VILLAGE CENTER DINING AND COMMUNITY COMMONS (VCDCC) Construction Documents University of Colorado Boulder 7 August 2015 Project No. PR007259 / HSG10910 Rev. CD Addendum 1 ‐ 5 October 2015 SECTION 08 62 00 UNIT SKYLIGHTS PART 1 ‐ GENERAL 1.01

A.

This Section includes the following: 1.

Prefabricated fixed skylights with curbs. B.

Related Sections: 1.

Division 01 Section "Sustainable Design Requirements" for recycled content of materials and low‐emitting materials. 2.

Division 06 Section "Rough Carpentry" for wood blocking at unit skylights. 3.

Division 07 Section "Sheet Metal Flashing and Trim" for flashing at unit skylights. 4.

Division 07 Section "Thermoplastic Polyolefin (TPO) Roofing". 5.

Division 07 Section "Roof Accessories" for curbs if not provided with syklights. C.

References: 1.

Aluminum Association (AA): Specifications for Aluminum Structures. 2.

American Society of Heating, Refrigerating and Air‐Conditioning Engineers (ASHRAE): ASHRAE 90.1 ‐ Energy Standard for Buildings except Low‐Rise Residential Buildings. 3.

ASTM B 221 ‐ Standard Specification for Aluminum and Aluminum‐Alloy Extruded Bars, Rods, Wire, Profiles, and Tubes. 4.

Factory Mutual System (FM Global): a.

FM ‐ Approval Guide, Chapter 18 ‐ Building Materials. b.

FM Standard 4430 ‐ Test Criteria for Heat and Smoke Vents. 1.02

SUMMARY 5.

National Fenestration Rating Council (NFRC): a.

NFRC 100 ‐ Procedure for Determining Fenestration Product U‐Factors. b.

NFRC 200 ‐ Procedure for Determining Fenestration Product Solar Heat Gain Coefficient and Visible Transmittance of Normal Incidence. 6.

North American Fenestration Standard (NAFS): AAMA/WDMA/CSA/101/I.S.2/A440 ‐ The Voluntary Performance Specification for Windows, Skylights, and Glass Doors. PERFORMANCE REQUIREMENTS A.

Skylights must conform with all federal, state and local code bodies having jurisdiction, and be designed to withstand all forces of nature deemed necessary by those code bodies for the specified project location. B.

Plastic unit skylights shall conform to recommendations of the AA Specifications for Aluminum Structures. C.

Skylights must be designed to carry a minimum 30 psf tributary roof load or greater per site as specified in the current International Building Code or prevailing model code. (Add. #1) UNIT SKYLIGHTS 08 62 00 ‐ 1 VILLAGE CENTER DINING AND COMMUNITY COMMONS (VCDCC) Construction Documents University of Colorado Boulder 7 August 2015 Project No. PR007259 / HSG10910 Rev. CD Addendum 1 ‐ 5 October 2015 D.

Skylights must be designed to carry loads as indicated on the Structural Drawings. (Add. #1) E.

Skylights must tested and labeled in accordance to AAMA/WDMA/CSA/101/I.S.2/A440 as required by Chapter 24 of the International Building Code. F.

Drop Test: 1.

A 200 lb drop test from a height of 24‐inches above the center (highest point) of dome shape and at mid points of both the 5 foot and 6 foot side (approximately 15‐inches and 18‐inches from center). 2.

The 200 lb load must be contained within a flexible bladder or sack having approximate dimensions no larger than 30‐inches long, 20‐inches wide, and 8‐inches high, filled with course sand or pea gravel. 3.

The dome must withstand the sack drop without inverting or breaking. 4.

Finished skylight domes sealed in frame must also handle 500 lb on 1 square foot point loading without inverting. 5.

The drop test must be witnessed and certified by the test laboratory which provides the NAFS certification. G.

Skylights must be certified by the NFRC. H.

Skylights must be certified by the NAFS. I.

Skylights must be Factory Mutual approved. 1.03

SUBMITTALS A.

Product Data: Manufacturer's data sheets on each product to be used, including: 1.

Preparation instructions and recommendations. 2.

Storage and handling requirements and recommendations. 3.

Installation methods. B.

LEED Submittals: 1.

Credit MRc4, Recycled Content: a.

Provide aluminum framing with overall recycled content values of minimum 80%. All secondary aluminum must comply with alloy and temper requirements outlined in article 2.02. b.

Overall recycled content must contain the following levels of post and pre consumer recycled content. 1)

Post consumer content no less than 55%. 2)

Pre consumer content no less than 22%. c.

Submit documentation outlining recycled content percentages (post and pre consumer content separately) and the weight of aluminum in proportion to the overall assembly weight. UNIT SKYLIGHTS 08 62 00 ‐ 2 VILLAGE CENTER DINING AND COMMUNITY COMMONS (VCDCC) Construction Documents University of Colorado Boulder 7 August 2015 Project No. PR007259 / HSG10910 Rev. CD Addendum 1 ‐ 5 October 2015 2.

Credit IEQc4.1, Low‐Emitting Materials, Adhesives and Sealants: Product data and material safety data sheets (MSDS) for adhesives and sealants used inside the building indicating VOC content of each product used. Indicate VOC content in g/L calculated according to 40 CFR 59, Subpart D. C.

Performance Values: Submit daylighting performance values for skylights. D.

Shop Drawings: Submit plan, section, elevation, and perspective drawings as necessary to depict each specified skylight. Include all flashing, connection, and termination details necessary for a proper and complete installation. E.

Selection Samples: For each finish product specified, two samples representing manufacturer's full range of available colors and finishes for selection by Architect. F.

Verification Samples: For each finish product specified, provide a full size sample representing actual product, color, and finish. Upon acceptance, the sample unit(s) may be used on the project provided no damage has occurred. 1.04

A.

Manufacturer Qualifications: All primary products specified in this section will be supplied by a single manufacturer with a minimum of ten years experience. B.

Installer Qualifications: All products listed in this section are to be installed by a single installer with a minimum of five years demonstrated experience in installing products of the same type and scope as specified. 1.05

DELIVERY, STORAGE, AND HANDLING A.

Store products in manufacturer's unopened packaging until ready for installation. B.

Store and dispose of hazardous materials, and materials contaminated by hazardous materials, in accordance with requirements of local authorities having jurisdiction. 1.06

A.

1.07

A.

QUALITY ASSURANCE PROJECT CONDITIONS Maintain environmental conditions (temperature, humidity, and ventilation) within limits recommended by manufacturer for optimum results. Do not install products under environmental conditions outside manufacturer's absolute limits. WARRANTY At project closeout, provide to Owner or Owners Representative an executed copy of the manufacturer's standard limited warranty against manufacturing defect, outlining its terms, conditions, and exclusions from coverage. UNIT SKYLIGHTS 08 62 00 ‐ 3 VILLAGE CENTER DINING AND COMMUNITY COMMONS (VCDCC) Construction Documents University of Colorado Boulder 7 August 2015 Project No. PR007259 / HSG10910 Rev. CD Addendum 1 ‐ 5 October 2015 PART 2 ‐ PRODUCTS 2.01

A.

2.02

A.

B.

2.03

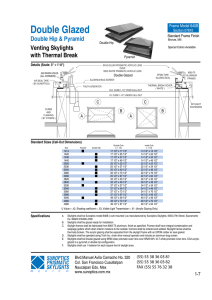

MANUFACTURER Basis of Design: Subject to compliance with requirements, provide "Sunoptics Signature Series Model 800MD (Curb Mounted) Prismatic Skylights #5050" as manufactured by Sunoptics: www.sunoptics.com, or equivalent product approved by Architect. 1.

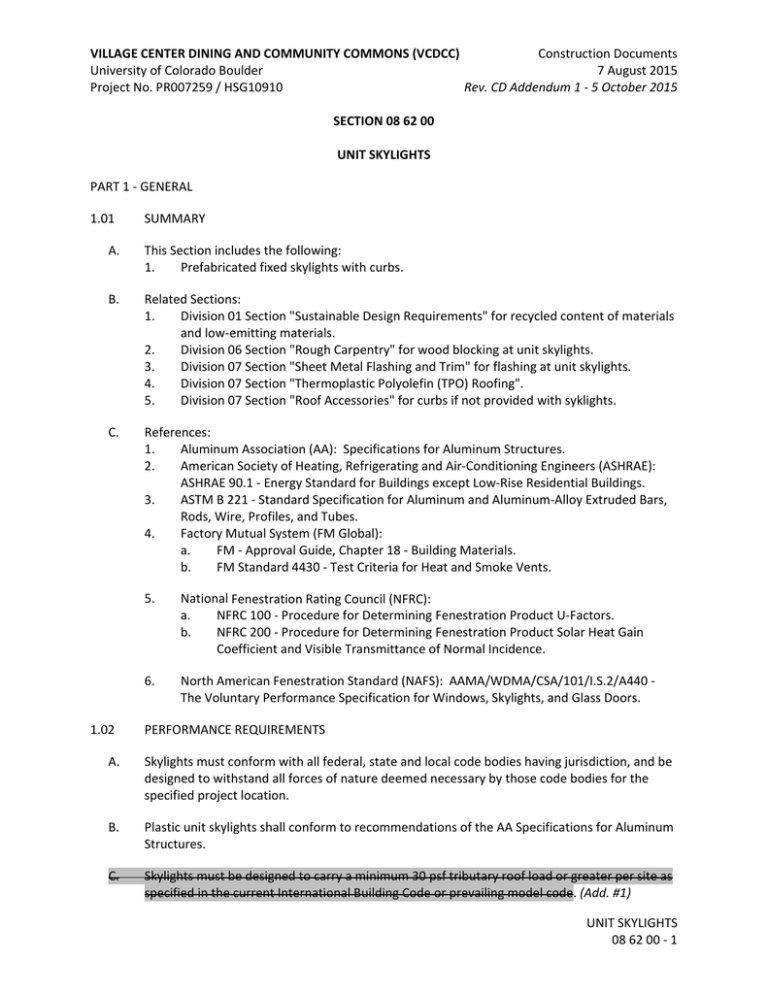

Requests for substitutions will be considered in accordance with provisions of Division 01 Section "Substitution Procedures". UNIT SKYLIGHTS Glazing Panels: 1.

Configuration: Double Hip – Double Glazed. a.

Outer Lens: SR 60 ‐ 100 percent impact modified clear prismatic acrylic of sufficient thickness recommended to meet the specified performance requirements. b.

Inner lens: SR25 White Prismatic Acrylic Lens. 2.

Energy Requirements: Glazing material must have a maximum light distribution characteristic that maximizes the shading factor. Per Addendum D of ASHRAE 90.1 – 2007, the diffusing qualities of glazing must have a minimum haze factor of 90 percent or greater. The combined inner/outer lens target values shall be as follows: a.

Light Transmittance: 67.8 percent minimum – 100 percent Class 3 Acrylic outer dome. b.

Diffusion / Haze Factor: 100 percent min. c.

Solar Heat Gain Coefficient (SHGC): 0.42 maximum. NFRC 200. d.

"U" Value: 0.74 or lower (glazing and framing) in accordance with NFRC 100 or "unlabeled skylight" default requirements of ASHRAE 90.1 – 2004. 3.

Hail Resistance Level: Class 3 as tested by certified engineering firm. Frame: 1.

ASTM B 221 alloy 6063‐T5 extruded aluminum frame with extruded aluminum dome retaining angle, Insulated thermal break, and integral condensate gutter. 2.

Finish: Manufacturer's standard mill finish. 3.

Provide pre‐installed 1‐1/2‐inch by 1/4‐inch foam rubber gasket between frame and curb. 4.

Provide weather sweep attached to frame. 5.

Curb Dimensions: Determined by skylight manufacturers inside dimension of extruded aluminum. Recommend a 1/2‐inch surround around finished and final flashed curb. ACCESSORIES A.

Fasteners (for anchorage of skylight to roof curb): #12 x 1‐1/2‐inch 300 series stainless steel screws with washers. Provide fasteners in sufficient quantity for complete installation. B.

Washers: Neoprene/stainless steel bonded washers. UNIT SKYLIGHTS 08 62 00 ‐ 4 VILLAGE CENTER DINING AND COMMUNITY COMMONS (VCDCC) Construction Documents University of Colorado Boulder 7 August 2015 Project No. PR007259 / HSG10910 Rev. CD Addendum 1 ‐ 5 October 2015 2.04

FABRICATION A.

Skylights must be factory assembled and glazed ready for installation. B.

Fabricate skylights weather tight and free of visual distortions and defects. C.

Protect exterior drip / counter flashing and drainage ports from weather and air‐borne debris. D.

Miter and full penetration weld all corners of curb and retaining frames. E.

Retaining frames that secure the glazing panels along each side under spring tension need not be welded and must be sealed with a silicone sealant along the full perimeter of the retaining frame. Skylight frames must be pre‐drilled for anchorage to roof curbs. F.

Seal glazing panels to base frame allowing for sufficient expansion and contraction. Provide exterior weep hole arrangement. PART 3 ‐ EXECUTION 3.01

A.

Do not begin installation until substrates have been properly prepared. B.

If substrate preparation is the responsibility of another installer, notify Architect of unsatisfactory preparation before proceeding. 3.02

Clean surfaces thoroughly prior to installation. B.

Prepare surfaces using the methods recommended by the manufacturer for achieving the best result for the substrate under the project conditions. A.

3.04

PREPARATION A.

3.03

EXAMINATION INSTALLATION Install in accordance with manufacturer's instructions. PROTECTION A.

Protect installed products until completion of project. B.

Touch‐up, repair or replace damaged products before Substantial Completion. UNIT SKYLIGHTS 08 62 00 ‐ 5 VILLAGE CENTER DINING AND COMMUNITY COMMONS (VCDCC) Construction Documents University of Colorado Boulder 7 August 2015 Project No. PR007259 / HSG10910 Rev. CD Addendum 1 ‐ 5 October 2015 3.05

INDOOR AIR QUALITY AND CONSTRUCTION WASTE MANAGEMENT A.

Manage indoor air quality in accordance with the provisions of Divisions 01 Section "Sustainable Design Requirements" and other sections as applicable. B.

Manage construction waste in accordance with provisions of Division 01 Section "Construction Waste Management and Disposal." END OF SECTION UNIT SKYLIGHTS 08 62 00 ‐ 6 08 62 00 Unit Skylights Product data sheets

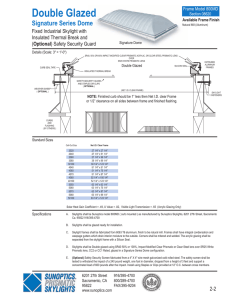

Signature

Series Dome

Fixed Industrial Skylight

Frame Model 800MD

AVAILABLE CERTIFICATIONS

FM Approval # 4431

High Velocity Hurricane Zone Approved

CE Certified

Class 1, Class 3 and Class 4 Hail Ratings Available (Class 1 Default)

PRODUCT PROFILE

No Exceptions Taken

UCB HDS

Please make sure Group 14 also

reviews/comments on this

submittal

DGZ LENSCLWH Option Shown

Details Not To Scale

INSULATED THERMAL BREAK

WEATHER SWEEP

EXTRUDED

ALUMINUM

FRAMES

TRIPLE LAYER

SILICON OR

URETHANE SEAL

Double Glazed

CURB SEAL TAPE

SAFETY-SECURITY GUARD

AND STAPLES OR CLIPS

( OPTIONAL )

(NET I.D. CLEAR FRAME)

SKYLIGHT

FASTENERS

NOTE: Finished curb should be 1” less than Net I.D. Clear Frame

or 1/2” clearance on all sides between frame and finished flashing.

ROOF CURB

ORDERED

SEPARATELY

SPECIFICATIONS

Skylights shall be Sunoptics model 800MD ( curb mounted ) as manufactured

by Sunoptics Skylights, an Acuity Brands Company, 6201 27th Street,

Sacramento CA 95822 916/395-4700.

Skylights shall be glazed ready for installation.

Skylight frames shall be fabricated from 6063 T6 aluminum, finish to be natural

mill. Frames shall have integral condensation and weepage gutters which drain

interior moisture to the outside. Corners shall be mitered and welded. The

acrylic glazing shall be separated from the skylight frame with a Silicon Seal.

Testing was performed on HVHZ skylights per Florida Building Code, Test

Protocols for High Velocity Hurricane Zone (HVHZ), Protocols TAS 201, TAS 202

and TAS 203. The samples tested met the performance requirements set forth in

the protocols for a ±60.0 psf Design Pressure rating.

Note: Specifications subject to change without notice.

Type

SHGC

U-Value

VLT

Single Glazed Acrylic CL1

.51

n/a

.74

Skylights shall be glazed using 50% or 100%, Impact Modified CC2 Prismatic

Acrylic and/or CC1 rated, Prismatic polycarbonate in a Signature Series

Dome configuration.

Single Glazed Poly

.51

n/a

.70

Double Glazed

.42

.74

.68

FM Approved Skylights shall be Double glazed using CLEAR ARMOR® Clear

Polycarbonate Prismatic over CLEAR ARMOR® High White Polycarbonate

Prismatic lens, CC1/Class A Rated, FM Approved, 5 year hail proof warranted.

Doubled Glazed (FM)

.42

.74

.64

FM Approved Skylights shall be tested and approved under Factory Mutual

#4431 testing method for fixed skylights. Class A / CC1 flame rating. Standard

Size units up to 5080 are tested and certified to AAMA/WDMA/CSA101/I.S.2/

A440 to comply with section 2405.5 of the International Building Code.

.42

.74

.65

Poly/Acrylic

.33

.62

.62

.33

.62

.63

Note: Multi-glazed units default to include Insulated Thermal Break (ITBR), Curb

Seal Tape, Weather Sweep (WSW) and screws. Single-glazed units default to not

included any of these options.

Acrylic/Acrylic

Poly/Poly

Double Glazed (HVHZ)

Triple Glazed Class 1

Acrylic/Acrylic/Acrylic

Triple Glazed Class 3

Acrylic/Acrylic/Acrylic

6201 27th Street, Sacramento, CA 95822 | (916) 395-4700 | (800) 289-4700 | (916) 395-9015 fax | sccq01@acuitybrands.com | www.sunoptics.com

1 of 2

ORDERING LOGIC

Fixture

SIG Signature Series

Incorrect

Lens Colors

LENSWH

LENSCL

LENSWHCL

LENSCLWH

LENSWHWH

LENSCLCL

LENSWHWHWH

LENSCLCLCL

LENSCLWHCL

LENSWHCLWH

LENSCLWHWH

LENSWHCLCL

ID Frame Call-Out

2020 27-1/4” x 27-1/4”

2040 27-1/4” x 51-1/4”

2080 27-1/4” x 99-1/4”

20100 27-1/4” x 123-1/4”

3030 39-1/4” x 39-1/4”

3050 39-1/4” x 63-1/4”

3060 39-1/4” x 75-1/4”

3080 39-1/4” x 99-1/4”

30100 39-1/4” x 123-1/4”

4040 51-1/4“ x 51-1/4”

4050 51-1/4“ x 63-1/4”

4060 51-1/4” x 75-1/4”

4070 51-1/4” x 87-1/4”

4080 52-1/4” x 100-1/4”

40100 52-1/4” x 123-1/4”

5050 63-1/4” x 63-1/4”

5060 63-5/8” x 75-5/8”

5558 67-3/4” x 70-3/4”

5070 63-1/4” x 87-1/4”

5080 63-1/4” x 99-1/4”

50100 63-1/4” x 123-1/4”

Use CUST for Custom sized units.

Signature Series Dome

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

692mm x 692 mm

692mm x 1302mm

692mm x 2521mm

692mm x 3131mm

997mm x 997mm

997mm x 1607mm

997mm x 1911mm

997mm x 2521mm

997mm x 3131mm

1302mm x 1302mm

1302mm x 1607mm

1302mm x 1911mm

1302mm x 2216mm

1327mm x 2546mm

1327mm x 3131mm

1607mm x 1607mm

1616mm x 1921mm

1721mm x 1797mm

1607mm x 2216mm

1607mm x 2521mm

1607mm x 3131mm

ID Frame Width

W27.250 (692 mm)

W27.250 (692 mm)

W27.250 (692 mm)

W27.250 (692 mm)

W39.250 (997 mm)

W39.250 (997 mm)

W39.250 (997 mm)

W39.250 (997 mm)

W39.250 (997 mm)

W51.250 (1302 mm)

W51.250 (1302 mm)

W51.250 (1302 mm)

W51.250 (1302 mm)

W52.250 (1327 mm)

W52.250 (1327 mm)

W63.250 (1607 mm)

W63.625 (1616 mm)

W67.750 (1721 mm)

W63.250 (1607 mm)

W63.250 (1607 mm)

W63.250 (1607 mm)

ID Frame Length

L27.250 (692 mm)

L51.250 (1302 mm)

L99.250 (2521 mm)

L123.250 (3131 mm)

L39.250 (997 mm)

L63.250 (1607 mm)

L75.250 (1911 mm)

L99.250 (2521 mm)

L123.250 (3131 mm)

L51.250 (1302 mm)

L63.250 (1607 mm)

L75.250 (1911 mm)

L87.250 (2216 mm)

L100.250 (2546 mm)

L123.250 (3131 mm)

L63.250 (1607 mm)

L75.625 (1921 mm)

L70.750 (1797 mm)

L87.250 (2216 mm)

L99.250 (2521 mm)

L123.250 (3131 mm)

Glazing

SGZ Single Glaze

DGZ Double Glaze

TGZ Triple Glaze

Lens Material

CC1HVHZ Polycarbonate

CC1

Polycarbonate

CC2CL1

Acrylic Class 1

CC2CL3

Acrylic Class 3

W__.___ Custom Width L__.___ Custom Width

Unit Type

White (Single Glaze Default) 1

800MD Standard Frame

Clear 1

800SC So-Cal Skylight

White Clear 2

805SC Continuous Vent

Clear White (Double Glaze Default) 2

White White 2

Clear Clear 2

White White White 3

Clear Clear Clear 3

Clear White Clear (Triple Glaze Default) 3

White Clear White 3

Clear White White 3

White Clear Clear 3

Continous Venting

(blank) No venting

1BL

1 Blade Continuous Vent

2BL

2 Blade Continuous Vent

3BL

3 Blade Continuous Vent

4BL

4 Blade Continuous Vent

5BL

5 Blade Continuous Vent

6BL

6 Blade Continuous Vent

7BL

7 Blade Continuous Vent

8BL

8 Blade Continuous Vent

9BL

9 Blade Continuous Vent

10BL 10 Blade Continuous Vent

Skylight Frame Finish

MI Mill (Default)

WH White

BZ Bronze

CF Custom

Options

(blank)

FMRTG

HVHZ

CE

LARR

ITBR

NITBR

WSW

NWSW

SCRN

No Options

Factory Mutual Approved 4,5

High Velocity Hurricane Zone 4,5

European Standard Certified 4

Los Angeles Approved 4

Insulated Thermal Break

No Insulated Thermal Break

Weather Sweep 6

No Weather Sweep

Bug Screen 7

1) Single Glaze

2) Double Glaze

3) Triple Glaze

4) Certified units can ONLY be Single or Double Glazed, and are NOT available for the following sizes: 20100, 30100, 40100, 5558, 50100

5) FMRTG and HVHZ options available only with CC1HVHZ or CC1 Lens Material only

6) Weather Sweep available with Mill finish only

7) Bug Screen available with Continuous Venting units only

6201 27th Street, Sacramento, CA 95822 | (916) 395-4700 | (800) 289-4700 | (916) 395-9015 fax | sccq01@acuitybrands.com | www.sunoptics.com

©2012 Acuity Brands Lighting, Inc. All Rights Reserved.

01/08/2013

2 of 2