KAF-TECH Pocket Guiderequire Adobe Reader

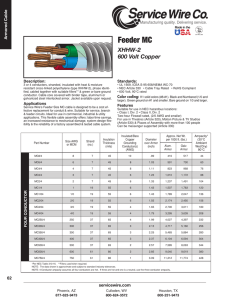

advertisement

9/21/06 5:35 PM Page 1 Production Facility 2000 Tall Pines, Largo, FL 33771 Installation Pocket Guide Head Quarters & Sales 272 Duchaine Blvd., New Bedford, MA 02745 800-757-6996 Fax 508-998-1447 www.alliedeg.com MC Tuff, Mc Lite, AC-90, AC-Lite, HCF-90, HCF-Lite, and Kaf-Tech, and Tyco are trademarks or registered trademarks of Tyco and/or its affiliates in the United States and in other countries. All other brand names, product names, or trademarks belong to their respective owners. 2000KT-0610 2.5M AFC’S T YPE MC & AC CABLES — FEATURING THE RAINBOW ID SYSTEM MC AC KT pocket guide cvr spred2006 • Proper Installation methods for Type MC and Type AC • NEC References • Illustrated details AC MC KT pocket guide cvr spred2006 9/21/06 5:35 PM Page 3 Cable Color ID System Cable Color ID System kt pocket guide insides2006 9/21/06 6:19 PM Page 1 Armored cable (Type AC) and metal clad cable (Type MC) are increasingly becoming the wiring solution of choice for engineers, contractors and building owners across America. AC & MC Cables SECTION 1 Introduction to Type AC and Type MC cables including the differences between these two products. Identifies important references from the National Electrical Code.® SECTION 2 Explanation of the proper techniques for installing AC and MC cable including cutting and derating. The title National Electrical Code® and NEC® are trademarks registered to the National Fire Protection Association. 1 kt pocket guide insides2006 9/21/06 6:19 PM Page 2 SECTION 1 Armored (Type AC) Cable Construction Introduction to AC & MC Cables Armored cable (Type AC) and metal clad cable (Type MC) provide a fast and efficient way of wiring both new construction and remodeling work. Their flexible metal armor provides mechanical protection of the electrical conductors while enabling them to bend around corners. The cables are pre-wired at the factory eliminating the need to pull conductors into a raceway, which in turn greatly reduces the possibility of conductor damage during pulling. The National Electrical Code has accepted AC and MC cables for decades, with statistics showing that they have an excellent fire safety record. Because AC & MC cable can be fished for long distances, it is quick and easy to install. It’s own weight can carry it between partitions and it can be run without concern for its contact with pipes or other obstructions. Wire pullers, fish ropes or tapes, dispensers and lubricants are eliminated. AC & MC cable does the job in less space, with fewer bending restrictions and less cutting and connecting than most other wiring products. Armored cable (Type AC) and Metal Clad cable (Type MC) have a flexible metal armor of similar outward appearance, but that is where the similarity ends. There are major differences in construction and uses permitted. 2 As described by the National Electrical Code NEC® 2002 Article 320, armored cable Type AC is a “fabricated assembly of insulated conductors in a flexible metallic enclosure.” Type AC cable is manufactured to UL Standard 4. It consists of 2 to 4 copper conductors in sizes 14 AWG to 1 AWG inside an interlocked metal armor of steel or aluminum construction. Type AC cable can have no more than four insulated conductors plus a grounding conductor (for a total of 5 conductors only) and cannot be manufactured larger than 1 AWG per UL 4. A 16 AWG aluminum bonding wire is inside of, and in physical contact with, the metal armor providing a low-impedance fault-return path required for the operation of overcurrent protection devices. The bonding wire is unique to AC cable and allows the outer metal armor in conjunction with the bonding wire to be used as an equipment ground. It is important to remember that the bare bond wire is not an equipment grounding conductor. It is the bond wire that, in combination with the interlocked metal armor, provides a low impedance equipment grounding path. Each of the copper conductors is covered with a thermoplastic insulation (THHN with a 90°C rating) and are individually wrapped in a moisture resistant, fire retardant paper. According to NEC Article 320.40, an insulated (antishort) bushing is required when installing Type AC cable. It is installed at the time of termination and designed to protect the conductors from damage. Kaf-Tech provides bushings in bags packaged with the cable. 3 kt pocket guide insides2006 9/21/06 6:19 PM Page 4 AC AC AC-90® and AC Lite® Armored Cables Type AC Cable - Uses Permitted The uses permitted for AC cable are governed by NEC Article 320 and any applicable local codes. AC-90 ® and AC-Lite ® are manufactured with a black armor for easy identification of cable type. Additional color bands identify circuit/phase conductor colors. • Where not subject to physical damage for branch circuits and feeders in both exposed and concealed work and in cable trays where identified for such use • In dry locations and embedded in plaster finish on brick or other masonry, except in damp or wet locations • Run or fished in the air voids of masonry block or tile walls where the walls are not exposed or subject to excessive moisture or dampness • Under raised floors, above suspended ceilings and in other environmental air-handling spaces per NEC 300.22(C) Galvanized Steel Armor (Color-Coded Black) Insulated Bushing Bare Aluminum Bonding Strip Copper Conductors Paper Wrap (Each Conductor) AC-90 Nylon Thermoplastic THHN Insulation ® • In both exposed and concealed work • In dry locations • Embedded in plaster finish or brick or other masonry, except in damp or wet locations • To be run or fished in the air voids of masonry block or tile walls where such walls are not exposed or subject to excessive moisture or dampness • FPN: The “uses permitted” is not an all-inclusive list Type AC Cable - Uses NOT Permitted Aluminum Interlocked Armor (Color-Coded Black) Insulated Bushing Bare Aluminum Bonding Strip Copper Conductors According to NEC Article 320.12, AC cable can not be installed in the following locations: • Where subject to physical damage • In damp or wet locations Paper Wrap (Each Conductor) AC-Lite® Nylon Thermoplastic THHN Insulation • In air voids of masonry block or tiles where such walls are exposed or subject to excessive moisture or dampness • Where exposed to corrosive fumes or vapors • Embedded in plaster finish on brick or other masonry in damp or wet locations 4 5 kt pocket guide insides2006 9/21/06 6:19 PM Page 6 AC AC Health Care Facilities Cable HCF-90 ® and HCF-Lite ® are manufactured with a green armor for easy identification of cable type. Additional color bands identify circuit/phase conductor colors. Galvanized Steel Armor (Color-Coded Green) Insulated Bushing Bare Aluminum Bonding Strip Copper Conductors Copper Ground Paper Wrap (Each Conductor) Nylon Thermoplastic THHN Insulation HCF-90 ® Aluminum Interlocked Armor (Color-Coded Green) Insulated Bushing Bare Aluminum Bonding Strip Copper Conductors Copper Ground Paper Wrap (Each Conductor) HCF-Lite ® Nylon Thermoplastic THHN Insulation Type AC cable is available in standard AC, AC-Lite® (aluminum) or Health Care Facilities Cable (Kaf-Tech’s HCF-90® and its aluminum version HCF-Lite®). HCF, or hospital grade cable, is constructed in the same manner as standard AC cable, but with the addition of a green grounding conductor. Kaf-Tech’s HCF-90 ® and HCF-Lite® Health Care Facilities Cable This additional ground allows HCF to be used in patient care areas of health care facilities (other than hazardous locations) including hospitals, nursing homes, dental offices, outpatient facilities and medical centers per NEC 517.13. The separate green grounding conductor satisfies the requirement of Article 517.13(A) that: “Wiring Method: All branch circuits serving patient care areas shall be provided with a ground path for fault current by installation in a metal raceway system, or a cable having a metallic armor or sheath assembly. The metal raceway system, or metallic cable armor, or sheath assembly shall itself qualify as an equipment grounding return both in accordance with 250.118.” HCF Cables satisfy: NEC 517.13(B) . . . “The grounding terminals of all recepticals and all noncurrent carrying conductive surfaces of fixed electric equipment likely to become energized that are subject to personal contact operating at over 100 volts, shall be grounded by an insulated copper conductor. The equipment grounding conductor shall be sized in accordance with Table 250.122 and installed in metal raceways or as part of listed cables having a metallic armor or sheath assembly with the branch-circuit conductors supplying these receptacles or fixed equipment.” (NOTE: HCF cables may not be used on emergency circuits in a health care setting except as noted 517.303(C)(C). 6 7 kt pocket guide insides2006 9/21/06 6:19 PM Page 8 MC MC Metal Clad (Type MC) Cable Construction MC TUFF® and MC-Lite® Metal Clad Cables Kaf-Tech manufactures its lightweight steel MC TUFF™ cable with a blue armor for easy identification of cable type. Additional color bands identify circuit/phase conductor colors. Galvanized Steel Armor (Color-Coded Blue) Assembly Tape Copper Conductors Copper Ground MC TUFF ® Nylon Thermoplastic THHN Insulation As described by NEC Article 330, Metal Clad Type MC cable is a “factory assembly of one or more insulated circuit conductors with or without optical fiber members enclosed in an armor of interlocking metal tape or a smooth or corrugated metallic sheath.” Type MC cable is manufactured to UL Standard 1569. MC cables have 2 or more solid or stranded conductors in sizes 18 AWG and larger. The number of conductors allowed in an MC cable is not restricted by UL. The conductors may be of copper, aluminum or copper-clad aluminum. The metal armor may be a smooth tube, a corrugated tube, or an interlocked metal armor. Kaf-Tech manufactures MC cable with interlocked metal armor and copper conductors. The make-up of Kaf-Tech’s 600 volt interlocked armor MC cable consists of: • Copper circuit and grounding conductors covered with thermoplastic insulation • An overall polypropylene cable assembly tape • An outer galvanized steel or aluminum interlocked armor Unlike Type AC cable, the armor of interlocked Type MC cable is not an equipment grounding means and Type MC cable requires a bare or green grounding conductor. 8 9 kt pocket guide insides2006 9/21/06 6:19 PM Page 10 MC Type MC Cable - Uses Permitted The uses permitted for MC cable are governed by NEC Article 330 and any applicable local codes. Uses Permitted For MC Cable Let’s review the major differences between AC and MC cables. • Where not subject to physical damage for services, feeders and branch circuits • For power, lighting, control, and signal circuits TYPE AC CABLE TYPE MC CABLE NUMBER OF CONDUCTORS Limited to a maximum of 4 conductors plus a grounding conductor. Not limited to the number of conductors. SIZE OF CONDUCTORS 14 AWG to 1 AWG 18 AWG or larger GROUNDING Contains a 16 AWG bond wire in constant contact with the metal armor allowing the armor and bond wire combination to be used as an equipment ground. Does not contain a bonding wire and the armor is not an equipment ground, but supplements the internal grounding conductor equaling one grounding path. CONDUCTOR WRAPPING Individual conductors are wrapped in a moisture resistant, fire retardant paper. Individual conductors are not wrapped in paper but do have an overall polypropylene assembly tape. • Indoors, exposed or concealed • Direct buried where identified for such use • Under raised floors, above suspended ceilings and in other environmental air-handling spaces per NEC 300.22(C) • Outdoors or in wet locations where the armor has an overall outer, moisture resistant PVC jacket • In places of assembly • In cable tray or raceway or as open runs • In locations classified as hazardous as permitted in NEC Articles 501, 502, 503, 504, and 505 • As aerial cable on a messenger 10 Along with these differences in construction, there are also differences in the uses permitted for these cables as discussed in the previous pages. 11 kt pocket guide insides2006 9/21/06 6:19 PM Page 12 SECTION 2 For example, according to NEC Table 310.16, a cable with three 12 AWG copper, 90°C THHN insulated conductors is rated at 30 amperes. Project Planning Project planning is an important step in the installation of any wiring method. Proper planning will enable a safe and efficient cable installation. Circuit planning is developed from the plans and specifications produced by the design engineer. The project estimator and project manager plan the circuits and cable runs to meet the design requirements in a safe and efficient manner. The final “as-built” drawings are developed and submitted to the building owner reflecting the actual field installation of the electrical circuitry. An important component of circuit planning is ampacity and cable derating. Cable Ampacity and Derating The ampacity of a cable is the maximum amount of current it can carry in a given situation without exceeding its temperature rating. Most AC & MC cables have a temperature rating of 90°C. AC or MC Cable With Three Or Less Current Carrying Conductors The amperage rating of an AC or MC cable containing three current carrying conductors or less can be found in Table 310.16 of the NEC. These values are based on an ambient temperature of 30°C (86°F). You must use the correction factors at the bottom of the Table 310.16 for other ambient temperatures. 12 In the above example, if the ambient temperature is 38°C rather than 30°C, the correction factor of .91 found at the bottom of the table is used to derate the conductors by 91%. This is done by multiplying the .91 by the 30 amperes for a resulting ampacity of 27.3 amperes. If there is a * beside the AWG size then you must refer to the fine print note at the bottom of the page which directs you to NEC Section 240.4(D). This section explains the over-current protection required for certain wire gauge sizes and ampacities. AC or MC Cable With More Than Three Current Carrying Conductors When utilizing a multi-conductor cable assembly of more than three current carrying conductors, the conductors must be derated. To derate the cable, use the adjustment factors in NEC Table 310.15(B)(2)(a). If harmonic loads exist, the neutral conductors must also be considered to be “current carrying” and included in the derating process. Again, refer to NEC section 240.4(D) for AWG sizes with a * beside them. For example, a 12 AWG cable with 4-6 conductors has an available ampacity of 30, but per Table 310.15(B)(2)(a) must be reduced to 80% (multiplied by .80) leaving the available ampacity at 24. See sample calculation in Figure 1. When 7 to 9 conductors are used in a raceway or cable, per Table 310.15(B)(2)(a), the table value of ampacity must be reduced by a 0.70 multiplier. Refer to Table 310.15(B)(2)(a) for quantities greater than 9 conductors. 13 kt pocket guide insides2006 9/21/06 6:19 PM Page 14 Figure 1 Armored Cable Derating Example 90°C RATED ARMORED CABLE 12 AWG WITH 4 COPPER CONDUCTORS. 1) Find conductor ampacity in NEC Table 310.16 - 12AWG, 90°C = 30 amperes 2) Find adjustment factor in NEC Article 310.15(B)(2)(a). - 30 x .80 = 24 amperes Cutting AC & MC Cable Type AC and MC cable should be cut with an armored cable rotary cutter. Rotary cutters have many advantages over other methods. Nicking and cutting of the conductors is eliminated and the cuts can be made quickly and safely. Bundled 12 AWG Type AC or MC Cables Where multi-conductor cables are stacked or bundled for more than 24 inches, without maintaining spacing, the conductors must be derated except that the ampacity of 12 AWG Type AC and MC cables are not adjusted according to Table 310.15(B)(2)(a). The derating of bundled 12 AWG AC and MC cables is determined by Exception No. 5 to NEC Section 310.15(B)(2). Double Derating When installing an MC cable consisting of more than three current-carrying conductors in an area where the ambient temperature is other than 30°C (86°F), the correction factors at the bottom of NEC Table 310.16 are used with the adjustment factors in NEC Article 310.15(B)(2)(a). This is considered double derating of the cable. For example, a 12 AWG cable with five 90°C insulated conductors is run through an ambient temperature of 105°F. Using the adjustment factors in NEC Article 310.15(B)(2)(a), each conductor must be derated 80% of the ampacity of 30 amperes taken from Table 310.16. An additional derating of 87% must also be applied using the correction factors at the bottom of Table 310.16 to account for the high ambient temperature. Thus, the resulting ampacity is limited to 20.88 amperes per conductor. 14 An armored cable rotary cutter. Instructions For Use: 1) Place the cable in the tool and tighten the tool to the armor. 15 kt pocket guide insides2006 9/21/06 6:19 PM Page 16 The first step in the rough-in phase is to determine the number of home run circuits and from where the wiring will originate. Once this is done, time should be taken to determine the best and shortest routes for each cable run. Long runs of spider web type routing not only require more cable but increase voltage drop. This is very important to consider when locating boxes for receptacles, lights and switches. If long runs are required, oversizing the circuit conductors is recommended to limit voltage drop. 2) Rotate the handle a couple of brisk turns. AC & MC cable is available on reels and in coils. If using a reel, simply draw the cable from the end of the reel. If using a coil, draw the cable from the center of the coil to prevent kinking. 3) Remove the cable from the tool, and twist the armor to separate. Installing AC & MC Cable Type AC & MC cable is installed after the rough-in phase of locating and setting all boxes and enclosures. Rough-in occurs when all the interior and exterior walls are framed but before the sheet rock is installed. 16 A coil of MC cable 17 kt pocket guide insides2006 9/21/06 6:19 PM Page 18 Bridging Cable Across Open Spaces In general, AC and MC cable must hug the surface it is wired over. The NEC prohibits bridging across open spaces with the following five exceptions: 1) When the cable is fished. 2) When flexibility is required a box may be installed near a motor or appliance using a short piece of free AC cable up to 24 inches long, between the box and motor or appliance. 3) Lengths of not more than 6 feet from the last point of support for connections within an accessible ceiling to lighting fixtures or equipment. 4) Where installed in cable trays. 5a) For Type AC cable in other than vertical runs through holes or notches in framing members where distance between members does not exceed 4.5 feet and is securely fastened in place by an approved means within 12 inches of each box, cabinet, conduit body or other cable termination. 5b) For Type MC cable in other than vertical runs through holes or notches in framing members where the distance between members does not exceed 6 feet. Cables containing four or fewer conductors sized no larger than AWG 10 must be secured within 12 inches of each box, cabinet, fitting or other cable termination. Type MC Cable running through punched holes in metal framing members. Bending Radius Care should be taken not to exceed the bending radius of the cables when routing around corners. According to NEC Article 320.24, for AC cable, the radius of the curve of the inner edge of any bend shall not be less than 5 times the diameter of the cable. NEC Article 330.24(B) states that for MC Cable, the radius shall not be less than 7 times the external diameter of the cable. Supporting AC & MC Cables All cable runs must be continuous from outlet to outlet. According to NEC Article 320.30, AC cable must be supported and secured at intervals of 4.5 feet or less (unless routed through a framing member) and within 12 inches of every termination. 18 19 kt pocket guide insides2006 9/21/06 6:19 PM Page 20 According to NEC Article 330.30, MC cable must be supported and secured at intervals of 6 feet or less (unless routed through a framing member) and cables containing four or fewer conductors sized no larger than 10 AWG must be secured within 12 inches of every termination. Type MC cable secured in a vertical cable tray Terminating AC & MC Cables As noted, AC and MC cable support requirements are waived when the cable is fished. This is a major advantage of AC and MC cable in remodeling work over other wiring products that cannot be fished. AC and MC cable may also be installed in cable tray, per NEC Article 392. Cable is only required to be secured in this installation for vertical runs. 20 When terminating or splicing at a junction, outlet or switch box, cut the cable so that 6 inches of free conductor is left for connections or splices. Use an approved connector and insure a proper bond by firmly tightening the connectors to both the box and the cable. Please note: set screw connectors cannot be used with aluminum armor Type AC cable. To terminate an AC cable, insert an anti-short bushing and bend back the exposed length of bonding wire. The bonding wire can be bent back before or after the bushing is inserted. There are several techniques used for this procedure as pictured on the next page. 21 kt pocket guide insides2006 9/21/06 6:19 PM Page 22 A bushing must be used with Type AC cable. Here is an example of an approved connector for AC and MC cables. Insert the cable into the connector and secure the connector into the box. Be sure that the anti-short bushing is plainly visible in the connector for easy inspection. The same procedure is followed for MC cable with the exception that there is no bonding wire. Although anti-short bushings are only required by the NEC for AC cable, most manufacturers recommend their use with MC cable. MC cable installed in a box with 6 inches of free conductors left for connections or splices. 22 23 kt pocket guide insides2006 9/21/06 6:19 PM NOTES Page 24 KT pocket guide cvr spred2006 9/21/06 5:35 PM Page 3 Cable Color ID System Cable Color ID System 9/21/06 5:35 PM Page 1 Production Facility 2000 Tall Pines, Largo, FL 33771 Installation Pocket Guide Head Quarters & Sales 272 Duchaine Blvd., New Bedford, MA 02745 800-757-6996 Fax 508-998-1447 www.alliedeg.com MC Tuff, Mc Lite, AC-90, AC-Lite, HCF-90, HCF-Lite, and Kaf-Tech, and Tyco are trademarks or registered trademarks of Tyco and/or its affiliates in the United States and in other countries. All other brand names, product names, or trademarks belong to their respective owners. 2000KT-0610 2.5M AFC’S T YPE MC & AC CABLES — FEATURING THE RAINBOW ID SYSTEM MC AC KT pocket guide cvr spred2006 • Proper Installation methods for Type MC and Type AC • NEC References • Illustrated details AC MC