Banks Engineering

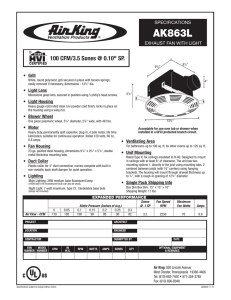

advertisement

Abbreviations, Fan Terminology and Definitions ARR. Arrangement of fan. BHP Brake horsepower, the fan’s power consumption. CCW Counterclockwise. Used to describe the rotation of an impeller. Rotation is determined by viewing the impeller from the drive side on centrifugal fans. CFM Cubic feet per minute, the volume of air moved per minute. CL. Class of fan. The class identifies the limit of the fan’s performance range. CW Clockwise. Used to describe the rotation of an impeller. Rotation is determined by viewing the impeller from the drive side on centrifugal fans. dBA Estimated sound pressure level in the space using “A” weighting. DWDI EFFICIENCY FPM A Ratio of the useful energy (work) provided by a system to the energy supplied to it. Used to provide a relative performance comparison of fans. Feet per minute, the velocity of the airstream. HP Horsepower, the fan’s motor size. I.D. Inside diameter of fan, duct or transition. Lp Sound Pressure Level. Describes the loudness level of the sound, like the brightness level of a light bulb. This value varies with the distance from the sound source and the environment surrounding the sound source. Sound pressure is usually expressed in decibels with a reference level to 0.0002 microbars. Lw Sound Power Level. Describes the total amount of acoustical energy the fan emits, like the watt rating of a light bulb describes the total amount of energy the light emits. This value is independent of location, distance, and environment. Sound power is usually expressed in decibels with a reference level to 10–12 watts. LwA Sound Power Level ‘A’ weighted. This is a single value representing the fan’s overall sound power level. ‘A’ weighting adjusts the sound power level for the response of the human ear. This value is often used in the calculation of sound pressure levels. ME Mechanical efficiency (or Total efficiency). Mechanical efficiency is a ratio of the total fan power output to the power supplied to the fan. Mechanical efficiency uses total pressure, which includes the kinetic energy, to calculate the efficiency. O.D. OV RPM Outside diameter of fan, duct or transition. Outlet velocity, the average air velocity at the outlet of the fan. Outlet velocity is calculated by dividing the CFM by outlet area. Revolutions per minute, the number of rotations the fan shaft makes per minute. SE Static efficiency. Static efficiency is a ratio of the fan power output to the power supplied to the fan. Static efficiency uses static pressure, which does not include the kinetic energy, to calculate the efficiency. It can be found by multiplying the Mechanical efficiency by the ratio of the fan static pressure to the fan total pressure. SP Static pressure is the measure of the potential energy of the airstream. SP acts equally in all directions. It is this pressure in the duct that tends to burst or collapse the duct. SWSI 2 Double width double inlet. Single width single inlet. TP Total pressure, the measure of the energy content of the airstream. It is the sum of static pressure (SP) and velocity pressure (VP). TS Tip speed, the speed of the fan blade tip. VP Velocity pressure, the measure of the energy content of the airstream. Velocity pressure acts in the direction of the airflow. It is the pressure necessary to accelerate the air. Engineering Resource Guide Formulas For Fan Applications Mechanical Efficiency, ME = CFM x TP x 100 6356 x BHP Static Efficiency, SE = CFM x SP x 100 6356 x BHP Total Pressure, TP = Velocity, V CFM = Area in Sq. Ft. Velocity Pressure, VP = (where SP is in inches H2O) SP + VP 2 V (1096.7 ) x density in pounds per cubic foot If the density is 0.075 lbs/ft3, the equation for VP reduces to = 2 V ) (4005 SYSTEM CURVE EQUATION The following formula is used to find other points on the system line when SP1 and CFM1 are known. Most, but not all, systems follow this relationship. SP2 = SP1 (CFM CFM ) 2 2 1 How to Use the Fan Laws for Performance Changes There are two reasons why a fan’s performance may need to be changed: ● The system or area requires additional airflow (CFM). ● The actual system static pressure (SP) is different from the design value. When these situations occur, it is important to understand how they can affect the fan’s performance. The effect on the fan’s performance can be shown by using the Fan Laws, shown below. FAN LAW EQUATIONS RPM2 CFM2 = RPM1 x CFM1 RPM2 SP2 = RPM1 ( RPM2 BHP2 = RPM1 ( 3. After installing the fan, the Plant Manager wants to increase the airflow into the plant to 41,500 CFM. The fan laws are used to determine how this fan will be affected by the new system requirements. 4. The known values are CFM1 = 33,120 CFM CFM2 = 41,500 CFM BHP1 = 20.01 BHP 6. Using the fan law equations, the unknown values are calculated as follows 41,500 x RPM2 = 33,120 620 = 777 RPM2 x SP1 SP2 x BHP1 BHP2 777 = 620 2 ( ) x 2.5" = 3.93" SP 777 = ( 620 ) x 20.01 = 39.39 BHP 2 3 3 ) RPM2 = ?? SP2 = ?? BHP2 = ?? 5. The unknown values are 2 ) SP1 = 2.5" SP RPM1 = 620 RPM 2 7. What does this information tell us? Subscript 1 = existing conditions Subscript 2 = new conditions EXAMPLE 1. Assume a customer requires a fan to operate at 33,120 CFM at 2.5" SP, at standard air density. Per the specifications, a BC backward inclined fan is required. 2. Based on the above information, from Twin City Fan & Blower’s Bulletin 300, a 490 BC SWSI, CL. II fan is selected. This fan will operate at 620 RPM and 20.01 BHP to meet the required performance. Engineering Resource Guide In order to use the same fan for an airflow of 41,500 CFM, the RPM needs to be increased to 777 RPM. The new performance increases the fan’s horsepower requirement from 25 HP to 50 HP. If the fan is sped up to 777 RPM the motor must be resized. IMPORTANT NOTE: The new RPM should be checked to make sure it does not exceed the maximum allowable RPM for the fan that is installed. If this information is not provided in the catalog or you would like Twin City Fan & Blower to review the application, please contact your local representative, the factory, or the Twin City Fan Selector® program. 3 Performance Correction for Temperature & Altitude In each fan catalog the performance tables are based on standard air density, which is defined as dry air at 70°F at sea level (29.92 Hg barometric pressure). This is equal to 0.075 lb./ft3 density. The fan performance tables provide the fan RPM and brake horsepower requirements for the given CFM and static pressure, at standard air density. When the fan performance is not at standard conditions, the performance must be converted to standard conditions before entering the fan performance tables. The fan performance is converted to standard conditions by using the correction factor in the Temperature and Altitude Correction Chart shown below. The following are examples explaining how to convert the fan’s performance to standard conditions. Temperature and Altitude Correction Factors AIR TEMP °F –50 0 50 70 100 150 200 250 300 350 400 450 500 550 600 650 700 750 800 850 900 950 1000 0 1000 2000 29.92 1.293 1.152 1.039 1.000 .946 .869 .803 .747 .697 .654 .616 .582 .552 .525 .500 .477 .457 .439 .420 .404 .389 .376 .363 28.86 1.247 1.111 1.003 .964 .912 .838 .774 .720 .672 .631 .594 .561 .532 .506 .482 .460 .441 .423 .404 .391 .376 .363 .350 27.82 1.201 1.071 .967 .930 .880 .808 .747 .694 .648 .608 .573 .542 .513 .488 .465 .444 .425 .407 .389 .376 .363 .350 .338 ALTITUDE IN FEET ABOVE SEA LEVEL 3000 4000 5000 6000 7000 8000 BAROMETRIC PRESSURE IN INCHES OF MERCURY 26.82 25.84 24.90 23.98 23.09 22.22 1.159 1.116 1.076 1.036 .997 .960 1.032 .995 .959 .923 .889 .856 .932 .897 .864 .833 .801 .772 .896 .864 .832 .801 .772 .743 .848 .818 .787 .758 .730 .703 .770 .751 .723 .696 .671 .646 .720 .694 .668 .643 .620 .596 .669 .645 .622 .598 .576 .555 .624 .604 .580 .558 .538 .518 .586 .565 .544 .524 .505 .486 .552 .532 .513 .493 .476 .458 .522 .503 .484 .466 .449 .433 .495 .477 .459 .442 .426 .410 .470 .454 .437 .421 .405 .390 .448 .432 .416 .400 .386 .372 .427 .412 .397 .382 .368 .354 .410 .395 .380 .366 .353 .340 .393 .379 .365 .351 .338 .326 .375 .362 .350 .336 .323 .311 .363 .349 .336 .324 .312 .300 .349 .336 .324 .312 .300 .289 .337 .325 .313 .301 .290 .279 .325 .314 .302 .291 .280 .270 9000 10000 15000 21.39 .924 .824 .743 .714 .676 .620 .573 .533 .498 .467 .440 .416 .394 .375 .352 .341 .326 .313 .300 .289 .279 .269 .259 20.58 .889 .792 .715 .688 .651 .598 .552 .514 .480 .450 .424 .401 .380 .361 .344 .328 .315 .303 .290 .279 .268 .259 .250 16.89 .729 .650 .586 .564 .534 .490 .453 .421 .393 .369 .347 .328 .311 .296 .282 .269 .258 .248 .237 .228 .220 .212 .205 How To Convert the Fan’s Performance to Standard Conditions When Operating Conditions Are Known: Assume a 365 BC, SWSI fan is to handle 17,000 CFM, 2.5" SP, at 300°F and 3000 ft. altitude. This fan is not operating at standard conditions; therefore, the performance needs to be converted to standard conditions to find the fan’s speed and brake horsepower. The fan’s performance is converted to standard conditions as follows: 1. From the table above, the correction factor for 300°F and 3000 ft. altitude is 0.624. 2. The static pressure, at standard air density, is calculated by dividing the operating SP by the correction factor; i.e., 2.5" ÷ 0.624 = 4" SP. The static pressure is 4" at standard air density. 3. Knowing the CFM and the static pressure, at standard air density, the fan RPM and BHP can be found. Enter the 365 BC, SWSI fan performance table (Bulletin 300) with 17,000 CFM and 4" SP. 4. In this example, the RPM and BHP are between the values listed in the performance table; therefore, the RPM and BHP are determined by interpolation. The RPM is determined by the following equation RPM – 915 17,000 – 16,850 17,620 – 16,850 = 929 – 915 4 6. Subtracting the top and bottom values reduces the equation to 150 RPM – 915 770 = 14 7. Dividing the values on the left side and multiplying each side by 14 reduces the equation to 0.19 x 14 = RPM – 915 8. Multiplying the values on the left side and adding 915 to each side reduces the equation to 2.66 + 915 = RPM 9. Solving the left side of the equation results in a fan RPM equal to RPM = 918 RPM 10. Next, the BHP is determined by the following equation 17,000 – 16,850 BHP – 14.20 17,620 – 16,850 = 15.03 – 14.20 11. Subtracting the top and bottom values reduces the equation to 150 BHP – 14.20 770 = 0.83 12. Dividing the values on the left side and multiplying each side by 0.83 reduces the equation to 0.19 x 0.83 = BHP – 14.20 Engineering Resource Guide 13. Multiplying the values on the left side and adding 14.20 to each side reduces the equation to 0.16 + 14.20 = BHP 14. Solving the left side of the equation results in a fan BHP equal to BHP = 14.36 BHP Conclusions — For this example, the required fan RPM is 918 RPM and the brake horsepower at standard conditions is 14.36 BHP. The brake horsepower, 14.36 BHP at standard conditions (70°F at sea level), is also referred to as the cold or starting brake horsepower. If the fan is installed at a higher altitude than sea level, such as described in this example, the cold or starting brake horsepower at that altitude is determined by the following equation Cold BHP at altitude = BHPstd x Correction Factor at Required Elevation and 70°F For this example, the cold or starting brake horsepower at 3000 ft. altitude and 70°F is 14.36 x 0.896 = 12.87 BHP, cold BHP @ 3000 ft. altitude To determine the BHP at operating conditions, 300°F and 3000 ft. altitude, multiply the BHP at standard conditions by the factor for these conditions: 14.36 x 0.624 = 8.96 BHP at operating conditions, 300°F and 3000 ft. altitude The fan performance information for 17000 CFM, 2.5" SP, at 300°F and 3000 ft. altitude is ● 918 RPM ● 8.96 BHP at operating conditions (300°F and 3000 ft. altitude) ● 12.87 BHP (cold BHP, 70°F and 3000 ft. altitude) ● 14.36 BHP at standard conditions or cold BHP at 70°F and sea level ● 4" SP at standard conditions When Operating Density Is Known: Assume a 365 BC, SWSI fan is to handle 23,500 CFM, 3.0" SP, at 0.06364 lb./ft3. This fan is not operating at standard conditions; therefore, the performance needs to be converted to standard conditions to find the fan’s speed and brake horsepower. The fan’s performance is converted to standard conditions as follows: 1. Using the operating density of 0.06364 lb./ft3, the correction factor is determined by dividing the operating density by the standard density, 0.075 lb./ft3. Operating Density Correction Factor = Standard Density = 0.848 2. The static pressure at standard air density is calculated by dividing the operating SP by the conversion factor, i.e., 3.0" ÷ 0.848 = 3.5" SP. The static pressure is 3.5" at standard air density. 3. Knowing the CFM and the static pressure at standard air density, the fan RPM and BHP can be found. Enter the 365 BC, SWSI fan performance table (Bulletin 300) with 23,500 CFM and 3.5" SP. 4. This example also finds the RPM and BHP between the values listed in the performance table; therefore, the RPM and BHP are determined by interpolation. 5. The RPM is determined by the following equation RPM – 1015 23,500 – 22,980 24,510 – 22,980 = 1054 – 1015 6. Subtracting the top and bottom values reduces the equation to 520 RPM – 1015 1530 = 39 7. Dividing the values on the left side and multiplying each side by 39 reduces the equation to 0.3 x 39 = RPM – 1015 8. Multiplying the values on the left side and adding 1015 to each side reduces the equation to 13 + 1015 = RPM Engineering Resource Guide 9. Solving the left side of the equation results in a fan RPM equal to RPM = 1028 RPM 10. Next, the BHP is determined by the following equation BHP – 20.15 23,500 – 22,980 24,510 – 22,980 = 22.48 – 20.15 11. Subtracting the top and bottom values reduces the equation to 520 BHP – 20.15 1530 = 2.33 12. Dividing the values on the left side and multiplying each side by 2.33 reduces the equation to 0.34 x 2.33 = BHP – 20.15 13. Multiplying the values on the left side and adding 20.15 to each side reduces the equation to 0.79 + 20.15 = BHP 14. Solving the left side of the equation results in a fan BHP equal to BHP = 20.94 BHP Conclusions — For this example, the required fan RPM is 1028 RPM and the brake horsepower is 20.94 BHP at standard conditions. The brake horsepower, 20.94 BHP at standard conditions (70°F at sea level), is also referred to as the cold or starting brake horsepower. To determine the BHP at operating conditions, multiply the BHP at standard conditions by the conversion factor for these conditions: 20.94 x 0.848 = 17.76 BHP at operating conditions The fan performance information for 23,500 CFM, 3.0" SP, at 0.06364 lb./ft3 is ● 1028 RPM ● 17.76 BHP at operating conditions of 0.06364 lb./ft3 ● 20.94 BHP at standard conditions (70°F at sea level) ● 3.5" SP at standard conditions. 5 Capture Velocities (or Airflow) For Exhaust Hoods Exhaust hoods are critical devices used to protect workers from process fumes or dust. Exhaust hoods induce airflow from the work station to the hood to remove contaminants or particles from the work area. The “capture velocity” is the air velocity required to move the contaminants from the work station to the hood. Capture velocities and hood designs depend on the type of fume or dust being removed. Hood designs include canopy hoods, downdraft hoods, booth-type hoods, slot hoods, etc. The chart at right shows the capture velocity and hood design for a given process. PROCESS Abrasive Blasting Auto Parking Garage Bag Loading for Grain Elevators, Feed Mills, Flour Mills Ceramic: Dry Pan Dry Press Spraying (Lead Glaze) Cooling Tunnels (Foundry) Core Sanding (on Lathe) Crushers & Grinders Degreasing; Evaporation From Tanks Forge (Hand) Furniture Stripping Tank Metal Cutting Bandsaw Metal Spraying Outboard Motor Test Tank Packaging Machines Note: The flow rates and velocities shown in the charts on this page are based on standard air density. For conditions not at standard density such as high temperature, moisture or elevation, convert the operating conditions to standard air conditions using the correction factors found in the Temperature and Altitude Correction Chart on page 4. TYPE OF HOOD Downdraft Hood Crossdraft Hood 2 Level Canopy Hood Enclosure Hood Local at Die Local at Die At Supply Bin Booth Hood Enclosure Hood Downdraft Hood Under Work Enclosure Hood Canopy Hood Booth Hood Slot Hood Booth Hood Booth Hood Spray Booth Side Draft Hood Booth Hood Downdraft Hood Complete Enclosure Canopy Hood Canopy Hood Canopy Hood Hood Against Wall Island Type Hood Booth Hood Steam Kettles Varnish Kettles Wire Impregnating Canopy Hood Canopy Hood Covered Tanks Paper Machine Pickling Metals Plating Metals Restaurant Range AIRFLOW OR CAPTURE VELOCITY 60-100 CFM/ft2 of Floor 100 CFM/ft2 of Wall 500 CFM/Parking Space 100 CFM/ft2 Open Face Area 500 FPM Maximum 200 FPM Thru All 0penings 500 CFM 500 CFM 500 CFM 400 FPM (Face) 75-100 CFM Per Running Foot of Enclosure 100 FPM at Source 200 FPM Thru Openings 50-100 FPM 200 FPM at Face 45 CFM/ft2 of Tank Area 225 CFM/ft2 of Open Area a) 150 CFM/ft2 of Face Area, Non-toxic b) 200 CFM/ft2 of Face Area, Toxic 200 CFM/ft2 of tank openings 50-100 FPM at Face 95-150 FPM Down 100-400 FPM Opening 200-300 FPM at Face 200-250 FPM 225-250 FPM 80 CFM/ft2 of Hood Area 125 CFM/ft2 of Hood Area a) 200 CFM/ft2 for Face Area Up To 4 ft2 b) 150 CFM/ft2 for Face Area Over 4 ft2 150 FPM at Face 200-250 FPM at Face 200 CFM/ft2 of Opening From American Conference of Governmental Industrial Hygienists: Industrial Ventilation (ACGIH®): A Manual of Recommended Practice, 22nd Ed. Copyright 1995, Cincinnati, OH. Reprinted with permission. Minimum Duct Velocities For Conveying Materials After the exhaust hood removes the fumes or dust from the work station, the velocity downstream of the hood must be high enough to prevent the material from clogging the ductwork. The velocity downstream of the hood is defined as the minimum duct velocity and is determined by the type of material being conveyed through the duct. The table at right shows typical duct velocities for various materials. AVG. VELOCITY TO CONVEY MATERIAL (FPM) MATERIAL VERY FINE LIGHT DUST: Cotton Lint, Wood Flour, Litho Powder DRY DUSTS & POWDERS: Fine Rubber Dust, Jute Lint, Cotton Dust, Light Shavings, Soap Dust AVERAGE INDUSTRIAL DUST: Grinding Dust, Buffing Lint-Dry, Wool Jute Dust-Shaker Waste, Shoe Dust, Granite Dust, Silica Flour, General Material Handling, Brick Cutting, Clay Dust, Foundry-General, Limestone Dust, Packaging & Weighing Asbestos Dust in Textile Industries HEAVY DUSTS Sawdust-Heavy & Wet, Metal Turnings, Foundry Tumbling Barrels & Shake-Out, Sandblast Dust, Wood Blocks, Brass Turnings, Cast Iron Boring Dust, Lead Dust HEAVY OR MOIST: Lead Dusts with Small Chips, Moist Cement Dust, Asbestos Chunks From Transite Pipe Cutting Machines, Buffing Lint-Sticky, Quick-Lime Dust 2500–3000 3000–4000 3500–4000 4000–4500 4500 & Up From American Conference of Governmental Industrial Hygienists: Industrial Ventilation (ACGIH®): A Manual of Recommended Practice, 22nd Ed. Copyright 1995, Cincinnati, OH. Reprinted with permission. 6 Engineering Resource Guide Air Change Rates for Ventilation The volume of fresh air (CFM) required to a given area can be easily estimated by the “air change method.” This method is recommended for standard commercial type applications where environmental control of hazards, heat and/or odors is not necessary. Other items to consider when determining the number of air changes required are: ● Local code requirements on air changes. ● How the space is used. ● The type of climate in the area, e.g., hot, moderate or cold. The air volume (CFM) can be estimated by using the following equation and the chart at right that defines the number of air changes for given area. Volume of Air = Room Volume (ft3) No. of Air Changes (min./change) AREA TYPE ASSEMBLY HALL BAKERY BAR BOWLING ALLEY BOILER ROOM CAFETERIA CHURCH CLASSROOM ENGINE ROOM FACTORY FORGE SHOP FOUNDRY GENERATOR ROOM HOSPITAL KITCHEN LABORATORY LAUNDRY LOCKER ROOM MACHINE SHOP MILL OFFICE RESTAURANT RETAIL STORE RESTROOM/TOILET TRANSFORMER ROOM WAREHOUSE MINUTES PER CHANGE 3-10 1- 3 2- 4 3- 7 1- 3 3- 5 4-10 4- 6 1- 3 2- 7 1- 2 1- 5 2- 5 4- 6 2- 3 2- 5 2- 4 4-15 3- 6 3- 8 2- 8 5-10 5-10 2- 5 1- 5 4-10 Velocity-to-Velocity Pressure Conversion Chart Values based at Standard Density, 0.075lbs/ft3. Calculated by the formula: VP = 2 ( ) V 4005 For other densities use the formula: VP = 2 ( ) x Density V 1097 Where: V is velocity in ft./min. Density is in lb/ft3. Engineering Resource Guide V-VELOCITY FPM 100 200 300 400 500 600 700 800 900 1000 1100 1200 1300 1400 1500 1600 1700 1800 1900 2000 2100 2200 2300 VP-VELOCITY PRESSURE IN. WATER 0.0006 0.0025 0.0056 0.010 0.016 0.023 0.031 0.040 0.051 0.063 0.076 0.090 0.106 0.123 0.141 0.160 0.181 0.203 0.226 0.250 0.276 0.303 0.331 V-VELOCITY FPM 2400 2500 2600 2700 2800 2900 3000 3100 3200 3300 3400 3500 3600 3700 3800 3900 4000 4100 4200 4300 4400 4500 4600 VP-VELOCITY PRESSURE IN. WATER 0.360 0.391 0.423 0.456 0.490 0.526 0.563 0.601 0.640 0.681 0.723 0.766 0.810 0.856 0.903 0.951 1.00 1.05 1.10 1.16 1.21 1.27 1.32 V -VELOCITY FPM 4700 4800 4900 5000 5100 5200 5300 5400 5500 5600 5700 5800 5900 6000 6100 6200 6300 6400 6500 6600 6700 6800 6900 7000 VP-VELOCITY PRESSURE IN. WATER 1.38 1.44 1.50 1.56 1.63 1.69 1.76 1.82 1.89 1.96 2.03 2.10 2.18 2.25 2.33 2.40 2.48 2.56 2.64 2.72 2.81 2.89 2.98 3.06 7 Definitions of English & Metric Units °C cfm cm °F ft fpm g Hg hp hpm hr. = = = = = = = = = = = degrees Celsius cubic feet per minute centimeter degrees Fahrenheit foot feet per minute gram mercury horsepower metric horsepower hour in. kg km kPa l lb. lbf lbm m min. = = = = = = = = = = inch kilogram kilometer kilopascal liter pound pound force pound mass meter minute mm N Nm oz. psi rpm rps sec. W wg = = = = = = = = = = millimeter Newton Newton-meter ounce pounds per square inch revolutions per minute revolutions per second second Watts water gauge Pressure Equivalent Chart This chart shows pressure values in inches water gauge and the equivalent pressure in other commonly used units. INCHES WATER (IN. WG) 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 8 INCHES MERCURY (IN. Hg) 0.0733 0.1467 0.2200 0.2934 0.3667 0.4400 0.5134 0.5867 0.6601 0.7334 0.8067 0.8801 0.9534 1.027 1.100 1.173 1.247 1.320 1.393 1.467 1.540 1.613 1.687 1.760 1.834 1.907 1.980 2.054 2.127 2.200 2.274 2.347 2.420 2.494 2.567 2.640 2.714 2.787 2.860 2.934 3.007 3.080 3.154 3.227 3.300 OUNCES PER SQ. IN. (oz/in2) 0.577 1.154 1.730 2.307 2.884 3.461 4.038 4.614 5.191 5.768 6.345 6.922 7.498 8.075 8.652 9.229 9.806 10.382 10.959 11.536 12.113 12.690 13.266 13.843 14.420 14.997 15.574 16.150 16.727 17.304 17.881 18.458 19.034 19.611 20.188 20.765 21.342 21.918 22.495 23.072 23.649 29.226 24.802 25.379 25.956 POUNDS PER SQ. IN. (lb/in2) 0.0360 0.0720 0.1081 0.1441 0.1801 0.2161 0.2522 0.2882 0.3242 0.3602 0.3962 0.4323 0.4683 0.5043 0.5403 0.5763 0.6124 0.6484 0.6844 0.7204 0.7565 0.7925 0.8285 0.8645 0.9005 0.9366 0.9726 1.009 1.045 1.081 1.117 1.153 1.189 1.225 1.261 1.297 1.333 1.369 1.405 1.441 1.477 1.513 1.549 1.585 1.621 PASCALS (Pa) KILOPASCALS (kPa) 250 500 750 990 1240 1490 1740 1990 2240 2480 2730 2980 3230 3480 3730 3970 4220 4470 4720 4970 5220 5460 5710 5960 6210 6460 6710 6950 7200 7450 7700 7950 8200 8440 8690 8940 9190 9440 9690 9930 10180 10430 10680 10930 11180 0.25 0.50 0.75 0.99 1.24 1.49 1.74 1.99 2.24 2.48 2.73 2.98 3.23 3.48 3.73 3.97 4.22 4.47 4.72 4.97 5.22 5.46 5.71 5.96 6.21 6.46 6.71 6.95 7.20 7.45 7.70 7.95 8.20 8.44 8.69 8.94 9.19 9.44 9.69 9.93 10.18 10.43 10.68 10.93 11.18 MILLIMETERS WATER (mm WG) 25.4 50.8 76.2 101.6 127.0 152.4 177.8 203.2 228.6 254.0 279.4 304.8 330.2 355.6 381.0 406.4 431.8 457.2 482.6 508.0 533.4 558.8 584.2 609.6 635.0 660.4 685.8 711.2 736.6 762.0 787.4 812.8 838.2 863.6 889.0 914.4 939.8 965.2 990.6 1016.0 1041.4 1066.8 1092.2 1117.6 1143.0 Engineering Resource Guide English & Metric Conversions AREA MULTIPLY in 2 ft2 m2 BY 0.006944 0.0006452 645.16 144 0.09290 92903 10.76 1550 106 PRESSURE TO OBTAIN ft2 m2 mm2 in2 m2 mm2 ft2 in2 mm2 MULTIPLY psi in-wg DENSITY MULTIPLY BY TO OBTAIN lb/ft3 16.02 kg/m3 kg/m3 0.06243 lb/ft3 in-Hg LENGTH MULTIPLY ft in m mm BY 12 0.3048 304.80 0.0833 0.02540 25.4 3.2808 39.37 1000 0.003281 0.03937 0.001 TO OBTAIN in m mm ft m mm ft in mm ft in m Pa mm-wg MASS MULTIPLY lbm oz grams kg BY 16 453.59 0.45359 0.0625 28.35 0.0283 0.002205 0.03527 0.001 2.2046 35.274 1000 TO OBTAIN oz grams kg lbm grams kg lbm oz kg lbm oz grams MOMENT OF INERTIA MULTIPLY lb-in2 lb-ft 2 2 kg-m BY 0.0069 0.0002926 144 0.04214 23.73 3417.2 TO OBTAIN lb-ft2 kg-m2 lb-in2 kg-m2 lb-ft2 lb-in2 POWER MULTIPLY HP ft-lb/min ft-lb/s W kg-m/sec BY 33000 550 745.7 0.7457 76.04 0.0000303 0.0167 0.0226 0.0023 0.0018 60 1.3558 0.1388 0.00134 44.254 0.73756 0.1019 0.01 434.78 7.20 9.81 TO OBTAIN ft-lb/min ft-lb/s W kW kg-m/sec HP ft-lb/s W kg-m/sec HP ft-lb/min W kg-m/sec HP ft-lb/min ft-lb/s kg-m/sec hp ft-lb/min ft-lb/s W Engineering Resource Guide mm-Hg atm BY 27.728 2.036 6894.8 704.28 51.715 0.06805 0.03607 0.07343 248.66 25.4 1.8651 0.002454 0.49115 13.619 3386.4 345.91 25.4 0.03342 0.000145 0.004022 0.0002953 0.10215 0.007501 0.0000099 0.00142 0.03937 0.002891 9.7898 0.07343 0.0000966 0.01934 0.53616 0.03937 133.32 13.619 0.001316 14.696 407.48 29.921 101300 10350 760 VELOCITY TO OBTAIN in-wg in-Hg Pa mm-wg mm-Hg atm psi in-Hg Pa mm-wg mm-Hg atm psi in-wg pa mm-wg mm-Hg atm psi in-wg in-Hg mm-wg mm-Hg atm psi in-wg in-Hg Pa mm-Hg atm psi in-wg in-Hg Pa mm-wg atm psi in-wg invHg Pa mm-wg mm-Hg MULTIPLY fpm fps in/sec m/s m/min RPM RPS Hertz BY 0.0167 0.0167 60 1 60 1 TO OBTAIN rps Hertz rpm Hertz rpm rps ft3 in3 l m3 lb-in lb-ft N-m BY 0.083 0.11298 12 1.3558 0.73756 8.8507 TO OBTAIN lb-ft N-m lb-in N-m lb-ft lb-in TEMPERATURE CFM m3/sec m3/min m3/hr l/s °F = 9/5 C + 32 °C = 5/9 (F – 32) See page 12 for expanded Temperature Conversion table. BY 1728 28.317 0.02832 0.000579 0.01639 0.0000164 0.03531 61.024 0.001 35.315 61024 1000 TO OBTAIN in3 l m3 ft3 l m3 ft3 in3 m3 ft3 in3 l VOLUME FLOW MULTIPLY TORQUE MULTIPLY TO OBTAIN fps in/sec m/s m/min fpm in/sec m/s m/min fpm fps m/s m/min fpm fps in/sec m/min fpm fps in/sec m/s VOLUME MULTIPLY ROTATING SPEED MULTIPLY BY 0.0167 .2 0.005080 0.30480 60 12 0.30480 18.288 5 0.0833 0.02540 1.524 196.85 3.2808 39.37 60 3.2808 0.05468 0.65617 0.0167 l/min BY 0.0004719 0.02832 1.6990 0.47195 28.317 2118.9 60 3600 1000 60000 35.315 0.0167 60 16.667 1000 0.58858 0.0167 0.0003 0.2778 16.667 2.1189 0.001 0.06 3.6 60 0.03531 0.000016 0.001 0.06 0.0167 TO OBTAIN m3/sec m3/min m3/hr l/s l/min CFM m3/min m3/hr l/s l/min CFM m3/sec m3/hr l/s l/min CFM m3/min m3/sec l/s l/min CFM m3/sec m3/min m3/hr l/min CFM m3/sec m3/min m3/hr l/s 9 Friction Loss Per 100 Feet of Round Duct Data is for duct roughness of 0.0005 feet. If a special duct material is being used, please contact the duct material manufacturer for the friction losses. Friction loss in inches H2O. VEL. 2000 2200 2400 2600 2800 3000 3200 3400 3600 3800 4000 4200 4400 4600 4800 5000 5200 5400 5600 5800 6000 6200 6400 6600 6800 7000 4" CFM 175 192 209 227 244 262 279 297 314 332 349 367 384 402 419 437 454 471 489 506 524 541 559 576 594 611 VEL. 2000 2200 2400 2600 2800 3000 3200 3400 3600 3800 4000 4200 4400 4600 4800 5000 5200 5400 5600 5800 6000 6200 6400 6600 6800 7000 10 5" FL 1.85 2.21 2.59 3.04 3.49 4.00 4.52 5.10 5.68 6.33 6.97 7.69 8.39 9.18 9.95 10.80 11.63 12.50 13.45 14.37 15.39 16.38 17.47 18.52 19.68 20.80 CFM 273 300 327 355 382 409 437 464 491 518 546 573 600 627 655 682 709 737 764 791 818 846 873 900 928 955 14" CFM 2138 2352 2566 2779 2993 3207 3421 3635 3848 4062 4276 4490 4704 4917 5131 5345 5559 5773 5986 6200 6414 6628 6842 7055 7269 7483 6" FL 1.39 1.67 1.97 2.30 2.65 3.02 3.43 3.85 4.30 4.77 5.28 5.80 6.35 6.91 7.53 8.14 8.78 9.47 10.16 10.88 11.62 12.41 13.19 14.00 14.87 15.73 16" FL 0.39 0.47 0.55 0.64 0.74 0.85 0.96 1.08 1.20 1.34 1.48 1.63 1.78 1.94 2.11 2.28 2.46 2.65 2.85 3.05 3.26 3.48 3.70 3.93 4.16 4.41 CFM 2793 3072 3351 3630 3910 4189 4468 4747 5027 5306 5585 5864 6144 6423 6702 6982 7261 7540 7819 8099 8378 8657 8936 9216 9495 9774 CFM 393 432 471 511 550 589 628 668 707 746 786 825 864 903 943 982 1021 1061 1100 1139 1178 1218 1257 1296 1336 1375 FL 1.11 1.33 1.57 1.83 2.11 2.41 2.72 3.07 3.43 3.80 4.21 4.62 5.05 5.51 5.99 6.49 7.00 7.54 8.10 8.67 9.26 9.88 10.51 11.16 11.84 12.53 18" FL 0.33 0.40 0.47 0.55 0.63 0.72 0.82 0.92 1.02 1.14 1.26 1.38 1.51 1.65 1.79 1.94 2.09 2.25 2.42 2.59 2.77 2.95 3.14 3.34 3.54 3.75 CFM 3534 3888 4241 4595 4948 5302 5655 6008 6362 6715 7069 7422 7776 8129 8483 8836 9189 9543 9896 10250 10603 10957 11310 11664 12017 12370 FL 0.29 0.34 0.41 0.47 0.55 0.62 0.71 0.79 0.89 0.99 1.09 1.20 1.31 1.43 1.55 1.68 1.81 1.95 2.10 2.25 2.40 2.56 2.72 2.89 3.07 3.25 DUCT DIAMETER 7" CFM FL 535 0.92 588 1.10 642 1.30 695 1.51 748 1.74 802 1.99 855 2.25 909 2.53 962 2.83 1016 3.14 1069 3.47 1123 3.82 1176 4.17 1230 4.56 1283 4.95 1337 5.36 1390 5.78 1443 6.22 1497 6.68 1550 7.15 1604 7.65 1657 8.15 1711 8.68 1764 9.22 1818 9.78 1871 10.34 CFM 698 768 838 908 977 1047 1117 1187 1257 1327 1396 1466 1536 1606 1676 1746 1815 1885 1955 2025 2095 2164 2234 2304 2374 2444 FL 0.77 0.93 1.10 1.28 1.47 1.68 1.91 2.15 2.40 2.66 2.94 3.23 3.54 3.86 4.19 4.54 4.90 5.27 5.66 6.07 6.48 6.91 7.35 7.81 8.28 8.77 CFM 1091 1200 1309 1418 1527 1636 1745 1854 1963 2073 2182 2291 2400 2509 2618 2727 2836 2945 3054 3163 3272 3381 3491 3600 3709 3818 FL 0.59 0.71 0.83 0.97 1.12 1.28 1.45 1.63 1.82 2.02 2.23 2.46 2.69 2.93 3.18 3.45 3.72 4.00 4.30 4.61 4.92 5.25 5.59 5.93 6.29 6.66 CFM 1571 1728 1885 2042 2199 2356 2513 2670 2827 2985 3142 3299 3456 3613 3770 3927 4084 4241 4398 4555 4712 4869 5027 5184 5341 5498 FL 0.47 0.56 0.67 0.78 0.90 1.02 1.16 1.30 1.45 1.62 1.79 1.96 2.15 2.34 2.54 2.76 2.97 3.20 3.44 3.68 3.93 4.20 4.47 4.74 5.03 5.32 DUCT DIAMETER 20" CFM FL 4363 0.25 4800 0.30 5236 0.36 5672 0.42 6109 0.48 6545 0.55 6981 0.62 7418 0.70 7854 0.78 8290 0.87 8727 0.96 9163 1.05 9599 1.15 10036 1.26 10472 1.37 10909 1.48 11345 1.60 11781 1.72 12218 1.85 12654 1.98 13090 2.11 13527 2.25 13963 2.40 14399 2.55 14836 2.70 15272 2.86 22" CFM 5280 5808 6336 6863 7391 7919 8447 8975 9503 10031 10559 11087 11615 12143 12671 13199 13727 14255 14783 15311 15839 16367 16895 17423 17951 18479 FL 0.22 0.27 0.32 0.37 0.43 0.49 0.55 0.62 0.70 0.77 0.85 0.94 1.03 1.12 1.22 1.32 1.42 1.53 1.64 1.76 1.88 2.01 2.14 2.27 2.40 2.55 24" CFM 6283 6912 7540 8168 8796 9425 10053 10681 11310 11938 12566 13195 13823 14451 15080 15708 16336 16965 17593 18221 18850 19478 20106 20735 21363 21991 FL 0.20 0.24 0.29 0.33 0.39 0.44 0.50 0.56 0.63 0.70 0.77 0.84 0.92 1.01 1.10 1.19 1.28 1.38 1.48 1.58 1.69 1.81 1.92 2.04 2.16 2.29 30" CFM 9817 10799 11781 12763 13744 14726 15708 16690 17671 18653 19635 20617 21598 22580 23562 24544 25525 26507 27489 28470 29452 30434 31416 32397 33379 34361 FL 0.15 0.19 0.22 0.26 0.29 0.34 0.38 0.43 0.48 0.53 0.59 0.65 0.71 0.77 0.84 0.91 0.98 1.05 1.13 1.21 1.29 1.38 1.47 1.56 1.65 1.75 8" 10" 12" Engineering Resource Guide Area and Circumference of Circles DIA. (IN.) 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 AREA IN2 0.785 3.14 7.07 12.57 19.63 28.27 38.48 50.27 63.62 78.54 95.03 113.00 133.00 154.00 177.00 201.00 227.00 254.00 284.00 314.00 346.00 380.00 415.00 452.00 491.00 531.00 573.00 616.00 661.00 707.00 755.00 804.00 855.00 908.00 FT2 0.005 0.022 0.049 0.087 0.136 0.196 0.267 0.349 0.441 0.545 0.659 0.785 0.921 1.07 1.23 1.40 1.57 1.77 1.97 2.18 2.40 2.64 2.88 3.14 3.41 3.68 3.97 4.27 4.58 4.90 5.24 5.58 5.93 6.30 CIRCUMFERENCE IN FT 3.14 0.262 6.28 0.523 9.42 0.785 12.57 1.054 15.71 1.31 18.85 1.57 21.99 1.83 25.13 2.09 28.27 2.36 31.42 2.62 34.56 2.88 37.70 3.14 40.84 3.40 43.98 3.66 47.12 3.93 50.27 4.19 53.41 4.45 56.55 4.71 59.69 4.97 62.83 5.23 65.97 5.50 69.12 5.76 72.26 6.02 75.40 6.28 78.54 6.54 81.68 6.80 84.82 7.07 87.96 7.33 91.11 7.59 94.25 7.85 97.39 8.11 100.53 8.37 103.67 8.64 106.81 8.90 DIA. (IN.) 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 AREA IN2 962 1018 1075 1134 1195 1257 1320 1385 1452 1521 1590 1662 1735 1810 1886 1963 2043 2124 2206 2290 2376 2463 2552 2642 2734 2827 2922 3019 3117 3217 3318 3421 3526 3632 FT2 6.68 7.06 7.46 7.87 8.29 8.72 9.16 9.61 10.08 10.55 11.04 11.53 12.04 12.56 13.08 13.62 14.17 14.74 15.31 15.89 16.49 17.09 17.71 18.33 18.97 19.62 20.28 20.95 21.63 22.32 23.03 23.74 24.46 25.20 CIRCUMFERENCE IN FT 109.96 9.16 113.10 9.42 116.24 9.68 119.38 9.94 122.52 10.21 125.66 10.47 128.81 10.73 131.95 10.99 135.09 11.25 138.23 11.51 141.37 11.78 144.51 12.04 147.65 12.30 150.80 12.56 153.94 12.82 157.08 13.08 160.22 13.35 163.36 13.61 166.50 13.87 169.65 14.13 172.79 14.39 175.93 14.65 179.07 14.92 182.21 15.18 185.35 15.44 188.50 15.70 191.64 15.96 194.78 16.23 197.92 16.49 201.06 16.75 204.20 17.01 207.35 17.27 210.49 17.53 213.63 17.80 DIA. (IN.) 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 100 AREA IN2 3739 3848 3959 4072 4185 4301 4418 4536 4657 4778 4902 5027 5153 5281 5411 5542 5675 5809 5945 6082 6221 6362 6504 6648 6793 6940 7088 7238 7390 7543 7698 7854 FT2 25.95 26.70 27.47 28.25 29.04 29.84 30.66 31.48 32.31 33.16 34.01 34.88 35.76 36.64 37.54 38.45 39.37 40.31 41.25 42.20 43.17 44.14 45.13 46.13 47.14 48.15 49.18 50.23 51.28 52.34 53.41 54.50 CIRCUMFERENCE IN FT 216.77 18.06 219.91 18.32 223.05 18.58 226.19 18.84 229.34 19.10 232.48 19.37 235.62 19.63 238.76 19.89 241.90 20.15 245.04 20.41 248.19 20.67 251.33 20.94 254.47 21.20 257.61 21.46 260.75 21.72 263.89 21.98 267.04 22.24 270.18 22.51 273.32 22.77 276.46 23.03 279.60 23.29 282.74 23.55 285.88 23.81 289.03 24.08 292.17 24.34 295.31 24.60 298.45 24.86 301.59 25.12 304.73 25.38 307.88 25.65 311.02 25.91 314.16 26.17 Equations: Area = r2 (r = radius of circle) Circumference = 2r or d (r = radius of circle; d = diameter of circle) Gauges & Equivalent Metal Thickness Steel Sheet Gauges & Weights GAUGE 1" 3/4" 5/8" 1/2" 3/8" 5/16" 1/4" 3/16" 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 Engineering Resource Guide THICKNESS IN. 1 3/4 5/8 1/2 3/8 5/16 1/4 3/16 .1793 .1644 .1495 .1345 .1196 .1046 .0897 .0747 .0673 .0598 .0538 .0478 .0418 .0359 .0329 .0299 .0269 .0239 .0209 .0179 .0164 MM 25.4000 19.0500 15.8750 12.7000 9.5250 7.9375 6.3500 4.7625 4.5542 4.1758 3.7973 3.4163 3.0378 2.6568 2.2784 1.8974 1.7094 1.5189 1.3665 1.2141 1.0617 0.9119 0.8357 0.7595 0.6833 0.6071 0.5309 0.4547 0.4166 WEIGHT LB/FT2 41.829 31.372 26.143 20.915 15.686 13.072 10.457 7.843 7.500 6.875 6.250 5.625 5.000 4.375 3.750 3.125 2.813 2.500 2.250 2.000 1.750 1.500 1.375 1.250 1.125 1.000 0.875 0.750 0.688 KG/M2 204.379 153.280 127.73 102.187 76.640 63.867 51.093 38.320 36.644 33.591 30.537 27.483 24.429 21.376 18.322 15.268 13.744 12.215 10.993 9.772 8.550 7.329 6.718 6.107 5.497 4.886 4.275 3.664 3.361 11 Fractions to Equivalent Decimal Values FRACTION 1 ⁄64 1 ⁄32 3 ⁄64 1 ⁄16 5 ⁄64 3 ⁄32 7 ⁄64 1 ⁄8 9 ⁄64 5 ⁄32 11 ⁄64 3 ⁄16 13 ⁄64 7 ⁄32 15 ⁄64 1 ⁄4 17 ⁄64 9 ⁄32 19 ⁄64 5 ⁄16 21 ⁄64 11 ⁄32 FRACTION 23 ⁄64 3 ⁄8 25 ⁄64 13 ⁄32 27 ⁄64 7 ⁄16 29 ⁄64 15 ⁄32 31 ⁄64 1 ⁄2 33 ⁄64 17 ⁄32 35 ⁄64 9 ⁄16 37 ⁄64 19 ⁄32 39 ⁄64 5 ⁄8 41 ⁄64 21 ⁄32 43 ⁄64 11 ⁄16 DECIMAL .016 .031 .047 .063 .078 .094 .109 .125 .141 .156 .172 .188 .203 .219 .234 .250 .266 .281 .397 .313 .328 .344 DECIMAL .359 .375 .391 .406 .422 .438 .453 .469 .484 .500 .516 .531 .547 .563 .578 .594 .609 .625 .641 .656 .672 .688 FRACTION 45 ⁄64 23 ⁄32 47 ⁄64 3 ⁄4 49 ⁄64 25 ⁄32 51 ⁄64 13 ⁄16 53 ⁄64 27 ⁄32 55 ⁄64 7 ⁄8 57 ⁄64 29 ⁄32 59 ⁄64 15 ⁄16 61 ⁄64 31 ⁄32 63 ⁄64 1 DECIMAL .703 .719 .734 .750 .766 .781 .797 .813 .828 .844 .859 .875 .861 .906 .922 .938 .953 .969 .984 1.00 Temperature Conversions °C –40 –39 –38 –37 –36 –35 –34 –33 –32 –31 –30 –29 –28 –27 –26 –25 –24 –23 –22 –21 –20 –19 –18 –17 –16 –15 –14 –13 –12 –11 –10 –9 –8 –7 –6 –5 –4 –3 °F –40.0 –38.2 –36.4 –34.6 –32.8 –31.0 –29.2 –27.4 –25.6 –23.8 –22.0 –20.2 –18.4 –16.6 –14.8 –13.0 –11.2 –9.4 –7.6 –5.8 –4.0 –72.2 –0.4 1.4 3.2 5.0 6.8 8.6 10.4 12.2 14.4 15.8 17.6 19.4 21.2 23.0 24.8 26.6 °C –2 –1 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 °F 28.4 30.2 32.0 33.8 35.6 37.4 39.2 41.0 42.8 44.6 46.4 48.2 50.0 51.8 53.6 55.4 57.2 59.0 60.8 62.6 64.4 66.2 68.0 69.8 71.6 73.4 75.2 77.0 78.8 80.6 82.4 84.2 86.0 87.8 89.6 91.4 93.2 95.0 °C 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 °F 96.8 98.6 100.4 102.2 104.0 105.8 107.6 109.4 111.2 113.0 114.8 116.6 118.4 120.2 122.0 123.8 125.6 127.4 129.2 131.0 132.8 134.6 136.4 138.2 140.0 141.8 143.6 145.4 147.2 149.0 150.8 152.6 154.4 156.2 158.0 159.8 161.6 163.4 °C 74 75 76 77 78 79 80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 100 105 110 115 120 125 130 135 140 145 150 155 °F 165.2 167.0 168.8 170.6 172.4 174.2 176.0 177.8 179.6 181.4 183.2 185.0 186.8 188.6 190.4 192.2 194.0 195.8 197.6 199.4 201.2 203.0 204.8 206.6 208.4 210.2 212.0 221.0 230.0 239.0 248.0 257.0 266.0 275.0 284.0 293.0 302.0 311.0 °C 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240 245 250 255 260 265 270 275 280 285 290 295 300 305 310 315 320 325 330 335 340 345 °F 320 329 338 347 356 365 374 383 392 401 410 419 428 437 446 455 464 473 482 491 500 509 518 527 536 545 554 563 572 581 590 599 608 617 626 635 644 653 °C 350 355 360 365 370 375 380 385 390 395 400 410 420 430 440 450 460 470 480 490 500 510 520 530 540 550 560 570 580 590 600 650 700 750 800 °F 662 671 680 689 698 707 716 725 734 743 752 770 788 806 824 842 860 878 896 914 932 950 968 986 1004 1022 1040 1058 1076 1094 1112 1202 1292 1382 1472