Surface - Baseefa 02 ATEX 0199X, PDF

advertisement

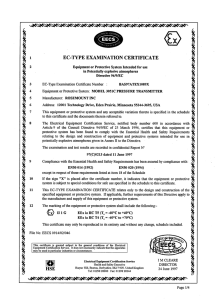

1 Certificate Number Issued 6 February 2003 Page 1 of 3 BaseefaO2ATEXO199X EC -TYPE EXAMINATION 2 CERTIFICATE Equipment or Protective SystemIntended for use in Potentially Explosive Atmospheres Directive 94/9/EC 3 EC -Type ExaminationCertificate Number: BaseefaO2ATEXO199X 4 Equipmentor protectivesystem: The Type DIK XX-XD-XD Solenoids 5 Manufacturer: G.W. Lisk Company Incorporated 6 Address: 2 South Street, Clifton Springs, New York, 14432,USA 7 This equipmentand any acceptablevariationtheretois specifiedin the scheduleto this certificateandthe documentstherein referredto. 8 Baseefa(2001)Ltd. Notified body number 1180in accordancewith Article 9 of the CouncilDirective 94/9/ECof23 March 1994,certifies that this equipmentor protectivesystemhasbeenfound to complywith the EssentialHealthand Safety Requirementsrelatingto the designand constructionof equipmentandprotectivesystemsintendedfor use in potentially explosiveatmospheresgiven in Annex n to the Directive. The examinationand testresultsare recordedin confidential ReportNo. 02(C)0465 Compliancewith the EssentialHealthand SafetyRequirementshasbeenassuredby compliancewith: 9 EN 50014(1997)+ Amendments 1 & 2; EN 50019(2000); EN 50028(1987) exceptin respectof thoserequirementslisted at item 18 of the Schedule. 10 If the sign "X" is placedafterthe certificate number,it indicatesthatthe equipmentor protectivesystemis subjectto special conditions of safeuse specifiedin the scheduleto this certificate. 11 This EC -TYPE EXAMINATION CERTIFICATErelatesonly to the designand constructionof the specifiedequipmentor protectivesystem.If applicable,furtherrequirementsof this Directive applyto the manufactureand supplyof this equipment or protectivesystem. 12 The marking of the equipmentor protectivesystemshallincludethe following: @ n 2G EEx me n T( SeeSchedule) -54°C ~ Tamb ~ +40oC or -54°C ~ Tamb~ +60oC This certificate may only be reproducedin its entirety, without any change,scheduleincluded. Baseefa(2001)Ltd. CustomerReferenceNo. 0435 ProjectFile No.O2/0465 r This certificateis grantedsubjectto the generaltermsand conditionsof Baseefa(2001)Ltd. It doesnot necessarilyindicate that the equipment maybe used in particular industriesor circumstances. ~- Baseefa (2001) Ltd. Health and Safety Laboratory Site, Harpur Hill, Buxton, Derbyshire SK17 9JN Telephone +44 (0) 129828255 Fax +44 (0) 129828216 e-mail info@baseefa2001.biz web site www.baseefa2001.biz Registered in England No. 4305578 at 13 Dovedale Crescent, Buxton, Derbyshire, SK17 9BJ \/, l!., ~ RSSINCLAIR DIRECTOR On behalf of Baseefa(2001)Ltd. Certificate Number BaseefaO2ATEXO199X Issued 6 February 2003 Page 2 of 3 Schedule 15 Description of Equipment or Protective System The Type D/K XX-XD-XD Solenoids comprise an encapsulated coil solenoid fitted with an increased safety terminal enclosure. Additionally the Type K solenoids are fitted with a bridge rectifier and a shunt varistor. The coil and components are encapsulated in a glass fibre filled polyester resin. The solenoid is fitted to a core tube, which containsthe solenoid armature.The core tube is provided with a mountingthreadto customerspecification.The solenoidis retainedon the coretube by a spacerand nut. Internal and external earth facilities are provided. An M20 cable entry is provided for connection of the users cabling. The solenoid is designedand rated for mounting on a specifiedvalve body (see sheet 8 of drawing number HI 7423). The Type designation represents the following information; i) ii) Iii) iv) The first characteris eitherD for d.c. input or K for a.c.input. The first two digits (10, 12, 13, 14, 15, 16, 17, 18 or 19) identif)' the diameterof the core tube in 1/16 inches. The subsequent1, 2, 3, or 4 digits identify information specific to the customer.Associatedwith these digits is the characterD which indicatesthatthe coil is an explosionprotectiondesign(EEx me). The final group of 3 numberssignify the voltage andwattageratings. Both d.c. and a.c. versionsare fitted with a thermal fuse rated with an operatingtemperatureaccordingto the applicabletemperatureclassificationas follows; For T6 versionsa 75°C rated thermalfuse is fitted. For T5 versionsa 90°C rated thermalfuse is fitted. For T4 versionsa 125°Crated thermalfuse is fitted. The solenoid coil may be wound for use with suppliesof up to 250V d.c. (Type D) or 250V a.c. 50Hz or 60Hz (Type K). The maximumstabilizedpower dissipationfor a given maximumambienttemperatureandtemperature classificationfor the solenoidmountedon a specifiedvalve body are given in the table below. MAXIMUM PERMITTED STABILIZED POWER (Warts) SolenoidType Ambient~p~ature (OC) T6 mo, KIO 40 60 6 D12, K12, D13, K13, 40 13 Dl4, K14, DlS, KIS 12 60 4 Dl4, K14, DlS, KIS 40 16 60 7 D16, K16, D17, K17, D18,K18,D19, K19 40 25 60 10 Power(Watts) T5 T4 18 11 22 11 23 13 37 22 30 25 36 30 39 30 50 42 18 Certificate Number Issued 6 February 2003 Page 3 of 3 BaseefaO2ATEXO199X 16 ReportNo. 02(C)O465 17 SpecialConditions for SafeUse1. The solenoidmust only be mountedon a valve body which hasa heatdissipationequalto or greaterthan the valve body shownon sheet8 of drawing numberH17423.The solenoidvalve mustbe complete beforethe coil is energised. 2. The solenoidandthe valve body on which it is mountedmustnot be thermallylagged. 3. The fluid flowing throughthe valve must not exceedthe specifiedambienttemperatureof 40°C or 60°C. 4. The solenoidshallbe protectedby fusesrated for a prospectiveshort circuit currentof at least4000A. EssentialHealthand SafetyRequirements None additionalto thosecoveredby the standardslisted at item 9 19 Drawingsand Documents Number ~ ~ Descriotion H17423 sheet1 A 05 JUD01 GeneralArrangement H17423 sheet2 A 05 IuD 01 DimensionalDetails H17423 sheet3 A 05 IUD01 Terminal Box H17423 sheet4 A 05 IUD01 Circuit Details H17423 sheet5 A 05 IUD 01 Coil Details H17423 sheet6 A 05 JUD01 CertificationLabel H17423 sheet7 A 05 Jun 01 Voltage & PowerRatings H17423 sheet8 A 05 JUD 01 Heat Sink(Valve Body) Details H17423 sheet9 A 05 IUD 01 EncapsulantDetails