M125 LED Installation

advertisement

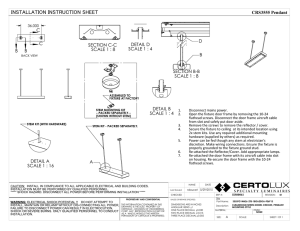

M125 LED Installation Instructions For Recessed Linear LED Tools Required for all mountings: 1 5mm Allen Key 2 4mm Allen Key 3 Philips Head Screw Driver 4 7/16 Wrench Perimeter Mount (PM) (2x) Clearance holes for ¼” mounting hardware, mounting hardware supplied and installed to code(s) in the field by others. 1. Secure wall bracket to the wall. 2. Secure wall angle to the wall. 3. Lift fixture up and level. 4. Screw nut over bolt to hold in place. 5. M ake electrical connection and test the function of the luminaire. 4 Wall Bracket by Selux #10 Screws (or equal) Wall Angle by Selux by others Wall Mount (W) (4x) Clearance holes for ¼” mounting hardware, mounting hardware supplied and installed to code(s) in the field by others. Wall Bracket by Selux Hollow Tube (welded to fixture) by Selux 1. Secure wall bracket to the wall. 2. Make electrical connection. 3. Slide fixture onto wall bracket. 4. Secure fixture from bottom with provided fasteners. 5. Test the function of the luminaire. 2 Mounting Hardware by Selux Rotating Crossbar (RC) 1. Adjust leg height for mounting material thickness. 2. Make electrical connections. 3. Remove door assembly by loosening door screws. 4. Insert fixture into ceiling. 5. T ighten rotating crossbar screw, which will draw fixture into ceiling. 6. Secure door assembly back to fixture by tightening door screws. 7. Test the function of the luminaire. Adjustable Leg Height Rotating Crossbar Screw Gear Tray Door 3 CAUTION! 1 Captive Door Screw Only work on de-energized equipment Selux Corporation © 2013 • TEL 845-834-1400 • 800-735-8927 • FAX 845-834-1401 • www.selux.us Please Note: Disconnect electricity to fixture before working. To be performed by trained personnel only. It is the responsibility of the installer to ensure all electrical, Page 1 of 3 mechanical, and thermal compatibility of the installation site and luminaires prior to installation. Please observe all relevant building codes and regulations. Keep these (Rev. 06/13) instructions after unpacking fixture. For detailed spec sheets and more information on this and our full range of products, please visit our website at selux.us. Warranty information: http://www.selux.us/en/resources/terms-and-warranty.html M125 LED Install_Inst_06 M125 LED Installation Instructions For Recessed Linear LED Surface Mount (F) 1. Remove door assembly by loosening door screws. 2. Make electrical connection. 3. Insert supplied sealing washer with ¼-20 Hardware (hardware by others) and screw them through provided holes to secure fixture in place. 4. Secure door assembly back to fixture by tightening door screws. 5. Test the function of the luminaire. Sealing Washers by Selux ¼ -20 Hardware by others Gear Tray Door Captive Door Screw 2 Suspension Brackets (SH) Suspension Wire by others Suspension Bracket 1. Secure fixture via thru-holes in suspension brackets. 2. Make electrical connection and test the function of the luminaire. Threaded Stud (TS) Threaded Coupler by others ¼ -20 x 1” Threaded Stud by Selux 1. Connect ¼ -20 x 1” threaded stud to ¼ -20 threaded coupler (by others). 2. Screw to secure fixture in place. 3. M ake electrical connection and test the function of the luminaire. CAUTION! Only work on de-energized equipment Selux Corporation © 2013 • TEL 845-834-1400 • 800-735-8927 • FAX 845-834-1401 • www.selux.us Please Note: Disconnect electricity to fixture before working. To be performed by trained personnel only. It is the responsibility of the installer to ensure all electrical, Page 2 of 3 mechanical, and thermal compatibility of the installation site and luminaires prior to installation. Please observe all relevant building codes and regulations. Keep these (Rev. 06/13) instructions after unpacking fixture. For detailed spec sheets and more information on this and our full range of products, please visit our website at selux.us. Warranty information: http://www.selux.us/en/resources/terms-and-warranty.html M125 LED Install_Inst_06 M125 LED Installation Instructions For Recessed Linear LED Nipple Connector (NC) 3/8” IP Nipple 2. Connector Gasket pre-applied to one housing Outside Nuts and Sealing Washers 1. Remove door assembly by loosening door screws. 2. Remove nuts and sealing washers that are outside of both housings and slide nipple connectors through clearance holes bringing both the housings together. 3. A pply sealing washers and nuts from inside of housing onto threaded nipple connectors and tighten securely to ensure a watertight seal is maintained. 4.Feed wires through one of the nipples and make electrical connection. 5. S ecure door assembly back to fixture by tightening door screws. 6. Test the function of the luminaire. Inside Nuts and Sealing Washers 3. Sealing Washer 3/8” IP Square Nut End Feed (EF) M125 End Cap supplied with clearance hole for 1/2” Chase Nipple Lock Washer by others 1. Remove door assembly by loosening door screws. 2. Install 1/2” watertight chase nipple (by others). 3. F eed wires/cord through the nipple and make electrical connection. 4. Secure door assembly back to fixture by tightening door screws. 5. Test the function of the luminaire. 1/2” Watertight Chase Nipple supplied and installed in the field by others. CAUTION! Only work on de-energized equipment Selux Corporation © 2013 • TEL 845-834-1400 • 800-735-8927 • FAX 845-834-1401 • www.selux.us Please Note: Disconnect electricity to fixture before working. To be performed by trained personnel only. It is the responsibility of the installer to ensure all electrical, Page 3 of 3 mechanical, and thermal compatibility of the installation site and luminaires prior to installation. Please observe all relevant building codes and regulations. Keep these (Rev. 06/13) instructions after unpacking fixture. For detailed spec sheets and more information on this and our full range of products, please visit our website at selux.us. Warranty information: http://www.selux.us/en/resources/terms-and-warranty.html M125 LED Install_Inst_06