Color versions of one or more of the figures in this paper are available online at http://ieeexplore.ieee.org. Digital Object Identifier 10.1109/TPS.2007.896781 Fig. 1. Structure of the plasma actuator used in wind tunnel experiments. electrodes on the upper flow facing surface (Fig. 1) in order to introduce 3-D flow across the span of the cavity. The induced fluid motion along the surface of the dielectric board led to the formation of streamwise vortical structures, between a pair of actuators, that convected downstream with the mean flow and impeded the development of the vortices in the cavity shear layer, disrupting and minimizing the feedback mechanism that was required for sustaining fluid dynamic oscillations. More details related to fluid dynamics and acoustics of the system can be found in [1]. To improve the authority of plasma actuators, different driving methods using unsteady actuation [7] and sawtooth signal [8] have been presented. The former method was employed in this paper to improve the power efficiency. Rather than using linear power amplifier [2], [8], our power supply uses power switching circuit that restricts the plasma driving signal to square wave. Fig. 1 shows that a driving signal with an adjustable duty cycle (Cd ) is generated by a pulse width modulation module of a dSPACE real-time system. Several experiments using a signal generator indicated the optimal driving frequency is 3.2 kHz for the present plasma actuator in terms of its attenuation effect. The driving signal is subsequently modulated by a control signal with an adjustable period (Cp ) and a variable duty cycle (Cd2 ). The duty cycles of both square waves are set to 50%, unless otherwise stated. The modulated driving signal is fed into a MOSFET driver to reduce the switching loss of a power MOSFET. As the power 0093-3813/$25.00 © 2007 IEEE 694 IEEE TRANSACTIONS ON PLASMA SCIENCE, VOL. 35, NO. 3, JUNE 2007 Fig. 2. Overall system working in a wind tunnel. MOSFET is switched by the plasma driving signal, a step-up transformer generates high voltage output sufficient to induce discharges. The performance of the plasma actuator, therefore, can be controlled by adjusting Cp and Cd , respectively. Experiments were conducted in a wind tunnel facility at the University of Southampton (Fig. 2). A cavity model manufactured from Perspex was used as a testbed to develop the plasma actuator control system. The investigation was performed for cavity geometries at flow speeds ranging from 10 to 20 m/s. The tones generated by the cavity were recorded using a Panasonic WM-60A omnidirectional condenser microphone that was flush mounted to the surface of the front wall of the cavity. The microphone’s signal was passed through an antialiasing filter and was subsequently sampled with a PC sound card at 44.1 kHz. A 4096 point fast Fourier transform with a Hanning window function was applied to process the sampled data. The sound pressure level (SPL) result was averaged over 300 signal blocks for statistical confidence in the results. The experimental procedure was adjusting Cp first and then adjusting Cd at the proper Cp . Fig. 3(a) shows that the flow-induced tones are attenuated successfully with the system operating at Cd2 = 100%. Other than attenuating flow-induced tones, the plasma actuator also produces high-frequency acoustic tones and electromagnetic radiations. If Cp = 500 µs, Fig. 3(b) shows that the switching power supply works ineffectively and the plasma actuator generates insufficient plasma in the weak electric field, thus affecting little over the flow field. The same phenomenon was also discovered for conditions of Cd < 50% or Cd > 60%. If Cp = 50 ms, given Cd2 = 50%, the flow-induced noise is attenuated successfully in 25 ms, while it develops again in the consecutive 25 ms. Fig. 3(c) shows that its overall attenuation effect is not satisfactory. On the contrary, the flow-induced noise fails to develop substantially if Cp < 20 ms. Fig. 3(d) shows the result with the system operating at Cp = 5 ms and Cd = 60% that is the optimal driving signal for this paper, in terms of power efficiency and attenuation effect. As displayed in Fig. 4, its attenuation effect is 6 dB higher than the baseline result while approximately 50% of the system power is saved. Fig. 3. SPL results at U∞ = 20 m/s: (a) Cd2 = 100%; (b) Cp = 500 µs; (c) Cp = 50 ms; (d) Cp = 5 ms, Cd = 60%. HUANG et al.: ATMOSPHERIC PLASMA ACTUATORS FOR AEROACOUSTIC APPLICATIONS 695 R EFERENCES [1] S. Chan, X. Zhang, and S. Gabriel, “The attenuation of cavity tones using plasma actuators,” presented at the 11th AIAA/CEAS Aeroacoustics Conf., Monterey, CA, 2005, AIAA Paper 2005-2802. [2] J. R. Roth, “Aerodynamic flow acceleration using paraelectric and peristaltic electrohydrodynamic effects of a one atmosphere uniform glow discharge plasma (OAUGDP),” Phys. Plasmas, vol. 10, no. 5, pp. 1166– 1172, 2003. [3] J. R. Roth, “Electrohydrodynamically induced airflow in a one atmosphere uniform glow discharge surface plasma,” in Proc. IEEE Int. Conf. Plasma Sci., Jun. 1998, p. 291. no. 6P–67. [4] J. R. Roth, D. M. Sherman, and S. P. Wilkinson, “Electrohydrodynamic flow control with a glow-discharge surface plasma,” AIAA J., vol. 38, no. 7, pp. 1166–1172, Jul. 2000. [5] E. Moreau, “Airflow control by non-thermal plasma actuators,” J. Phys. D, Appl. Phys., vol. 40, no. 3, pp. 605–636, Feb. 2007. [6] J. R. Roth, Industrial Plasma Engineering: Applications to Nonthermal Plasma Processing, vol. 2. London, U.K.: Inst. Phys. Publishing, 2001, ch. 18. [7] O. F. Thomas, A. Kozlov, and C. T. Corke, “Plasma actuators for landing gear noise reduction,” presented at the 11th AIAA/CEAS Aeroacoustics Conf., Monterey, CA, 2005, AIAA Paper 2005–3010. [8] C. L. Enloe, T. E. McLaughlin, R. D. Van Dyken, K. D. Kachner, E. J. Jumper, and T. C. Corke, “Mechanisms and responses of a single dielectric barrier plasma actuator: Plasma morphology,” AIAA J., vol. 42, no. 3, pp. 589–594, 2004. Xun Huang was born in Hangzhou, China, in 1977. He received the B.Eng. degree in astronautics from the Northwestern Polytechnical University, Xi’an, China, the M.Eng. degree in automatic control from Tsinghua University, Beijing, China, and the Ph.D. degree in aeronautics and astronautics from the University of Southampton, Southampton, U.K., in 1999, 2002, and 2006, respectively. He was a Research Engineer in the Shanghai Laboratory of the GE Global Research Center in 2003. He was a Research Assistant in 2006 and became a Research Fellow in 2007 in the School of Engineering Sciences, University of Southampton. His research interests include control, plasma, and parallel computation, especially for aerospace applications. Dr. Huang received the Edison Technology Excellence Award in 2003. Fig. 4. Relationships between the system power and the dominant amplitudes of (a) the flow-induced tones and (b) the radiated plasma actuator noise. Meanwhile, the radiated noise of the plasma actuator is still lower than the flow-induced noise. II. C ONCLUSION In summary, the plasma actuator was applied to a flowinduced noise control problem to demonstrate its effectiveness in aeroacoustic applications. The system was tested in the wind tunnel. The results show that both the duty cycle of the driving signal (Cd ) and the period of the control signal (Cp ) affect the performance of the plasma actuator. The optimal values could be achieved by several experiments with the present hardware system rapidly. The results help to guide the selection of proper parameters, leading to a more intelligent and efficient system using closed-loop methodologies. ACKNOWLEDGMENT This work was performed under an extended studentship between October and December 2006 at Southampton University. Sammie Chan was born in the U.K. in 1980. He received the M.Eng. degree in aerospace engineering and the Ph.D. degree, investigating the attenuation of flow induced tonal noise using plasma actuators, from the University of Southampton, Southampton, U.K., in 2002 and 2006, respectively. He is currently a Research Fellow with the Aerodynamics and Flight Mechanics Group, University of Southampton, performing research with plasma actuators applied to noise control. Xin Zhang received the B.Eng. degree in aerospace engineering from the Beijing University of Aeronautics and Astronautics, Beijing, China, and the Ph.D degree in fluid mechanics from Cambridge University, Cambridge, U.K. He is a Professor of aerodynamics in the School of Engineering Sciences, University of Southampton, Southampton, U.K. His main research interests are in the areas of unsteady aerodynamics, computational aeroacoustics, engine and airframe noise, ground effect aerodynamics, race car aerodynamics, and flow control. He has conducted studies of self-sustained fluid flow oscillations, turbulent flow control through streamwise vortices, flow control jets, engine and duct acoustics, etc. He is the Principal Investigator of many projects funded by the U.K. government, EU, Airbus, and U.K. aerospace and motor-racing industries, and has acted as a Consultant for a number of industrial companies. Dr. Zhang is a Fellow of the Royal Aeronautical Society and an Associated Fellow of the American Institute of Aeronautics and Astronautics.