GE Healthcare

Life Sciences

Application note 28-9501-39 AB

Bioreactor systems

A rapid filtration method for

harvesting mammalian cell culture

grown in Cellbag™ bioreactors

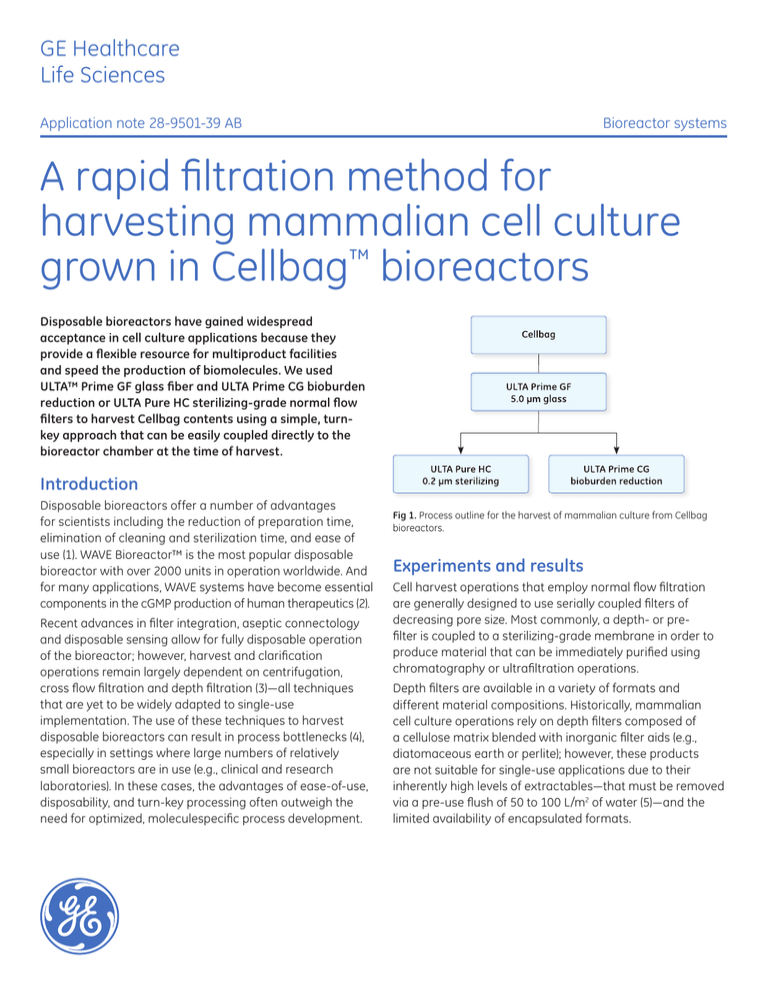

Disposable bioreactors have gained widespread

acceptance in cell culture applications because they

provide a flexible resource for multiproduct facilities

and speed the production of biomolecules. We used

ULTA™ Prime GF glass fiber and ULTA Prime CG bioburden

reduction or ULTA Pure HC sterilizing-grade normal flow

filters to harvest Cellbag contents using a simple, turnkey approach that can be easily coupled directly to the

bioreactor chamber at the time of harvest.

Introduction

Disposable bioreactors offer a number of advantages

for scientists including the reduction of preparation time,

elimination of cleaning and sterilization time, and ease of

use (1). WAVE Bioreactor™ is the most popular disposable

bioreactor with over 2000 units in operation worldwide. And

for many applications, WAVE systems have become essential

components in the cGMP production of human therapeutics (2).

Recent advances in filter integration, aseptic connectology

and disposable sensing allow for fully disposable operation

of the bioreactor; however, harvest and clarification

operations remain largely dependent on centrifugation,

cross flow filtration and depth filtration (3)—all techniques

that are yet to be widely adapted to single-use

implementation. The use of these techniques to harvest

disposable bioreactors can result in process bottlenecks (4),

especially in settings where large numbers of relatively

small bioreactors are in use (e.g., clinical and research

laboratories). In these cases, the advantages of ease-of-use,

disposability, and turn-key processing often outweigh the

need for optimized, moleculespecific process development.

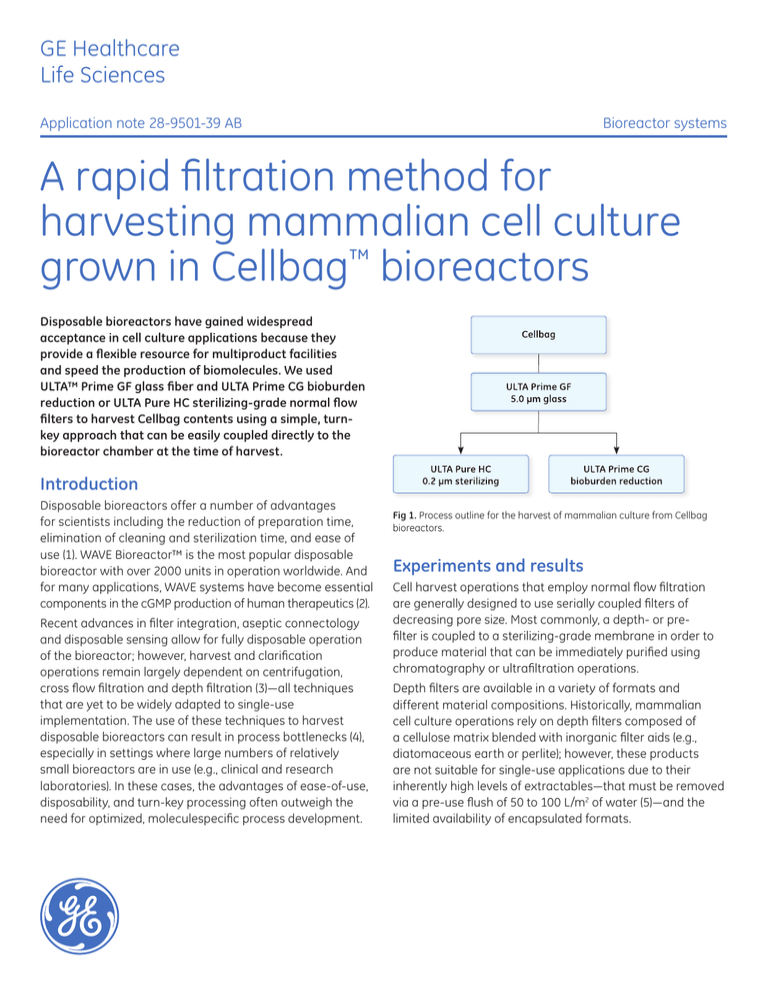

Fig 1. Process outline for the harvest of mammalian culture from Cellbag

bioreactors.

Experiments and results

Cell harvest operations that employ normal flow filtration

are generally designed to use serially coupled filters of

decreasing pore size. Most commonly, a depth- or prefilter is coupled to a sterilizing-grade membrane in order to

produce material that can be immediately purified using

chromatography or ultrafiltration operations.

Depth filters are available in a variety of formats and

different material compositions. Historically, mammalian

cell culture operations rely on depth filters composed of

a cellulose matrix blended with inorganic filter aids (e.g.,

diatomaceous earth or perlite); however, these products

are not suitable for single-use applications due to their

inherently high levels of extractables—that must be removed

via a pre-use flush of 50 to 100 L/m2 of water (5)—and the

limited availability of encapsulated formats.

1. Glass fiber has a high void volume and well-defined filter

matrix that provides longevity and efficient cell removal.

2. Glass fiber filters can be preflushed and dried at the point

of manufacture thereby eliminating any need for pre-use

flushing by the end-user.

3. Glass fiber is compatible with common sterilization

techniques such as autoclaving and gamma-irradiation.

Sterilizing-grade membranes are generally coupled to

depth filters in order to facilitate additional removal of cell

debris and particles or fines that may be shed by the depth

filter. In this study, we tested two membrane-based options

for this secondary clarification step—ULTA Prime CG and

ULTA Pure HC. ULTA Pure HC is a sterilizing-grade (0.2 μm)

filter that incorporates an onboard 0.6 μm polyethersulfone

prefilter. ULTA Prime CG is a bioburden reduction filter

(validated for 5 LRV of B. diminuta) that incorporates an

onboard 0.6 μm polyester prefilter. Providing the option of

sterilizing-grade versus bioburden reduction enables the

end-user to choose between lower cost (ULTA Prime CG) and

maximum quality assurance (ULTA Pure HC).

Eight pilot scale experiments were performed on three cell

lines at varying levels of viability and cell density (Fig 2).

All eight cultures were grown in WAVE Cellbag bioreactors

of sizes varying from 5 to 10 liters. All the experiments

were performed with capsule filters under constant flow

conditions. We chose flow rates that allowed complete

processing of the Cellbag contents in one hour.

Cell viability (%)

Meth-A

Hybridoma

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

1 000 000

10 000 000

Total cell density (cells/mL)

Fig 2. Cell culture characteristics. (Two experiments performed at the same

culture conditions).

2 28-9501-39 AB

(error bars represent one standard deviation)

90

80

70

60

50

40

30

20

10

0

ULTA Prime GF

ULTA Prime CG

ULTA Pure HC

Primary filter

Secondary filter

Process step

Fig 3. Capacity of primary and secondary filters.

Based on the experimental results, filter recommendations

were developed for each Cellbag size up to the Cellbag 50 L

(Table 1).

Table 1. Recommended filters for Cellbag harvest

Filter sizing and selection

CHO

Primary (i.e., ULTA Prime GF) and secondary (ULTA Pure HC

or ULTA Prime CG) filters were run in series with pressure

transmitters located upstream of each filter. Filtrate volume

and pressure data was collected as a function of time. Each

experiment was continued until a total pressure drop of

1 bar was observed or until the feed vessel was exhausted.

Capacity calculations were performed for both filters (Fig 3).

Capacity (L/m2)

In this study, we focused on glass-fiber based depth filters

over traditional depth-filter technologies for the following

reasons:

Cellbag

size

Culture

volume (L)

ULTA Prime GF

5.0 μm

ULTA Prime CG or

ULTA Pure HC

2L

up to 1

2 in

2 in

10 L

1 to 5

5 in

6 in

20 L

5 to 10

10 in

5 in

50 L

10 to 25

20 in

10 in

100 L

25-50

2 × 20 in

30 in

200 L

50-100

3 × 30 in

2 × 30 in

Conclusions

Ordering information

ULTA Prime GF filters coupled to a sterilizing-grade ULTA

Pure HC or bioburden reduction ULTA Prime CG filter is

a highly efficient method for harvesting WAVE Cellbag

bioreactors. This combination provides a rapid solution

that can be implemented with very little preparation. Glass

fiber and polyethersulfone membranes are inherently low

in extractables and are validated for low levels of endotoxin

and other contaminants. The methods presented in this work

provide a reliable solution designed to work in the majority of

mammalian cell culture applications with no upfront process

development efforts.

Product

References

1.

2.

Fries, S. et al. Evaluation of disposable bioreactors—Rapid Production of

Recombinant Proteins. By several Animal cell Lines. BioProcess International Vol. 3,

Supplement 6 (2005).

Disposable bioreactors become standard fare. Genetic Engineering & Biotechnology

News 25, No. 14 (2005).

3.

Shukla, A. et al. Harvest and recovery of monoclonal antibodies from large-scale

mammalian cell culture. BioPharm International. 21, No. 5 (2008).

4.

Tathagata, R. et al. Cell culture clarification by depth filtration. Biospectrum Asia.

http://www.biospectrumasia.com/content/100908IND7060.asp (2008).

5.

Application note: Using Millistak+® HC Filters for mammalian cell culture

clarification. Millipore Corporation, AN1100EN00 (2003).

Code number

ULTA Prime GF, 2 in

28-9084-27

ULTA Prime GF, 5 in

28-4136-61

ULTA Prime GF, 10 in

28-4136-64

ULTA Prime GF, 20 in

28-4136-68

ULTA Prime GF, 2 × 20 in

28-4136-68

ULTA Prime GF, 3 × 30 in

28-4136-72

ULTA Prime CG, 2 in

28-9085-17

ULTA Prime CG, 6 in

28-9085-23

ULTA Prime CG, 5 in

28-4137-08

ULTA Prime CG, 10 in

28-4137-12

ULTA Prime CG, 30 in

28-4137-18

ULTA Prime CG, 2 × 30 in

28-4137-18

ULTA Pure HC, 2 in

28-4002-31

ULTA Pure HC, 6 in

28-4002-37

ULTA Pure HC, 5 in

28-4004-27

ULTA Pure HC, 10 in

28-4004-28

ULTA Pure HC, 30 in

28-4004-30

ULTA Pure HC, 2 × 30 in

28-4004-30

28-9501-39 AB 3

For local office contact information, visit

www.gelifesciences.com/contact

www.gelifesciences.com/readytoprocess

GE Healthcare Bio-Sciences AB

Björkgatan 30

751 84 Uppsala

Sweden

GE, imagination at work and GE monogram are trademarks of General

Electric Company.

Cellbag, WAVE Bioreactor, and ULTA are trademarks of GE Healthcare

companies.

Millistak is a trademark of Millipore.

© 2009–2012 General Electric Company — All rights reserved.

First published Jan. 2009.

All goods and services are sold subject to the terms and conditions of

sale of the company within GE Healthcare which supplies them. A copy

of these terms and conditions is available on request. Contact your

local GE Healthcare representative for the most current information.

GE Healthcare UK Limited

Amersham Place

Little Chalfont

Buckinghamshire, HP7 9NA

UK

GE Healthcare Europe, GmbH

Munzinger Strasse 5

D-79111 Freiburg

Germany

GE Healthcare Bio-Sciences Corp.

800 Centennial Avenue, P.O. Box 1327

Piscataway, NJ 08855-1327

USA

imagination at work

GE Healthcare Japan Corporation

Sanken Bldg., 3-25-1, Hyakunincho

Shinjuku-ku, Tokyo 169-0073

Japan

28-9501-39 AB 09/2012