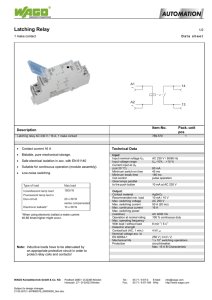

I/O-SYSTEM/Interface Modules

advertisement