R

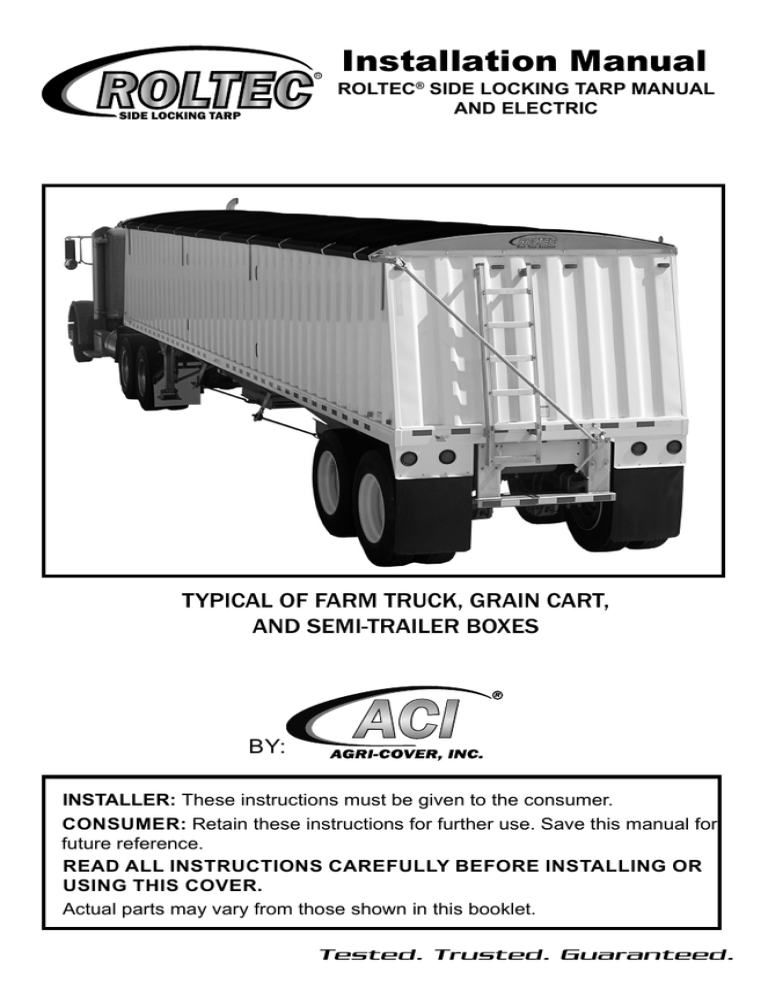

SIDE LOCKING TARP

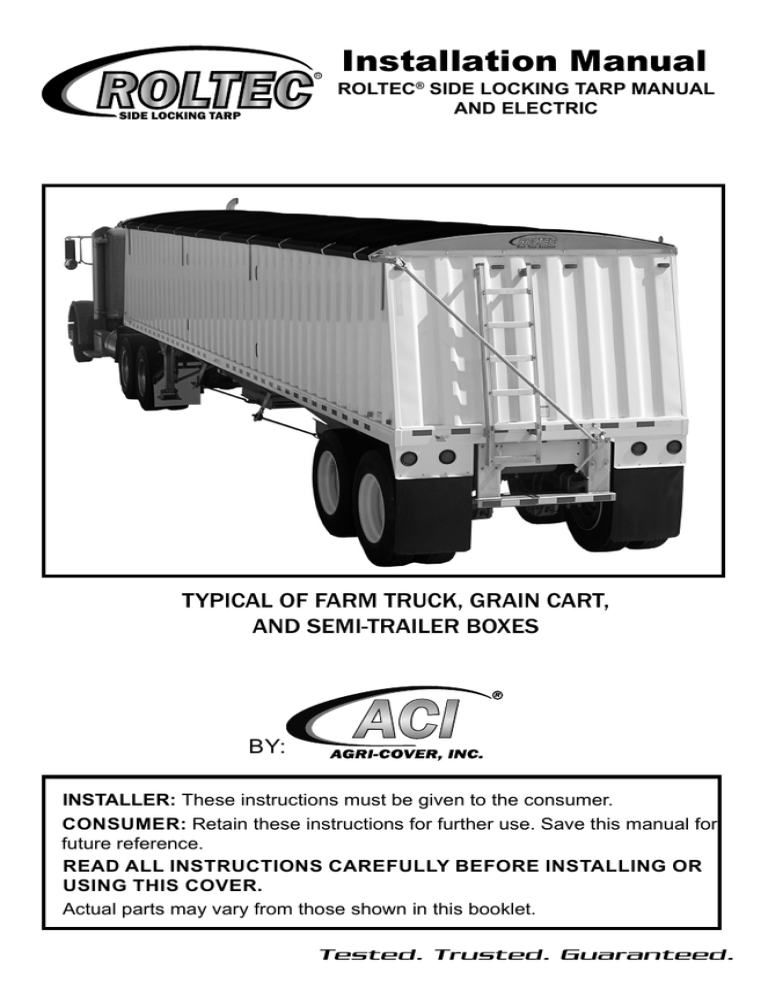

Installation Manual

ROLTEC® SIDE LOCKING TARP MANUAL

AND ELECTRIC

TYPICAL OF FARM TRUCK, GRAIN CART,

AND SEMI-TRAILER BOXES

R

BY:

INSTALLER: These instructions must be given to the consumer.

CONSUMER: Retain these instructions for further use. Save this manual for

future reference.

READ ALL INSTRUCTIONS CAREFULLY BEFORE INSTALLING OR

USING THIS COVER.

Actual parts may vary from those shown in this booklet.

Tested. Trusted. Guaranteed.

TABLE OF CONTENTS

PREPARATION/TOOLS..........................................................................Pages 3-4

INSTALLATION INSTRUCTIONS........................................................... Pages 5-43

OPERATING/INSTRUCTIONS/SAFETY/INFORMATION..............Pages 34, 44, 50

PARTS AND DIAGRAMS.................................................................. Pages 46-49

INSPECTION AND MAINTENANCE..........................................................Page 51

FASTENERS AND HARDWARE ........................................................Pages 52-55

WARRANTY...........................................................................................Back Cover

This owner’s manual applies to the ROLTEC® Hand Operated Tarp and the

ROLTEC® Electric Operated Tarp Systems. For your convenience, the following symbols appear throughout these instructions to aid in installing, operating

and maintenance of your tarp system.

This symbol indicates steps that apply to the hand

crank tarp.

This symbol indicates steps that apply to the electric

motor operated tarp.

Both symbols indicate steps that apply to

both the hand crank and electric operated

tarp systems.

!

NOTICE TO CONSUMER: This owner’s manual applies to the

ROLTEC® Side Locking Tarp. Before using this product, read

the operating instructions, maintenance and safety sections of

this owner’s manual and save for future reference.

NOTICE TO INSTALLER: It is recommended you take the time to read

these instructions carefully before installing this cover even if already

familiar with the product. Often improvements are made without prior

notice. Always handle components with care to avoid personal injury or

damage to components. If you find a part missing or defective, or if you are

having trouble installing this product, please have serial number ready (found

on decal included with kit) and call the customer service number on the back

page. When done, these instructions must be given to the customer.

FOR YOUR RECORDS:

DATE PURCHASED

WHERE PURCHASED

SERIAL NUMBER

2

PREPARATION

IMPORTANT NOTES:

The illustrations used in this manual show a semi-trailer box, however, steps

and procedures also apply to farm trucks and grain carts.

The truck or trailer on which installation is being done must be parked on

a level surface. This prevents box from twisting, which can cause a poor

installation.

Box must be square and straight. Center must not be pulled together or

spread apart. Make adjustments prior to installation.

Inspect box for sharp edges or points that make contact with tarp and/or

cables. Remove or grind smooth.

It may be necessary to remove or reposition ladders or other devices that

may interfere with tarp. If any modifications to box are needed, consult box

manufacturer.

If you have an extension on top of your box, make sure it is secure by bolting

in place.

Most fasteners used in this installation are a 3/8” x 1” self threading bolt. A

5/16” hole must be drilled to obtain correct tap drill hole size. Attach these

bolts only to secure structures on box. In some cases it will be necessary

to use washer and nuts or other types of fasteners (NOT FURNISHED) to

ensure a solid anchor.

Before you begin, measure the outer length and width of your box. Also measure the length of the tarp and the width of the end caps to ensure you have

received the correct size. The tarp must measure between 8” and 16” shorter

than the box length. The end caps must be at least 1/2” narrower than box

width, usually 1/2” to 3” narrower. NOTE: Some systems may require end

cap variations which will result in short outer tarp lengths.

3

PREPARATION (Continued)

Tools & Equipment

Most installations will require use of all these items

Tools for Manual and Electric Install

- Protective eyewear

- Marking pencil

- Step ladders or scaffolding

- Lock pliers

- Drill with 5/16” and 3/8” drill bits

- Tape measure

- Impact wrench with 9/16” socket

- Two 1/2” wrenches, a 9/16” and 3/4” wrench

- Hammer

- Welder and helmet

- C-clamps

Additional tools for Electric Install

- Drill with 3/16”, 7/32”, and 11/16” drill bits, #3 Phillips driver bit

- 3/8” wrench

- Heat gun

- #25 Torx driver

- Torque wrench (inch lbs.)

- 1/8” Allen wrench

- #1 Phillips head screw driver

4

INSTALLATION INSTRUCTIONS

1. END CAPS

CAUTION: DO NOT STAND OR WALK ON END CAP

A. FRONT END CAP

Center side mount style end cap on front box. Hold firmly in place against

box, drill 5/16” holes in box wall at each factory hole in end cap. Fasten with

3/8” x 1” self threading bolts. (See Figure 1A) Tilt end cap up 1/4” at center

on ribbed side and use factory etch mark on caps as guide to drill 5/16” hole

into top of box. Fasten with 3/8” x 1” self threading bolt. (See Figure 1B)

Repeat at other end of cap.

Maintain

equal dim.

on both

sides

Front end cap

Cap must be

shorter than box

1/2” min.

1-1/2” max.

3/8” x 1” self threading

bolts at each hole in cap

FIGURE 1A

3/8” x 1” self threading bolt

Drill 5/16” hole at etched

mark on cap

Tilt end cap up 1/4” then

mark and drill holes

FIGURE 1B

TIP: Sometimes it is necessary to modify end caps for proper fit by

notching overhang, removing protruding objects from box, or by trim

cutting end caps shorter if too wide for box. Both front and rear end

cap should measure at least 1/2” narrower than top of box.

5

1. END CAPS (Continued)

CAUTION: DO NOT STAND OR WALK ON END CAP

INSTALLATION TIP: Some kits require non-standard end caps. These

kits will have 2 front style end caps. Skip rear end cap instructions and

follow front end cap instructions for end cap at rear of box.

B. REAR END CAP

Center top mount style rear end cap on back of box. Position end cap to

overhang back of box by 1/4”. Mark deepest location at each slotted hole

on top of box at rear of end cap. After marks are made remove end cap, drill

5/16” holes at these locations. Turn 3/8” x 1” self threading bolts halfway

in. Slide end cap slot under bolt heads. Ensure 1/4” overhang and finish

tightening bolts. (See Figure 1C) Tilt end cap up 1/4” at center on ribbed side

and use factory etch mark as guide to drill 5/16” hole into top of box. Fasten

with 3/8” x 1” self threading bolt. (See Figure 1D) Repeat at other side of end

cap.

1/4”

Sealing rib in

end cap (do not

place a bow

here)

Tilt end cap

up 1/4” at

center

All self threading bolts shown

partially turned in to allow end cap

slots to slide under bolt head,

then finish tightening.

FIGURE 1C

1/4”

overhang

at rear of

box

SIDE VIEW OF REAR END CAP

3/8” self threading bolt

Drill 5/16”

hole at

etched mark

on cap

FIGURE 1D

Drill 5/16”

holes

VIEW OF REAR END CAP

6

2. MOUNTING BOWS AND RIDGE STRAP

NOTE: Bows supplied in this kit are not designed to hold box together.

Leave all existing bows, braces or chains in place.

A. BOW POCKETS/BOW EXTENSION

The first bow should be placed 30” in from front of box. The last bow should

be placed 30” in from rear of box. Position remaining bows evenly spaced

between first and last bow. (See Figure 2B on page 8 for bow placement)

Attach bow pocket to inner sides of box, flush with top. Drill 5/16” hole at

each location and use 3/8” x 1” self threading bolts. When possible secure

bolts with flat washer, lock washer and nut.

Bow

extension

Flat washer

Nut

Bow pocket

Lock

washer

3/8” x 1” self

threading bolt

Box Rail

Drill 5/16” holes in box rail, turn self

threading bolts into holes - insert

bow & extension - then tighten bolts

FIGURE 2A

7

2. MOUNTING BOWS AND RIDGE STRAP (continued)

B. BOWS

Start with first bow at front of box. Insert bow extension into bow. Place

each end of bow into bow pocket. Center bow in an upright position. Adjust

bow to set 1” higher than end cap. Drill 5/16” hole through end of bow and

in extension. Drill hole so bolt head will not rub tarp. Turn 3/8” x 1” self

threading bolt into bow assembly. IMPORTANT: Purpose of bolt is to hold

bow rigid at properly set height.

TIP: First, set front and rear bows to correct height. Install ridge strap

on top of all bows and draw tight until no slack. Adjust remaining bows

to just touch bottom of ridge strap.

* Example:

If - 2 bows are left, divide

by 3 for 3 equal spaces

If - 4 bows are left, divide

by 5 for 5 equal spaces

Standard one ridge

strap in center

Optional 2 ridge

straps off center

Last bow at rear

First Bow

From Front

er

b

um

n

by

ce ne

a

sp s o

ing ft plu

n

i

a

le

rem ows

b

ide

of

iv

*D

Warning: All bows must be used

Clamp lock

pliers on bow

extension to

hold bow in

place

With bow inserted in bow pocket and adjusted to set 1” higher

than end caps - drill 5/16” hole 1” from end of bow and secure

with self threading bolt.

FIGURE 2B

8

2. MOUNTING BOWS AND RIDGE STRAP (continued)

C. RIDGE STRAP

Attach hook end of strap to hole in center of front end cap. If installing two

ridge straps, attach straps to the off center holes. Run strap over bows.

Attach ratchet end of strap to rear end cap. Draw strap tight. DO NOT OVER

TIGHTEN. Trim cut extra strap to about 8”.

Rear end

TIP: Twisting the ridge

cap

strap prior to attaching it

to ratchet will help deTwist ridge strap

crease the chance of grain

at ratchet end

bouncing off of strap. The

number of twists needed

depends on the length

of the trailer, adjust acFront

cordingly. Make sure not

end cap

Trim cut

to wind any twist in the

excess ridge

ratchet.

strap

Bow

ALTERNATE RIDGE ROPE OPTION

Attach hook end of rope to hole in center of front end cap. If installing two

ridge ropes, attach hooks to the off center holes. Run rope over bows. Attach

ratchet end of rope to rear end cap. Thread rope through ratchet as shown

in Figure 2E, pull on loose end of rope to remove slack. Ratchet rope tight,

need at least 4 wraps. DO NOT OVER TIGHTEN. Trim cut extra rope to

about 8” and tie a knot to prevent fraying.

Rear end

cap

Ratchet

Front

end cap

Bow

Pull rope

through loop

to remove

slack, knot

end to prevent fraying

Loop rope

through

ratchet

FIGURE 2E

9

3. LATCH PLATE

A. POSITION LATCH PLATE

Mount latch plate on side of box opposite from tarp stop brackets 0” to 3”

down from top of box rail. Start flush with end of box and stop flush at other

end of box. (See Figure 3A & 3B) Note: On some boxes, latch plate may

have to be moved up due to interference with hinges, swinging rear doors or

the design of the top rail.

TIP: Use C-clamp to hold latch plate in proper position for drilling holes

and bolting.

Latch plate mounted

continuously over length

of box - flush at each end.

Trim if necessary.

FIGURE 3A

10

3. LATCH PLATE (continued)

B. BOLTING LATCH PLATE

Use small groove line on latch plate as center point to drill 5/16” holes and

fasten with 3/8” x 1” self threading bolts. Place first bolt 1-1/2” in from ends

and joints, second bolt 12” in from ends and joints and remaining bolts

spaced 24” apart.

Face of cap

Round

corner

of box

Starting edge of latch plate

Drill 5/16” hole centered on

groove (typical)

Top of box

Preferably

0” to 3”

”

24

”

/2

1-1

Typical of all

remaining bolt

locations

”

12

Start and stop

latch plate flush

at edge of box

Typical for first bolt in

from ends and joints

Typical for second bolt

in from ends and joints

FIGURE 3B

11

4. TARP STOPS

A. TARP STOP LOCATION

These brackets secure the stationary side of the tarp to the box. For normal

roll applications, mount brackets on PASSENGER side of box. For reverse

roll applications, mount brackets on DRIVER side of box. Mark locations of

first and last bracket preferably 8” in from each air dam. Divide remaining

space by number of brackets left plus 1 to get equal spacing. Select

appropriate tarp stop procedure shown on pages 17 and 18 and begin

mounting tarp stops.

8”

nu *Divi

mb de

er

r

of ema

bra ini

ck ng

ets sp

lef ace

tp

lus by

on

e

8”

EXAMPLE:

If - 2 quick release brackets

are left, divide by 3 for 3

equal spaces.

If - 3 quick release brackets

are left, divide by 4 for 4

equal spaces.

If - 4 quick release brackets

are left, divide by 5 for 5

equal spaces.

FIGURE 6

12

4. TARP STOPS (continued)

B. Place first and last tarp stop brackets (wide tarp stops with set screws)

preferably 10” in from air dam on outside of box so top of bracket is 1/4”

down from top of box. For first and last tarp stop bracket, drill (4) 5/16” holes

and use (4) 3/8” x 1” self threading bolts to mount brackets. For interior tarp

stop brackets drill (2) 5/16” holes and use (2) 3/8” x 1” self threading bolts to

mount interior brackets.

C. Align lower hole in tarp stop with lower hole in bracket. Assemble with

clevis pin and bow tie pin. Leave bracket in open position for now.

D. For grain cart boxes, if using optional base bracket,

see bolting procedure at bottom of page.

1/4”

Tarp stop

base bracket

TIP: To remove bow tie pin,

rotate it 1/4” turn, then pull

it out from clevis pin.

Clevis pins

1/4”

Drill 5/16” holes and use (2)

3/8” x 1” self threading bolts

for all interior brackets

8”

air from

da

m

Drill 5/16” holes

and use (4) 3/8” x 1” self

threading bolts for first

and last bracket

Bow tie

pins

VIEW AT TOP FRONT CORNER OF BOX (passenger side)

OPTIONAL OFFSET

BASE BRACKET

Optional offset

base bracket

Grain cart box rail

Use (2) or (4) 3/8”

x 1” self threading

bolts with lock

washers and nuts.

Tarp stop base bracket

Drill 5/16” holes

and use (2) 3/8” x

1” self threading

bolts with lock

washer and nut

13

4. TARP STOPS (continued)

Drill 5/16” holes through tarp and box rail

and use (2) 3/8” x 1” self threading bolts

Tarp

stop

8”

3”

Optional offset

base bracket

Grain cart

box rail

Tarp stop

OPTIONAL TARP STOPS

E. At front, start first tarp stop 10”

from air dam. With tarp centered

on box, allow stationary tube to

hang about 3” down from top of

box rail. Position tarp stop over

fixed tube, drill 5/16” holes through

tarp and box rail and fasten with

(2) 3/8” x 1” self threading bolts.

OPTIONAL TARP STOP WITH

OPTIONAL OFFSET BRACKET

F. For grain cart boxes, if using

optional offset base bracket, follow

bolting procedure shown.

Drill 5/16” hole.

Use (2) 3/8” x 1” self

threading bolts with lock use (2) 3/8” x 1”

bolts with lock

washers and nuts

washer and nut

Drill 5/16” holes through tarp and box rail

and use (2) 3/8” x 1” self threading bolts

Top mount

tarp stop

Top of

box rail

Stationary

tube in

tarp stop

14

OPTIONAL TOP MOUNT TARP

STOP

G. At front, start first tarp stop 10”

from air dam. With tarp centered

on box, position top mount tarp

stop on top of box rail. Stationary

tube should be in loop of tarp

stops. Use holes on tarp stop as

guide and drill 5/16” holes through

tarp and box rail and use 3/8” x 1”

self threading bolts to secure each

tarp stop to box.

5. FIXED STATIONARY TUBE ASSEMBLY

A. Spread tarp out on flat surface and pull tight lengthwise and across

width. For boxes over 23 feet 6 inches, insert swaged end of fixed tube section into full end of second tube section. Align tube, weld, allow weld to cool,

and grind smooth.

B. Install end plug into full end of tube weldment. Insert tube, end plug first,

into 4” pocket on tarp.

4” Pocket

Fixed stationary tube

Drive rivet

End

plug

4” pocket

on tarp

End

plug

Fixed

tube

Pull tarp tight

across width

Spread tarp out on flat

surface and pull tight

lengthwise

15

5. FIXED STATIONARY TUBE ASSEMBLY (continued)

End plug on

fixed tube

Drive rivet

C. Extend fixed tube 1/4”

beyond edge of tarp. Drill

7/32” hole and set drive

rivet.

Drill 7/32” hole

Tarp

Drive rivet

Drill 7/32” hole

D. Pull tarp by hand to

stretch tarp along fixed tube

and pull out wrinkles, drill

7/32” hole and set second

drive rivet.

Tarp

Swaged end of

fixed tube

Cut here 1/4”

beyond tarp

E. Cut fixed tube 1/4”

beyond edge of tarp. Grind

smooth.

Tarp

Discard left

over portion

F. Install another end plug.

End plug

Tarp

16

6. ROLL TUBE AND U-CLAMPS

A. For boxes over 23 ft. 6 in,

insert swaged end of roll tube

into full end of other roll tube.

Align tubes, weld, allow weld

to cool, and grind smooth.

Large 5” tarp pocket

Splined shaft at rear of tarp

B. For square back box

trailers, roll tube length is total

of box length plus distance

to standoff minus 2 inches.

Then cut roll tube at front,

removing swaged end. Grind

edges smooth. Slide roll tube

into large tarp pocket with

splined end to rear of tarp and

box. For slant back boxes

see step 5C on next page.

Roll tube length

Box length

90

Cut here

Handle holder standoff

Stationary

tube in tarp

2” roll tube

Full end of roll

tube section

Swaged end of roll

tube section

Splined

shaft

17

6. ROLL TUBE AND U-CLAMPS (continued)

Roll tube length

Box length

90

Cut here

Handle

holder

standoff

Rear

of box

1”

3-5”

Front

tarp

strap

5” pocket

on tarp

C. For slant back box

trailers, roll tube length is

total of box length at top,

plus distance of slant and

standoff minus 2 inches.

Then cut roll tube at front

removing swaged end.

Grind edges smooth. Slide

roll tube into large tarp

pocket with splined end to

rear of tarp.

D. Roll tarp up onto roll tube

completely. Lift tarp onto

box and center it. Secure

tarp to box with tarp stops.

See page 19. NOTE: If kit

was ordered with ridge

pole, assemble it to tarp

prior to placing tarp onto

box.

E. Center first U-clamp on

front tarp strap. Position

screw on crease at bottom

of tarp pocket. Fasten with

screw.

1”

U-clamp

Self drilling

screw

Rear tarp

strap

Splined shaft

U-clamp

18

F. Pull tarp snug along roll

tube towards spline end.

Install U-clamp on rear tarp

strap. Then install U-clamp

on remaining tarp straps.

Driver may leave a sharp

edge on head of screws,

deburr if needed.

7. SETTING TARP ASSEMBLY ON BOX

A. SETTING TARP ASSEMBLY

Roll tarp assembly by hand to its open position, large tube to small tube.

Have tarp stop clevis pins readily available for next sequence. Place rolled

tarp up on top of side of box with tarp stop brackets. Center assembly from

front to back of box. BE CAREFUL NOT TO LET TARP ROLL OFF BOX.

Place small tube with tarp into brackets. Swing tarp stops up, align their

holes with bracket holes and insert upper clevis pin. Repeat for all tall and

short tarp stops. Insert all bow tie pins. This secures roll assembly to box.

By hand, unroll tarp to the other side of box and let tarp hang down in the

closed position. Check to make sure tarp is still centered from front to back of

box and make adjustments as needed.

Quick release

tarp stop

TIP: To remove bow tie pin,

rotate it 1/4” turn, then pull it

out from clevis pin.

Bow tie pins

Stationary tube

shown locked in the

quick release bracket

with clevis pin

Quick release

base bracket

19

8A. BUNJI STRETCH CORD RETURN

Choose appropriate step 8 instructions based on your return system.

Bunji stretch cord roll return use pages 20-21, spring roll return use

pages 22-23 procedure or synthetic cable box returns use pages 24-25.

A. BUNJI STRETCH CORD ROLL RETURN

Bunji stretch cord return is pre-assembled and folded in half when shipped.

Unfold assembly, align open ends and connect tubes together.

NOTE: For electric tarp kits, install this roll return in rear of tube,

opposite end of tarp motor.

Corner

guide

PVC tubes joined

together

End

plug

Protective

cord cover

20

8A. BUNJI STRETCH CORD RETURN (continued)

NOTE: Before installing, hold corner guide at location and inspect path

of cord. Bunji cord should follow a natural path on top of end cap without interference from edge of tarp or wind deflector on end cap. If any

sharp edges, burrs or corners interfere with path of cord, remove where

needed.

B. Insert return assembly into roll tube

and tap in place.

Insert return

assembly into

roll tube and

tap in place

End

plug

C. Fasten plug with #8 x 1/2” Phillips

head self drilling screw.

End

plug

#8 x 1/2” Phillips head

self drilling screw

1/2”

Bunji

guide

D. Place corner guide 1/2” back from

end cap/latch plate. Mark and drill two

5/16” holes. Fasten guide with two

3/8” x 1” self threading bolts.

3/8” x 1” self threading

bolts (2x)

Path of cord

E. Cord path should go up and over

end cap. Inspect path for sharp edges

and remove if needed.

Cord

cover

21

8B. SPRING RETURN

A. SPRING RETURN

Spring return is pre-assembled and folded in half when shipped. Unfold assembly and apply adhesive (supplied in kit) on all sides of male end of PVC

connection. Slide PVC tubes together, tape joint, and let glue set, dry time

will vary on environment. Handle this joint with care.

NOTE: For electric tarp kits, install this roll return in rear of tube, opposite end of tarp motor.

PVC tubes

End plug

e tu

Slid

Corner guide

PVC connections,

apply adhesive

here, all sides

Synthetic cable

22

her

get

to

bes

8B. SPRING RETURN (continued)

NOTE: Before installing, hold corner guide at location and inspect path

of cord. Cord should follow a natural path on top of end cap without

interference from edge of tarp or wind deflector on end cap. If any

sharp edges, burrs or corners interfere with path of cord, remove where

needed.

B. Insert return assembly into roll tube

and tap in place.

Insert return

assembly into

roll tube and

tap in place

End

plug

C. Fasten plug with #8 x 1/2” Phillips

head self drilling screw.

End

plug

#8 x 1/2” Phillips head

self drill screw

1/2”

Corner

guide

D. Place corner guide 1/2” back from

end cap/latch plate. Mark and drill two

5/16” holes. Fasten guide with two

3/8” x 1” self threading bolts.

3/8” x 1” self threading

bolts (2x)

Path of cord

E. Cord path should go up and over

end cap. Inspect path for sharp edges

and remove if needed.

23

8C. FRONT AND REAR CABLE RETURN

A. Align bottom edge of cable return with top edge of box behind cap. Slide

cable return to roll tube side until tab meets bottom of hem. (See Figure 8A)

Ensure synthetic cable runs unobstructed along entire path of travel.

B. Mark and drill 5/16” holes at mounting tab at each end. Secure cable

return with 3/8” x 1” self threading bolts, lock washers and nuts.

C. Place center mounting bracket (tab up) at center of cable return box. Mark

and drill 5/16” hole and attach using 3/8” x 1” self threading bolt, lock washer

and nut.

D. Slide cable return loop over roll tube. Next slide cable retainer and

retaining collar on roll tube. Secure collar with #8 x 1/2” Phillips head self

drilling screw. Now slide vinyl cap over end of roll tube (See Figure 8B)

End cap

Turn 3/8” x 1” self threading bolt

through bracket and 5/16” hole with

lock washer & nut

Align bottom edge of cable return with

top of box behind cap

Top of box behind cap

Butt tab up to

bottom of hem

Turn 3/8” x 1” self threading bolt through 5/16”

hole secure with lock washer & nut (both sides)

FIGURE 8A

24

8C. FRONT AND REAR CABLE RETURN (continued)

Cable retainer

Roll tube

extension

Retaining collar

#8 X 1/2” Phillips

head self drilling

screw

Vinyl cap

FIGURE 8B

Front Cable Return Option (Non-Square)

NOTE: For square cap use mounting location similar to Figure 8A

Front cable return option (See Figure 8C for mounting location) Make

sure roll tube extends 4” beyond edge of box. Slide cable return loop, cable

retainer, retaining collar, and new vinyl cap onto roll tube. Secure retaining

collar with #8 x 1/2” Phillips head self drilling screw. (See Figure 8B)

Existing non-square end caps

Turn 3/8” x 1” self threading

bolt through bracket (tab down)

and 5/16” hole with lock washer

& nut

Mount cable return as close to edge of

box as possible, mounting tab may be

bent around corner

Turn 3/8” x 1” self threading bolt

through 5/16” hole with lock washer

& nut (both sides)

FIGURE 8C

25

9. REAR BUNJI RETURN KIT

NOTE: This bunji kit is OPTIONAL on manual tarps. If ordered, install it

at rear of box.

A. EXTRA BUNJI RETURN KIT

Start with bunji guide on cord end next to collar. Place it on latch plate at rear

of box for manual system as shown, or at front of box for electric system.

Adjust it to extend 5/16” to 3/4” beyond face of end cap. Make sure cord path

will clear bolt heads on face of end cap. (See Figure 9A and 9B) Hold bunji

guide in correct position and mark hole locations. Drill two 5/16” holes. Mount

bunji guide with 3/8” x 1” self threading bolts.

Bunji cord

Allow for clearance

between bolt heads

and bunji cord

Bunji guide

5/16” to 3/4”

FIGURE 9A

5/16” to 3/4”

Bunji

guide

Collar

3/8” x 1” self

threading bolts

FIGURE 9B

26

9. REAR BUNJI RETURN KIT (continued)

B. Take bunji guide on opposite end, hold it up on latch plate and pull until

slack is out of cord. Then stretch it another 12 inches and mount bunji guide

at this location. Drill two 5/16” holes and fastening with 3/8” X 1” self threading bolts.

P

ko

ac

sl

ull

ord

fc

o

ut

2”

+1

Bunji

guide

3/8” x 1” self threading

bolts (2x)

Mount bunji

guide here

27

10. CRANK HANDLE ASSEMBLY

NOTE: For electric tarp installs, skip steps 10 through 14.

Continue with step 15.

A. U-JOINT AND HANDLE EXTENSION

Align sleeve end of U-joint with single hole end of handle extension. Make

sure hole in U-joint is in line with hole on handle. Swing spline end 90 degrees to handle. Use rubber hammer to drive sleeve over end of handle until

holes line up. Drive spring pin into holes. NOTE: The U-joint and handle

shaft are designed for tight fit. A coating of grease will ease this process.

B. CRANK HANDLE AND HANDLE EXTENSION

Insert crank handle into handle extension selecting 1 of 4 holes according

to desired length and align holes to bolt together using 3/8” x 1-3/4” bolt and

nut.

3/8” x 1-3/4” bolt

Handle extension

Nut

Crank handle

Handle extension

Spring pin

Sleeve end of U-joint

C. ATTACH HANDLE TO SPLINE

With tarp and roll tube hanging loose below latch plate, slide

U-joint onto splines so that the

handle hangs straight down parallel with box wall. Insert wire lock

pin to secure U-joint to roll tube.

28

Apply coat of

grease here

around tube

10. CRANK HANDLE ASSEMBLY (continued)

D. ADJUSTING HANDLE LENGTH

Handle length should be about 18” above ground when hanging straight

down. To adjust, remove bolts and slide lower portion of handle up or down

inside upper handle and select hole location closest to 18” and re-bolt. (See

below)

NOTE: On grain carts, crank roll tube up tight under latch plate, hold

and bring handle straight down to grade. There should be about 6

inches of clearance from handle to grade. Adjust handle length if

needed.

Handle length

adjustment bolt

Approx. 18”

Roll tube

Handle must be

90o on slant back

boxes

Bunji collar

Roll tube

VIEW IF ON A SLANT BOX

29

11. MOUNTING PINLESS HANDLE HOLDER

NOTE: For Grain Carts, refer to single sheet instruction on mounting

handle holder extension.

A. HANDLE HOLDER

Using crank, turn roll tube up (counter clockwise) until it is firmly secured

under latch plate. Bring crank arm down toward box to full vertical position.

Hold crank arm firmly with both hands and lift it toward center of box, until

you find location you want to mount crank holder bracket. The pinless handle

holder should be located above handle portion of crank. Mark and drill two

5/16” holes and secure holder bracket with 3/8” x 1” self threading bolts.

Attach pinless crank holder to bracket with 1/2” x 1” bolt.

Crank handle

and mount

Safety/

operating

decal

Pinless crank

holder

Holder

bracket

3/8” X 1” self

threading bolt

Crank handle

in holder

30

Spacer

1/2” X 1”

bolt

12. ATTACH SAFETY / OPERATING DECAL

A. OPERATING DECAL

With crank handle placed in holder to secure it, locate the spot for the safety/

operating decal. This sticker must be placed in a visible location near

handle holder on vehicle or all warranties are void! For warranty claims,

provide serial number shown on this decal.

IMPORTANT:

Peel warning

stickers from sheet

and attach to visible

area near unloading

controls inside cab

and on box or trailer.

STOP WARNING STICKER

31

13. TARP TENSION ADJUSTMENT

A. SETTING TARP TENSION

Check orientation of U-joint and wire lock pin. First, make sure that U-joint

is in correct position for maximum strength when locked at 90 degree angle

as shown in Figure 13A below. Make correction if needed. Next, make sure

that wire lock pin is in correct position to encompass around spline shaft as

shown in Figure 13B below. Make correction if needed.

INCORRECT

CORRECT

FIGURE 13A

CORRECT

INCORRECT

FIGURE 13B

32

14. TARP TENSION ADJUSTMENT (continued)

B. TEST TENSION

Start with tarp hanging loose down along side of box. Hold crank firmly

with both hands and turn roll tube closed up under latch plate and bring

crank handle down vertical to ground. Then tighten tarp by lifting handle up

toward handle holder and place it in holder. NOTE: Normally an 8 ft. handle

is adjusted to 25 lbs. of lift to place it in the handle holder. (See chart for

normal tension settings for other handle lengths and add about 5 lb.

extra at initial tarp installation.)

C. SET TENSION

Remove U-joint from spline shaft, rotate one to two teeth and reattach onto

shaft. Secure with lock pin. Turn roll tube tight as described above. Repeat

procedure until correct tension is acquired.

NEVER OPEN OR CLOSE TARP WITHOUT U-JOINT SECURELY

FASTENED TO SPLINE SHAFT WITH WIRE LOCK PIN.

D. SAFETY DECALS

Safety and operating procedure decals that come with this kit are provided

for YOUR SAFETY. They should be kept clean at all times. Replace any

decal that is worn, damaged, painted over or unreadable.

Recommended Tarp Tension:

Handle Lgth. = lbs, of Lift

8 ft. Long = 25 lbs.

10 ft. Long = 20 lbs.

12 ft. Long = 15 lbs.

REPLACEMENT DECALS

ARE AVAILABLE THROUGH

AGRI-COVER®, INC, OR

AGRI-COVER DEALERS.

33

MANUAL CRANK OPERATING INSTRUCTIONS

CLOSING FROM OPEN POSITION

1. Crank the tarp

up under the

latch plate.

2. Bring the crank

arm down to a

vertical position.

3. Lift the crank

arm up to the

crank retainer.

Crank

retainer

Crank arm

Latch

plate

See chart

lbs. of lift

Down

Lift

To adjust the tarp tension:

1. Allow the tarp to roll down away from the latch plate.

2. Remove the crank arm from the splined shaft.

3. Rotate the crank one or two teeth and reassemble.

Recommended Tarp Tension:

Handle Lgth. = lbs, of Lift

8 ft. Long = 25 lbs.

10 ft. Long = 20 lbs.

12 ft. Long = 15 lbs.

OPENING FROM CLOSED POSITION

1. Lift crank arm up out of crank retainer.

2. Bring crank arm up to a comfortable position and crank tarp open.

3. Bring crank arm down to a vertical position and lift it up into crank retainer.

IMPORTANT: OPEN TARP when loading or unloading box. Unloading box with

tarp closed will create a vacuum which could cause damage to tarp system.

CLOSE TARP when transporting or storing. A closed tarp will extend the life of your

tarp system.

34

15. UPPER PIVOT ARM AND MOTOR

(Continue here for electric operated tarps)

A. Assemble motor to bracket on upper pivot arm. Use three 5/16” x 3/4”

bolts with lock washers. Attach motor cover with hex flange screws and nylon

spacers. Then locate lower pivot arm mounting bracket and lower pivot arm

and proceed to next step.

5/16” x 3/4”

bolts (3x)

Nylon

spacer

Lock washer

Hex flange

screw

Upper

pivot arm

Electric

motor

Motor cover

35

16. UPPER PIVOT ARM AND PIVOT POINT

A. PIVOT ARM BRACKET LOCATION

For lower pivot arm, locate pivot arm bracket on outside of box about 36”

down from bottom of end cap at center of box. Mount pivot arm bracket to a

solid area on box. Use holes in bracket to mark location and drill a 5/16” hole

at each mark. Mount bracket with 3/8” x 1” self threading bolts. Align hole in

lower pivot arm with hole in bracket and turn 1/2” x 1” flanged head bolt into

lock nut welded on back. Leave bolt just loose enough for arm to pivot freely.

(See Figure 16A) Tap plug into end of lower pivot arm.

36”

INSTALLATION TIP: Some vehicles may have obstructions that require

moving the pivot point up higher than normal or even to the rear of

the box. To do this the top pivot arm must be cut shorter. DO NOT CUT

SHORTER THAN 10”.

3/8” x 1”

self threading bolts

Pivot arm

bracket

Cable ties

Lower Upper

pivot

pivot

arm

arm

1/2 of bo

x width

1/2” x 1”

bolt

FIGURE 16A

36

17. MOTOR ADAPTER AND ALIGNMENT

A. MOTOR ADAPTER

At front of roll tube, apply thin layer of grease to motor adaptor then slide

adapter onto tube. Slide return loop over motor adapter. (See Figure 17A)

Do not drill or bolt to roll tube yet.

B. MOTOR TO ROLL TUBE

Position upper pivot arm with motor over top of lower pivot arm. Hold onto

motor and slide drive shaft with thin layer of grease into motor adapter on roll

tube. Turn adapter by hand until its hole aligns with hole in motor shaft. Insert

3/8” x 1-3/4” bolt and tighten with lock nut.

C. SQUARE ALIGNMENT

Adjust pivot arms to be square with roll tube by sliding motor with adapter

forward or backward on roll tube - if not square, motor will bind and wobble

during operation. Inspect travel line of motor and arms to be clear of

obstructions across front of box when opening and closing. Note: Cord

should NOT ride on top of cap - it should travel in front of cap as roll

tube opens. Photos show a properly aligned system. Now drill hole in roll

tube and use 3/8” x 2-3/4” bolt to secure motor adapter.

Top of box

When fully assembled,

cord should have

sufficient tension to

almost lift tarp tube. If

needed, adjust cord

tension by tying new

knot at far end of cord

TIP: Periodically

grease drive shaft

and motor adapter

3/8” x 2-3/4”

bolt

Motor adapter

3/8” x 1-3/4”

bolt with lock

nut

Roll tube

Cord collar

Motor shaft

90o

Cord

Cord collar

FIGURE 17A

37

18. ELECTRIC MOUNTING INSTRUCTIONS

TIP: Dielectric silicone is provided for electric wire connections. Use as

needed.

NOTE: For farm trucks with hoist, run wire to rear around hoist pin and

back to front of box. (There will be no plug connection.)

A. WIRE ROUTING

At front of box, bring 6 gauge wire up to pivot point, loop it around and leave

slack for movement. Continue with wire along pivot arms sufficient to reach

motor connections. Use nylon cable ties to hold wire to upper pivot arm. Do

not connect wires to motor yet. Next, select best routing for 6 gauge wire

along frame towards cab near existing wire harness and up to battery. (See

wire schematic on page 48) For semis use dual pole connector at front of

trailer. (See page 39 for details)

FIGURE 18A

6 ga. double strand wire (from

solenoid to tarp motor)

14 ga. wire from

switch to solenoid

Solenoid

Caution/operating decal

HD dual pole connector

Rocker switch inside cab

Circuit breaker 40 amp

6 ga. double strand wire (from

solenoid to tarp motor)

Place only the lower portion of this decal in a location

visible to the operator or all warranties are void!

IMPORTANT: Peel warning stickers from

sheet and attach to visible area near unloading

controls inside cab and on box or trailer.

38

Caution/Operating Decal

18. ELECTRIC MOUNTING INSTRUCTIONS (continued)

DUAL POLE CONNECTOR

Mount plug connector to suitable location on semi-tractor, adjacent to existing

plugs. Mount socket to suitable location on trailer. Prep wires by stripping off

insulation as needed. On wires at socket, slide heat shrink tube over wire,

attach ring terminals and apply heat to shrink tubes. Bolt terminals tight. On

wires at plug, insert bare wires into plug tubes and secure with set screws.

Loosen set screws slide

bare wire into tubes – turn

both set screws tight into

each bare wire

Thread cutting bolt 2x,

if unable to use nut

behind frame drill 1/4”

hole and turn thread

cutting bolt into frame

Lock washer

Dual pole

Flat

washer

Nut

socket

Bolts

for ring

terminals

Dual pole plug

Strip wire insulation

off as needed

Red (+) wire to (+)

battery terminal

Insert wire

retainer

clip in plug

as shown

Use set screw to

anchor wire to plug

receptacle

Heat shrink

tube

Red wire to

terminal 2 on

motor

Phillips head screw

at end plug

39

18. ELECTRIC MOUNTING INSTRUCTIONS (continued)

NOTE: If installing the optional Command Station or COMMAND-10®

Wireless Remote, skip step 18B through 18H. Use instructions that

come with those kits.

B. SWITCH LOCATION AND INSTALLATION

Select convenient location in cab to mount switch bracket with two #14 x 1”

self drilling Phillips screws through slots in back of bracket. (See Figures

18A & 18B)

Route 14 ga. wire from switch to location of solenoid near battery. Rubber

grommet is supplied for area where wire enters cab, 11/16” hole is needed

for grommet.

At switch, strip 14 ga. wire ends about 3/8” back and attach push-on

connectors and crimp. Pull wires through mount bracket and attach to switch.

(See Figure 18B) Push switch into mount bracket until it snaps (locks) onto

bracket.

C. CAUTION/OPERATING AND STOP WARNING STICKERS

Locate a suitable location at front driver side of box. Clean surface and apply

caution sticker. (See Figure 18A) Locate visible area near unloading controls

inside cab and on box. Clean surface and apply STOP warning stickers.

D. SOLENOID

Mount solenoid in protected area near battery using (2) #2 x 1” self drilling

Phillips screws. For reference, see schematic on page 48.

1/2” eyelet for (+) battery post

3/8” eyelet for (-) battery post

5/16” eyelet for circuit breaker

and motor terminals

1/4” eyelet for solenoid

terminals

Black to

open

”

5/8

Green to

center

Typical for all heavy

gauge wire eyelets

White to

close

Front of

bracket

Typical heat

shrink tube for

all heavy gauge

wire connections

#14 x 1” Phillips

head self drilling

screw

FIGURE 18B

40

Rubber terminal boots

for solenoid and motor

connections only

FIGURE 18C

18. ELECTRIC MOUNTING INSTRUCTIONS (continued)

E. LIGHT GAUGE WIRES

Prepare end of black and white light gauge wires from switch with push on

connectors for solenoid terminals. Connect white wire to left terminal. Connect black wire to right terminal. Prepare end of light gauge green wire from

switch with 1/4” ring terminal.

F. HEAVY GAUGE WIRES

Split heavy gauge wire at solenoid about 4” back. Prep ends of black and

red heavy gauge wires leading from motor and battery with heavy gauge

1/4” ring terminals, heat shrink tubes and rubber boots for (4) solenoid studs.

(See Figure 18C) Attach wires to studs on solenoid. Note the light gauge

jump wire leads through same rubber boot with black (-) wire from battery.

The green light gauge jump wire leads through same rubber boot with red (+)

wire from battery. When attaching ring terminals always hold base nut while

tightening top nut. Do not over tighten. Connect white light gauge wire to left

terminal and black wire to right terminal (See wiring schematic on page 48).

G. CIRCUIT BREAKER

Install circuit breaker in line on red (+) wire close to battery using 5/16” ring

terminals and heat shrink. (Prep wires as shown on page 40)

H. BATTERY

Prepare end of heavy gauge black wire for battery (-) post with heat shrink

tube and 3/8” ring terminal. Prep end of heavy gauge red wire for battery (+)

post with heat shrink tube and 1/2” ring terminal. Do not connect wires to

battery now.

5/16” terminal

at motor

1/2” terminal

Heat shrink

tube (typical)

Circuit

breaker

3/8”

terminal

Red

1/4”

terminal

Black

Green

Black

Black

Jump wire

INSTALLATION TIP: Wire

Schematic Page 48.

#2 self drilling

Phillips head screw

White

FIGURE 18D

41

19. MOTOR CONNECTIONS

A. WIRING MOTOR

Prepare wire ends for motor terminals with rubber terminal boots, heat shrink

tubes and 5/16” ring terminals. Attach BLACK wire to terminal 1 on motor.

Attach RED wire to terminal 2. Always hold base nut while tightening top nut.

Torque to 42 LB-IN.

At battery, first attach RED wire to (+) post. Then attach BLACK wire to (-)

post. Check power by activating switch to open position. If motor turns tarp in

wrong direction, reverse black and white 14 gauge wires at solenoid. Check

system again. When done, make sure all connections are secure and all

wires are clear of sharp edges.

Always hold base nuts while

tightening top nut

Heat shrink

tube

Flat washer

Red wire

Flange nut, torque

to 42 LB-IN

NOTE: Image shown without terminal boots and motor cover off.

42

20. TARP TUBE FASTENERS

Check to make sure stationary tube is centered on box. At front and rear

wide tarp stops, tighten set screws with Allen wrench. IMPORTANT: These

set screws prevent tube and tarp system from sliding back when

raising box or from road vibration.

Wide tarp stop

at front and

rear of tarp

1” Stationary tube

Tighten set screw

with Allen wrench

ROLL TUBE DEFLECTOR

#14 x 1” Phillips head self

drilling screw

Roll tube

deflector

Roll tube deflectors fasten to side of

box to keep roll tube from damaging

paint on sides of trailer.

Fasten with #14 x 1” Phillips head

self drilling screw. Use caution do

not over torque screw, this may

damage deflector.

#14 x 1” Phillips head self

drilling screw

43

ELECTRIC MOTOR OPERATING INSTRUCTIONS

NOTE: For kits with Command Station or the COMMAND-10® Remote Control refer to those manuals for operating instructions.

STEP 1: CLOSING FROM OPEN POSITION.

Push switch to the CLOSED position and hold. Visually view tarp position and

release switch when tarp is fully closed. Fully closed is when tarp roll tube is

tight up under latch plate.

STEP 2: OPENING FROM CLOSED POSITION.

Push switch to the OPEN position and hold. Visually view tarp position and

release switch when tarp is fully open. Fully open is when tarp roll touches

tarp stops. TOO TIGHT in open position could cause damage to tarp stops,

tubes and tarp.

IMPORTANT: Electric tarp system is equipped with a modified reset

circuit breaker. Holding switch until circuit breaker trips is too

long. When this occurs, breaker will trip and reset if the breaker

is overloaded by the motor. To reduce unnecessary strain on

components, always release switch before breaker trips. If breaker trips

and does not reset, it may have detected a continuous short and will

not reset until the short is repaired.

IMPORTANT:

OPEN TARP when loading or unloading box. Unloading box with

tarp closed will create a vacuum which could cause damage to tarp

system.

CLOSE TARP when transporting or storing. A closed tarp will extend

the life of your tarp system.

44

SERIAL NUMBER LOCATION

TO ORDER A REPLACEMENT TARP FIND YOUR

TARPS SERIAL NUMBER WHERE SHOWN.

Serial number is printed at the rear of the tarp

on the stationary tube side.

45

24

5

46

22

19

25

23

3

2

12

11

1

9

26

21

4

20

26

13

10

17

16

6

15

14

18

25

8

7 26

29

28

27

ROLTEC SIDE LOCKING TARP PARTS DIAGRAM

ROLTEC SIDE LOCKING TARP PARTS LIST

Item

Description

1

Bunji cord

2

Bunji return end plug, 2” (internal)

3

Bunji return cord cover

4

Front end cap (side mount shown)

5

Latch plate (aluminum)

6

Standard tarp stop ASM (quick release)

7

Crank handle stand-off (7” shown)

8

Pinless crank handle retainer

9

2” steel roll tube

10

Stationary tube

11

Bunji return tube, swaged end

12

Bunji return tube, open end

13

U-joint

14

Crank handle

15

Handle extension

16

Roll pin

17

Wire lock pin

18

Stationary tube end plug

19

Bow

20

Bow extension

21

Bow pocket

22

Ridge strap

23

Bunji guide

24

U-clamp & screw

25

Drive rivet

26

3/8” x 1” self threading bolt

27

Spacer

28

1/2” x 1” bolt, serrated flange

29

Wide tarp stop ASM (quick release)

47

WIRE SCHEMATIC DIAGRAM

WIRE SCHEMATIC DIAGRAM

RED HEAVY GAUGE

BLACK HEAVY GAUGE

SOLENOID

RED HEAVY GAUGE

GREEN 14 GA

WHITE 14 GA

BLACK 14 GA

JUMPER WIRE

MOTOR

CLOSE

OPEN

ROCKER SWITCH

(IN CAB)

BLACK HEAVY GAUGE

BATTERY

48

40 AMP

BREAKER

ELECTRIC PARTS

Qty.

Part#

Description

2

10914

Phillips Self Drilling Screw #14 x 1

2

30312

Eyelet Terminal Ring 6 ga. x 5/16”

4

40627

Hex Nut Serrated Fig/ 5/16” - 24

1

40649

Rocker Switch 12v

10 Lin. Ft.

40653

Wire, 3 Conductor, 14 ga.

1

40664

7/16” ID Rubber Grommet

1

40673

Switch Mounting Bracket

1

20047

Socket, Dual Pole Connector

1

20048

Plug, Dual Pole Connector

1

40991

Lower Pivot Arm

1

10774

Upper Pivot Arm

1

10739

Circuit Breaker, 40 Amp

2

80006

Washer, Flat #10

1

10739

Circuit Breaker 40 Amp

1

70498

Solenoid GRP (includes jump wire)

1

70491

Wire ASM, Jumper

1

30314

Terminal Ring 1/2” 6 ga.

1

30313

Terminal Ring 3/8” 6 ga.

2

30647

Terminal Ring #10 6 ga.

1

50948

Electric Motor

1

30723

Mount Bracket Pivot Arm

1

40956

1/2 x 1” Pivot Bolt

2

10178

Self Lock Nuts

1

40964

Electric Motor Adapter

1

30454

O-Ring/Bunji Collar

2

60779

Bunji Corner Guide

1

10905

3/8 x 2-3/4” Bolt

1

10902

3/8” Lock Nut

1

10268

Bunji Cord

20046

6 ga. Double Strand Cable (Spec. Lgth.)

1

30649

Heat Shrink Kit

1

50390

Electric Operating Decal

1

30648

Breaker Cover

4

50996

Terminal, Ring 1/4” 6 GA Non-Insulated

4

70278

Cover, Terminal, 8-2 GA Rubber Boot

2

70298

Screw, PH Pan head #2 Self Drilling, 10-16 x 1 Zinc PL

5

70428

Terminal, 1/4” 14 GA Push on Female Insulated

1

70446

Terminal, Ring 1/4” 14 GA Insulated

49

SAFETY INFORMATION

! SAFETY INFORMATION

• Always use adequate caution when operating tarp.

• Make sure tarp is open before unloading or loading.

• Make sure nobody is on or near tarping system before and

during operation.

• Do not operate tarp with box hoisted in an elevated position.

• If tarp is covered with snow, its removal is important before

operating.

• End caps must be free from grain that may be piled on them.

Grain should not be heaped higher than end caps.

• Do not operate this vehicle at highway speeds, while tarp system

is in the “open” position.

• Instruct everyone who will operate this tarp the proper

procedures, or have them read this entire manual.

• Avoid direct pressure washer spray to electric motor and motor

connections.

50

INSPECTION MAINTENANCE

!

INSPECTION / MAINTENANCE

• Periodic preventive maintenance should be practiced. Inspect

tarp and hardware for abrasions or loosened bolts that may

need adjustment and/or repair and adjust tension when

needed. Tarp must be kept to a recommended tension setting

equally on both ends, or excessive tarp wear may occur.

• If installed correctly, tarp should always operate as well as

when first installed. If tarp does not pass this simple inspection,

make all appropriate repairs or adjustments immediately before

serious damage occurs.

• Always use genuine Agri-Cover, Inc. replacement parts if

repairs are needed.

• Bunji cord recoil memory will typically take longer if left open for a

long period of time or when operated in cold weather.

• Periodically remove handle and apply grease to splines.

• Routinely grease zerk fitting on crank handle U-joint.

• Check the tightness of mounting bolts and electrical

connections, remove any dirt or corrosion that may have

accumulated on the electrical connections.

• Do not attempt to disassemble the motor or gearbox.

Disassembly will void warranty.

SAVE THIS MANUAL FOR FUTURE REFERENCE

51

Agri-Cover Fasteners and Hardware

Parts are not actual size. Each part may not be included in every kit.

All are subject to change without notice.

Bolts

52

Bolts

53

Washers

Nuts

54

Terminal Rings

Pins

55

MANUFACTURER’S LIMITED WARRANTY

Agri-Cover, Inc. extends the following limited warranty on its ROLTEC® Side Locking Tarp to the

original retail purchaser:

Agri-Cover, Inc. warrants its ROLTEC® Side Locking Tarp to be free from defects in material and

workmanship under normal use for one (1) year from date of manufacture unless accompanied by

proof of purchase.

ANY IMPLIED WARRANTY APPLICABLE TO THE ROLTEC® SIDE LOCKING TARP IS LIMITED

IN DURATION TO ONE YEAR FROM THE DATE OF MANUFACTURE UNLESS ACCOMPANIED

BY PROOF OF PURCHASE. Agri-Cover Inc.’s sole obligation under this warranty or any implied

warranty is limited to the repair or replacement at its option, of defective parts only. No labor or

service allowance is given or implied. IN NO EVENT SHALL AGRI-COVER, INC. BE LIABLE FOR

INCIDENTAL, CONSEQUENTIAL, OR SPECIAL DAMAGES. Some states do not allow limitations

on how long an implied warranty lasts or exclusions of incidental or consequential damages, so the

above limitations and exclusions may not apply to you.

For warranty call our Customer Service Department at 800-233-4655 to determine if only a

replacement part is needed or if the cover needs to be returned for inspection and repair. Goods

to be returned must have a pre-authorized RA # (Returned Authorization Number) – obtained by

calling the number above. Mark the number on the package and ship it freight prepaid to address

below. Agri-Cover will pay freight to return goods to sender.

This warranty does not cover any failure due to abuse, misuse, alteration, neglect, improper

assembly or installation, or improper maintenance.

This warranty gives you specific legal rights and you may have other rights which vary from state to

state.

R

SIDE LOCKING TARP

Agri-Cover, Inc.

Customer Service Dept

PO Box 508 | 3000 Hwy 281 SE

Jamestown, ND 58402

Phone: 800-233-4655

ROLTEC ® is a registered United States trademark of AGRI-COVER, INC.

For ACI patent information, please visit: http://www.agricover.com/patents/

PHONE 800-233-4655 8:00 am - 5:00 pm CST Monday through Friday except Holidays

56

PN 60856_N

Product subject to change without notice

© 2016 AGRI-COVER, INC. ALL RIGHTS RESERVED.

072816