IMPROVEMENT OF POWER QUALITY OF CFL BULBS USING

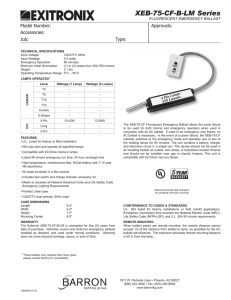

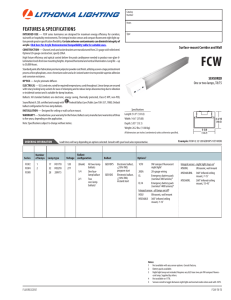

advertisement